Quick Summary

As sustainability becomes a defining goal in global packaging, recycled PET (rPET) has emerged as the most balanced solution — combining circularity, clarity, and performance. Unlike traditional single-use plastics, rPET utilizes recycled polyethylene terephthalate, reducing carbon emissions and plastic waste. For global businesses, adopting rPET packaging is both an environmental commitment and a market necessity.

DASHAN, a professional food packaging manufacturer with extensive thermoforming experience, integrates advanced rPET technology, quality control, and OEM/ODM export capabilities to provide safe, durable, and eco-conscious PET and rPET packaging solutions for international brands.

1. Introduction: The Global Shift Toward Recycled Plastics

In the last decade, the global packaging industry has undergone a rapid transformation. The shift from virgin plastics to recycled and bio-based materials reflects a growing consensus: sustainability is no longer optional — it’s strategic. Governments, corporations, and consumers alike are demanding packaging that minimizes environmental impact while maintaining functionality.

Recycled PET (rPET), derived from post-consumer PET bottles and packaging, represents the most mature and scalable recycled plastic system in the world. Its closed-loop recyclability and stable supply chain make it the preferred material for beverage cups, food containers, and sushi boxes.

As nations introduce stricter plastic regulations — such as the EU’s Single-Use Plastics Directive, U.S. Extended Producer Responsibility (EPR) programs, and China’s Green Packaging Plan — rPET has evolved from a sustainability trend into a compliance requirement.

For food packaging producers like DASHAN, this shift offers both opportunity and responsibility: to deliver recycled materials that meet international safety and aesthetic standards, while maintaining production efficiency and global competitiveness.

2. Understanding rPET: What Makes It Different

rPET, or recycled polyethylene terephthalate, is created through the reprocessing of used PET materials — mainly beverage bottles. While its chemical backbone is identical to virgin PET, the difference lies in the processing history and purification steps that determine its safety and clarity.

Production Process

-

Collection and Sorting

Post-consumer PET bottles are collected through municipal or industrial systems and sorted by polymer type and color. -

Washing and Flake Preparation

The sorted material is crushed into flakes and washed in alkaline solutions to remove labels, adhesives, and contaminants. -

Re-extrusion and Solid-State Polymerization (SSP)

Clean flakes are melted and re-polymerized under controlled temperature and vacuum to restore intrinsic viscosity (IV) — ensuring mechanical strength and safety. -

Pelletizing and Sheet Extrusion

The final rPET pellets are transformed into sheets or films, ready for thermoforming into products such as cups, lids, and boxes.

This advanced recycling process allows rPET to achieve food-grade safety certification under regulations like U.S. FDA 21 CFR 177.1630 and EU Regulation No 282/2008, provided proper decontamination and traceability are maintained.

Key Advantages of rPET

-

Lower Carbon Footprint: Up to 60% fewer CO₂ emissions than virgin PET.

-

Closed-loop Recyclability: Enables continuous material recovery and reuse.

-

High Clarity and Strength: Maintains transparency and toughness comparable to virgin resin.

-

Food Safety Compliance: Compatible with global food-contact standards.

3. Global rPET Policies and Market Trends

The acceleration of rPET adoption is closely tied to policy-driven sustainability frameworks around the world.

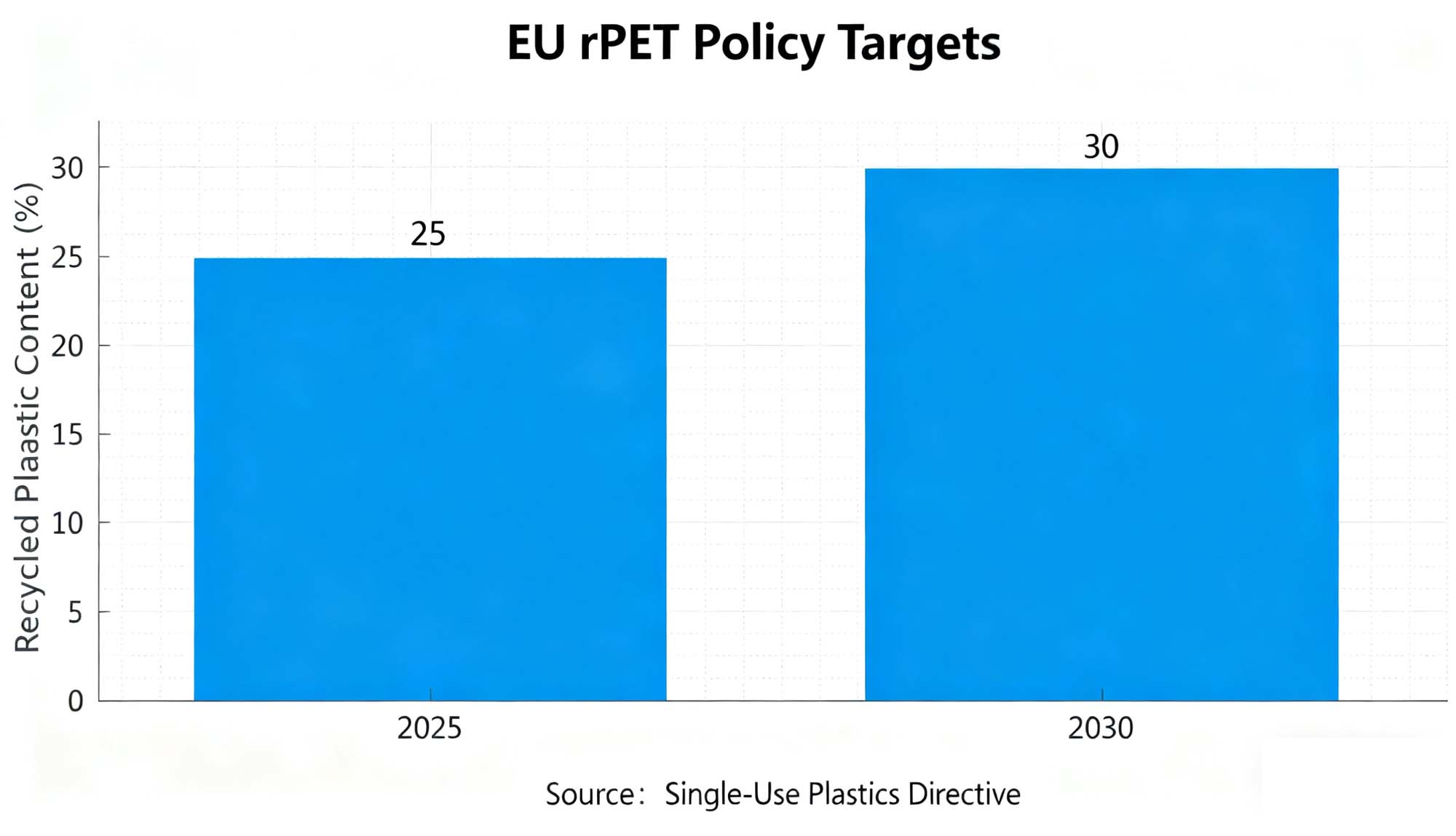

Europe

The European Union has set ambitious targets:

-

At least 25% recycled plastic in PET bottles by 2025,

-

30% by 2030 under the Single-Use Plastics Directive.

To support these goals, many European brands now source certified rPET packaging to meet compliance and brand reputation requirements.

United States

Several U.S. states, including California and Washington, enforce recycled content mandates for beverage packaging — 15% by 2022, increasing to 50% by 2030. The U.S. packaging sector is also moving toward Extended Producer Responsibility (EPR) programs that place financial responsibility for recycling on producers.

Japan

Japan leads Asia in PET recycling efficiency, achieving over 85% collection rates through its nationwide bottle return program. The Japanese market emphasizes high-purity rPET for both beverages and food packaging, setting a global benchmark.

China

China’s “Green Packaging Development Guidelines (2020)” emphasize recyclable materials, particularly PET, as a core component of the domestic circular economy. The government supports rPET infrastructure expansion, fostering growth in both local consumption and exports.

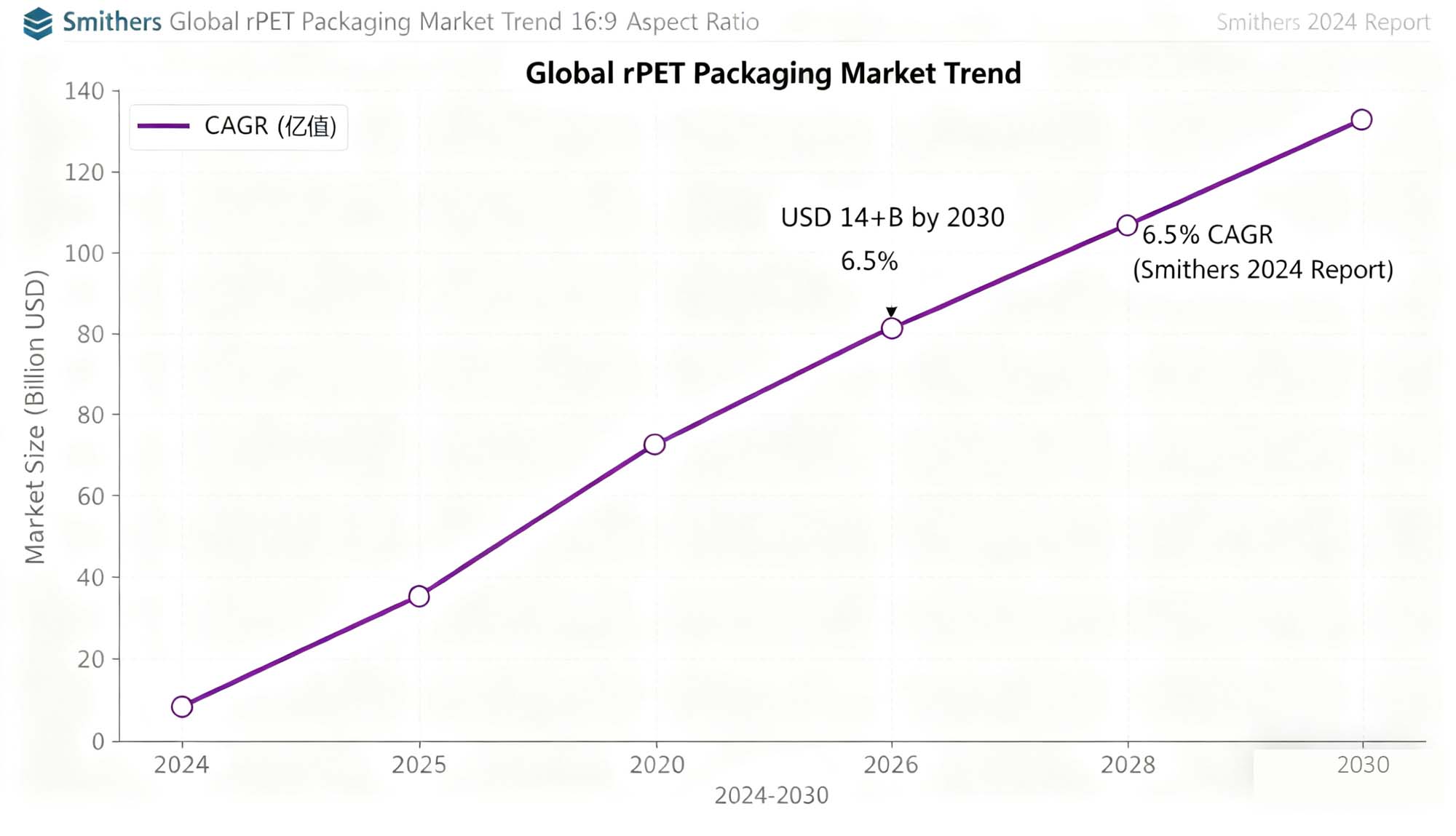

Global Outlook

According to Smithers’ 2024 market report, the global rPET packaging market is projected to exceed USD 14 billion by 2030, growing at 6.5% CAGR. This surge reflects not only environmental awareness but also technological progress and rising consumer preference for sustainable brands.

4. Technological Advancements in rPET Production

Modern rPET technology combines precision engineering, purification chemistry, and data-driven quality assurance. The goal: deliver high-purity, odor-free, crystal-clear recycled material suitable for food contact.

Core Innovations

-

Hot and Cold Washing Systems: Improve contaminant removal and flake brightness.

-

Melt Filtration Technology: Eliminates micro-impurities and stabilizes viscosity.

-

SSP Reactors: Rebuild molecular chains to restore mechanical integrity.

-

Optical Sorting Systems: Utilize near-infrared (NIR) scanners to achieve >99.9% PET purity.

-

AI-driven Quality Control: Detects color deviations and contamination in real-time.

DASHAN’s Technical Edge

DASHAN integrates these technologies within its thermoforming lines, ensuring that both PET and rPET sheets maintain uniform thickness, clarity, and hygiene.

The company’s in-house QC system uses spectrophotometric and tensile strength analysis to ensure compliance with FDA, EFSA, and ISO 22000 standards.

This commitment to technology enables DASHAN to produce safe, durable, and export-ready rPET boxes and cups for global foodservice partners.

5. Applications of rPET in Modern Food Packaging

rPET has become the new standard across a wide range of foodservice and retail sectors, thanks to its performance stability and aesthetic appeal.

-

Cold Beverages: Clear PET and rPET cups used in cafes, juice bars, and fast-food chains.

-

Sushi and Salad Boxes: Lightweight, transparent containers that enhance food visibility and shelf appeal.

-

Bakery and Dessert Packaging: Offers moisture resistance and rigidity.

-

Ready-to-Eat Meals: Ideal for grab-and-go cold food due to excellent barrier properties.

DASHAN’s Market Reach

With exports to over 50 countries, DASHAN supplies OEM/ODM solutions for supermarkets, restaurants, and airlines.

Its custom thermoforming and printing services help international clients enhance branding while achieving sustainability goals.

6. Balancing rPET with Virgin PET: A Realistic Sustainability Path

While rPET represents the future of sustainable packaging, virgin PET remains vital in ensuring consistent performance, clarity, and hygiene in certain applications.

Optimal Blending Strategy

A blend of 30–50% rPET with virgin PET often delivers the best balance between sustainability and performance — lowering carbon emissions without compromising optical or mechanical quality.

DASHAN’s Dual-Line Approach

DASHAN operates parallel production lines for PET and rPET, enabling precise material control for diverse market needs.

This hybrid approach ensures customers can transition to rPET gradually without sacrificing visual appeal, durability, or food safety.

7. Future Innovations: Beyond rPET

The packaging industry is evolving beyond conventional recycling into next-generation circular systems.

-

Chemical Recycling: Converts PET waste back into monomers for infinite reuse.

-

Hybrid Materials: Blending rPET with bio-based PLA to combine renewability and recyclability.

-

AI-Based Sorting: Improves global recycling rates and reduces contamination.

-

Design for Disassembly: Simplifies recycling by minimizing mixed materials.

DASHAN is actively exploring these frontiers through R&D collaborations and pilot-scale innovations, aiming to achieve carbon-neutral packaging solutions by the end of the decade.

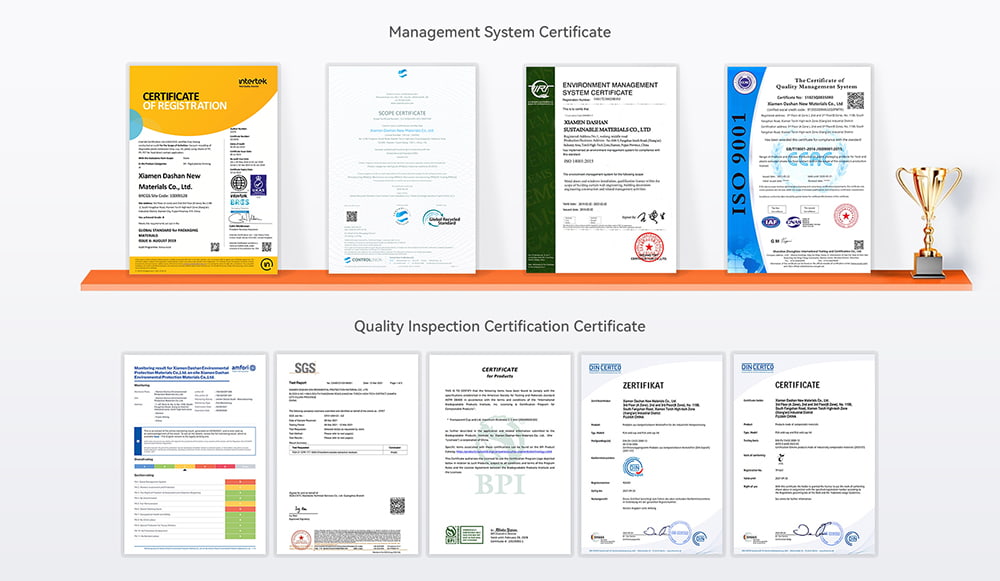

8. Quality Assurance and International Standards

High-quality rPET packaging must meet stringent food-safety and performance benchmarks.

Key Certifications

-

FDA (U.S. Food and Drug Administration) approval for food-contact use.

-

EFSA (European Food Safety Authority) compliance for decontamination process validation.

-

REACH and RoHS compliance for chemical safety.

-

ISO 9001 & ISO 22000 certification for manufacturing and food safety systems.

DASHAN’s Quality Framework

Every batch of DASHAN’s rPET sheet undergoes:

-

Molecular weight and IV testing to ensure mechanical consistency.

-

Optical inspection for clarity and color uniformity.

-

Contaminant analysis via chromatography for food safety assurance.

This rigorous approach guarantees the trustworthiness and global reliability of DASHAN’s products.

9. DASHAN’s Expertise: Precision Thermoforming and Global OEM Support

As a leading Chinese packaging manufacturer, DASHAN combines years of thermoforming experience with a strong commitment to innovation and sustainability.

The company provides end-to-end OEM/ODM services — from rPET material development and mold design to custom printing, branding, and logistics.

Its fully automated lines ensure efficient mass production with stable quality for international clients.

Through continuous R&D and collaboration with partners in Europe, Japan, and North America, DASHAN drives progress in lightweight structure design, recyclability, and material circularity — supporting global businesses in achieving both economic and environmental goals.

Conclusion

rPET is no longer just a sustainable option — it’s the foundation of the future packaging economy.

With strong global policies, advanced recycling technologies, and responsible manufacturers like DASHAN, the transition from virgin plastics to circular materials is accelerating.

By delivering high-quality, food-safe, and export-ready PET and rPET packaging, DASHAN continues to empower international partners in building a cleaner, smarter, and more sustainable packaging future.

FAQ

1. What is rPET?

rPET stands for recycled polyethylene terephthalate — a material made from used PET bottles that are collected, cleaned, and reprocessed into new packaging products.

2. Is rPET safe for food packaging?

Yes. When processed through certified decontamination systems, rPET meets FDA and EFSA standards for direct food contact.

3. What are the benefits of rPET compared to virgin PET?

rPET reduces carbon emissions, conserves resources, and supports circular economy goals while maintaining similar clarity and strength.

4. Can rPET be customized for branding?

Absolutely. DASHAN offers OEM/ODM solutions for custom printing, embossing, and design to meet brand and sustainability requirements.

5. How does DASHAN ensure product quality?

Every rPET sheet and product undergoes strict QC testing for optical clarity, tensile strength, and safety — certified to ISO and FDA standards.

References

-

European Commission. “Directive (EU) 2019/904 on Single-Use Plastics.”

-

U.S. FDA. “Guidance for Industry: Use of Recycled Plastics in Food Packaging.”

-

PET Resin Association (PETRA). “rPET Market Overview 2024.”

-

Ellen MacArthur Foundation. “Circular Economy in Plastics.”

-

Smithers. “The Future of rPET Packaging to 2030.”

-

Japan PET Bottle Recycling Association. “Recycling Statistics 2023.”

-

China Green Packaging Development Guidelines (2020).

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.