As sustainability takes centre stage in the foodservice industry, businesses are seeking alternatives to single-use plastic. Among the most promising solutions is Sugarcane Bagasse Packaging, known for its compostability and performance. Another popular choice is Paper Pulp, widely used for bakery trays and moulded fibre products.

Both materials offer eco-friendly benefits, but which is better suited for modern food packaging needs? This article provides a comprehensive comparison of sugarcane bagasse packaging and paper pulp, looking at sustainability, durability, resistance to oil and water, and cost. We will also explore why Xiamen Dashan is a trusted manufacturer in delivering these solutions globally.

✅ 1. Quick Comparison: Bagasse vs Paper Pulp

| Feature | Bagasse | Paper Pulp |

|---|---|---|

| Environmental Impact | ✅ Made from agricultural waste, fully compostable | ❌ Requires trees or recycled fibres, higher carbon footprint |

| Water & Oil Resistance | ✅ Excellent for liquids and oily foods | ❌ Needs coating, weak against moisture |

| Heat Resistance | ✅ Microwave and freezer safe | ❌ Deforms with heat |

| Best Applications | Hot meals, takeaway boxes, drink cups | Bakery trays, dry food packaging |

✅ 2. Environmental Sustainability

Bagasse is a by-product of sugarcane, turning waste into valuable packaging. It’s compostable in about 90 days and has a lower carbon footprint.

Paper pulp, made from wood fibres or recycled paper, is also biodegradable, but its production often involves energy-intensive processes and additional coatings for performance.

Verdict: Bagasse clearly leads in sustainability, especially for businesses aiming to reduce their environmental impact.

✅ 3. Performance in Food Packaging

Bagasse packaging is strong, leak-resistant, and suitable for hot and cold foods. It doesn’t require extra coatings for oil and water protection and works well for microwave reheating and freezer storage.

Paper pulp is more suitable for dry items and bakery goods, but without coatings, it softens when exposed to moisture or heat.

✅ 4. Cost and Branding

Both materials can be moulded into different shapes and customised with branding. Bagasse tends to be more cost-effective because it uses agricultural waste and requires fewer chemical treatments than paper pulp.

✅ Applications at a Glance

- Bagasse: Takeaway boxes, plates, drink cups, hot meals.

- Paper Pulp: Bakery trays, dessert packaging, where smooth branding is essential.

Why Choose Xiamen Dashan?

At Xiamen Dashan, we specialise in producing eco-friendly packaging solutions, including Bagasse food containers and PLA products. Our products are:

✔ Compostable and biodegradable

✔ Oil and water-resistant

✔ Customisable with branding options

✔ Certified for global food safety standards

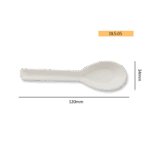

From takeaway boxes and salad bowls to biodegradable plates and cutlery, we help businesses switch to sustainable packaging without compromising on quality or performance.

✅ Final Thoughts

If your priority is hot meals, oily dishes, or takeaway delivery, Bagasse offers superior performance and sustainability. Paper Pulp works well for dry foods and bakery packaging but falls short on heat and water resistance.

As environmental regulations tighten, Bagasse packaging will become a key solution for foodservice businesses worldwide—and Xiamen Dashan is here to help you make the transition smoothly.

✅ References

- European Bioplastics – Benefits of Using Bagasse for Sustainable Packaging

https://www.european-bioplastics.org - FAO (Food and Agriculture Organization) – Agricultural Residues for Packaging Materials

https://www.fao.org - GreenBlue – Sustainable Packaging Coalition – Moulded Fibre vs. Bagasse: Environmental Impact

https://sustainablepackaging.org - ScienceDirect – Comparative Study on Biodegradability of Bagasse and Paper-Based Materials

https://www.sciencedirect.com - Compost Manufacturing Alliance – Commercial Compostability of Fibre-Based Packaging

https://compostmanufacturingalliance.com

Disclaimer & Copyright Notice

This article is created by the Dashan Packing editorial and research team.All information presented here is for educational and industry reference purposes only.Some data and standards cited in this article are sourced from publicly available materials,official regulatory documents, or third-party publications, which are properly credited where applicable.

All rights to third-party trademarks, images, and content belong to their respective owners.If any copyrighted material has been used inadvertently, please contact us at angel@chndashan.com.We respect intellectual property rights and will promptly remove or revise any material upon verification.