Introduction

Food packaging plays a crucial role in safeguarding the quality and safety of food products. However, packaging materials also have the potential to affect the food they encase—either through contamination, migration of harmful substances, or unintended chemical reactions. The FDA (Food and Drug Administration) is the central regulatory authority in the United States responsible for ensuring that food packaging materials do not pose a risk to public health.

The FDA’s regulations set the standards for a wide range of packaging materials, including plastics, biodegradable materials, glass, and paperboard. The agency requires manufacturers to comply with specific testing and approval processes before packaging materials can enter the market.

In this article, we will provide a comprehensive guide to the role of the FDA in food packaging compliance, discussing everything from FDA guidelines to testing procedures and real-world compliance examples.

What is the FDA?

The FDA is a division of the U.S. Department of Health and Human Services, tasked with protecting public health through the regulation of food, drugs, medical devices, and more. In the context of food packaging, the FDA ensures that materials that come into contact with food do not contain harmful substances or lead to any unintended health risks.

FDA Regulatory Scope:

-

Food Contact Substances (FCS): Materials intended to touch food directly, such as packaging films, trays, and containers.

-

Indirect Food Additives: Chemicals and substances that may indirectly affect food quality, such as inks used in packaging or additives used in the manufacturing process.

Key Responsibilities of the FDA:

-

Ensuring Food Safety: The FDA evaluates packaging materials to ensure they do not release harmful chemicals into food.

-

Setting Standards for Materials: The agency sets strict regulations on food contact substances, ensuring that they meet safe migration levels for chemicals.

-

Regulating Food Labeling: The FDA oversees packaging labels to ensure they accurately represent product contents and provide consumers with essential safety information.

FDA’s Regulatory Framework for Food Packaging

The FDA maintains a rigorous regulatory framework that governs food packaging. This framework consists of guidelines for the approval of materials, as well as safety protocols for manufacturers to follow.

Key Regulations:

-

21 CFR Part 177: This part of the Code of Federal Regulations (CFR) governs food contact substances and provides a list of approved materials and substances. It outlines the standards that packaging materials must meet to be deemed safe for direct contact with food.

-

21 CFR Part 178: This regulation deals with indirect food additives, including chemicals used in food packaging manufacturing processes. It also covers substances that might come into indirect contact with food, such as printing inks, adhesives, and coatings.

-

Food Contact Substance Notifications (FCN): Manufacturers must submit an FCN to the FDA before new materials or chemicals can be used in food packaging. This process ensures that all new materials meet FDA’s migration standards.

FDA’s Testing and Approval Process

Before food packaging materials can be used commercially, they must undergo a series of tests to confirm their safety. The FDA requires that manufacturers conduct migration testing, where substances are tested to ensure they do not leach into food at unsafe levels.

Migration Testing:

Migration refers to the movement of chemicals from packaging materials into the food they hold. Migration testing simulates various food types (e.g., oily, aqueous, alcoholic) to determine if any chemicals migrate into food at levels deemed unsafe by the FDA.

-

Simulated Food Tests: The FDA uses food simulants (water, ethanol, olive oil) to test how packaging materials interact with food.

-

Threshold Limits: The FDA sets migration limits for chemicals to ensure the safety of food packaging materials. For example, phthalates and BPA are carefully regulated because of their potential health risks.

Table 1: FDA’s Migration Testing Requirements

| Material | Test Type | FDA Approved Migration Limit | FDA Regulation |

|---|---|---|---|

| Plastic (PET) | Simulated migration test | 0.05 mg/kg | 21 CFR Part 177 |

| Biodegradable (PLA) | Simulated migration test | 0.01 mg/kg | 21 CFR Part 177.1520 |

| Polystyrene (PS) | Simulated migration test | 0.05 mg/kg | 21 CFR Part 177 |

| Aluminum | Migration & stress test | No defined threshold for aluminum | 21 CFR Part 178 |

FDA Compliance: The Role of Manufacturers

Food packaging manufacturers are responsible for ensuring that the packaging materials they produce comply with FDA regulations. This involves submitting packaging materials to the FDA for approval before they can be marketed, conducting required safety testing, and providing documentation on chemical migration and material composition.

Good Manufacturing Practices (GMP):

Manufacturers are also required to adhere to Good Manufacturing Practices (GMP), which ensure that the food packaging is produced in a safe and controlled environment. GMP covers the entire manufacturing process, from sourcing raw materials to the final packaging product.

Table 2: FDA Submission Process for Packaging Approval

| Step | Description | Timeline |

|---|---|---|

| Pre-market Approval | Manufacturers submit their packaging materials to the FDA for review. | 90-120 days |

| Migration Testing | Testing to confirm that no harmful substances migrate into food. | Varies based on material |

| FCN Submission | Manufacturers submit a Food Contact Substance Notification for FDA approval. | 60-90 days |

| Post-Approval Monitoring | Continuous monitoring of packaging materials to ensure ongoing compliance. | Ongoing |

FDA’s Role in Sustainable Food Packaging

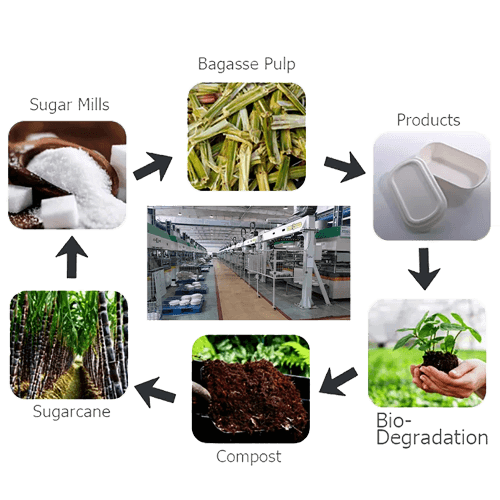

Sustainability is becoming increasingly important in the food packaging industry. With growing concerns about environmental impacts, such as plastic waste and carbon footprints, many manufacturers are turning to biodegradable materials like PLA, sugarcane bagasse, and cornstarch for food packaging.

The FDA plays a role in ensuring that these materials are not only environmentally friendly but also safe for consumers. While biodegradable materials have benefits, such as compostability, they still need to undergo rigorous testing to ensure they do not introduce harmful chemicals into food.

Challenges with Biodegradable Packaging and FDA Approval:

Biodegradable materials like PLA are still relatively new compared to traditional plastics, and their migration profiles must be thoroughly studied. PLA, for instance, is derived from plant-based sources like corn starch, but it can degrade into lactic acid and other chemicals under certain conditions. The FDA must test these substances to ensure that they are not harmful.

Table 3: Comparison of Biodegradable Food Packaging Materials

| Material | Environmental Benefit | FDA Testing Requirements | Common Applications |

|---|---|---|---|

| PLA (Polylactic Acid) | Biodegradable, compostable | Migration testing for lactic acid residues | Cups, food trays, cutlery |

| Sugarcane Bagasse | Compostable, renewable | Migration testing for chemical safety | Takeout boxes, food trays |

| Cornstarch | Biodegradable, compostable | Migration testing, biodegradability studies | Cutlery, trays |

FDA Labeling Requirements for Food Packaging

The FDA regulates food packaging labels to ensure they provide consumers with accurate and reliable information about the contents of the package. Labels must include nutritional information, ingredient lists, and allergen warnings. In addition, sustainability claims such as compostable, biodegradable, or recyclable must be substantiated by data.

FDA Labeling Guidelines:

-

Nutritional Facts: Required on all food packaging that contains nutritional components (e.g., calories, fat content, sugars).

-

Ingredient Lists: Must list all ingredients used in the food product.

-

Sustainability Claims: When manufacturers claim that their packaging is compostable or biodegradable, they must adhere to strict standards to ensure these claims are accurate.

Table 4: FDA Labeling Requirements for Food Packaging

| Label Requirement | Regulation | Purpose |

|---|---|---|

| Nutritional Facts | 21 CFR Part 101 | Provides consumers with detailed nutritional information |

| Allergen Warnings | 21 CFR Part 101 | Alerts consumers about potential allergens like peanuts or gluten |

| Recycling Information | 21 CFR Part 1020 | Guides consumers on how to dispose of packaging responsibly |

Conclusion: The FDA’s Crucial Role in Food Packaging Compliance

The FDA’s comprehensive regulations ensure that food packaging materials are safe for consumers and meet stringent health and safety standards. Through migration testing, food contact substance notifications, and sustainability initiatives, the FDA plays an essential role in regulating the materials used in food packaging.

As food packaging evolves to meet sustainability goals and respond to consumer demand for eco-friendly products, the FDA continues to adapt its regulations to support both food safety and environmental responsibility.

FAQ

-

What materials are FDA-approved for food packaging?

-

FDA-approved materials include plastics (PET, PP), biodegradable plastics (PLA), glass, and paper, each subject to different testing requirements.

-

-

How does the FDA ensure food packaging materials are safe?

-

The FDA requires migration testing and pre-market approval for all materials that come into direct contact with food.

-

-

Can biodegradable packaging materials be FDA-approved?

-

Yes, materials like PLA and bagasse can be FDA-approved, but they must undergo migration testing to ensure they do not release harmful chemicals.

-

-

What happens if packaging materials fail FDA approval?

-

Packaging materials that do not meet FDA standards may not be marketed, and manufacturers could face penalties, including recalls.

-

-

How does the FDA regulate food packaging labeling?

-

The FDA mandates accurate labeling of nutritional information, allergen warnings, and sustainability claims to ensure consumer safety and transparency.

-

References

-

U.S. Food and Drug Administration (FDA). (2023). Food Contact Substances (FCS). Retrieved from https://www.fda.gov/food/food-labeling-nutrition/food-contact-substances-fcs

-

U.S. Food and Drug Administration (FDA). (2023). CFR – Code of Federal Regulations Title 21: Food and Drugs. Retrieved from https://www.ecfr.gov/cgi-bin/text-idx?SID=32d23040a52c360d5570a0a03b16b395&mc=true&node=pt21.3.177&rgn=div5

-

EFSA (European Food Safety Authority). (2020). Food Contact Materials: Migration of Chemicals from Packaging to Food. European Food Safety Authority. Retrieved from https://www.efsa.europa.eu/en/topics/topic/food-contact-materials

-

Bhat, R., & Deka, S. (2021). Migration of Chemical Substances from Packaging Materials into Food. International Journal of Environmental Research and Public Health, 18(10), 5354. https://doi.org/10.3390/ijerph18105354

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.