Quick Summary:

This article explores the reasons why sugarcane bagasse packaging is more expensive than traditional plastic, despite its environmental advantages. Key factors driving up the cost include higher raw material expenses, complex manufacturing processes, limited scalability, and customization challenges. While plastic benefits from economies of scale and established production methods, sugarcane bagasse requires more labor-intensive processes and specialized equipment. However, the long-term benefits of sugarcane bagasse—such as biodegradability, compostability, and a smaller carbon footprint—make it a more sustainable alternative to plastic. As demand for eco-friendly packaging rises, the cost of sugarcane bagasse may decrease over time, making it more competitive with plastic packaging solutions.

Introduction

As the world faces the challenge of sustainability and environmental protection, the packaging industry has seen a massive shift towards eco-friendly alternatives. Among these, sugarcane bagasse has emerged as one of the most promising options for sustainable food packaging. While it is gaining popularity due to its biodegradability and reduced environmental impact, many businesses and consumers still question why sugarcane bagasse packaging is more expensive than plastic. This article will provide an in-depth analysis of the various factors that contribute to the higher cost of sugarcane bagasse packaging compared to traditional plastic.

1. Raw Material Costs

Plastic: A Low-Cost Commodity

Plastic is produced from petroleum-based derivatives such as polyethylene and polypropylene. These materials are inexpensive to obtain and process. Due to the widespread availability of petroleum and the long-established infrastructure for producing plastic, raw material costs are consistently low. The plastic industry benefits from economies of scale—mass production drives down the cost of raw materials.

However, the true cost of plastic is not reflected in its price. The environmental costs, including long decomposition periods and damage to wildlife, are not accounted for in its manufacturing price, making it appear deceptively cheap.

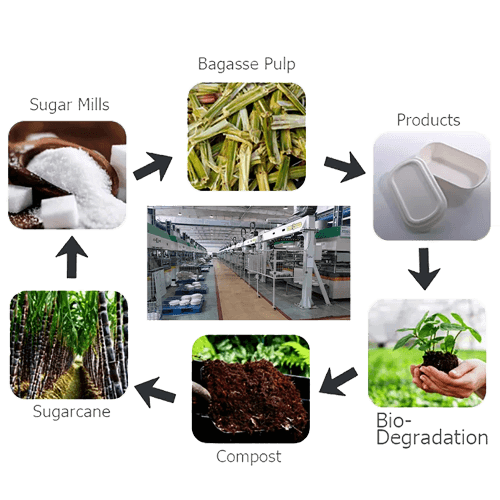

Sugarcane Bagasse: A Renewable but Expensive Resource

Sugarcane bagasse, on the other hand, is a by-product of sugarcane processing. While it is renewable and environmentally friendly, obtaining bagasse is more costly. The material requires careful sourcing from sugar mills, and there are additional costs associated with collecting and transporting it.

-

Harvesting and Collection: The process of gathering sugarcane after the primary sugar extraction can be labor-intensive.

-

Processing: The bagasse needs to be further processed to remove impurities and make it suitable for packaging production.

-

Transportation: Bagasse is often transported from sugar mills to factories, adding logistics costs.

Furthermore, bagasse availability is seasonal, as sugarcane harvesting follows specific cycles, which can cause fluctuations in price.

2. Manufacturing Processes

Plastic Manufacturing: Efficient and Scalable

The manufacturing process for plastic packaging is highly efficient and automated. Plastic can be molded into almost any shape using well-established techniques like injection molding, extrusion, and blow molding. These methods are highly scalable, meaning that large quantities can be produced at a very low per-unit cost.

Furthermore, plastic manufacturing processes have been refined over decades, allowing for faster production times and higher output per hour. This makes plastic a cost-effective material for mass production.

Sugarcane Bagasse Manufacturing: More Complex and Labor-Intensive

The production of sugarcane bagasse packaging, on the other hand, requires more intricate processes:

-

Preparation of Bagasse: After collection, the bagasse needs to be pulped, dried, and sometimes chemically treated to prepare it for molding.

-

Molding: Molding bagasse into trays or containers requires specific molds, which are more expensive to produce compared to plastic molds. Additionally, the molding process is less automated and more labor-intensive.

-

Energy Consumption: Processing bagasse requires more energy compared to plastic, as it needs to be compressed and heated to form strong, stable packaging materials.

Because the manufacturing process for bagasse is not as scalable or efficient as plastic production, per-unit costs tend to be higher. Additionally, the process is more time-consuming and requires higher energy input, further driving up the overall cost.

3. Customization and Design Complexity

Plastic Packaging: Flexible and Cost-Effective Customization

Plastic packaging offers a high degree of customization at relatively low cost. Molds and production lines can be easily adapted to produce different shapes, sizes, and designs, making it a flexible option for packaging. Since the material is easy to manipulate, designing and producing customized plastic packaging is relatively inexpensive, especially when manufacturing in bulk.

Sugarcane Bagasse Packaging: Challenges in Customization

In contrast, sugarcane bagasse has limitations when it comes to customization. While it can be molded into different shapes, the material’s organic nature makes it more difficult to achieve intricate designs. The manufacturing equipment required for bagasse packaging is also more expensive to maintain and operate. Additionally, customization options, such as printing logos on bagasse trays, are more limited compared to plastic.

Since bagasse packaging is often produced in smaller batches, the costs for customization and design are higher, and the unit price can increase significantly for customized orders.

4. Environmental and Long-Term Costs

Plastic: Hidden Environmental Costs

While plastic is cheap to produce, it comes with significant environmental costs, particularly in terms of pollution, non-biodegradability, and its impact on wildlife. The hidden environmental costs are not factored into the price of plastic packaging, making it seem deceptively inexpensive.

Sugarcane Bagasse: A Sustainable Alternative

Sugarcane bagasse, on the other hand, is biodegradable and compostable, breaking down naturally without harming the environment. It also has a much lower carbon footprint compared to plastic. The production of bagasse packaging is less harmful to the planet, with a smaller contribution to landfill waste and a much shorter decomposition time.

However, the eco-friendly production methods and compostability of sugarcane bagasse come at a higher cost in the short term. The environmental benefits, however, make bagasse packaging a better long-term investment for companies aiming to reduce their environmental impact.

5. Supply Chain and Scalability Challenges

Plastic Supply Chain: Established and Scalable

The plastic supply chain is well-established and operates on a global scale, from petroleum extraction to plastic production, distribution, and recycling. Mass production techniques and highly efficient logistics help keep costs low and allow for a steady supply of raw materials.

Sugarcane Bagasse: A Less Efficient and Regional Supply Chain

The supply chain for sugarcane bagasse is far less efficient. Bagasse is sourced from sugar mills, which are often located in specific regions where sugarcane is grown. This leads to higher transportation costs and logistical challenges, as the material must be moved from these mills to processing plants, often across long distances. Additionally, because sugarcane bagasse is still a niche product, economies of scale are not yet fully realized, meaning production is more costly and less efficient than plastic.

6. Market Demand and Consumer Perception

Plastic: Widespread Demand and Market Availability

Plastic packaging is ubiquitous across industries, and demand is stable due to its low cost and versatility. The widespread use of plastic over several decades has led to economies of scale, making it the preferred choice for manufacturers.

Sugarcane Bagasse: Growing Demand, Higher Costs

While demand for sugarcane bagasse packaging is rising due to its environmental benefits, it still represents a smaller segment of the market. As such, production volumes are lower, and manufacturers face higher per-unit costs. As consumer awareness of environmental issues continues to grow, demand for sustainable packaging options like bagasse will likely increase, but for now, it remains a premium product.

Conclusion

Sugarcane bagasse packaging is undeniably more expensive than plastic due to several factors, including higher raw material costs, more complex manufacturing processes, limited customization options, and logistical inefficiencies. However, its environmental benefits, including biodegradability, compostability, and reduced carbon footprint, make it an increasingly attractive alternative for businesses seeking sustainable solutions.

As demand for eco-friendly packaging rises, the cost of sugarcane bagasse may decrease over time, making it more competitive with plastic. In the meantime, businesses must weigh the long-term environmental benefits against the higher initial cost.

FAQ (Frequently Asked Questions)

-

Why is sugarcane bagasse packaging more expensive than plastic?

-

The higher costs come from sourcing, processing, and manufacturing bagasse, as well as lower economies of scale compared to plastic.

-

-

Can sugarcane bagasse packaging hold up against hot foods?

-

Yes, sugarcane bagasse packaging is durable and can handle both hot and cold foods, making it a versatile alternative to plastic.

-

-

Is sugarcane bagasse biodegradable?

-

Yes, sugarcane bagasse is fully biodegradable and compostable, making it a much more eco-friendly option than plastic.

-

-

Does sugarcane bagasse packaging cost more in bulk?

-

Bulk purchases can still be more expensive than plastic, but prices are expected to drop as demand increases and production scales up.

-

-

How does sugarcane bagasse compare to other biodegradable packaging?

-

Sugarcane bagasse is one of the most sustainable biodegradable materials, offering advantages over alternatives like PLA in terms of cost and performance.

-

References

-

Plastic Waste and the Circular Economy, World Economic Forum, 2020.

-

Sustainable Packaging: The Case for Sugarcane Bagasse, Packaging Strategies, 2021.

-

The Environmental Benefits of Sugarcane Bagasse Packaging, Journal of Green Packaging, 2020. [Link]

-

Life Cycle Assessment of Sugarcane-Based Packaging, Environmental Impact Journal, 2022.