Quick Summary

Packaging solutions that succeed in Europe often fail in the Middle East due to heat, food characteristics, logistics stress, and different regulatory priorities. Buyers who adapt materials, testing methods, and expectations achieve far more stable results than those who simply replicate European standards.

Introduction: “It Works in Europe” Is Not a Guarantee

Many buyers assume that if a packaging solution performs well in Europe, it will work just as well in other markets.

On the surface, this sounds logical. European packaging standards are strict, suppliers are experienced, and products are thoroughly tested.

But in the Middle East, buyers often learn the hard way that “proven in Europe” does not always mean “reliable locally.”

Containers that look perfect on arrival may warp during storage. Lids that seal well in Europe may loosen after heat exposure. Leakage complaints appear only after launch—not during testing.

This article explains why that happens, and what experienced buyers do differently when sourcing packaging for Middle Eastern markets.

1. Heat Changes Everything

Why Europe and the Middle East Are Not Comparable

Most European packaging is designed for moderate temperatures. Even in summer, storage and transport conditions are relatively controlled.

In the Middle East, packaging is exposed to:

-

High ambient temperatures

-

Heat buildup inside shipping containers

-

Non–air-conditioned warehouses and delivery vehicles

This heat is not occasional—it is continuous.

What Heat Does to Packaging

Under sustained heat:

-

Plastics soften slightly

-

Structural rigidity decreases

-

Lids lose tight fit over time

The container may still look “okay,” but its performance margin is gone.

From DASHAN’s export experience, many failures appear after several hours of heat exposure combined with stacking pressure, not during initial use.

Buyer takeaway:

If packaging is not designed for prolonged heat, European test results alone are not enough.

2. Middle Eastern Food Puts More Stress on Packaging

A Key Difference Buyers Often Miss

European food packaging is often designed for:

-

Cold or warm food

-

Short holding times

-

Quick consumption

In the Middle East, food service looks very different:

-

Hot meals packed immediately after cooking

-

High oil and sauce content

-

Longer delivery and holding times

This combination dramatically increases packaging stress.

Common Failure Scenarios

Buyers frequently report:

-

Oil leakage after 30–60 minutes

-

Lids popping during delivery

-

Containers losing shape under stacked weight

These are not quality defects—they are application mismatches.

Buyer takeaway:

Packaging that works for cold or short-use scenarios may fail with hot, oily food.

3. Why “Eco-Friendly” Choices Can Backfire

Many buyers try to transfer European sustainability choices directly into the Middle East.

This often creates unexpected problems.

Where the Problem Starts

Some materials that perform well in Europe:

-

Lose strength under high temperatures

-

Absorb oil or moisture

-

Have limited local disposal infrastructure

In real use, this can lead to:

-

Higher breakage rates

-

More food waste

-

Customer complaints

What Experienced Buyers Do Instead

Rather than chasing labels, they focus on:

-

Real-use performance

-

Food safety consistency

-

Infrastructure reality

From DASHAN’s perspective, buyers who treat sustainability as a system decision, not a material swap, achieve far more stable results.

Buyer takeaway:

A sustainable choice must work in local conditions, not just look good on paper.

4. Same Standards, Different Expectations

Food-contact safety standards are broadly similar worldwide.

However, what regulators and importers focus on is different.

In Europe, buyers often emphasize:

-

Recycling labels

-

Environmental claims

-

Lifecycle assessments

In the Middle East, the focus is usually on:

-

Practical food safety

-

Material stability

-

Clear and consistent import documentation

A product accepted without question in Europe may still face scrutiny during Middle Eastern customs clearance if documentation is unclear.

Buyer takeaway:

Compliance is not just about materials—it is about context and paperwork.

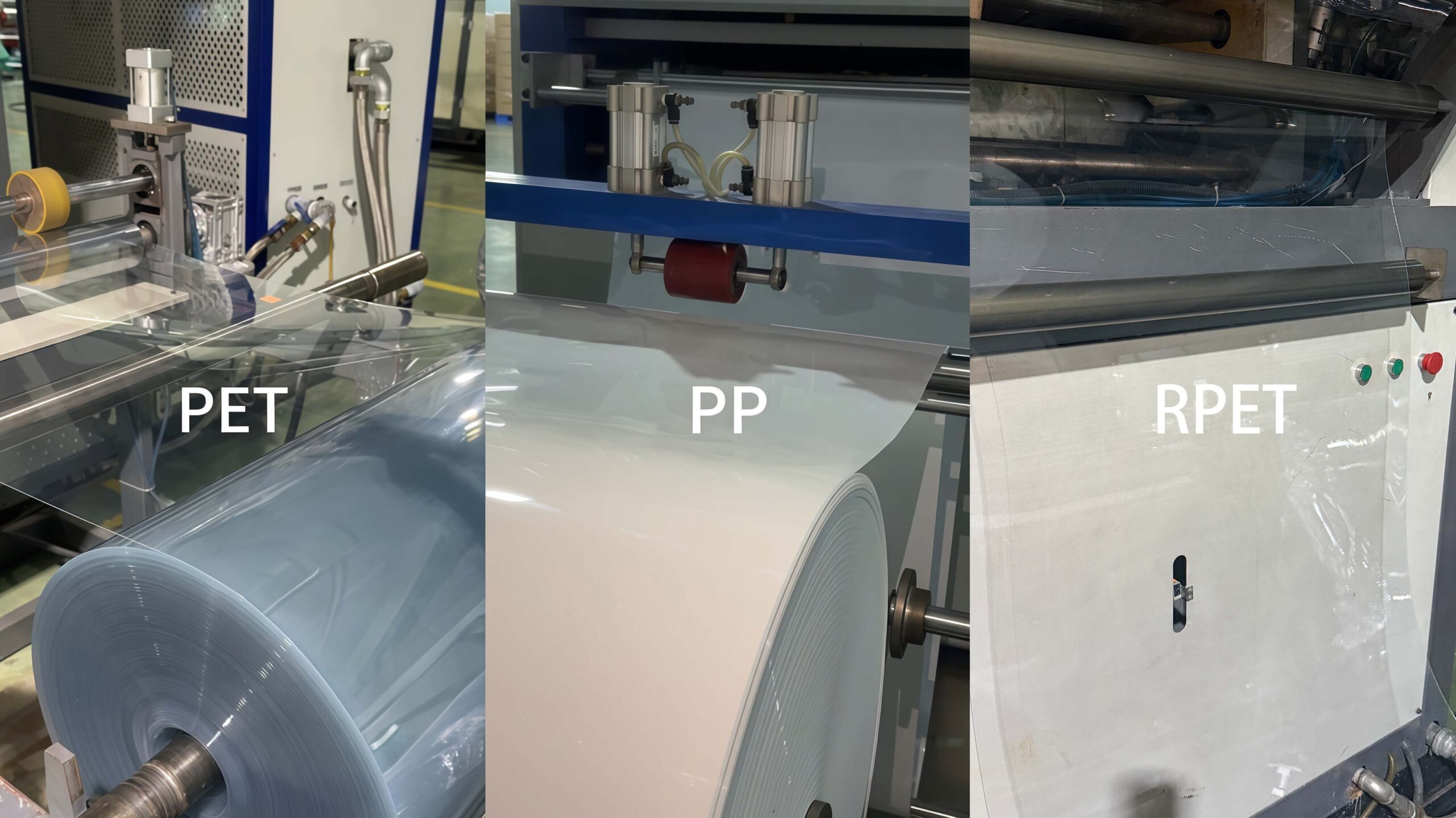

5. Why PET and PP Still Dominate in the Middle East

Despite sustainability discussions, PET and PP remain widely used.

This is not resistance to change—it is practicality.

These materials:

-

Perform reliably under heat

-

Resist oil and moisture

-

Maintain structure during transport

PP, in particular, is often preferred for hot food due to its higher heat resistance and dimensional stability.

Many experienced buyers keep PET, rPET, and PP as parallel options, choosing based on use case rather than ideology.

6. Logistics Adds Another Layer of Risk

Long-Distance Shipping Stress

Packaging destined for the Middle East often faces:

-

Long transit times

-

Stacking pressure inside containers

-

Temperature fluctuation during transport

These factors compound before the packaging is ever used.

The Hidden Cost of Failure

When packaging fails, the cost is rarely just replacement:

-

Food waste

-

Customer complaints

-

Brand damage

-

Contract disputes

For foodservice operators, even a small failure rate can escalate quickly.

Buyer takeaway:

Packaging must survive logistics—not just final use.

7. How Experienced Buyers Adapt Successfully

Buyers who perform well in the Middle East rarely copy European packaging directly.

Instead, they:

-

Test under heat and real food conditions

-

Increase structural margins where needed

-

Approve multiple materials for different scenarios

This flexible approach reduces risk and avoids sudden, costly changes.

At DASHAN, material development follows this same principle—performance first, compliance always, adaptation over assumption.

Common Buyer Mistakes to Avoid

-

Assuming certification guarantees performance

-

Underestimating heat and oil impact

-

Choosing materials based only on sustainability claims

-

Ignoring logistics stress

Avoiding these mistakes often matters more than choosing the “perfect” material.

A Simple Buyer Checklist

Before approving packaging for the Middle East, ask:

-

Can it handle sustained heat exposure?

-

Does it seal reliably with hot, oily food?

-

Will it survive stacking and long transport?

-

Is the documentation clear for import clearance?

This checklist alone prevents many failures.

FAQ

1. Why does packaging that works in Europe fail in the Middle East?

Because higher temperatures, hot food applications, and longer logistics chains place much greater stress on packaging materials.

2. Is heat really the biggest factor in Middle Eastern packaging issues?

Yes. Sustained heat affects material rigidity, lid fit, and sealing performance, especially during transport and storage.

3. Are European food contact certifications enough for Middle East markets?

Not always. While safety standards overlap, Middle Eastern importers focus more on performance stability and clear documentation.

4. Why are PET and PP still widely used in the Middle East?

They offer reliable heat resistance, oil tolerance, and structural stability under real operating conditions.

5. Can eco-friendly packaging replace plastic in the Middle East?

In some cases, yes—but only when matched to local heat, food type, and disposal infrastructure. Poor adaptation often leads to failure.

6. What packaging problems do buyers most commonly report?

Warping, oil leakage, loose lids, deformation during stacking, and failures that appear only after delivery.

7. How can buyers reduce packaging risk in Middle Eastern markets?

By testing under real heat conditions, approving multiple materials, and prioritizing performance over assumptions.

Conclusion: Adaptation Beats Replication

Packaging that works in Europe does not automatically work in the Middle East.

Climate, food habits, logistics, and regulatory expectations all change the rules. Buyers who adapt their packaging strategy succeed. Those who simply replicate European solutions often pay the price later.

In Middle Eastern markets, packaging must be chosen for reality—not reputation.

References

-

European Commission – Food Contact Materials

https://food.ec.europa.eu/safety/chemical-safety/food-contact-materials_en -

EFSA – Plastics and Food Contact Safety

https://www.efsa.europa.eu/en/topics/topic/food-contact-materials -

Gulf Standardization Organization (GSO) – Technical Regulations

https://www.gso.org.sa -

Dubai Municipality – Food Safety Regulations

https://www.dm.gov.ae/municipality-business/food-safety -

Packaging Europe – Heat and Material Performance Insights

https://packagingeurope.com

Copyright Statement

© 2026 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.