Introduction

In an increasingly competitive and environmentally conscious world, food packaging has become a crucial part of a business’s operations. Whether it’s for food preservation, convenience, branding, or sustainability, the material used in food packaging plays a significant role in determining its success. Among the various materials available, PP material (Polypropylene) stands out as one of the most widely used and favored choices in the food packaging industry.

Polypropylene, commonly referred to as PP material, is a thermoplastic polymer that has revolutionized the way food packaging is manufactured. Its excellent balance of durability, heat resistance, chemical stability, and recyclability makes it a preferred option for many businesses. From PP food containers to microwave-safe trays, PP material offers a multitude of benefits that contribute to its popularity in food packaging.

In this article, we will explore why businesses choose PP material for food packaging, covering everything from its inherent properties and environmental advantages to its wide range of applications and customization options.

1. The Properties of PP Material That Make It Ideal for Food Packaging

1.1 Durability and Strength

One of the standout characteristics of PP material is its exceptional durability. Unlike other plastics, PP material is resistant to cracking, breaking, and deformation under stress, making it ideal for food packaging. This is particularly important for packaging items that are frequently handled, stacked, or transported, such as food trays, containers, and lids.

For businesses that require packaging that maintains its integrity throughout the supply chain, PP material ensures that food products remain secure and undamaged, from production to point of sale.

1.2 Heat Resistance

In the food packaging industry, heat resistance is a critical factor, especially for products that require microwaving or exposure to high temperatures. PP material is well-regarded for its ability to withstand temperatures up to 120°C (248°F) without losing its structural integrity. This makes PP packaging ideal for applications where food might be microwaved or subjected to hot conditions, such as PP microwave trays and hot food containers.

Businesses in the ready-to-eat and fast-food industries rely on PP material for packaging hot meals and snacks that need to be transported or served to customers. The heat resistance of PP material ensures that food stays secure without damaging the packaging or altering the product.

1.3 Transparency and Clarity

Consumers increasingly value the ability to see the product they are purchasing, and PP material offers excellent clarity and transparency. This feature is particularly beneficial for packaging fresh produce, deli items, and ready-to-eat meals, as it allows consumers to evaluate the freshness and quality of the food before making a purchase.

Whether it’s a PP salad container, sandwich box, or fresh fruit tray, the high level of clarity provided by PP material enhances the visual appeal of the food product, contributing to better consumer satisfaction.

1.4 Chemical Resistance

Food packaging needs to withstand exposure to oils, fats, acids, and other chemicals without degrading. PP material excels in this aspect, offering excellent resistance to many chemicals, oils, and solvents. This is particularly important for packaging fatty foods, sauces, or spicy dishes that might otherwise cause deterioration or staining in other materials.

The chemical stability of PP material ensures that food packaging maintains its functionality and does not compromise food quality due to external factors. This makes PP containers ideal for a wide range of food types, from greasy take-out meals to delicate salads.

2. Environmental and Economic Benefits of PP Material

2.1 Cost-Effectiveness

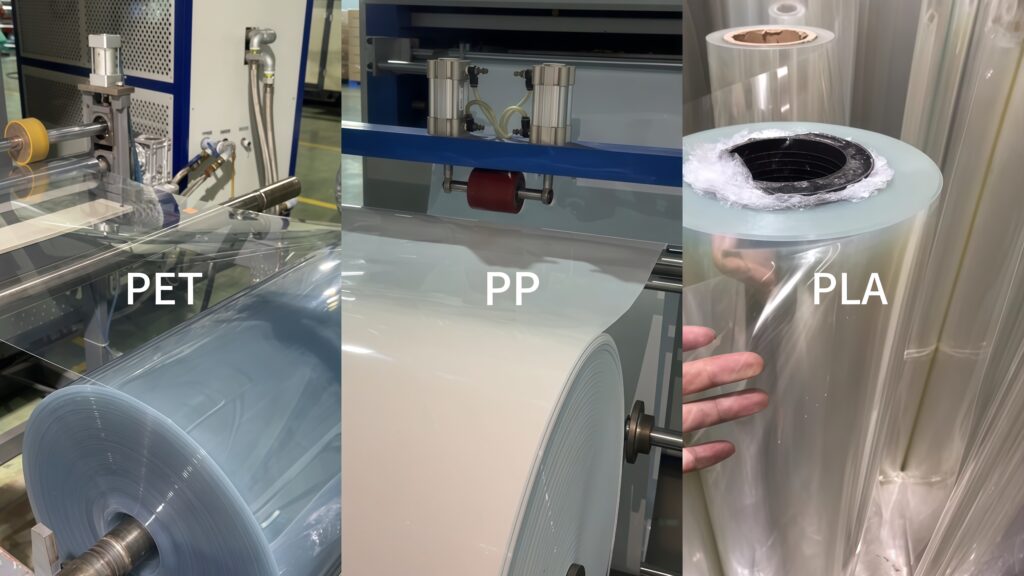

One of the main reasons why businesses opt for PP material is its cost-effectiveness. When compared to other materials like PET or PLA, PP material is relatively inexpensive to manufacture. This affordability makes PP packaging a popular choice for companies looking to reduce packaging costs while maintaining high standards of food protection and presentation.

For businesses in the food service industry, PP packaging provides a way to keep costs low while delivering high-quality, durable packaging. Additionally, the cost-effectiveness of PP material allows companies to invest in other areas of their business, such as product development or marketing.

2.2 Sustainability

Sustainability is an increasingly important factor in consumer purchasing decisions, and businesses are under pressure to adopt more eco-friendly practices. While PP material is not biodegradable like PLA, it is fully recyclable. In regions with established recycling systems, PP packaging can be collected, processed, and reused, making it a more sustainable option than many other packaging materials.

Companies can take advantage of PP material‘s recyclability to bolster their environmental credentials, positioning themselves as part of the solution to plastic waste. Many PP food containers and packaging solutions are designed with recycling in mind, which contributes to a more sustainable food packaging ecosystem.

2.2.1 Energy Efficiency in Production

The production of PP material is more energy-efficient compared to other plastic materials like PET. This results in a lower carbon footprint during the manufacturing process. As energy consumption becomes a more critical factor in determining sustainability, businesses that choose PP material can contribute to reducing overall environmental impact.

2.3 Food Safety

Food safety is a top priority for any packaging material, and PP material excels in this area. It complies with food safety regulations, ensuring that it is safe for direct food contact. Unlike some plastics, PP material does not leach harmful chemicals or plasticizers into food, making it a safe and reliable choice for food packaging.

For businesses that need to meet stringent food safety standards, PP food packaging offers a peace of mind, ensuring that their products remain uncontaminated by the packaging itself.

2.4 Recycling and Circular Economy

As the world shifts towards a more circular economy, PP material plays a crucial role in reducing waste and conserving resources. Since it is recyclable, PP packaging can be reused in future manufacturing processes, reducing the need for new raw materials.

Companies that invest in PP material can contribute to a more sustainable supply chain by adopting PP recycling programs and encouraging consumers to recycle packaging after use. This circular approach aligns with the growing trend toward sustainable packaging solutions.

3. Versatility of PP Material in Food Packaging Applications

3.1 Takeaway Packaging

PP material is widely used in the takeaway food packaging sector. Its ability to retain food quality, along with its resistance to heat, makes it perfect for takeout containers, sandwich boxes, and salad bowls. Whether for hot meals or cold salads, PP containers offer excellent performance in maintaining the integrity and freshness of food.

The stackable nature of PP packaging makes it easy to transport, while its ability to keep food secure and intact makes it the ideal choice for takeout food. Customization options, such as branded logos and colors, allow businesses to further personalize their packaging and enhance their branding.

3.2 Fresh Produce Packaging

Fresh produce, such as fruits, vegetables, and herbs, requires packaging that is both protective and breathable. PP material is commonly used for fresh produce packaging due to its strength, lightweight nature, and ability to allow air circulation. This ensures that produce stays fresh for longer periods while being protected from damage during handling and transportation.

PP trays and clamshell containers are often used to package fresh produce, offering consumers a clear view of the product inside. Additionally, PP material is non-toxic and food-safe, making it a trusted option for packaging perishable goods.

3.3 PP Plastic Cups and Lids for Beverages

For beverages, PP cups and lids are a popular choice due to their durability and ability to maintain the freshness of the contents. Whether it’s for cold drinks, smoothies, or takeaway coffee, PP cups provide a safe, transparent option for beverage packaging. The material’s resistance to cracking and ability to maintain clarity makes it ideal for high-traffic establishments like fast food chains and cafes.

Additionally, PP lids are available in various designs, including flat and dome styles, and can be customized with logos, making them a versatile packaging option for businesses in the beverage industry.

3.4 Food Trays for Ready Meals

Ready meals are a fast-growing segment in the food packaging industry. PP food trays are commonly used for ready-to-eat meals because they provide a secure and microwave-safe option for packaging. Consumers can easily heat their meals in the microwave without worrying about damaging the packaging or compromising the food.

The versatility of PP trays means they can be used for a wide range of meal types, from pasta dishes to rice bowls. Their durability and ability to withstand high temperatures ensure that food stays fresh and hot until it reaches the consumer.

3.5 Fast Food and Fast Casual Packaging

Fast food businesses benefit greatly from PP material packaging. Its strength, affordability, and ease of use make it an ideal choice for high-volume food packaging. From burgers and fries to chicken wings and salads, PP food packaging ensures that food stays fresh and secure while maintaining a low cost for businesses.

In the fast-casual sector, where presentation is key, PP packaging offers opportunities for customization, allowing businesses to showcase their branding while delivering practical, eco-friendly solutions.

4. Customization and Branding Opportunities with PP Material

4.1 PP Material and Customization

Customization is a crucial element in food packaging, especially for businesses looking to build a strong brand identity. PP material is highly adaptable to different shapes, sizes, and designs, allowing businesses to create packaging that is both functional and aesthetically appealing.

Whether it’s adding custom logos, printed designs, or embossed patterns, PP food packaging provides a versatile canvas for businesses to enhance their branding. Customized packaging not only improves brand recognition but also offers a unique customer experience, helping businesses stand out in a crowded market.

4.2 Eco-Friendly Branding

As sustainability becomes a priority for both businesses and consumers, adopting PP material for food packaging offers companies a way to align their packaging with eco-friendly values. By using recyclable PP packaging, businesses can promote their commitment to environmental responsibility while still providing durable and effective food storage solutions.

4.3 Enhanced Consumer Experience

Consumers appreciate the opportunity to interact with packaging that is not only functional but also visually appealing. PP material enables businesses to design packaging that enhances the overall consumer experience. Whether it’s through clear, vibrant designs or practical features like microwave-safe containers, PP material helps businesses meet the expectations of today’s savvy consumers.

5. The Future of PP Material in Food Packaging

5.1 Growing Demand for Sustainable Packaging Solutions

As the demand for sustainable packaging solutions increases, PP material is likely to remain a key player in the food packaging industry. Its recyclability, cost-effectiveness, and durability make it a material that businesses can rely on to meet both functional and environmental goals.

With consumers increasingly seeking eco-friendly options, PP material offers a balance between sustainability and practicality, making it an ideal solution for businesses committed to reducing their environmental impact.

5.2 Innovations in PP Material Packaging

The packaging industry is continuously evolving, with innovations in materials, designs, and production methods. As technology advances, PP material is expected to become even more versatile, offering improved performance, better recyclability, and more sustainable production methods. Businesses can look forward to even more customized, eco-friendly, and functional packaging solutions in the near future.

5.3 PP Packaging and Food Safety Regulations

With the growing emphasis on food safety regulations, PP material will continue to meet the strict standards set by health and safety authorities. Its non-toxic, food-safe nature ensures that PP food containers and packaging remain a top choice for businesses seeking regulatory compliance in the food industry.

Conclusion

In conclusion, PP material is an invaluable asset to the food packaging industry. Its exceptional durability, heat resistance, transparency, and recyclability make it a preferred choice for businesses looking to deliver high-quality, cost-effective, and eco-friendly packaging solutions. Whether for takeaway containers, microwave-safe trays, or fresh produce packaging, PP material offers a wide range of applications that meet the needs of both businesses and consumers.

With its combination of practicality, customization options, and sustainability, PP material is set to remain a key player in the food packaging industry for years to come. Businesses that embrace PP material not only benefit from its performance but also contribute to a more sustainable and efficient packaging solution for the future.

FAQs (Frequently Asked Questions)

1. What makes PP material a good choice for food packaging?

PP material is preferred for food packaging because of its durability, heat resistance, and chemical stability. It offers high clarity, making it ideal for products that need to be visually appealing. Moreover, it is cost-effective, recyclable, and food-safe, making it suitable for a variety of food applications, from takeaway containers to microwave-safe trays.

2. Is PP material microwave-safe?

Yes, PP material is microwave-safe and can withstand temperatures up to 120°C (248°F) without deforming. This makes it ideal for packaging hot meals or products that will be reheated in the microwave. PP food containers and trays are commonly used in the fast-food and ready-to-eat meal sectors for this reason.

3. Is PP material recyclable?

Yes, PP material is fully recyclable. Many regions have established systems for recycling PP packaging, which can be reused to create new products. While PP material is not biodegradable, its recyclability makes it a more sustainable option than other single-use plastics.

4. Can PP material be used for both hot and cold foods?

Yes, PP material is versatile and can be used for both hot and cold food packaging. Its heat resistance ensures that it can handle hot meals, while its ability to maintain the integrity of cold items makes it ideal for salads, fresh fruits, and beverages.

5. Does PP material leach harmful chemicals into food?

No, PP material is food-safe and does not leach harmful chemicals or plasticizers into food. It complies with food safety regulations, ensuring that food remains uncontaminated when packaged in PP containers. This makes it a reliable and trusted option for food packaging.

References

-

Food Packaging Materials: Properties and Applications. (2022). Journal of Food Science and Technology. Link to journal.

-

Polypropylene: An Overview. (2021). Plastic Materials & Their Applications. Polymer Society. Link to source.

-

The Impact of Recycled PP on Packaging Sustainability. (2023). Packaging & Sustainability Journal. Link to article.

-

PP Material in Food Packaging: Trends and Future Directions. (2023). Packaging Technology Review. Link to source.

-

Recycling and Circular Economy in Food Packaging. (2022). Global Packaging Conference. Link to conference proceedings.

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.