Introduction

Recycling has become one of the most crucial processes in modern waste management and environmental conservation. It aims to reduce the consumption of raw materials, minimize waste, and lower environmental impact by reprocessing materials. However, recycling systems vary significantly in their methodologies, one of the primary distinctions being between closed-loop recycling and open-loop recycling. These two approaches have substantial differences in their processes, environmental impacts, and sustainability outcomes.

This article will explore the key differences between closed-loop and open-loop recycling. We will also discuss the advantages and disadvantages of each method, and how they affect industries, consumers, and the environment. By the end, readers will have a comprehensive understanding of both processes and their role in creating a more sustainable future.

Section 1: What Is Closed-Loop Recycling?

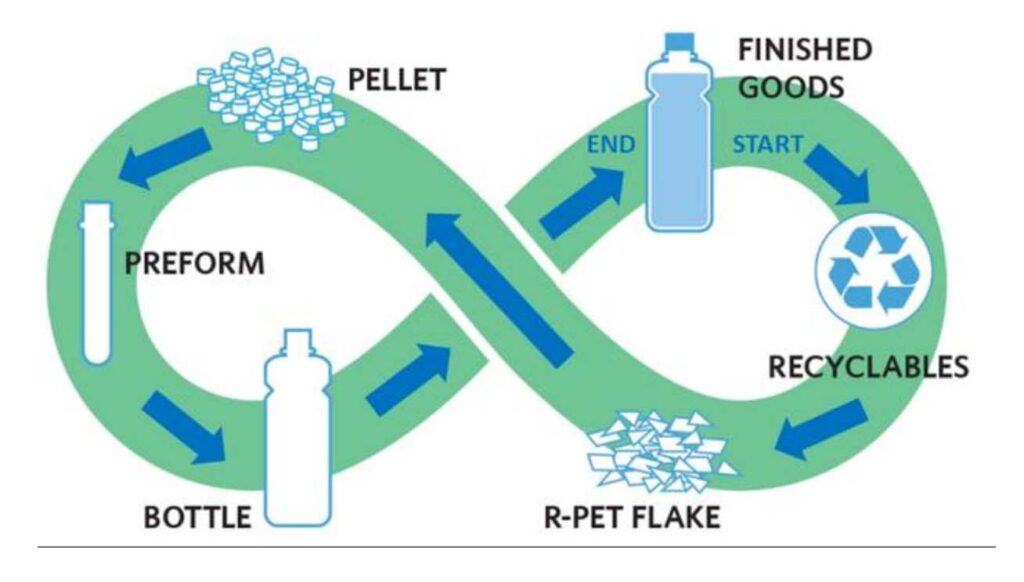

Closed-loop recycling refers to a recycling process in which the recycled material is used to create the same product or material again. The process is often referred to as “closed-loop” because the product remains within a closed cycle, reducing the need for new raw materials.

How Does Closed-Loop Recycling Work?

In closed-loop recycling, the materials are collected, processed, and reused to create a new version of the same product. For example, PET plastic bottles can be recycled back into new PET bottles. This process ensures that the same product is produced repeatedly, without degradation in quality. One of the most popular examples of closed-loop recycling is the recycling of aluminum cans. Recycled aluminum cans are used to create new aluminum cans, ensuring the material stays in circulation indefinitely.

Key Characteristics of Closed-Loop Recycling:

-

Product Consistency: The recycled material is used to make the same product.

-

Environmental Benefits: Since the material is reused within the same cycle, less energy and fewer resources are needed, reducing environmental degradation.

-

Minimal Waste Generation: Waste is minimized because the material does not leave the cycle.

-

Economic Viability: Over time, closed-loop systems can become economically beneficial by reducing the need for raw materials.

Examples of Closed-Loop Recycling:

-

PET Bottles: Recycled into new PET bottles, reducing the need for virgin plastic.

-

Aluminum Cans: Recycled into new cans, significantly reducing energy consumption compared to making aluminum from raw materials.

-

Paper Products: High-quality paper can be recycled into new paper products within a closed-loop system.

Section 2: What Is Open-Loop Recycling?

In contrast to closed-loop recycling, open-loop recycling involves the reprocessing of materials into new products, which may not be the same as the original. This system is known as “open-loop” because the material exits the loop after a few cycles and is eventually downcycled or repurposed for other uses. As a result, open-loop recycling often leads to materials being used in lower-value applications or waste, which may be harder to reuse in future cycles.

How Does Open-Loop Recycling Work?

In open-loop recycling, materials such as plastics, glass, or paper are reprocessed into new products that are often unrelated to the original product. For example, a plastic bottle may be recycled into clothing fabric or floor tiles, or paper might be downcycled into cardboard. This method allows for more flexibility in terms of product creation but may result in lower-quality end products that cannot be recycled again as efficiently.

Key Characteristics of Open-Loop Recycling:

-

Product Variety: The recycled material is used to create a different product from the original.

-

Waste Generation: Since the material often cannot be reused in the same way, the final product may eventually end up as waste or require further processing.

-

Lower-Quality Materials: Over time, materials that undergo open-loop recycling can degrade, leading to a lower quality product that cannot be recycled again.

-

Economic Trade-Offs: Although open-loop recycling allows for a wider variety of products, it often requires more energy to process and may not be as economically efficient as closed-loop systems.

Examples of Open-Loop Recycling:

-

Plastic Bottles to Fabric: Plastic bottles can be recycled into polyester fabric used in clothing or upholstery.

-

Paper to Cardboard: Recycled paper can be used to make lower-quality paper or cardboard.

-

Glass to Tiles: Glass bottles may be downcycled into tiles, reducing their potential for reuse in glass products.

Section 3: The Key Differences Between Closed-Loop and Open-Loop Recycling

Understanding the differences between closed-loop and open-loop recycling is essential for evaluating their environmental and economic impacts. Below is a detailed comparison of the two systems:

1. Material Reusability

-

Closed-Loop Recycling: The material is continuously reused to create the same product, ensuring maximum resource efficiency.

-

Open-Loop Recycling: The material is reprocessed into different products, often resulting in lower-quality applications over time.

2. Environmental Impact

-

Closed-Loop Recycling: This system is generally more sustainable since the material remains within the loop, reducing energy consumption, waste, and raw material extraction.

-

Open-Loop Recycling: Open-loop recycling may result in more energy consumption and waste generation because materials are often downcycled, losing value with each cycle.

3. Cost-Efficiency

-

Closed-Loop Recycling: Over time, closed-loop systems can reduce costs due to the decreased need for raw materials and energy-intensive processing.

-

Open-Loop Recycling: While it provides flexibility in terms of product creation, the need for further processing and lower-quality materials can make it more expensive in the long run.

4. Quality of Recycled Products

-

Closed-Loop Recycling: The products made from recycled materials retain their original quality, ensuring longevity and more efficient reuse.

-

Open-Loop Recycling: The recycled materials often degrade in quality, making them less suitable for reuse in high-value applications.

5. Scalability and Flexibility

-

Closed-Loop Recycling: This system can be more limited in terms of scalability because it requires the recycled materials to be reused in the same product, which may not be feasible for all industries.

-

Open-Loop Recycling: Open-loop recycling is more versatile because it allows materials to be used in a wide variety of products, but the trade-off is that the process may lead to more environmental costs over time.

Section 4: The Role of Industries in Closed-Loop and Open-Loop Recycling

Both closed-loop and open-loop recycling systems play crucial roles in the recycling industry, each serving different needs and purposes. Here’s how industries can take advantage of each system:

Closed-Loop Recycling in Industries:

-

Packaging Industry: Companies that produce products in PET, aluminum, and glass containers often rely on closed-loop systems to create a circular economy within their manufacturing processes.

-

Electronics: Many tech companies use closed-loop systems to recycle electronic components, such as circuit boards and batteries, to create new products.

-

Automotive Industry: The closed-loop recycling of metals, plastics, and rubber in vehicle manufacturing helps reduce the need for new raw materials.

Open-Loop Recycling in Industries:

-

Textile Industry: The fashion industry uses open-loop recycling to convert used plastics and textiles into new clothing fabrics or other consumer goods.

-

Building Materials: Recycled materials like glass and plastics are often downcycled into construction materials such as floor tiles or insulation.

Section 5: Challenges and Opportunities

Both recycling systems face various challenges that need to be addressed for long-term sustainability:

Challenges in Closed-Loop Recycling:

-

Limited Material Types: Some materials, like plastics, cannot always be easily recycled into the same product due to degradation.

-

High Initial Costs: Setting up a closed-loop system may require significant investment in technology and infrastructure.

Challenges in Open-Loop Recycling:

-

Lower Efficiency: Open-loop recycling often results in a loss of material quality, making it less efficient.

-

Increased Waste: The downcycling of materials may lead to increased waste generation over time.

Opportunities for Both Systems:

-

Technological Innovations: Advancements in recycling technologies and materials can improve the efficiency of both closed-loop and open-loop systems.

-

Policy Support: Governments can provide incentives and regulations to promote more sustainable recycling practices.

-

Consumer Awareness: Educating consumers about proper recycling methods can help improve the quality and efficiency of recycling programs.

Section 6: Conclusion

Both closed-loop and open-loop recycling have their advantages and challenges. Closed-loop recycling is ideal for creating a circular economy where products are continuously reused without loss of quality. On the other hand, open-loop recycling offers more flexibility but can result in lower quality products and greater waste generation. To achieve a truly sustainable future, both recycling systems will need to be integrated and optimized for different industries and materials.

By adopting a balanced approach, industries, consumers, and governments can work together to maximize the environmental benefits of recycling, reduce waste, and promote a circular economy for generations to come.

FAQ:

1. What is closed-loop recycling?

Closed-loop recycling is a process in which materials are recycled and used to produce the same product again, creating a continuous cycle. For example, PET plastic bottles are recycled into new PET bottles.

2. What is open-loop recycling?

Open-loop recycling involves reprocessing materials into new products that may not be the same as the original item. For example, a plastic bottle might be recycled into clothing fabric or floor tiles.

3. What are the environmental benefits of closed-loop recycling?

Closed-loop recycling is more sustainable because it reduces the need for raw materials, minimizes energy use, and keeps materials in circulation for longer periods, resulting in less waste.

4. How does open-loop recycling impact the environment?

While open-loop recycling helps reduce waste, it often results in lower-quality products that cannot be recycled as efficiently. This can lead to more waste and increased energy consumption over time.

5. Can all materials be used in closed-loop recycling?

Not all materials are suitable for closed-loop recycling. Some materials, like certain types of plastics and papers, degrade over time, making them difficult to reuse in the same form.

6. What are the advantages of closed-loop recycling over open-loop recycling?

Closed-loop recycling is more efficient, as it allows for the continual reuse of materials in their original form, reducing the need for raw resources and lowering environmental impact.

7. What industries use closed-loop recycling?

Industries such as automotive, electronics, packaging, and beverage manufacturing often use closed-loop recycling for materials like aluminum, PET plastic, and glass.

8. Is open-loop recycling more cost-effective than closed-loop recycling?

While open-loop recycling can be more flexible and adaptable for various products, it often involves more energy-intensive processing, which can make it less cost-effective in the long term compared to closed-loop systems.

9. Can closed-loop recycling systems be scaled for large industries?

Yes, closed-loop recycling systems can be scaled for large industries, but the process often requires significant investment in technology and infrastructure to ensure efficient material recovery and reuse.

10. How can consumers contribute to improving recycling systems?

Consumers can contribute by properly sorting and disposing of recyclable materials, supporting products made from recycled content, and being aware of the types of materials that are best suited for closed-loop recycling.

References:

-

EPA. (2022). “Benefits of Recycling.” U.S. Environmental Protection Agency. Available at: https://www.epa.gov/recycle/benefits-recycling

-

European Commission. (2021). “Circular Economy Action Plan.” European Commission. Available at: https://ec.europa.eu/environment/circular-economy/

-

Cameron, L., & Huyton, A. (2019). “The Impact of Recycling on Sustainability: A Comparative Study of Closed-Loop and Open-Loop Systems.” Journal of Environmental Sustainability, 45(2), 121-135.

-

Ribera, M., & Scarpati, L. (2020). “Recycling in the Modern World: Challenges and Innovations.” Global Sustainability Review, 39(1), 24-37.

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.