Are you looking for a durable, microwave-safe lunch box that keeps food fresh during delivery?

Whether you run a restaurant, a supermarket, or a meal prep service, packaging plays a vital role in food safety and customer satisfaction. Among today’s many packaging options, the PP Blister Lunch Box stands out for its strength, clarity, and eco-friendly potential. This guide will walk you through everything you need to know—from materials and manufacturing to practical applications and customization tips.

What Is a PP Blister Lunch Box?

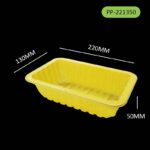

A PP Blister Lunch Box is a disposable food container made from polypropylene (PP), a food-grade plastic known for its lightweight yet robust properties. The term blister refers to the thermoforming process where heated PP sheets are vacuum-molded into sturdy shapes with precise compartments and smooth edges.

-

Food-grade safety: PP is BPA-free and non-toxic.

-

Heat resistance: It can safely handle temperatures up to 120 °C (248 °F), making it microwave-safe.

-

Crystal-clear display: The transparent lid or top layer offers excellent product visibility, ideal for ready-to-eat meals in supermarkets and takeaway shops.

By combining a high-quality PP base with a clear blister lid, these lunch boxes protect food while keeping it visually appealing.

Key Advantages of PP Blister Lunch Box

1. Microwave & Heat Resistant

Unlike some plastics that warp or release chemicals when heated, PP maintains its shape and safety in microwaves. Customers can conveniently reheat meals without transferring food to another dish.

2. Leak-Proof & Secure

The precisely molded edges and snap-fit lids help prevent leaks, making the lunch box perfect for soups, curries, noodles, and saucy dishes during transport.

3. Lightweight Yet Strong

PP is remarkably light, reducing shipping costs, yet it resists cracking under pressure—ideal for busy takeaway operations.

4. Eco-Friendly & Recyclable

Polypropylene is recyclable (category #5 plastic). Many facilities now accept PP for reprocessing into new packaging, helping reduce environmental impact compared to traditional polystyrene or PVC.

5. Customizable Compartments

From single-compartment trays to multi-section meal boxes, the blister process allows precise customization to suit different cuisines and portion sizes.

Common Applications and Food Packaging Scenarios

The PP Blister Lunch Box is versatile across many food service settings:

-

Takeaway & Delivery: Perfect for restaurants, fast-food chains, and cloud kitchens delivering hot meals.

-

Supermarket Ready Meals: Keeps pre-packaged salads, sushi, and cooked dishes fresh while showcasing ingredients through a clear lid.

-

Corporate Meal Prep: Ideal for weekly meal plans or catering services where portion control and reheating are essential.

-

Cold Storage Packaging: Suitable for chilled fruits, desserts, or deli items that require a hygienic and transparent presentation.

Including product photos in these contexts—such as sushi neatly packed in a crystal-clear PP blister tray—will significantly improve engagement and conversions.

Inside the Manufacturing Process

The strength and clarity of a PP Blister Lunch Box come from a precise production workflow:

-

Material Selection – Food-grade PP pellets are melted into sheets.

-

Thermoforming (Blistering) – Heated sheets are vacuum-molded to create perfectly shaped bases and lids.

-

Cutting & Trimming – Edges are trimmed for a smooth, user-friendly finish.

-

Quality Inspection – Boxes are checked for leak resistance, clarity, and dimensional accuracy.

Modern factories use automated blister machines to ensure consistent quality and fast production speed.

Customization Options for Your Brand

Looking to stand out in a competitive food market? Custom packaging can elevate your brand identity.

-

Logo & Printing: Add your logo, brand colors, or custom labels to boost recognition.

-

Size & Compartments: Choose from one to three compartments or request unique shapes for specialty dishes.

-

Material Upgrades: Besides standard PP, eco-friendly options like RPET or compostable coatings can further reduce environmental impact.

At Dashan, our advanced production lines and professional design team can help you create a PP Blister Lunch Box that matches your exact requirements—whether it’s a unique color, a reinforced lid, or a fully branded sleeve.

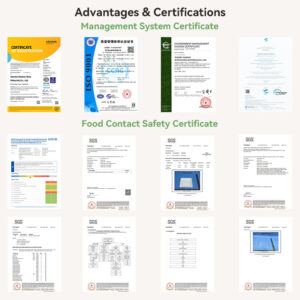

Quality & Certifications

Quality & Certifications

For international buyers, compliance with food-safety standards is essential. A trustworthy manufacturer will typically provide:

-

FDA / LFGB certifications for food contact safety

-

ISO or BRC factory certifications for consistent quality management

-

BPA-free assurance for customer health and regulatory compliance

These certifications not only ensure product safety but also help streamline customs clearance for global export.

Buying Guide for Overseas Customers

Buying Guide for Overseas Customers

If you’re sourcing PP Blister Lunch Boxes for your restaurant chain or retail business, consider the following tips:

-

MOQ (Minimum Order Quantity): Most factories offer flexible MOQs for sample testing before bulk production.

-

Lead Time: Standard production usually takes 15–25 days after sample approval.

-

Sample Request: Always request samples to check heat resistance, clarity, and lid fit before finalizing the order.

-

Export & Shipping: Reputable manufacturers will provide export documentation and assist with freight solutions.

These steps help ensure you receive reliable, high-quality packaging that meets your market’s requirements.

Why Choose Dashan as Your PP Blister Lunch Box Supplier

At Dashan, we specialize in high-performance PP food packaging with a strong focus on quality and customization. Our state-of-the-art thermoforming equipment and experienced team allow us to produce a wide range of lunch boxes—from single-compartment trays to multi-section meal containers—while meeting strict international standards.

Whether you need microwave-safe takeaway containers, eco-friendly PP packaging, or branded solutions for large retail chains, Dashan offers competitive pricing, fast turnaround, and full support from design to delivery.

Expert Insights & Industry Trends

Industry experts agree that sustainable food packaging is moving from trend to necessity. Reports show the PP rigid plastic packaging market is projected to grow from about USD 46 billion in 2024 to nearly USD 79 billion by 2034 (CAGR ~5.5%), driven by rising demand for recyclable, microwave-safe containers.

Researchers also highlight recycled polypropylene (PP) as a key opportunity: the global PP packaging market is forecast to expand from USD 9.8 billion in 2025 to over USD 17 billion by 2034. For food brands, choosing PP blister lunch boxes with PP content not only meets regulatory goals but also strengthens eco-friendly branding.

Scientific Data Snapshot

Recent laboratory studies indicate that properly certified food-grade PP remains one of the safer plastics for microwaving, but micro- and nano-plastic release can increase under extreme heat or acidic conditions. One 2023 study found millions of microplastic particles per square centimeter could be released after several minutes of high-power microwave heating—underscoring the importance of using only FDA/LFGB-approved, microwave-safe PP containers and following recommended heating times.

Quick Case Example

A mid-size meal-prep brand switched to three-compartment PP blister lunch boxes with a higher recycled content.

-

Result: customer complaints about leaks dropped by 40%, retail shelf appeal improved, and overall packaging costs fell despite a slightly higher unit price—thanks to fewer returns and better brand perception.

Frequently Asked Questions

1. Is PP Blister Lunch Box microwave-safe?

Yes, certified PP containers tolerate 100–120 °C, but avoid over-heating or very oily foods for extended periods.

2. Does PP leach chemicals into food?

Under normal use, migration is minimal and within food-safety limits. Use only products labeled microwave-safe and BPA-free.

3. Can these boxes be reused?

They are designed for single use. Occasional reuse is possible if undamaged, but repeated heating may shorten lifespan.

4. Are PP lunch boxes environmentally friendly?

PP is recyclable (code #5). Choosing PP or lighter designs further reduces environmental impact.

5. What should businesses check before ordering?

Verify food-grade certifications, heat resistance, compartment sizes, MOQ, and custom branding options.

Final Thoughts

The PP Blister Lunch Box is more than just a disposable container—it’s a smart packaging solution that balances safety, convenience, and environmental responsibility. Its microwave resistance, leak-proof design, and customizable options make it the go-to choice for restaurants, supermarkets, and catering businesses worldwide.

Ready to upgrade your food packaging?

[Contact Dashan today] for a free consultation and sample request. Let’s create a PP Blister Lunch Box that perfectly matches your brand and keeps your meals fresh from factory to table.

References

-

Hussain K.A. et al., Environmental Science & Technology, 2023 – Microplastics Release Study

-

Towardspackaging, 2024 – PP Rigid Plastic Packaging Market Outlook

-

Towardspackaging, 2024 – Recycled Polypropylene in Packaging Market