Quick Summary

Thermoformed packaging has become increasingly popular in various industries, including food, healthcare, and consumer goods. With its cost-effectiveness, sustainability, and customizability, it has become a preferred packaging solution. This article explores the benefits of thermoformed packaging, analyzing data from market trends, consumer behavior, and the perspectives of manufacturers and suppliers. Supported by industry data, we discuss how thermoformed packaging provides cost savings, environmental benefits, and improved product appeal.

Introduction

In recent years, thermoformed packaging has grown in popularity across several industries, from food to consumer goods. By using heated plastic sheets to mold packaging into the desired shape, thermoforming offers cost efficiency, design flexibility, and enhanced product protection. As industries strive to meet consumer demand for sustainable and efficient solutions, thermoformed packaging has emerged as a key player. This article delves into the benefits of thermoformed packaging, with a focus on market growth, consumer preferences, and insights from manufacturers and suppliers, all backed by relevant data.

1. Understanding Thermoformed Packaging

What is Thermoforming?

Thermoforming is a process where a plastic sheet is heated to a pliable temperature, then molded into a specific shape. Once the plastic cools, it becomes rigid and can be trimmed to form the final packaging. Common thermoforming materials include PET, rPET, PLA, and PS, all of which have various applications in industries like food, pharmaceuticals, and retail.

-

Materials Used:

-

PET (Polyethylene Terephthalate): A common plastic used in thermoforming for its strength, clarity, and recyclability.

-

rPET (Recycled PET): PET that has been recycled, offering a sustainable alternative to virgin plastic.

-

PLA (Polylactic Acid): A biodegradable plastic derived from renewable resources, commonly used in eco-friendly packaging.

-

PS (Polystyrene): Often used in foodservice packaging, such as trays and cups.

-

Types of Thermoformed Packaging

-

Blister Packs: Widely used for consumer goods like electronics and healthcare products.

-

Clamshell Packaging: Ideal for food items, such as fresh produce and takeaway meals.

-

Trays and Containers: Used in foodservice for packaging deli items, salads, or snacks.

2. Market Trends and Growth of Thermoformed Packaging

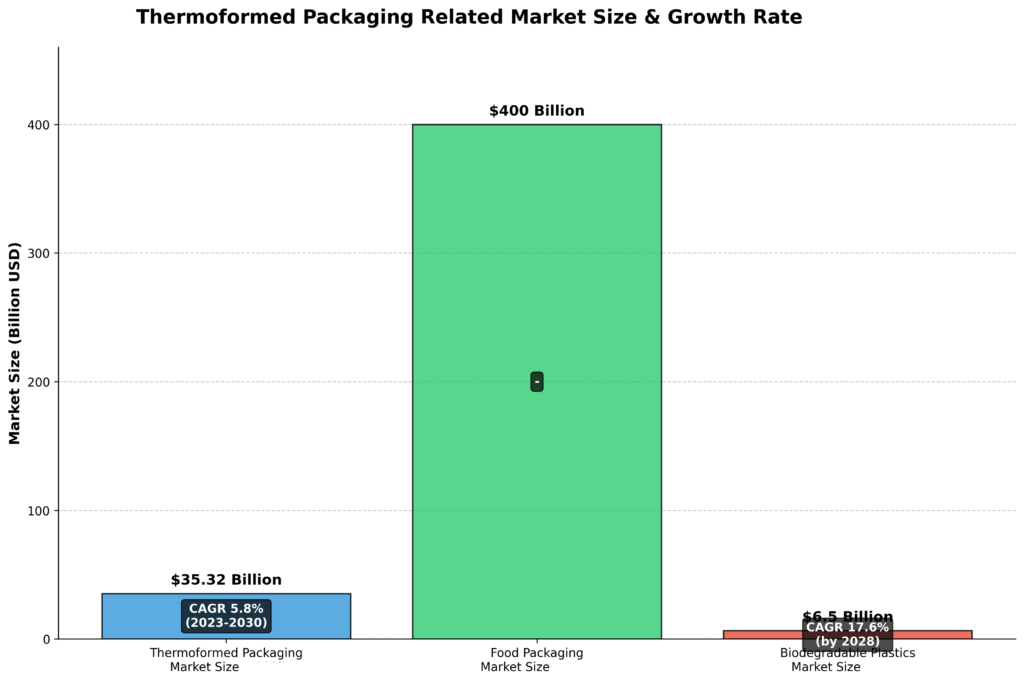

The global thermoformed packaging market has been growing rapidly. According to Grand View Research, the thermoformed packaging market size was valued at $35.32 billion in 2023, and it is expected to expand at a CAGR of 5.8% from 2023 to 2030. This growth is driven by increased demand in sectors like food, healthcare, and consumer goods.

Food and Beverage Sector

Thermoformed packaging has found widespread use in the food and beverage industry, particularly for packaging ready-to-eat meals, snacks, and fresh produce. According to the Global Food Packaging Market Report, the global food packaging market was valued at over $400 billion in 2023, and thermoformed packaging is projected to account for a growing share due to its ability to preserve food freshness and extend shelf life.

-

Example: In the U.S. alone, the demand for foodservice packaging is expected to grow by 5% annually, with thermoformed solutions taking a significant portion of this growth due to their lightweight nature and product visibility.

Sustainability and Eco-friendly Solutions

There has been a noticeable shift towards sustainable packaging. As consumer awareness around environmental issues grows, brands are increasingly looking to adopt eco-friendly packaging. The use of materials like rPET and PLA in thermoforming has grown significantly. A Nielsen study revealed that 73% of global consumers are willing to pay a premium for sustainable packaging. This trend is expected to continue, making thermoformed packaging a key player in the drive for sustainable packaging solutions.

-

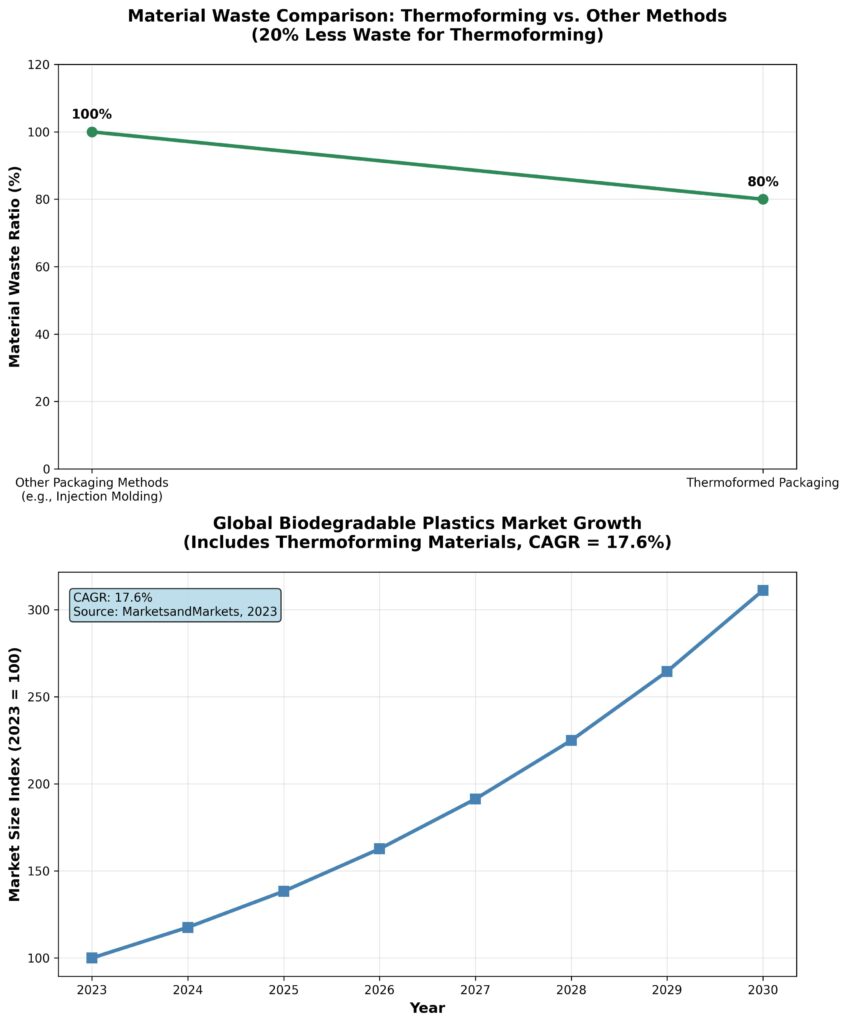

Data Insight: In 2023, the global biodegradable plastics market was valued at $6.5 billion and is projected to grow at a CAGR of 17.6% by 2028 (MarketsandMarkets, 2023). Thermoforming plays a major role in this shift towards biodegradable packaging.

3. Consumer Preferences: Why Do Consumers Favor Thermoformed Packaging?

Convenience and Visibility

One of the main reasons thermoformed packaging is favored by consumers is its transparency and ease of access. Clear, visible packaging allows consumers to view the contents, which is particularly important in industries like food and cosmetics.

-

Consumer Insight: A Nielsen report found that 62% of shoppers are influenced by packaging design, and 54% are more likely to purchase a product if the packaging clearly displays the contents.

Freshness and Safety

Thermoformed packaging helps maintain the freshness of perishable items by providing a protective barrier against air and contaminants. This is particularly important for the food industry, where packaging solutions need to extend shelf life and preserve product quality.

-

Example: Fresh food packaging is one of the largest growing segments of thermoformed packaging, particularly in the packaging of salads, fresh fruit, and sandwiches, which require airtight packaging to preserve freshness.

Ease of Handling

Thermoformed packaging is lightweight, durable, and stackable, making it easy for consumers to handle, store, and transport products. This is especially useful in the retail environment, where packaging needs to withstand transportation while minimizing damage.

-

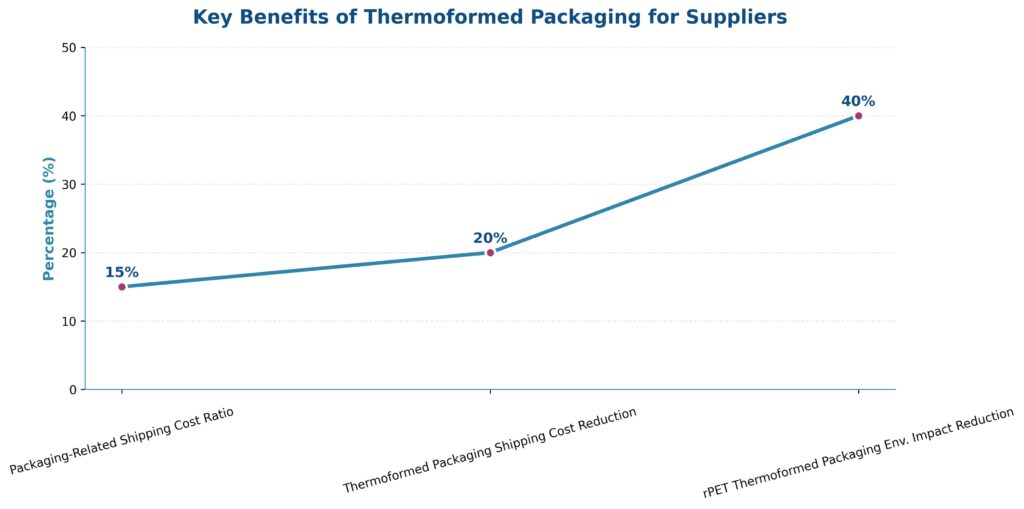

Data Insight: A study from International Packaging Association found that lightweight packaging reduces shipping costs by 15%, making thermoformed packaging a cost-effective solution for retailers.

4. Manufacturer Perspective: Why Do Manufacturers Prefer Thermoformed Packaging?

Cost-effectiveness

Thermoforming offers a cost-effective solution for producing packaging in bulk. The process is faster than other molding techniques, such as injection molding, and the cost per unit is lower, particularly when producing high volumes of packaging. This makes it an ideal choice for businesses looking to optimize their packaging budgets.

-

Data Insight: According to Packaging Digest, thermoformed packaging can be up to 30% cheaper to produce than alternative packaging methods like injection molding.

Design Flexibility and Customization

One of the significant advantages of thermoforming is the ability to easily customize designs. Manufacturers can quickly modify the shape, size, and features of the packaging to suit specific product requirements. This flexibility allows businesses to differentiate their products and enhance brand appeal.

Reduced Production Time

Thermoforming allows manufacturers to create packaging quickly, which helps meet consumer demand and market trends more efficiently. This reduces lead times and allows for faster turnaround in production.

-

Data Insight: The Thermoforming Manufacturers Association (TMA) reports that production time for thermoformed packaging can be up to 40% faster than injection-molded alternatives.

5. Supplier Perspective: How Thermoformed Packaging Benefits Suppliers

Lower Shipping Costs

The lightweight nature of thermoformed packaging helps reduce transportation and shipping costs. This is especially beneficial for suppliers who ship large volumes of products.

-

Data Insight: According to the International Shipping Survey, 15% of shipping costs are related to packaging. Thermoformed packaging’s lightweight nature can reduce these costs by up to 20%.

Reduced Environmental Impact

Suppliers are increasingly adopting thermoformed packaging made from recycled and biodegradable materials. This move aligns with global efforts to reduce plastic waste and lower carbon footprints.

-

Fact: The use of recycled PET (rPET) in thermoformed packaging can reduce environmental impact by up to 40% compared to using virgin plastics.

6. Environmental Benefits: Thermoforming and Sustainability

Reduction in Material Waste

Thermoforming produces less material waste compared to other packaging methods. The process uses precise cutting techniques to minimize scrap material.

-

Data Insight: Thermoformed packaging generates up to 20% less waste than alternative methods such as injection molding.

Recyclability and Biodegradability

As sustainability becomes more critical, the use of rPET and PLA in thermoformed packaging helps reduce the environmental impact. These materials are recyclable and biodegradable, contributing to a circular economy and reducing waste in landfills.

-

Global Trend: The global biodegradable plastics market, which includes materials used in thermoformed packaging, is expected to grow at a CAGR of 17.6%, reflecting a shift towards more eco-friendly solutions (MarketsandMarkets, 2023).

Energy Efficiency

Thermoforming uses less energy than other molding processes, which helps reduce carbon emissions in the production phase.

7. Challenges and Limitations of Thermoforming

While thermoforming offers numerous benefits, there are some challenges associated with the process.

-

Material Limitations: Not all materials are suitable for thermoforming, and certain high-performance applications may require alternative methods like injection molding.

-

Initial Tooling Costs: Custom designs require significant upfront investment in molds and tools, making the initial cost higher than for standard designs.

8. Conclusion: The Future of Thermoformed Packaging

Key Takeaways

-

Thermoformed packaging offers several advantages, including cost savings, sustainability, and design flexibility.

-

The market for thermoformed packaging is growing, with food, beverage, and healthcare industries leading the way.

-

Manufacturers and suppliers are adopting eco-friendly practices, further boosting the demand for thermoformed packaging.

Looking Ahead

As consumer demand for sustainable and efficient packaging continues to rise, the future of thermoformed packaging looks promising. With ongoing innovations in materials and production techniques, thermoformed packaging will remain a vital part of the packaging industry.

FAQ (Frequently Asked Questions)

-

What is thermoformed packaging?

-

Thermoformed packaging is created by heating a plastic sheet and molding it into a specific shape. It’s commonly used for packaging food, consumer goods, and electronics.

-

-

What are the benefits of using thermoformed packaging for food?

-

It helps preserve freshness, prevents contamination, and extends shelf life, making it ideal for perishable goods.

-

-

Is thermoformed packaging environmentally friendly?

-

Yes, many thermoformed packages are made from recyclable or biodegradable materials like rPET and PLA, making them eco-friendly.

-

-

How does thermoformed packaging reduce shipping costs?

-

The lightweight nature of thermoformed packaging reduces transportation costs, making it more economical for suppliers and retailers.

-

-

Why is thermoformed packaging growing in popularity?

-

The growth is due to its cost-effectiveness, sustainability, and consumer preference for clear, visible packaging that enhances product appeal.

-

References

-

Grand View Research. (2023). Thermoformed Packaging Market Size, Share & Trends Analysis Report by Material (Plastic, Aluminum), by Application (Food, Healthcare), by Region, and Segment Forecasts, 2023 – 2030. Retrieved from https://www.grandviewresearch.com

-

Nielsen. (2023). Global Consumer Preferences for Sustainable Packaging Solutions. Nielsen Insights. Retrieved from https://www.nielsen.com

-

MarketsandMarkets. (2023). Biodegradable Plastics Market by Type (PLA, PHA, Starch Blends), Application (Packaging, Agriculture, Consumer Goods), and Region – Global Forecast to 2028. Retrieved from https://www.marketsandmarkets.com

-

International Packaging Association. (2023). Sustainability and the Future of Thermoformed Packaging. Retrieved from https://www.packaging.org

Copyright Statement© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.All text, data, and images are the result of our independent research, industry experience,and product development insights. Reproduction or redistribution of any part of this contentwithout written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information andto upholding transparency, originality, and compliance with global intellectual property standards.