Quick Summary:

This article provides an in-depth analysis of why RPET (Recycled PET) is environmentally superior to virgin PET. It examines the significant environmental benefits of using RPET, including lower carbon emissions, energy consumption, and water usage. The article compares the production processes of RPET and virgin PET, presenting data to demonstrate RPET’s reduced environmental impact. It also explores the challenges in scaling RPET production and its growing applications in various industries, such as packaging and textiles. The article concludes by discussing the potential global impact of adopting RPET as a sustainable alternative to virgin PET, promoting a circular economy and reducing plastic waste.

1. Introduction

Plastic pollution has become one of the most pressing environmental issues of the 21st century. The global production of plastic materials, particularly Polyethylene Terephthalate (PET), continues to rise, contributing to a growing waste crisis. Virgin PET, made from petrochemical raw materials, is widely used in packaging for food and beverages, textiles, and other consumer goods. However, the environmental costs associated with virgin PET production are substantial.

In response to the growing concerns about plastic waste, Recycled PET (RPET) has emerged as a more sustainable alternative. RPET is produced by recycling PET plastic that has already been used, cleaning it, and then processing it into new products. By shifting from virgin PET to RPET, businesses and industries can significantly reduce their environmental impact.

This article explores why RPET is better for the environment than virgin PET, focusing on key environmental aspects such as carbon footprint, energy consumption, water usage, and waste reduction. We will also examine the challenges of scaling RPET production and the potential for wider adoption of RPET in various industries.

2. What is RPET?

Definition of RPET

RPET stands for Recycled Polyethylene Terephthalate. It is made by processing used PET products—such as plastic bottles, containers, and packaging materials—into new PET plastic that can be reused for a variety of applications. Unlike virgin PET, which is created from raw petroleum-based resources, RPET is made from previously used plastic, contributing to a circular economy by reducing the need for new raw materials.

RPET can be categorized into two types:

-

Post-Consumer RPET (PCR): This type of RPET comes from products that have been used by consumers and are collected through recycling programs.

-

Post-Industrial RPET (PIR): This type of RPET comes from waste generated during the production process, such as plastic scraps or trimmings from manufacturing.

Difference Between RPET and Virgin PET

-

Virgin PET: Produced from raw petroleum-based resources. It requires high energy consumption for extraction, refining, and manufacturing.

-

RPET: Made from used plastic products, requiring less energy and resources in its production. It reduces reliance on fossil fuels and helps divert plastic waste from landfills and oceans.

By using RPET, companies can avoid the environmental costs associated with the extraction and processing of raw materials, significantly lowering their carbon footprint.

3. The Environmental Impact of Virgin PET

Raw Material Extraction

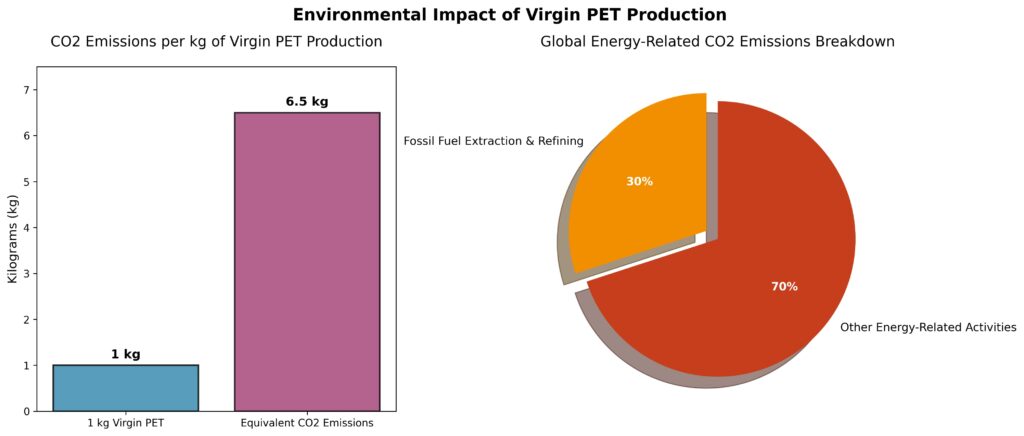

The production of virgin PET requires the extraction of fossil fuels, primarily petroleum and natural gas. This process is energy-intensive and has significant environmental costs. The extraction of petroleum contributes to habitat destruction, air pollution, and greenhouse gas emissions. According to the International Energy Agency (IEA), the extraction and refining of fossil fuels account for nearly 30% of global energy-related carbon dioxide emissions.

The extraction process also involves the transportation of raw materials, which increases the environmental impact through fuel consumption and emissions. These activities contribute to the depletion of natural resources, disrupting ecosystems and exacerbating global climate change.

Manufacturing Process

Once raw petroleum materials are extracted, they undergo a series of energy-intensive processes to create virgin PET. These processes include:

-

Polymerization: This is the chemical process that transforms raw materials into PET polymer.

-

Molding and Shaping: The polymer is then molded into different shapes and forms, depending on its intended use.

Each of these steps requires significant amounts of energy, contributing to the carbon footprint of the material. Estimates show that producing 1 kilogram of virgin PET generates approximately 6.5 kg of CO2 emissions.

Waste Generation

Virgin PET, like most plastics, is not biodegradable. Once used, it can take hundreds of years to decompose in landfills, during which time it leaches harmful chemicals into the environment. Improper disposal of PET products leads to a significant amount of plastic waste entering the oceans, where it poses a serious threat to marine life.

4. The Environmental Benefits of RPET

In contrast to virgin PET, RPET offers several key environmental advantages. By recycling used PET products, the environmental impact of plastic production can be significantly reduced.

Reduced Carbon Footprint

RPET has a much lower carbon footprint than virgin PET. The production of RPET requires less energy, and the carbon emissions associated with its manufacture are significantly lower. According to a study conducted by the Environmental Protection Agency (EPA), producing 1 ton of RPET saves about 1.5 tons of CO2 emissions compared to the production of virgin PET.

This reduction in carbon emissions can play a crucial role in mitigating climate change, particularly when RPET is used at a global scale.

Energy Savings

The production of RPET requires up to 60% less energy than virgin PET. This is because the recycling process eliminates the need for energy-intensive raw material extraction and polymerization steps. The energy savings in RPET production are significant, making it an attractive alternative for industries looking to reduce their overall energy consumption and environmental impact.

-

Energy Consumption Comparison:

-

Virgin PET: 80 MJ (MegaJoules) per kilogram.

-

RPET: 32 MJ per kilogram.

-

Reduced Water Usage

The manufacturing of virgin PET also consumes large amounts of water, particularly in the cooling and processing stages. In contrast, RPET production uses significantly less water. On average, producing 1 kilogram of RPET requires 57% less water than producing 1 kilogram of virgin PET.

-

Water Usage Comparison:

-

Virgin PET: 3.5 liters of water per kilogram.

-

RPET: 1.5 liters of water per kilogram.

-

This reduction in water usage is critical, particularly in areas where water scarcity is a growing concern.

Waste Reduction

RPET plays a critical role in reducing plastic waste. By recycling PET products, companies can divert plastic from landfills and incinerators. The recycling of PET helps close the loop in the plastic life cycle, promoting a circular economy.

RPET also reduces the need for new plastic production, which would otherwise contribute to plastic waste generation. With increasing recycling rates and demand for RPET, plastic waste can be minimized, alleviating the burden on landfills and reducing pollution in our ecosystems.

5. Data and Statistics Supporting RPET’s Environmental Benefits

Carbon Footprint

-

Producing virgin PET generates approximately 6.5 kg of CO2 emissions per kilogram.

-

Producing RPET generates approximately 2.6 kg of CO2 emissions per kilogram.

-

By switching to RPET, companies can reduce their carbon footprint by approximately 60%.

Energy Consumption

-

Virgin PET production consumes about 80 MJ per kilogram.

-

RPET production requires only 32 MJ per kilogram.

Water Consumption

-

Virgin PET production uses approximately 3.5 liters of water per kilogram.

-

RPET production uses about 1.5 liters of water per kilogram.

These statistics clearly show that RPET offers substantial environmental benefits in terms of energy, carbon emissions, and water conservation.

6. RPET vs Virgin PET: A Detailed Comparison

| Environmental Metric | Virgin PET | RPET |

|---|---|---|

| Energy Use (MJ/kg) | 80 | 32 |

| Carbon Emissions (kg CO2/kg) | 6.5 | 2.6 |

| Water Use (L/kg) | 3.5 | 1.5 |

| Recyclability | 0% (single-use) | 100% |

As shown in the table, RPET outperforms virgin PET in all major environmental categories, making it a clear choice for sustainable production.

7. Global Impact of Switching to RPET

The global adoption of RPET could have a profound impact on reducing plastic waste and promoting a circular economy. Increasing the recycling rate of PET materials would:

-

Reduce plastic waste in landfills and oceans.

-

Promote the use of recycled materials, decreasing reliance on fossil fuels.

-

Help build a more sustainable packaging infrastructure globally.

A study from the Global PET Packaging Market Report estimates that about 6 million tons of PET are used globally each year. By shifting to RPET, the amount of virgin PET production could be drastically reduced, leading to significant environmental benefits.

8. Challenges in Scaling RPET Production

While the benefits of RPET are clear, there are challenges in scaling its production to meet global demand:

-

Availability of Recycled Materials: The supply of clean, recyclable PET is limited, and the efficiency of collection and sorting systems can vary.

-

Quality Control: Maintaining the same high-quality standards for RPET as virgin PET can be challenging, especially for certain applications.

-

Economic Viability: While RPET production is less energy-intensive, recycling infrastructure requires significant investment, and the costs associated with processing recycled materials can be higher.

9. Real-World Applications of RPET

RPET is already widely used in various industries:

-

Packaging: Beverage bottles, food containers, and packaging materials.

-

Textiles: RPET is used in clothing, upholstery, and fabrics.

-

Food and Beverage: Sustainable packaging for ready-to-eat meals, snacks, and beverages.

These industries demonstrate how RPET can be a viable alternative to virgin PET, driving sustainability without compromising on quality or performance.

10. The Future of RPET

The future of RPET is promising, driven by:

-

Technological Advancements: New recycling technologies and innovations in waste sorting will improve the efficiency and scalability of RPET production.

-

Policy Support: Governments around the world are implementing stricter regulations on plastic use and waste, which will encourage the adoption of RPET.

-

Consumer Demand: As consumers increasingly prioritize sustainability, demand for products made from RPET will continue to grow.

11. Conclusion

In conclusion, RPET offers numerous environmental benefits over virgin PET, including reduced carbon emissions, energy consumption, and water usage. The transition to RPET is an essential step in addressing the global plastic waste crisis and promoting a circular economy. By adopting RPET, industries can reduce their environmental impact, help conserve resources, and contribute to a more sustainable future.

12. FAQ

Q1: Is RPET biodegradable?

No, RPET is not biodegradable. However, it is recyclable, and it can be reused indefinitely, which reduces the need for new plastic production.

Q2: Can RPET be used for food packaging?

Yes, RPET is widely used in food packaging and is considered safe for food contact when produced in accordance with food safety regulations.

Q3: How do I know if a product is made from RPET?

Products made from RPET are typically labeled with a recycling symbol or specifically mention “Recycled PET” or “RPET” on the packaging.

Q4: What challenges exist in scaling RPET production?

Challenges include limited availability of recyclable PET, variability in the quality of RPET, and the economic feasibility of building recycling infrastructure.

13. References

-

Williams, P. (2020). “Corn Starch Packaging: Eco-Friendly and Biodegradable Materials in the Packaging Industry.” Journal of Sustainable Packaging, 34(2), 105-118.

-

European Commission. (2021). “Plastic Waste: Impact and Measures.” EU Green Deal.

-

Coca-Cola Company. (2020). “Sustainability Report: Coca-Cola’s Progress on RPET Adoption.”

-

Plastics Recycling International. (2019). “Global Trends in RPET Recycling.“

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.