Quick Summary

Thermoforming plays a decisive role in how food trays perform in real-world use. Beyond material selection, heating, forming, cooling, and mold design directly influence thickness distribution, heat resistance, sealing quality, and long-term stability. Understanding thermoforming helps buyers avoid common failures such as warping, cracking, and inconsistent batch performance. This article explains why trays made from the same material can behave very differently—and why experienced buyers evaluate forming capability, not just resin type.

Introduction: Why Manufacturing Process Matters More Than Material

When buyers evaluate food trays, the first question is almost always about material: PP or PET, CPET or PLA, virgin or recycled. While material selection is important, experienced manufacturers know that material alone does not determine performance. In real-world applications, trays made from the same resin can behave very differently—warping under heat, cracking during transport, or failing to seal properly—despite sharing identical material specifications.

The reason lies in thermoforming.

Thermoforming is often treated as a background manufacturing step, something that happens after the “real decisions” are made. In reality, thermoforming is one of the most critical factors shaping how a food tray performs under heat, load, stacking, sealing, and transportation. Ignoring it is one of the most common reasons why packaging that looks fine on paper fails in practice.

This article explains how thermoforming directly changes the mechanical, thermal, and structural performance of food trays—and why understanding this process is essential for buyers who want stable, scalable packaging solutions.

What Thermoforming Really Is (Beyond the Simple Definition)

At its simplest, thermoforming involves heating a plastic sheet until it becomes pliable, forming it over a mold, and then cooling it to retain the new shape. While this definition is technically correct, it dramatically understates the complexity of the process.

In practice, thermoforming involves a tightly controlled interaction between:

-

Sheet formulation and extrusion quality

-

Heating temperature and uniformity

-

Forming method (vacuum, pressure, or combined)

-

Mold geometry and surface finish

-

Cooling speed and release conditions

Two commonly used forming methods are:

-

Vacuum forming, where air is evacuated to pull the heated sheet onto the mold

-

Pressure forming, where compressed air is added to improve detail, thickness control, and definition

Pressure forming generally produces trays with better dimensional accuracy and surface definition, but it also requires more precise temperature control and tooling. The choice between these methods directly affects wall thickness distribution, rigidity, and long-term stability.

How Heating and Cooling Change Material Behavior

Thermoplastics do not behave the same way before and after thermoforming. During heating, polymer chains gain mobility. As the sheet stretches over the mold, those chains reorient in response to stress and geometry. This molecular reorientation is not uniform across the tray.

Cooling then “locks in” this structure. If cooling happens too quickly or unevenly, internal stresses remain trapped inside the formed tray. These stresses often remain invisible until the tray is exposed to heat, weight, or time.

This is why trays that appear stable at room temperature may:

-

Warp during hot filling

-

Deform in microwave use

-

Twist after stacking in a warehouse

Controlled cooling is therefore not a cosmetic concern—it is essential for performance stability.

Thickness Distribution: Why “Average Thickness” Is Misleading

One of the most misunderstood aspects of thermoforming is thickness distribution. Buyers often evaluate trays by quoting an average sheet thickness (e.g., 0.8 mm or 1.0 mm). However, thermoforming does not preserve uniform thickness.

As the sheet stretches:

-

Bottom corners thin more than sidewalls

-

Deep draw areas experience greater material extension

-

Reinforced zones retain more thickness

This leads to trays where structural strength depends less on average thickness and more on where the thickness remains.

A tray with poor thickness distribution may crack under load even if it uses more material overall. Conversely, a well-designed tray with optimized draw ratios can outperform thicker trays while using less resin.

This is why professional suppliers evaluate trays based on functional thickness, not nominal sheet gauges.

Structural Design: Ribs, Corners, and Tray Geometry

Thermoforming performance is inseparable from structural design.

Elements such as ribs, flanges, and corner radii are not decorative—they are load paths. Properly designed ribs increase stiffness without adding material, while rounded corners reduce stress concentration during forming and use.

However, these features only work when they are designed with forming behavior in mind. Overly sharp ribs or deep vertical walls can create thinning, tearing, or uneven cooling. Geometry that looks strong in CAD can perform poorly when formed.

Experienced manufacturers design trays by balancing geometry and forming feasibility, not by copying shapes from existing products.

How Thermoforming Affects Heat Resistance

Heat resistance is often attributed solely to material choice, but thermoforming plays a significant role in how trays respond to heat in real use.

-

PP trays may soften unevenly if cooling is inconsistent

-

PET and RPET trays can warp if internal stresses release under heat

-

CPET trays, while more heat resistant, require precise crystallization control during forming

Impact on Sealing, Stacking, and Logistics

Thermoforming also affects downstream processes such as sealing and logistics.

Sealing requires flat, dimensionally stable flanges. Even slight warpage can compromise seal integrity, leading to leaks or seal failures during transport. Similarly, stacking performance depends on consistent geometry and controlled shrinkage.

Trays that nest poorly increase transport volume, reduce pallet efficiency, and raise logistics costs. These issues often emerge only after scale-up, making them expensive to correct.

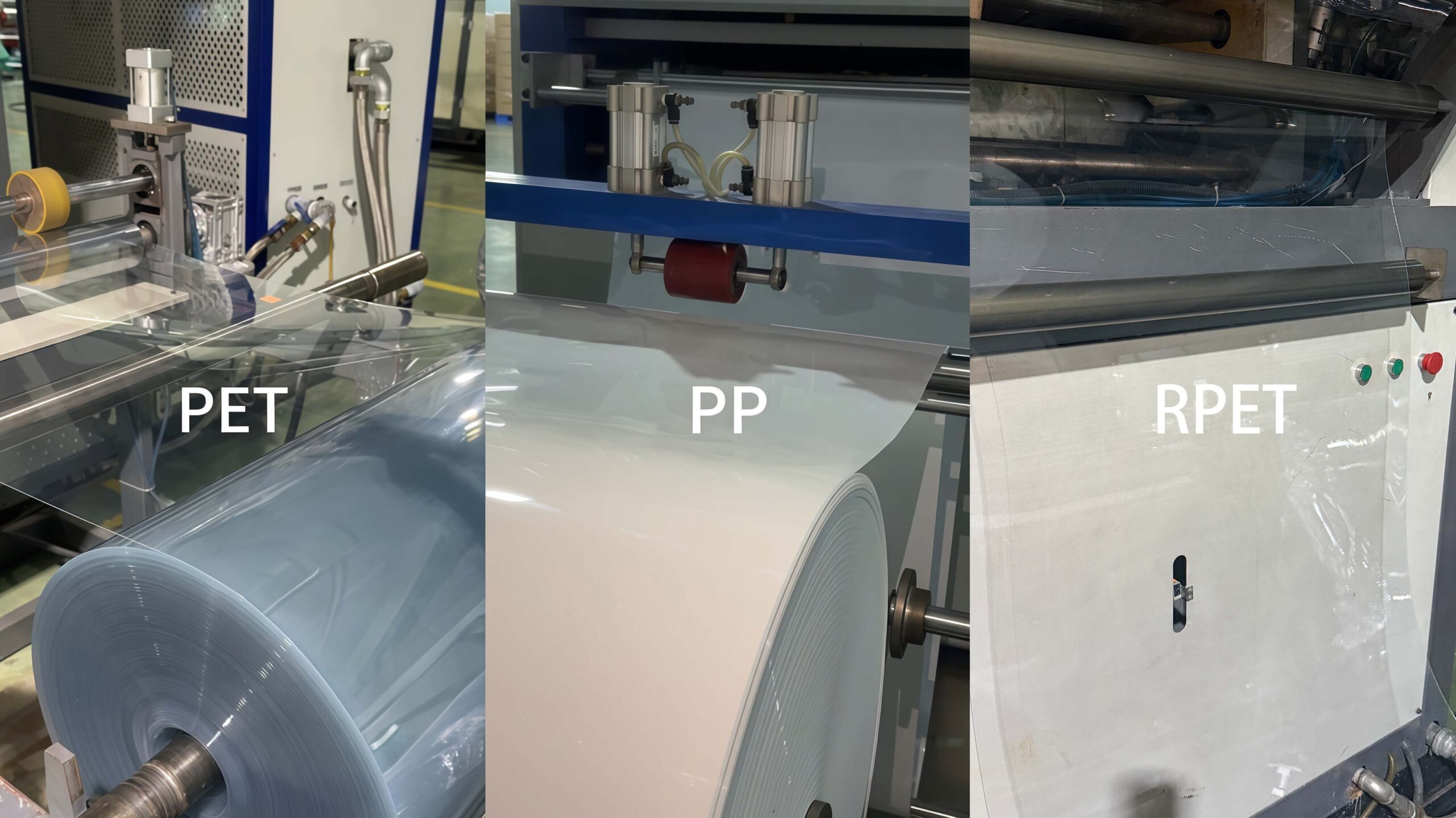

Performance Differences Across Materials

Different materials respond to thermoforming in distinct ways:

-

PP offers flexibility and toughness but requires careful temperature control

-

PET / RPET provides clarity and stiffness but is sensitive to cooling stress

-

CPET excels in high-heat applications but demands advanced tooling

Understanding these behaviors is essential when choosing both material and supplier.

Common Thermoforming-Related Failures Buyers Encounter

Many buyers experience issues that are incorrectly attributed to “material problems”:

-

Approved samples fail after mass production

-

Performance varies between batches

-

Trays deform only after extended storage

In most cases, the root cause is process inconsistency, not material quality.

What Experienced Suppliers Do Differently

Professional manufacturers treat thermoforming as a design tool, not just a production step. They:

-

Adjust forming parameters instead of adding material

-

Design molds around material flow behavior

-

Test trays under real-use conditions

At DASHAN, for example, tray development focuses on forming stability, thickness control, and application-specific performance rather than generic material claims. This approach reduces downstream risk for buyers and supports consistent large-scale supply.

What Buyers Should Ask Before Ordering

Buyers sourcing thermoformed food trays should ask:

-

How is thickness controlled in deep-draw areas?

-

How is cooling managed to reduce internal stress?

-

Has the tray been tested under actual use conditions?

Suppliers who can answer these questions clearly usually understand thermoforming beyond surface-level production.

FAQ

1. What is thermoforming in food tray manufacturing?

Thermoforming is a process where plastic sheets are heated, shaped over molds, and cooled to create food trays. The forming method and parameters significantly affect tray strength, stability, and heat performance.

2. Why do food trays made from the same material perform differently?

Differences in heating uniformity, stretching behavior, cooling speed, and mold design can change thickness distribution and internal stress, leading to varied performance even with identical materials.

3. Does thicker plastic always mean stronger trays?

No. Performance depends on where thickness remains after forming. Poor thickness distribution can cause weak points even in thicker trays.

4. How does thermoforming affect heat resistance?

Improper forming can trap internal stress, causing trays to warp or deform under heat. Even high-temperature materials like CPET require precise forming control to perform reliably.

5. Why do some trays warp after storage or transport?

Warping often results from residual stress introduced during forming and cooling, which may only release over time or under temperature changes.

6. What should buyers ask suppliers about thermoforming?

Buyers should ask about thickness control, cooling methods, forming consistency between batches, and whether trays are tested under real-use conditions.

Conclusion

Thermoforming is not a background manufacturing step—it is a performance decision. Understanding how forming parameters interact with material behavior allows buyers to select trays that perform consistently, scale reliably, and reduce operational risk. In food packaging, long-term success depends not just on what material is used, but on how it is formed.

References

-

Plastics Technology – Thermoforming Fundamentals

https://www.ptonline.com/articles/thermoforming-fundamentals -

SPI / PLASTICS Industry Association – Thermoforming Overview

https://www.plasticsindustry.org/industry-guide/thermoforming -

British Plastics Federation – Thermoforming Process Guide

https://www.bpf.co.uk/plastipedia/processes/thermoforming.aspx -

PlasticsEurope – Polymer Behavior and Processing

https://plasticseurope.org/knowledge-hub/ -

Packaging Europe – Food Packaging Performance Insights

https://packagingeurope.com/ -

European Food Safety Authority (EFSA) – Food Contact Materials

https://www.efsa.europa.eu/en/topics/topic/food-contact-materials

Copyright Statement

© 2026 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.