RPET Cups are transforming beverage packaging by turning recycled PET bottles into safe, food-grade drinkware. Unlike traditional disposable plastic, RPET supports a closed-loop recycling system, reduces carbon emissions, and meets growing sustainability demands. Backed by global policies and consumer awareness, RPET Cups are redefining sustainable drinking for coffee shops, juice bars, and brands worldwide—offering both environmental and business advantages.

Introduction

Every year, billions of disposable cups are consumed around the world, most of them made from virgin plastic that takes centuries to decompose. While recycling systems exist, the reality is that only a fraction of plastic waste gets truly recycled into new food-grade packaging. According to global statistics, less than 10% of all plastic produced has ever been recycled back into the same quality material. This linear model—produce, use, discard—creates an environmental burden that is no longer sustainable.

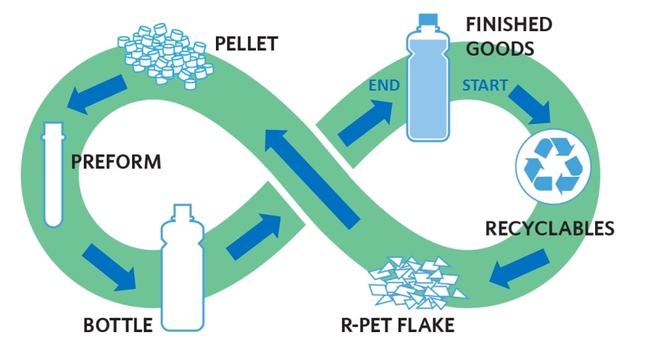

Enter RPET Cups. Made from Recycled Polyethylene Terephthalate (rPET), these cups are redefining how we drink beverages by turning yesterday’s plastic bottles into today’s safe, stylish, and sustainable drinkware. Instead of being downcycled into clothing or construction materials, rPET enables a bottle-to-bottle or bottle-to-cup closed-loop recycling system. This innovation doesn’t just reduce waste—it represents a new era in the circular economy of packaging.

In this blog, we’ll explore why RPET Cups are emerging as the future of sustainable drinking, their environmental and social benefits, regulatory frameworks shaping their adoption, and how businesses and consumers alike can play a part in making them the new norm.

What Are RPET Cups?

RPET Cups are beverage containers produced using recycled PET plastic, sourced primarily from discarded plastic bottles. PET is one of the most widely used plastics in the food and beverage industry because of its clarity, safety, and lightweight nature. When PET is collected and reprocessed into rPET, it can be turned back into food-grade packaging, provided it undergoes rigorous safety and quality testing.

Unlike traditional plastic cups made from virgin PET, RPET Cups reduce reliance on fossil fuels, conserve energy, and lower greenhouse gas emissions. They are identical in function to regular PET cups—transparent, durable, and suitable for cold beverages like iced coffee, smoothies, milkshakes, bubble tea, and sodas—but they carry the added advantage of being part of a closed recycling loop.

Why RPET Cups Matter in the Age of Sustainability

1. Tackling the Plastic Waste Crisis

Global beverage consumption is staggering. In Taiwan alone, 5 billion plastic bottles are used every year. While the island boasts a recycling rate of around 95%, most of this plastic is downcycled into textiles or building materials that eventually still end up as waste. This is often called a “false recycling loop” because it delays, rather than prevents, disposal.

By contrast, RPET Cups enable true recycling. Instead of being downcycled, the material can be processed into new food-grade containers multiple times—creating a genuine bottle-to-bottle or bottle-to-cup cycle that keeps plastic in circulation and out of landfills or incinerators.

2. Lower Carbon Footprint

Manufacturing virgin PET requires significant fossil fuel input. According to life cycle analyses, producing rPET reduces carbon emissions by up to 60% compared with virgin PET. For businesses that want to align with net-zero targets, switching to RPET Cups represents a meaningful step toward lowering Scope 3 emissions associated with packaging.

3. Consumer Demand for Sustainable Choices

Today’s consumers—especially Millennials and Gen Z—expect brands to reflect their values. A Nielsen study found that 73% of global consumers are willing to pay more for sustainable packaging. Coffee shops, juice bars, and quick-service restaurants that adopt RPET Cups not only reduce environmental impact but also enhance their brand image by meeting this growing demand.

Global Policies Driving RPET Adoption

European Union

The EU Single-Use Plastics Directive mandates that from 2025, all plastic beverage bottles must contain at least 25% rPET, rising to 30% by 2030. This legislation is forcing beverage brands to integrate recycled content into their packaging and is accelerating the shift toward food-grade rPET.

United States

In California, new laws require that beverage containers contain 15% recycled content by 2022, 25% by 2025, and 50% by 2030. Companies failing to comply face significant penalties. This has sparked rapid investment in rPET infrastructure across the U.S.

Taiwan’s Case Study

In 2023, Taiwan’s Homemakers United Foundation launched the first tea beverage packaged in 30% food-grade rPET bottles. The initiative showcased how closed-loop recycling could be implemented at scale, with each bottle capable of being recycled 3–5 times. Environmental groups are now urging the government to set mandatory rPET content requirements for food containers, ensuring that the island’s high recycling rate translates into a true circular economy.

These examples illustrate how government policies combined with consumer activism are reshaping the beverage packaging industry. RPET Cups are not just a trend—they are becoming a compliance necessity.

Benefits of RPET Cups for Businesses

-

Brand Differentiation – By adopting RPET Cups, coffee chains, juice brands, and foodservice operators can market themselves as sustainability leaders.

-

Cost Efficiency in the Long Term – While initial costs of rPET may be slightly higher, scaling production and regulatory compliance will make virgin PET more expensive over time.

-

Compliance and Risk Management – As more regions mandate recycled content, early adoption ensures businesses stay ahead of regulations.

-

Consumer Trust and Loyalty – Offering drinks in RPET Cups signals commitment to environmental responsibility, which builds customer loyalty.

Overcoming Challenges of RPET Cups

While RPET Cups hold great promise, challenges remain:

-

Supply Chain Limitations: High-quality food-grade rPET is in limited supply, leading to competition between industries.

-

Safety and Quality Testing: rPET must meet stringent food safety standards, requiring advanced decontamination technology.

-

Cost Factors: Currently, rPET can be more expensive than virgin PET, though this gap is narrowing as demand and infrastructure grow.

-

Consumer Education: Many consumers are unaware of the difference between PET and rPET. Brands need to communicate the environmental benefits clearly.

The Future of Sustainable Drinking with RPET Cups

The rise of RPET Cups represents a shift from a linear “take-make-waste” economy to a circular model where resources are continuously reused. Looking ahead, several trends are likely to shape the future:

-

Bottle-to-Cup Innovations – Scaling up closed-loop systems where collected PET bottles are directly recycled into new cups.

-

Digital Tracking – Using QR codes and blockchain to trace recycled content and reassure consumers about authenticity.

-

Hybrid Materials – Combining rPET with compostable coatings or additives for enhanced sustainability.

-

Consumer-Driven Policy Change – As more consumers demand circular packaging, governments will accelerate legislation.

Ultimately, RPET Cups are more than a packaging choice—they are a symbol of collective responsibility. By adopting them, businesses and consumers contribute to reducing plastic pollution, conserving resources, and creating a future where sustainability is woven into everyday drinking habits.

Conclusion

Plastic waste is one of the greatest environmental challenges of our time. While recycling rates in some regions are high, true circularity has remained elusive. RPET Cups change this equation by enabling food-grade recycling that reduces waste, lowers carbon emissions, and supports a sustainable lifestyle.

From the streets of Taipei to the cafés of Paris and Los Angeles, RPET Cups are redefining what it means to enjoy a beverage responsibly. They are not just cups—they are a powerful reminder that every sip can help build a more sustainable future.

References

-

European Commission. (2021). Plastic Waste and Recycling in the EU: Facts and Figures. Retrieved from: https://ec.europa.eu/eurostat/statistics-explained/plastic-waste-and-recycling

-

U.S. Food & Drug Administration (FDA). (2022). Guidance for Industry: Use of Recycled Plastics in Food Packaging (Chemistry Considerations). Retrieved from: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/use-recycled-plastics-food-packaging-chemistry-considerations

-

European Food Safety Authority (EFSA). (2021). Recycling Processes for Food-Contact Plastics. Retrieved from: https://www.efsa.europa.eu/en/topics/topic/recycling

-

Ellen MacArthur Foundation. (2020). The New Plastics Economy: Rethinking the Future of Plastics. Retrieved from: https://ellenmacarthurfoundation.org/the-new-plastics-economy

-

National Geographic. (2022). How Recycling Bottles Can Help Reduce Plastic Pollution. Retrieved from: https://www.nationalgeographic.com/environment/article/plastic-recycling

-

Plastics Europe. (2021). Plastics – the Facts 2021: An analysis of European plastics production, demand, and waste data. Retrieved from: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/

-

Closed Loop Partners. (2021). Recycled Plastics Market Report. Retrieved from: https://www.closedlooppartners.com/reports/