Quick Summary

The PP Tray 121165 is a lightweight, food-grade 950 ml tray designed for fresh meat, deli items, cooked foods, and ready meals. Made from durable polypropylene, it offers excellent sealing performance with standard film, ensuring freshness, hygiene, and leak resistance for retail and foodservice use.

Introduction

In today’s fast-moving food retail and foodservice sectors, packaging is no longer a simple container—it is a functional tool that influences product quality, shelf appeal, operational efficiency, and consumer trust. As supermarkets, food processors, delis, and ready-meal brands face rising expectations for hygiene, safety, convenience, and sustainability, the choice of packaging material becomes increasingly important.

Polypropylene (PP) trays have become one of the most widely adopted solutions for fresh food, cooked meals, and deli products. Their excellent resistance to moisture, fats, and temperature variations, combined with cost-efficiency and sealing compatibility, make them a reliable choice for both chilled and hot foods.

Among these solutions, the PP Tray Model 121165 stands out as a compact, lightweight, and highly functional container. Designed for food presentation and food safety, this tray is ideal for a wide range of applications—from fresh meat to prepared dishes. With a capacity of 950 ml, a weight of 10 g, and dimensions of 122 × 110 × 65 mm, the 121150 model offers a balanced combination of efficiency, strength, and practicality for modern food packaging operations.

This article provides a comprehensive overview of the PP Tray 121150, including material properties, functional benefits, application scenarios, sealing compatibility, sustainability considerations, and why it is increasingly preferred by global food businesses.

Product Overview

Model: PP Tray 121165

Material: Polypropylene (PP)

Size: 122 × 110 × 65 mm

Weight: 10 g

Capacity: 950 ml

Lid Option: No rigid lid; compatible with heat-sealing film

Suitable For: Fresh food, cooked food, ready meals, deli portions, small meal components

Sealing Method: Plastic sealing film using a standard tray-sealer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Model | Capacity (ml) |

Wegiht (g) |

Size(mm) | Packaging pcs/ctn |

Ctn Size (cm) |

| 121150 | 360 | 9 | 122*110*50 | 200 | 66.5*45.5*33.5 |

| 121165 | 950 | 10 | 122*110*65 | 300 | 67.5*47.5*37 |

| 1414-H35 | 420 | 11 | 140*140*35 | 1400 | 61*54*29 |

| 1414-H40 | 460 | 12 | 140*140*40 | 1400 | 61*54*29 |

| 1414-H60 | 500 | 13.5 | 140*140*60 | 1200 | 57*49*43 |

| 201435 | 600 | 14 | 200*140*35 | 800 | 61*54*29 |

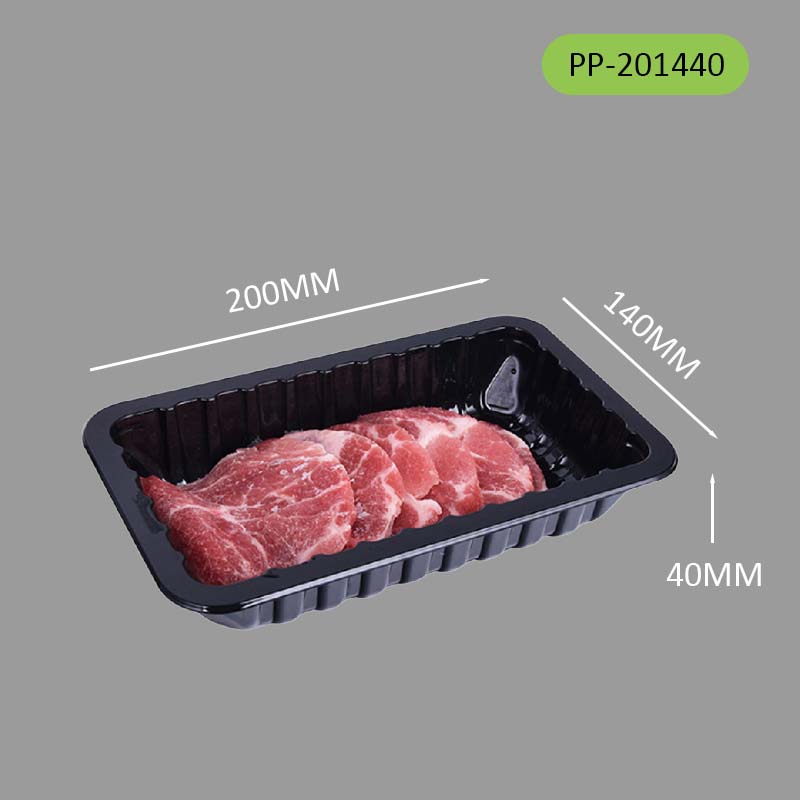

| 201440 | 600 | 14 | 200*140*40 | 800 | 61*54*29 |

| 201445 | 800 | 16 | 200*140*45 | 800 | 61*54*29 |

| 201455 | 950 | 17 | 200*140*55 | 800 | 61*54*29 |

| 201480 | 1350 | 23 | 200*140*80 | 500 | 61*54*29 |

| 221330 | 450 | 16 | 220*130*30 | 600 | 67*34*45.5 |

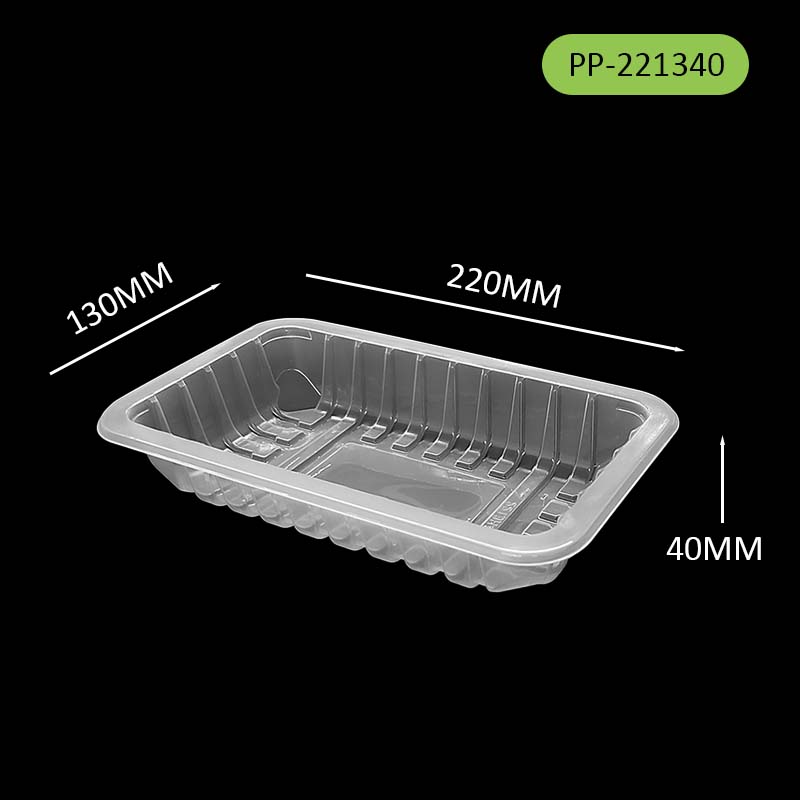

| 221340 | 620 | 19 | 220*130*40 | 600 | 67*34*45.5 |

| 221350 | 810 | 20 | 220*130*50 | 500 | 67*34*45.5 |

| 221360 | 1000 | 23 | 220*130*60 | 500 | 67*34*45.5 |

| 221370 | 1100 | 27 | 220*130*30 | 500 | 67*34*45.5 |

| 221375 | 1200 | 27 | 220*130*30 | 500 | 67*34*45.5 |

| 2617H70 | 1800 | 40 | 260*170*70 | 300 | 53.5*33*53 |

| 2618H110 | 2900 | 48 | 260*180*110 | 300 | 55*49*53.5 |

The compact structure and lightweight construction of the 121165 tray allow it to be easily integrated into supermarket shelves, deli counters, and ready-meal production lines. With its clean rectangular form and optimal depth of 65mm, it provides enough room for various food items while maintaining a neat, organized appearance.

Why PP Material Matters

Polypropylene is a high-performance thermoplastic widely used across the food packaging industry. Its robust mechanical properties and thermal stability make it an excellent choice for both fresh and cooked foods.

Food-Contact Safety

PP is naturally food-safe, BPA-free, odor-free, and resistant to chemical leaching. This makes the 121165 tray suitable for direct food contact across all food categories, including:

-

Meat and poultry

-

Fish and seafood

-

Fresh produce

-

Cooked meals

-

Salads and deli items

-

Stir-fried dishes

-

Bakery items

Its safety profile satisfies global food-contact standards commonly required by supermarkets, processors, and export-oriented manufacturers.

Heat Resistance & Microwave Suitability

One of the biggest advantages of PP is its ability to withstand high temperatures:

-

Microwave-safe

-

Hot-fill compatible

-

Resists deformation under warm or hot food

-

Maintains strength under sealing-machine heat

This makes the 121165 tray suitable not only for chilled foods but also for freshly cooked dishes packed while warm.

Moisture & Fat Resistance

PP’s non-absorbent structure prevents moisture, oils, and sauces from penetrating the container walls. This preserves food quality and hygiene, reduces contamination risks, and helps keep shelves clean.

Lightweight & Efficient

At only 10 g, the 121165 tray minimizes material usage without sacrificing structural stability. This lightweight design contributes to:

-

Lower transportation costs

-

Reduced packaging waste

-

Easier handling in production lines

Design Features of the PP Tray 121165

Compact Dimensions for Maximum Versatility

The 122 × 110 mm footprint fits easily into supermarket displays and refrigerated shelves without occupying excessive space. The 65 mm depth offers practical volume while allowing neat stacking in storage and during shipping.

Reinforced Sidewalls for Structural Stability

Despite its low weight, the tray features rigid walls reinforced through optimized molding. This prevents deformation during handling, sealing, or storage.

Smooth Interior & Hygienic Surface

The interior is designed to maintain food texture and prevent residue buildup. Smooth surfaces help maintain freshness and give an appealing presentation for:

-

Portions of meat

-

Ready-to-eat meals

-

Vegetables

-

Cut fruit

-

Tofu or bean-based products

Designed for Plastic Film Sealing

The tray does not require a rigid lid. Instead, it is made for heat-sealing, which provides multiple advantages:

-

Tight and hygienic seal

-

Extended shelf life

-

Leak prevention

-

Tamper resistance

-

Improved stackability

This makes the 121165 tray ideal for modern retail packaging lines.

Application Scenarios

The PP Tray 121165 is suitable for a wide range of food categories, making it one of the most adaptable SKUs for food packaging.

Supermarket Fresh Food Sections

Retailers can use the tray for:

-

Fresh meat slices

-

Chicken cubes or strips

-

Fish portions

-

Small seafood selections

-

Cut vegetables

Its ability to maintain hygiene and prevent leakage makes it ideal for fresh foods displayed in chilled aisles.

Prepared & Ready-to-Eat Meals

Deli counters, convenience stores, and meal prep brands often pack:

-

Cooked meats

-

Stir-fried dishes

-

Rice portions

-

Side dishes

-

Dim sum, dumplings, and snacks

Thanks to its microwave-safe PP material, the tray is perfect for heat-and-eat meals.

Central Kitchens & Catering Operations

Food factories and catering services benefit from:

-

Efficient sealing

-

Stable stacking

-

High production throughput

-

Consistent tray shape

Central kitchens producing thousands of meals daily prefer PP trays for reliability during transportation.

Online Food Delivery & Meal Prep Businesses

Sealed PP trays remain intact during transportation, maintaining product freshness and preventing spills.

Frozen Foods

PP can withstand freezing without cracking, making the tray suitable for:

-

Frozen dumplings

-

Frozen cooked meals

-

Frozen seafood

Sealing Method: Plastic Film Compatibility

Instead of a snap-on lid, the 121165 tray uses sealing film. This packaging style has become standard in modern food distribution due to multiple advantages:

Hygienic Seal

Protects food from contamination, dust, and handling.

Leak-Proof Packaging

Keeps sauces and liquids contained, improving customer experience and reducing waste.

Extended Shelf Life

Modified Atmosphere Packaging (MAP) can be applied during sealing to maintain freshness for fresh meats, salads, or ready meals.

Space Efficiency

Sealed trays stack more easily and reduce transport volume.

Professional Presentation

Provides clean, clear visibility for retail shelves, enhancing product appeal.

Sustainability Considerations

Although PP is a plastic material, it holds several sustainability advantages:

- 100% Recyclable

PP can be recycled repeatedly into new packaging and household products.

- Lightweight Design Saves Resources

10 g per tray significantly reduces material consumption compared with heavier plastics.

- Suitable for Film-Sealed Portion Control

Sealing helps reduce food waste—a major contributor to carbon emissions.

- Compatible With Lower-Impact Logistics

Its compact size and stackability reduce transportation impact.

Quality & Safety Standards

The PP Tray 121165 complies with common regulations for food-contact materials, including:

-

International food-contact polymer standards

-

Requirements of supermarkets and food processors

-

Migration test requirements for hot and cold foods

Depending on clients’ needs, trays can be produced in dust-free workshops and inspected under strict quality control.

Why Businesses Choose the PP Tray 121165

- Cost-effective for high-volume use

- Strong yet lightweight (only 10 g)

- Hygienic and safe for all food types

- Microwave-safe and heat-resistant

- Leak-proof when sealed with film

- Stable stacking for transportation and retail

- Attractive product presentation

- Highly versatile: fresh food + cooked food

Its large volume (950 ml) makes it the perfect choice for portion-controlled products and ready-meal components.

Why Choose DASHAN as Your Packaging Supplier

DASHAN specializes in a full range of food-grade packaging including PP trays, PET lids, bagasse tableware, and customized solutions for supermarkets, restaurants, and food factories.

By choosing DASHAN, you benefit from:

-

Consistent quality control

-

Stable raw material supply

-

High-precision tray molding

-

Competitive pricing

-

Fast production and delivery

-

Support for OEM/ODM projects

-

Professional guidance on sealing equipment and packaging design

Whether you need a single SKU like the 121150 tray or a complete food packaging solution, DASHAN provides reliable, factory-direct service tailored to your business needs.

FAQ

1. What is the capacity of the PP Tray 121165?

It has a 950 ml capacity, suitable for fresh food, deli products, and ready meals.

2. Can the tray be sealed with standard film?

Yes. The PP Tray 121165 is designed for heat-sealing with most standard food-grade sealing films.

3. Is the tray safe for hot or warm foods?

Yes. PP material withstands higher temperatures and is suitable for warm or cooked foods. (Microwaving depends on specific sealing film used.)

4. What food categories is this tray ideal for?

Fresh meat, poultry, seafood, deli items, cooked dishes, ready-to-eat meals, and supermarket prepared foods.

5. Is the PP tray recyclable?

Yes. Polypropylene (PP) is recyclable in many regions, depending on local recycling systems.

6. Does this tray come with a lid?

No. It is designed for use with heat sealing film for excellent freshness and leak protection.

7. Is the tray lightweight but strong?

Yes. At only 10 g, the tray provides rigid support while minimizing material usage.

Conclusion

The PP Tray 121165 is a practical, dependable, and versatile packaging solution designed to meet the demands of modern food retail and food production. Its lightweight structure, 950 ml capacity, and compatibility with plastic sealing film make it ideal for fresh foods, ready meals, deli items, and frozen products. With excellent PP material performance—microwave-safety, leak resistance, and food-grade hygiene—the tray is an efficient and professional choice for businesses seeking reliable packaging.

As food industries shift toward safer, cleaner, and more sustainable packaging formats, the PP Tray 121165 offers the ideal balance of performance, efficiency, and value. For enterprises looking to upgrade their packaging systems or streamline operations, partnering with a specialized supplier like DASHAN ensures consistent quality and long-term success.