Quick Summary

Global brands are no longer asking only about price. Today, they want proof of sustainability, documentation for compliance, realistic performance testing, and reliable long-term partnerships. “Eco” is shifting from marketing language to measurable standards: recyclability, compostability conditions, source traceability, and lifecycle impact. Suppliers who can explain materials, validate claims, and help customers avoid regulatory risks create real value. DASHAN participates in this shift by focusing on transparent material data, stable manufacturing processes, and practical guidance that helps buyers choose sustainable solutions that actually work in real kitchens and logistics systems.

1. Introduction — Sustainability Has Become a Business Requirement

In fewer than ten years, sustainable packaging has moved from trend to obligation. What once sounded like a marketing slogan — “eco-friendly,” “green,” “renewable” — has now become deeply embedded in procurement policies, retailer expectations, consumer trust, and regulatory frameworks across the world.

Global brands are no longer asking whether they should transition to eco packaging.

They are asking:

-

How fast?

-

How safely?

-

How credibly?

-

With what risks and hidden costs?

This article examines the questions global brands now ask suppliers, certification bodies, logistics partners, and sustainability teams. It also explains what sits behind those questions — operational risk, consumer perception, compliance, and financial responsibility.

Rather than hype-driven soundbites, this is a pragmatic view of how eco packaging actually works in the real world.

2. Question #1: “Is This Packaging Truly Eco — Or Just Marketing?”

The single biggest shift is skepticism.

Most large brands today have been burned at least once by what turned out to be exaggerated eco claims:

-

“100% compostable” that never composted in real systems

-

“Plastic-free” that still contained coatings

-

“Recyclable” but rejected by material recovery facilities

-

“Biodegradable” without clear timeframe or conditions

So the first question is no longer:

“Is this eco-friendly?”

It is:

“Based on which standards, verified by whom, in what real-life conditions?”

What “eco” actually means depends on context

Eco attributes can refer to multiple things, and rarely all at once:

-

Reduced fossil plastic content

-

Lower carbon footprint compared to baseline

-

Safer chemistry (no PFAS, BPA, SVHC concerns)

-

Lightweight design that reduces shipping emissions

A single product cannot realistically optimize everything.

Global brands now map which benefit matters most relative to their sustainability roadmap, for example:

-

Quick service restaurant chains → waste reduction + food safety

-

Retail grocery → recyclability + label transparency

-

Premium delivery brands → performance + credible compostability

-

Healthcare food service → compliance and contamination risk

Verification is not optional anymore

To avoid greenwashing, brands increasingly require:

-

Material composition declarations

-

Laboratory test reports

-

Certificates from recognized third parties

-

Lifecycle assessment (LCA) data or comparative analysis

-

Evidence explaining limitations and correct disposal guidance

Honesty — including discussing limits openly — is now valued more than aggressive claims.

3. Question #2: “Will It Comply in All the Markets We Sell To?”

A single eco packaging choice may have to enter:

-

The United States

-

The United Kingdom

-

Australia

-

Southeast Asian markets

-

Middle Eastern markets

Each market has evolving rules about:

-

Plastics

-

Chemicals of concern

-

Recyclability labeling

-

Compostable claims

-

Single-use items

-

Producer responsibility fees

Compliance is not just about food contact safety anymore. It includes:

-

Documentation (DoC)

-

Migration and heavy metal testing

-

Chemical disclosure

-

Labeling accuracy

-

Country-specific bans or restrictions

-

Record keeping and audit readiness

This is where experienced suppliers matter most: not as marketers, but as partners helping navigate complexity.

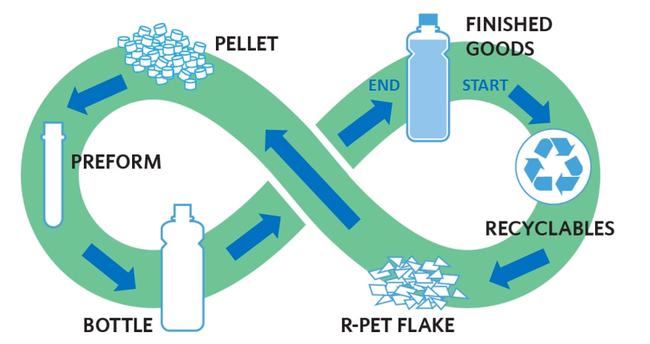

4. Question #3: “What Happens to This Packaging After Disposal?”

The sustainability claim collapses if the end-of-life reality contradicts the story.

Recyclable vs. actually recycled

A package may technically be recyclable, but if:

-

Infrastructure cannot sort it

-

There is no market demand for the recovered material

-

Contamination is too high

…it still becomes waste.

Brands are therefore asking:

-

Is there proven collection infrastructure?

-

Will local facilities accept this material form?

-

Are we unintentionally shifting burden to municipalities?

Compostable confusion

Labels like “compostable” create expectations — sometimes unrealistic.

Global brands now differentiate:

-

Industrial compostable (controlled conditions)

-

Home compostable (rare but consumer-friendly)

-

Biodegradable with no practical waste pathway

More brands are becoming careful not to promise environmental benefits that disposal systems cannot deliver.

5. Question #4: “Can Performance Match Our Existing Packaging?”

Eco packaging must still:

-

Prevent leaks

-

Withstand delivery

-

Handle hot and cold transitions

-

Resist grease

-

Remain stackable

-

Present food attractively

-

Protect branding experience

A sustainable package that fails operationally creates waste, complaints, and reputational damage. Many global brands now require stress testing before approval:

-

Transport vibration

-

Heat retention

-

Microwave tolerance

-

Freezer-to-heat transitions

-

Lidding compatibility

-

Condensation behavior

Performance is sustainability — because failed packaging increases food waste and replacement rate.

6. Question #5: “What Is the Real Cost — Not Just Unit Price?”

Executives today look at total cost of ownership:

-

Packaging price per unit

-

Storage requirements

-

Shipping volume and weight

-

Spoilage and breakage

-

Consumer complaints and returns

-

Regulatory fines or reformulation costs

-

Future-proofing against policy changes

Sometimes eco packaging appears more expensive initially, but reduces downstream risk. In other cases, shiny “sustainable” options raise hidden costs.

Sophisticated procurement teams now evaluate packaging like capital investment, not a commodity.

7. Question #6: “Is It Scalable and Stable for Long-Term Supply?”

Scaling eco packaging is harder than many assume.

Questions global brands commonly ask:

-

Can capacity expand with seasonal spikes?

-

How consistent are material properties?

-

Are molds standardized?

-

What happens if one factory has downtime?

-

How volatile is pricing for the raw material?

Brands increasingly prefer suppliers that:

-

Manage stable fiber sources

-

Maintain quality systems

-

Offer secondary backup production

-

Plan capacity proactively

Short-term novelty suppliers are losing favor. Long-term supply partnerships are winning.

8. Question #7: “Can We Tell an Honest Sustainability Story?”

Consumers quickly detect exaggeration.

Retailers scrutinize sustainability messaging.

Regulators penalize misleading claims.

Therefore brands now insist on:

-

Full traceability

-

Transparent explanations

-

Modest, factual language

-

Proper disclaimers about limitations

The goal is not to look “greener than everyone else,”

but to build credible trust that holds under public scrutiny.

9. Where Bagasse and Molded Fiber Fit — A Practical View

Bagasse and molded fiber have attracted major brands because they are:

-

Derived from agricultural by-products

-

Naturally renewable

-

Stronger than paper in many applications

-

Heat tolerant

-

Visually aligned with “natural” brand identity

However, leading brands also acknowledge limitations:

-

Oil-heavy foods may require additional barrier control

-

Compostability depends on local infrastructure

-

Moisture can influence structure over extended holding times

-

Costs vary with fiber availability and processing sophistication

Smart buyers don’t treat bagasse as a magic solution.

They integrate it where it realistically performs best.

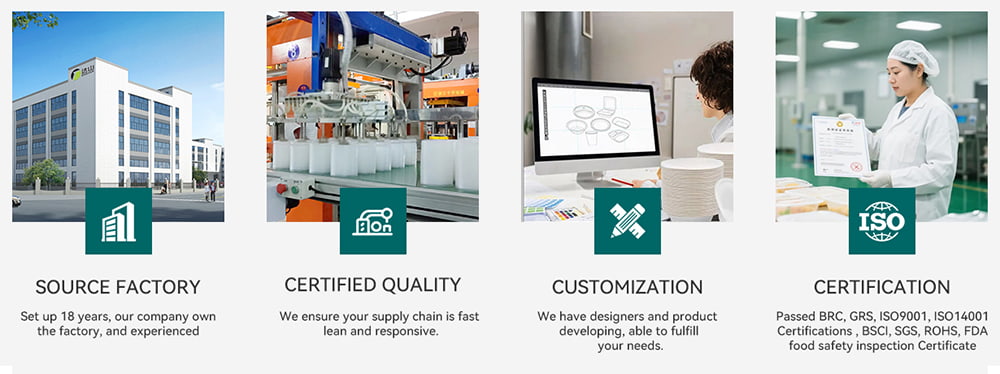

10. How Partners Like DASHAN Support These Evaluations (Light, Non-Promotional)

Companies like DASHAN operate less as product sellers and more as technical collaborators.

The most valuable contributions typically include:

-

Supporting application testing and prototyping

-

Providing test reports and documentation for compliance audits

-

Helping customers understand performance limits honestly

-

Advising on packaging system fit — lids, logistics, reheating

-

Planning scalable production for long-term programs

-

Maintaining stable quality rather than chasing lowest price

Rather than pushing aggressive claims, DASHAN emphasizes conversation:

“What are you trying to achieve — operationally, environmentally, and from a brand standpoint — and how do we design packaging that genuinely fits?”

That mindset aligns with how global brands now evaluate sustainability — with rigor instead of hype.

11. Action Checklist for Buyers

Below is a structured framework procurement teams increasingly use:

Ask suppliers for:

-

Full material composition

-

Migration and safety test reports

-

Any PFAS / intentional chemical disclosure

-

Certifications and validity periods

-

Production capacity details

-

End-of-life guidance aligned to local infrastructure

Internally validate:

-

Real-world application testing

-

Transport and reheating simulations

-

Label accuracy review with legal teams

-

Consumer service readiness for questions and complaints

Challenge every claim:

-

Where does this work?

-

Where does it fail?

-

What dependency exists on local systems?

-

What is the fallback plan?

Smart eco packaging strategies are built on clarity, not slogans.

FAQ

1. Why are global brands suddenly more strict about eco packaging?

Because regulations, retailer requirements, and consumer expectations are increasing. False or vague eco claims now create legal, financial, and reputational risk.

2. Does “compostable” always mean environmentally friendly?

Not necessarily. Many products require industrial composting facilities and do not fully break down in landfills. Claims must match real conditions.

3. What certifications matter most?

Depending on the market:

-

EN 13432, OK Compost, BPI (for compostability)

-

FDA or EU Framework Regulation 1935/2004 (food contact safety)

-

ISO standards for quality and environmental management.

Certifications should be valid, traceable, and product-specific.

4. Are brands replacing all plastics immediately?

No. Most are moving step-by-step: lighter materials, recycled content, renewable fibers, and better end-of-life options — while still protecting food safety and cost stability.

5. How does a supplier like DASHAN help?

By offering documentation, realistic performance testing, and guidance on material selection — not only selling products, but helping customers avoid compliance mistakes.

Conclusion — Eco Packaging Is Now Strategic

Eco packaging is no longer a marketing department project.

It is:

-

A compliance necessity

-

A brand integrity issue

-

An operational risk factor

-

A cost management decision

-

A supply chain strategy

The best-performing global brands are not chasing the loudest “green” product.

They are asking disciplined questions, testing thoroughly, and partnering with manufacturers capable of transparency, consistency, and long-term thinking.

In that environment, suppliers like DASHAN succeed not by promising miracles — but by working side-by-side with customers to develop packaging that performs responsibly, truthfully, and reliably.

Because sustainability is not just what the package claims.

It is how it behaves across its entire lifecycle — factory, kitchen, table, and beyond.

References

-

European Commission — Food Contact Materials Guidance

Overview of EU rules governing materials and articles intended to come into contact with food.

https://food.ec.europa.eu/safety/chemical-safety/food-contact-materials_en -

U.S. Environmental Protection Agency — Sustainable Materials Management

Framework for reducing environmental impacts through responsible material use and end-of-life strategies.

https://www.epa.gov/smm/sustainable-management-materials -

Ellen MacArthur Foundation — Plastics & Circular Economy

Research and guidance on circular packaging design, recyclability, and system thinking.

https://www.ellenmacarthurfoundation.org/explore/plastics-and-the-circular-economy -

European Bioplastics — Standards & Certification for Bioplastics

Explanation of compostability, biodegradability, labeling, and applicable testing standards.

https://www.european-bioplastics.org/standards -

TÜV Austria — OK Compost Certification

Certification program outlining criteria for industrial and home compostable products.

https://www.tuv-at.be/en/certification/ok-compost -

BPI — Compostable Products Certification Guide

Independent North American certification for compostable packaging and materials.

https://www.bpiworld.org/ -

ISO — International Standards Catalogue

Searchable database of quality, environmental, and sustainability standards relevant to packaging.

https://www.iso.org/standards.html -

OECD — Environment: Waste, Materials & Circular Economy

Policy insights on waste prevention, recycling systems, and product stewardship.

https://www.oecd.org/environment/waste

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.