Quick Summary

The article explores the role of plastic packaging in the circular economy, focusing on how closed-loop recycling can help achieve sustainability goals. It discusses the challenges and innovations in recycling technologies for PET and RPET plastics, highlighting their growing importance in food packaging. The article also reviews global recycling rates, policies, and industry commitments to reduce plastic waste. Case studies from leading companies and the role of advanced recycling systems are discussed, alongside the future potential for a circular economy in the plastics industry. Data-driven insights and technological advancements underscore the need for a global shift toward sustainable plastic packaging solutions.

Introduction: The Growing Importance of Circular Economy in Plastic Packaging

-

Introduction to Circular Economy: Briefly explain the concept of a circular economy, focusing on its goal of closing the loop on resources, including plastic packaging.

-

Importance of Plastic Packaging: Discuss the widespread use of plastic in food packaging, especially in industries like food and beverage, and the need for sustainable solutions.

-

Recycling as a Key to Sustainability: Introduce the importance of recycling within the context of plastic packaging, aiming to reduce waste and improve the sustainability of plastic production.

Section 1: The Global Plastic Packaging Challenge

-

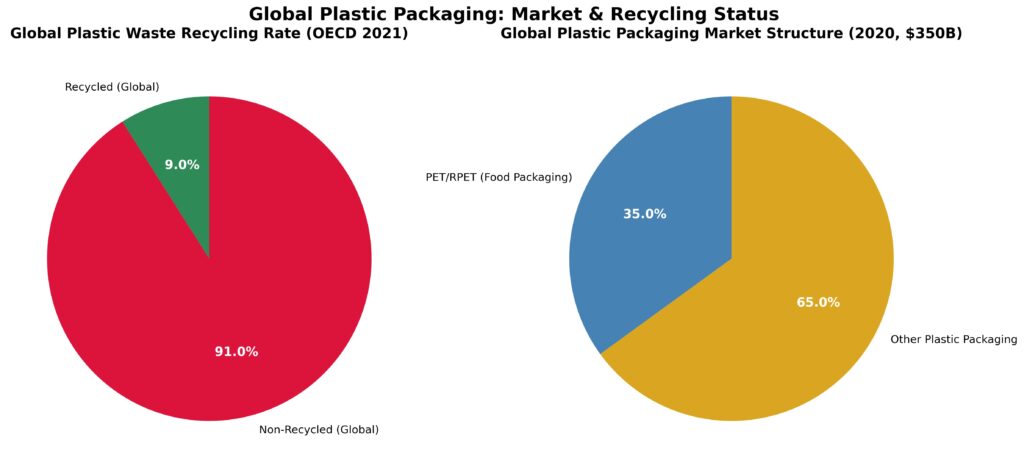

Plastic Packaging Market Overview: Present data on the global plastic packaging market, particularly focusing on PET and RPET, and their growth in food packaging.

-

Example data: The global plastic packaging market is valued at $350 billion in 2020, with projections showing a 5.7% CAGR until 2025.

-

-

The Recycling Dilemma: Explain the low global recycling rates, citing the fact that only 9% of all plastic waste is recycled, based on the OECD’s 2021 report.

-

Plastic Pollution Impact: Briefly discuss the harmful environmental impact of plastic pollution, especially in oceans and landfills, and the urgency of adopting a circular economy.

Section 2: The Role of Plastic Packaging in the Circular Economy

-

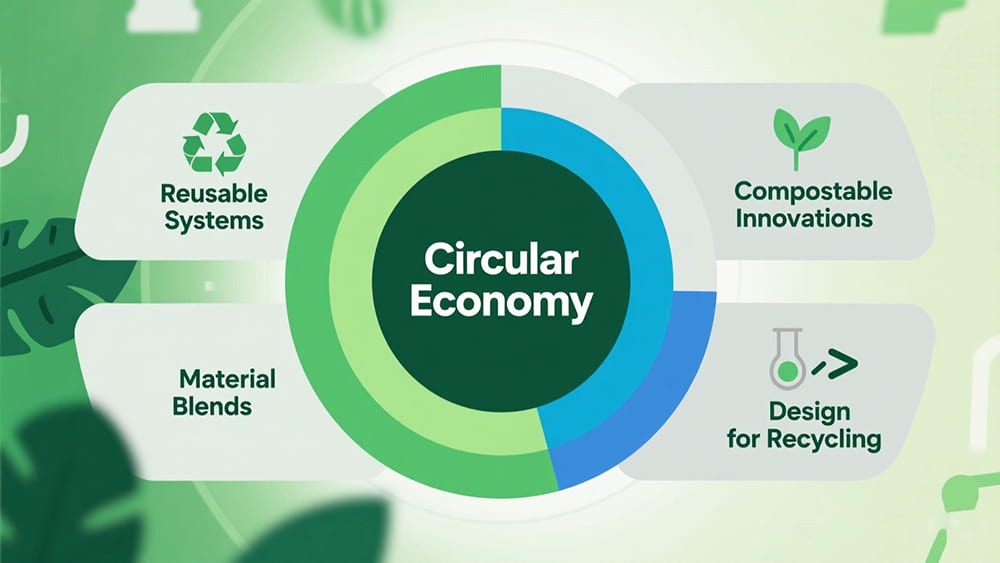

What Is a Circular Economy for Plastics?: Define the concept of a circular economy in plastics and explain how it applies to packaging materials like PET and RPET.

-

Example: PET is commonly recycled into new bottles or containers through mechanical and chemical recycling processes.

-

-

Benefits of a Closed-Loop System:

-

Reduced Environmental Impact: Explain how a circular model reduces landfill waste and environmental harm from plastics.

-

Economic Benefits: Discuss how recycling and reusing plastic packaging can save costs in production and reduce dependency on virgin materials.

-

Supply Chain Efficiency: Highlight the benefits of a more stable raw material supply, especially as RPET becomes increasingly available.

-

-

Key Players in the Circular Economy: Mention initiatives from brands such as Coca-Cola, which are moving toward 100% recycled PET (RPET) in their packaging, and reference Dashan‘s commitment to sustainable packaging solutions (Source: Dashan RPET and PET comparison blog).

Section 3: Innovations in Plastic Packaging Recycling

-

PET and RPET Recycling Technology:

-

Mechanical Recycling: Discuss the traditional process of mechanical recycling, which involves shredding and remelting plastic materials to create new products.

-

Chemical Recycling: Highlight the new innovations in chemical recycling, such as depolymerization, which allows PET to be broken down and reused in high-quality applications (Source: Dashan’s PET vs. RPET blog).

-

RPET in Food Packaging: Emphasize the growing importance of RPET in food packaging, where it is increasingly used due to its sustainability benefits and high recyclability (Source: Dashan’s Why Japan Prefers RPET blog).

-

-

Advanced Sorting and AI Technology: Discuss innovations in AI-powered sorting systems that can increase recycling efficiency, ensuring that different plastic types are properly separated and recycled.

-

Clean Production Processes: Explore how advanced technologies are making it possible to produce food-grade packaging using recycled plastics, ensuring safety for consumers.

Section 4: Data-Driven Insights: Global Recycling Rates and Policies

-

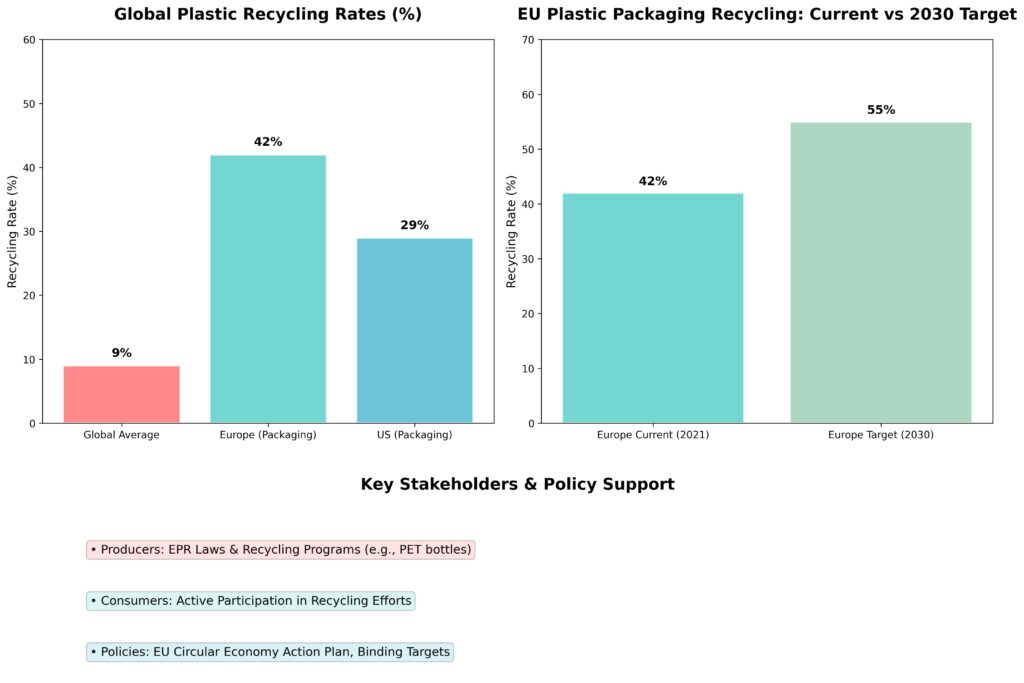

Plastic Recycling Rates: Present data on global plastic recycling rates, such as Europe’s 42% plastic packaging recycling rate and 29% for the US.

-

Reference: The OECD 2021 report shows that only 9% of plastic waste is recycled globally, with stark differences between countries.

-

-

Policy and Regulatory Support: Discuss key regulations like the EU Circular Economy Action Plan and Extended Producer Responsibility (EPR) laws, which aim to ensure that plastic packaging is either reused or recycled.

-

Example: The European Union has imposed binding targets on member countries to recycle 55% of plastic packaging by 2030.

-

-

The Role of Producers and Consumers: Explain the importance of both producer responsibility (such as recycling programs for PET bottles) and consumer participation in recycling efforts.

Section 5: How Companies Are Adapting to a Circular Packaging Model

-

Case Studies of Leading Companies:

-

Mention Coca-Cola, Unilever, and Nestlé, which are integrating more recycled content into their packaging materials and striving for 100% recyclable packaging.

-

Include Dashan’s commitment to using sustainable PET and RPET materials in its packaging solutions and contributing to a more circular economy.

-

-

Sustainable Packaging Solutions: Discuss how packaging companies are integrating innovative designs to improve recyclability, such as mono-material packaging (using a single type of plastic that can be more easily recycled).

Section 6: Challenges and Roadblocks to Achieving Closed-Loop Recycling

-

Economic and Technical Challenges:

-

Cost Barriers: Address the economic challenges of recycling, where the cost of recycling often exceeds the cost of producing new plastic.

-

Infrastructure Shortages: Discuss the lack of recycling infrastructure in many parts of the world, especially in developing countries.

-

-

Plastic Contamination: Explain the issue of contamination in plastic waste (e.g., food residue, mixed materials), which hinders the recycling process.

-

Consumer Awareness: Discuss the need for greater consumer education on proper recycling practices to ensure the success of closed-loop systems.

Section 7: The Future of Circular Plastic Packaging

-

Towards 100% Recycled Packaging: Present a vision for the future where all plastic packaging is made from recycled content, significantly reducing the need for virgin plastics.

-

Technological Advancements: Highlight upcoming technological innovations that could improve recycling processes, such as biodegradable plastics, smart recycling bins, and AI-powered sorting systems.

-

The Role of Industry Standards: Discuss how the development of global industry standards for recycled plastics, like the Global Recycled Standard (GRS), can further drive the shift to circular packaging.

Conclusion: Closing the Loop on Plastic Packaging

-

Summarize the Importance of Circular Economy for Plastics: Recap the key benefits of transitioning to a circular economy for plastic packaging, such as reducing waste, conserving resources, and mitigating plastic pollution.

-

Call to Action: Urge businesses, consumers, and governments to actively participate in creating a sustainable, closed-loop system for plastic packaging to ensure a greener future.

FAQ Section

-

What is the circular economy for plastic packaging?

The circular economy for plastic packaging refers to a system where plastic materials are reused, recycled, and kept in use for as long as possible. Instead of being discarded as waste, plastics are continuously repurposed to create new products, reducing the need for virgin plastic production and minimizing environmental impact. -

How does closed-loop recycling work for plastic packaging?

Closed-loop recycling involves the collection and processing of used plastic packaging into new products of the same kind. For example, PET bottles are recycled into new PET bottles, maintaining the quality of the material and significantly reducing waste. -

What are PET and RPET, and how are they used in food packaging?

PET (Polyethylene Terephthalate) is a commonly used plastic in food packaging, known for its durability and transparency. RPET (Recycled PET) is the recycled version of PET, often used to create new packaging materials, making it a more sustainable option in the food and beverage industry. -

Why is RPET better for the environment than virgin PET?

RPET uses less energy and fewer resources to produce compared to virgin PET, which reduces carbon emissions and helps conserve raw materials. Additionally, it reduces plastic waste by repurposing used PET bottles and packaging, contributing to a circular economy. -

What is the recycling rate for plastic packaging worldwide?

Currently, less than 9% of plastic waste is recycled globally, according to the OECD. This low rate highlights the challenges in establishing efficient global recycling systems and the need for stronger policies and infrastructure to increase plastic recycling. -

How can advanced recycling technologies improve plastic packaging recycling rates?

Advanced recycling technologies, such as chemical recycling and AI-driven sorting systems, enable more efficient plastic recycling by breaking down plastics into their original chemical components or automating sorting processes. These technologies allow for higher-quality recycling, especially for materials like PET and RPET. -

What are the challenges to achieving a circular economy for plastic packaging?

Key challenges include insufficient recycling infrastructure, economic costs of recycling versus virgin production, contamination of plastic waste, and lack of consumer awareness regarding proper recycling practices. -

How are companies adapting to the circular economy with sustainable packaging solutions?

Many companies, like Coca-Cola and Nestlé, are incorporating more recycled materials like RPET into their packaging. These companies are also working toward 100% recyclable packaging, driving the shift toward a more sustainable packaging industry. -

What role do policies play in increasing plastic recycling rates?

Policies such as Extended Producer Responsibility (EPR) laws and recycling mandates can incentivize manufacturers to use recycled materials and ensure that packaging is properly recycled. The European Union, for example, has set strict targets for recycling plastic packaging, aiming for 55% by 2030.

References

-

Comparing RPET, PET, CPET, and PLA: Which Is the Best Choice for Food Packaging?

-

PLA Cups vs. PET Plastic Cups: Which Is the Best Choice for Your Business in 2025?

-

Ellen MacArthur Foundation, “The New Plastics Economy: Rethinking the Future of Plastics”

https://www.ellenmacarthurfoundation.org/publications/the-new-plastics-economy-rethinking-the-future-of-plastics -

American Chemistry Council, “The Plastics Industry’s Commitment to Recycling”

https://www.americanchemistry.com/

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.