Quick Summary

Choosing food packaging is no longer about finding a single “best” material. Importers must balance regulations, food applications, logistics, and consumer expectations. PET, RPET, PP, PLA, bagasse, and cornstarch all serve different roles. Real sourcing success comes from matching materials to real-world use, not trends.

Sourcing food packaging is often underestimated by importers. At first glance, it may appear similar to purchasing any other consumer product: compare prices, review samples, place orders, and manage logistics. In reality, food packaging sourcing is far more complex. It sits at the intersection of food safety, regulatory compliance, logistics efficiency, and brand reputation.

For importers, mistakes in packaging sourcing are rarely minor. A poorly chosen material, an overlooked compliance requirement, or an inconsistent production batch can result in product recalls, shipment delays, customer complaints, or even market access restrictions. This article outlines what importers truly need to understand before sourcing food packaging—and why early decision-making matters more than price negotiations.

Why Food Packaging Sourcing Is Different from Other Products

Food packaging is not just a container. It directly interacts with food, consumers, and regulatory authorities. Unlike many consumer goods, packaging failures are highly visible and often irreversible.

Importers face several unique challenges:

-

Packaging must comply with food-contact regulations in the destination market

-

Performance must remain consistent across large volumes

-

Packaging must survive transport, storage, and end-user handling

-

Any defect can affect food quality, safety, or brand trust

This means sourcing decisions must be based on application logic, not just supplier promises or marketing claims.

Understanding the Application Comes First

Before discussing materials or prices, importers must clearly understand how the packaging will be used. Many sourcing problems begin because this step is skipped or oversimplified.

Key questions importers should clarify include:

-

Is the food hot, cold, or reheated?

-

Will the packaging be used in a microwave or oven?

-

Is the food oily, acidic, or liquid-based?

-

Is the packaging intended for single use or reuse?

-

How long will the food remain inside the packaging?

A container suitable for cold salads may fail completely when used for hot takeaway meals. Likewise, packaging designed for short-term use may deform or leak during delivery.

Importers who define application requirements clearly reduce the risk of performance-related failures later.

Material Selection: Looking Beyond Labels

One of the most common mistakes importers make is choosing materials based on labels such as “eco-friendly,” “biodegradable,” or “recyclable” without understanding performance implications.

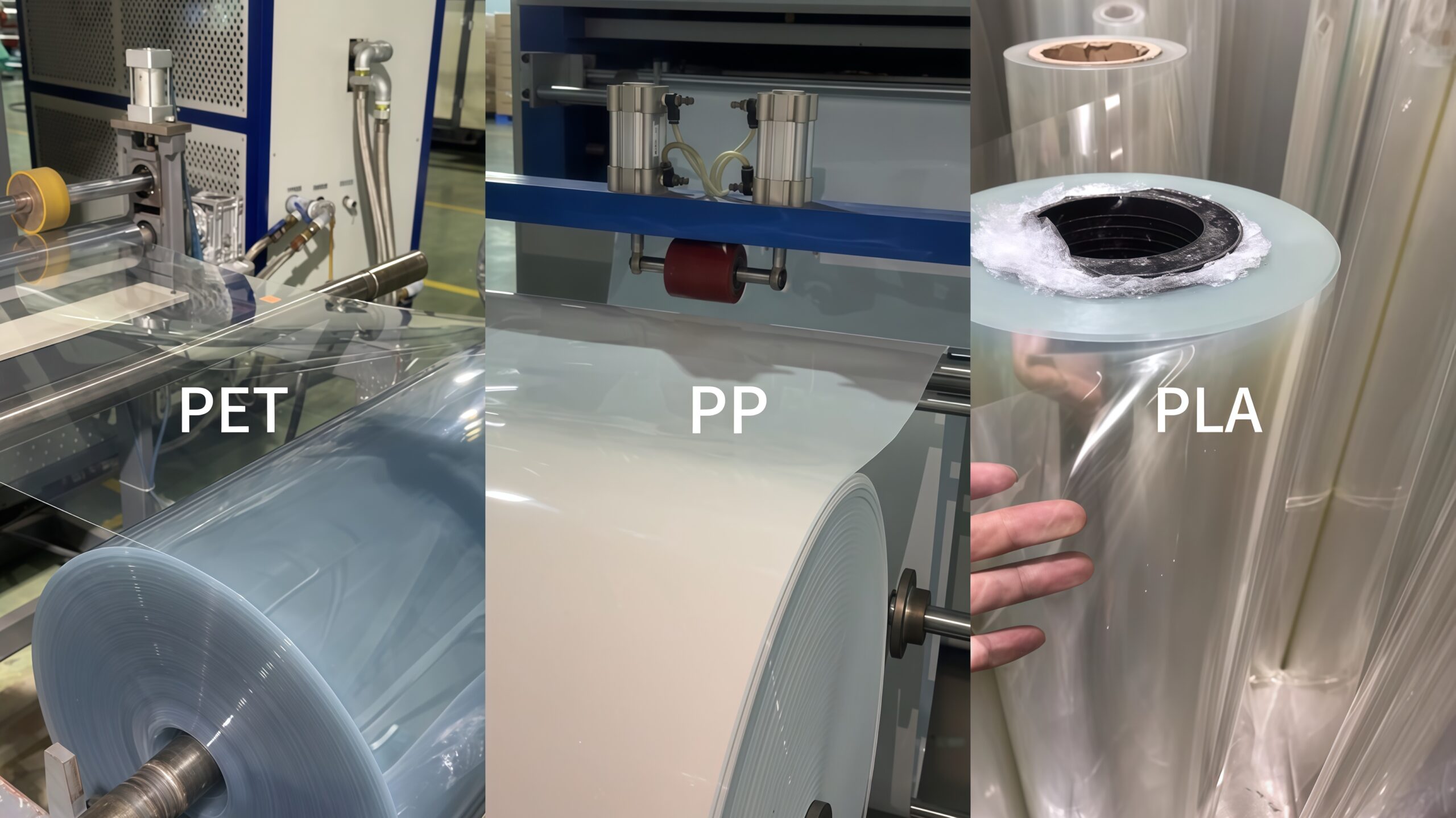

Each material has strengths and limitations:

-

PP (Polypropylene): Excellent heat resistance, durable, suitable for microwave and reuse

-

PET / RPET: High clarity, good for cold food and retail display, limited heat tolerance

-

PLA: Compostable under industrial conditions, best for cold food applications

-

Bagasse: Fiber-based, suitable for short-term hot food, limited durability

-

Corn starch blends: Lightweight, suitable for low-heat, low-stress applications

No material is universally superior. Importers must evaluate materials based on actual use scenarios, not marketing narratives.

Regulatory Compliance: The Importer’s Responsibility

Regulatory compliance is one of the most critical—and misunderstood—areas of food packaging sourcing. While manufacturers may provide certificates, the importer is ultimately responsible for compliance in the destination market.

Key regulatory considerations include:

-

Food contact material regulations (EU, FDA, etc.)

-

Migration testing and declarations of conformity

-

Material-specific restrictions

-

Documentation consistency and traceability

Importers should understand the difference between:

-

Generic material certifications

-

Product-specific test reports

-

Market-specific compliance requirements

Relying solely on supplier assurances without reviewing documentation can expose importers to serious legal and commercial risks.

Quality Consistency: Sample Approval Is Not Enough

Many importers approve samples and assume mass production will match. In reality, quality variation is one of the most common sourcing issues.

Potential risks include:

-

Inconsistent weight or thickness

-

Poor lid fit or sealing performance

-

Warping during transport

-

Variation between production batches

To reduce risk, importers should:

-

Define acceptable tolerances clearly

-

Request pre-production samples when possible

-

Implement inspection or quality checks for early shipments

Consistency matters more than perfection. Predictable quality allows importers to plan confidently.

Logistics and Transport: Packaging Must Travel Well

Packaging design affects logistics costs more than many importers realize. Stackability, rigidity, and carton design directly influence container utilization and damage rates.

Key logistics factors include:

-

Stack strength during palletization

-

Resistance to deformation during long-distance shipping

-

Carton size optimization

-

Protection against moisture and temperature changes

A well-designed container that reduces damage and maximizes loading efficiency can significantly lower overall sourcing costs—even if the unit price is higher.

Cost Structure: Why Unit Price Is Misleading

Focusing solely on unit price often leads to higher total costs. Importers should evaluate total cost of ownership, including:

-

Product failures and returns

-

Customer complaints and reputational impact

-

Additional handling or rework

-

Compliance-related delays or penalties

A slightly higher-priced product with stable performance often delivers better long-term value than the cheapest option.

Supplier Evaluation: What Importers Should Really Look For

Choosing the right supplier goes beyond factory size or product range. Importers should assess:

-

Understanding of application requirements

-

Communication clarity and responsiveness

-

Ability to support documentation and compliance

-

Production stability and delivery reliability

Suppliers who ask detailed questions early often prevent problems later. Good sourcing relationships are built on transparency, not just transactions.

Real-World Experience: What Long-Term Packaging Suppliers Learn Over Time

In real sourcing projects, many packaging issues do not appear during the sample stage. They surface only after products enter real foodservice environments—under heat, pressure, transport, and repeated handling.

From years of working with international buyers across foodservice, retail, and distribution channels, DASHAN has observed a consistent pattern: packaging performance problems are rarely caused by a single factor. They usually result from mismatched expectations between application, material choice, and real usage conditions.

For example, some buyers initially request a single packaging solution for both hot and cold food, expecting one material to cover all scenarios. In practice, DASHAN often recommends splitting applications by material—such as using PP containers for hot or microwave-ready meals, while selecting PET or RPET solutions for cold food display and takeaway salads.

This approach is not about promoting one material over another. It reflects a practical sourcing principle:

performance stability matters more than material trends.

Application-Based Product Matching in Practice

In many sourcing discussions, DASHAN’s technical team focuses first on usage details rather than product catalogs. Buyers are typically asked questions such as:

-

Will the food be reheated by the end consumer?

-

Is leakage during delivery a concern?

-

Does the product need to withstand stacking or long-distance transport?

-

Is reuse likely in the target market?

Based on these answers, packaging recommendations are adjusted accordingly.

For instance:

-

PP trays and containers are commonly selected for hot meals, central kitchens, and microwave use due to their thermal stability and durability.

-

RPET cups and lids are often chosen for cold beverages and food display, where clarity and visual presentation are priorities.

-

Fiber-based or plant-based products may be used in short-term foodservice scenarios where heat exposure and reuse are limited.

By separating applications instead of forcing a single solution, importers reduce failure rates and improve customer satisfaction downstream.

Lessons Importers Can Take from Real Sourcing Experience

What experienced suppliers learn over time is highly relevant to importers:

-

Samples do not represent all conditions

Real-world use exposes packaging to stress that samples never experience. -

Material performance outweighs material perception

Buyers may prefer certain materials, but performance failures quickly change priorities. -

Clear communication reduces long-term cost

Asking detailed questions early prevents expensive corrections later. -

Stable suppliers think in systems, not products

Packaging success depends on how materials, food, logistics, and users interact.

These insights explain why experienced importers increasingly value suppliers who challenge assumptions rather than simply confirming specifications.

Why This Matters for Importers

For importers, the value of a packaging supplier is not limited to manufacturing capacity. It also includes application understanding, risk awareness, and long-term consistency.

By working with suppliers who focus on real usage scenarios—rather than selling a single material solution—importers are better positioned to:

-

Reduce packaging-related complaints

-

Avoid costly reorders or market issues

-

Build stable product lines across different regions

In food packaging sourcing, quiet experience often matters more than loud claims.

Risk Management: How Experienced Importers Reduce Failures

Experienced importers rarely rely on a single decision point. Instead, they use layered risk management strategies, such as:

-

Starting with smaller trial orders

-

Testing products in real market conditions

-

Using multiple materials for different applications

-

Maintaining clear technical communication

These approaches reduce exposure and allow adjustments before large-scale commitments.

Why Early Decisions Matter More Than Negotiation

Many sourcing problems cannot be fixed by renegotiating price or changing suppliers later. Once packaging fails in the market, the damage is already done.

Successful importers invest time upfront in:

-

Understanding applications

-

Selecting appropriate materials

-

Verifying compliance

-

Aligning expectations with suppliers

Better decisions happen before the first order is placed.

FAQ

1. Is there a single most sustainable food packaging material?

No. Sustainability depends on application, local recycling systems, and usage patterns. Different materials perform better in different contexts.

2. Why do regulations allow multiple packaging materials instead of one solution?

Because food safety, logistics, and infrastructure vary widely by region. Regulations focus on reducing impact, not mandating one material.

3. Is plastic packaging always less sustainable than plant-based options?

Not necessarily. Durable, reusable, and recyclable plastics like PP or RPET can outperform single-use alternatives in certain use cases.

4. Should importers switch all products to one material to simplify sourcing?

Usually not. Splitting applications by material often reduces failures, complaints, and long-term costs.

5. How can importers reduce packaging risk?

By evaluating real usage conditions, testing beyond samples, and working with suppliers who understand application performance.

Conclusion: Sourcing Food Packaging Is a Strategic Decision

For importers, food packaging sourcing is not a routine purchasing task—it is a strategic decision with long-term implications. The right packaging supports food quality, protects brand reputation, and enables operational efficiency. The wrong choice introduces risk at every stage of the supply chain.

By focusing on application requirements, material performance, compliance, and consistency, importers can make informed decisions that reduce risk and create sustainable value. In food packaging sourcing, success is rarely about finding the cheapest option—it is about choosing the most reliable one.

Reference List

-

European Commission – Food Contact Materials

https://food.ec.europa.eu/safety/chemical-safety/food-contact-materials_en -

U.S. FDA – Indirect Food Additives (Packaging)

https://www.fda.gov/food/food-ingredients-packaging/indirect-food-additives -

PlasticsEurope – Polymer Properties and Applications

https://plasticseurope.org/knowledge-hub -

European Bioplastics – Materials Overview

https://www.european-bioplastics.org/bioplastics/materials -

Ellen MacArthur Foundation – Packaging and Circular Economy

https://ellenmacarthurfoundation.org/topics/plastics/overview