Quick Summary

The DASHAN PP Tray Series, represented by models such as 2617H70 and 2618H110, is designed for fresh food, ready meals, bakery items, and retail packaging. Made from food-grade polypropylene, these trays offer excellent heat resistance, sealing compatibility, and structural durability. With options ranging from deep 1800 ml capacities to shallow display trays, the series supports supermarkets, central kitchens, and food processors. Lightweight, stackable, and recyclable, DASHAN PP trays provide safe, efficient, and professional packaging for modern foodservice and retail industries.

1. Introduction

In today’s evolving food packaging landscape, manufacturers, supermarkets, and foodservice providers are increasingly seeking safe, durable, and cost-efficient solutions that support both operational efficiency and excellent product presentation. DASHAN’s PP (Polypropylene) Tray Series—represented by models 2617H70 and 2618H110—offers a robust packaging choice engineered specifically for the modern food industry. These trays are designed to perform consistently in fresh food environments, chilled chains, hot meals, and sealed packaging systems, making them ideal for a wide variety of food applications.

Polypropylene (PP) has long been recognized as one of the safest and most versatile food-grade plastics. It provides excellent temperature stability, impact resistance, chemical inertness, and a high tolerance to heat, allowing users to benefit from microwavability and reliable sealing compatibility. DASHAN’s PP tray lineup represents a combination of structural strength, light weight, and functional versatility—advantages that help reduce waste, improve logistics, and enhance the consumer experience.

2. Material Characteristics: Why PP Is the Ideal Choice

Polypropylene is widely selected in food packaging for its excellent mechanical properties and superior safety profile. The DASHAN PP Tray Series leverages these advantages to deliver reliable packaging performance across various settings.

Key Material Benefits

-

Food-Grade Safety

PP does not leach harmful chemicals, ensuring safe contact with raw, cooked, or acidic foods. -

High Heat Resistance

Suitable for microwaving and reheating. PP maintains stability without warping or releasing odors. -

Cold-Chain Compatible

Performs reliably in refrigerators and chillers, making it ideal for meat, seafood, and fresh produce. -

Lightweight Yet Strong

Provides excellent structural integrity while keeping logistics costs low. -

Chemical Resistance

The tray remains unaffected by oil, sauces, moisture, and seasonings. -

Recyclable

PP is one of the most commonly recycled plastics, supporting sustainability goals.

3. Model Overview:

Model 2618H110

-

Size: Compatible footprint; varies based on height

-

Height: 110mm

-

Best for:

-

Deli foods

-

Small pastries, snacks, side dishes

-

Processed foods and chilled meals

-

Sushi, desserts, bakery items

-

Thin-cut meats or sliced produce

-

The shallow design enhances product visibility and reduces excess material usage, making it ideal for retail shelves and lightweight food categories.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Model | Capacity (ml) |

Wegiht (g) |

Size(mm) | Packaging pcs/ctn |

Ctn Size (cm) |

| 121150 | 360 | 9 | 122*110*50 | 200 | 66.5*45.5*33.5 |

| 121165 | 950 | 10 | 122*110*65 | 300 | 67.5*47.5*37 |

| 1414-H35 | 420 | 11 | 140*140*35 | 1400 | 61*54*29 |

| 1414-H40 | 460 | 12 | 140*140*40 | 1400 | 61*54*29 |

| 1414-H60 | 500 | 13.5 | 140*140*60 | 1200 | 57*49*43 |

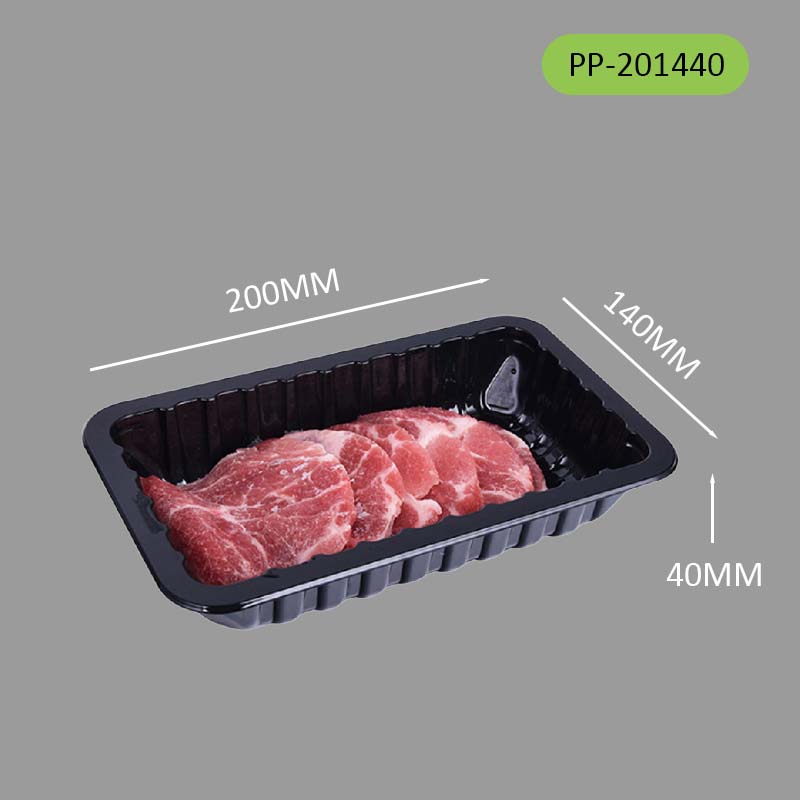

| 201435 | 600 | 14 | 200*140*35 | 800 | 61*54*29 |

| 201440 | 600 | 14 | 200*140*40 | 800 | 61*54*29 |

| 201445 | 800 | 16 | 200*140*45 | 800 | 61*54*29 |

| 201455 | 950 | 17 | 200*140*55 | 800 | 61*54*29 |

| 201480 | 1350 | 23 | 200*140*80 | 500 | 61*54*29 |

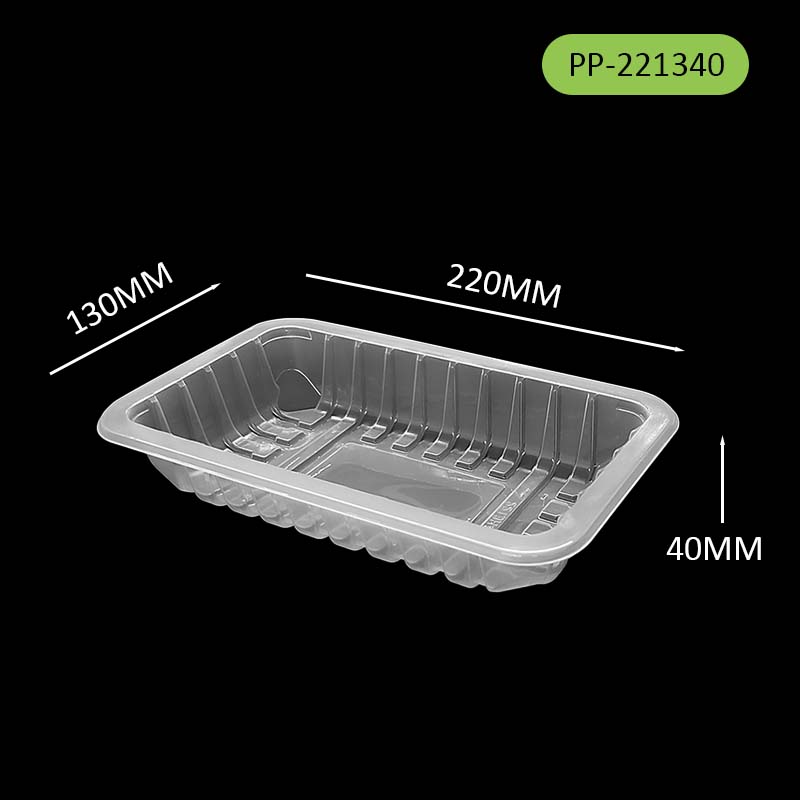

| 221330 | 450 | 16 | 220*130*30 | 600 | 67*34*45.5 |

| 221340 | 620 | 19 | 220*130*40 | 600 | 67*34*45.5 |

| 221350 | 810 | 20 | 220*130*50 | 500 | 67*34*45.5 |

| 221360 | 1000 | 23 | 220*130*60 | 500 | 67*34*45.5 |

| 221370 | 1100 | 27 | 220*130*30 | 500 | 67*34*45.5 |

| 221375 | 1200 | 27 | 220*130*30 | 500 | 67*34*45.5 |

| 2617H70 | 1800 | 40 | 260*170*70 | 300 | 53.5*33*53 |

| 2618H110 | 2900 | 48 | 260*180*110 | 300 | 55*49*53.5 |

4. Structural Design & Functional Advantages

4.1 Rigid Rim & Reinforced Corners

Both trays include a reinforced rim designed to maintain stability during sealing, stacking, and transport. The structure prevents deformation under pressure, ensuring operational reliability.

4.2 Smooth, Hygienic Interior

The inner walls feature a smooth surface that prevents residue buildup, making the tray ideal for fresh, wet, or oily food products. This feature also improves sealing integrity by reducing film interference.

4.3 Film-Sealing Compatibility

The tray is engineered for use with:

-

Heat-sealing film

-

MAP (Modified Atmosphere Packaging) systems

-

Automatic sealing machines used in factories and supermarkets

This enhances food freshness, reduces contamination risks, and improves shelf life.

4.4 Temperature Performance

-

Microwave-safe

-

Refrigerator-safe

-

Withstands common foodservice temperature ranges without deformation

4.5 Logistics Efficiency

The trays stack neatly, maximizing storage space and making transport convenient for factories, warehouses, and retailers.

5. Applications Across Food Industries

The DASHAN PP Tray Series is versatile enough to serve multiple sectors:

5.1 Supermarkets & Grocery Stores

-

Meat & seafood packaging

-

Fresh produce trays

-

Marinated foods

-

Chilled ready meals

5.2 Food Processors & Central Kitchens

-

Pre-portioned ingredients

-

Prepared meal sets

-

Vacuum-sealable or MAP-packaged products

5.3 Restaurants & Foodservice

-

Takeaway meals

-

Buffet items

-

Bento concepts

5.4 Bakery & Pastry

-

Cakes, snacks, desserts, puffs, and pastries (especially for the shallow 2618H18 model)

5.5 E-Commerce Food Delivery

-

Fresh food kits

-

Bulk ingredients

-

Meal prep packaging

6. Sustainability Considerations

While PP is not biodegradable, it is highly recyclable and widely accepted in standard recycling systems. Using PP trays contributes to circular-economy initiatives when collected and processed correctly. Its long service life and low energy demand during production help reduce the environmental impact compared to heavier materials.

DASHAN ensures that its PP trays are manufactured with strict quality control and minimal material waste, supporting responsible production and environmental stewardship.

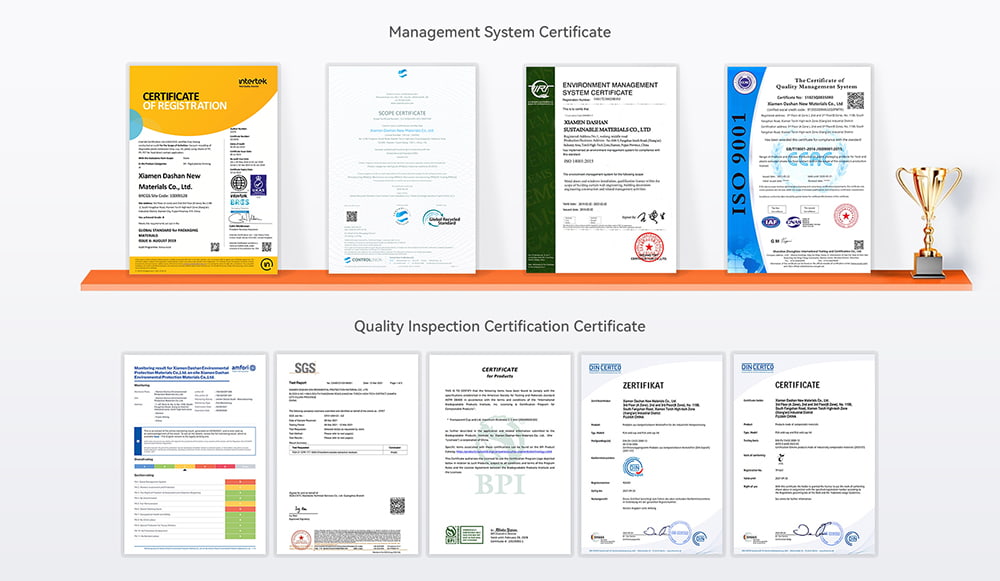

7. Why Choose the DASHAN?

DASHAN is a global manufacturer committed to eco-innovation in food packaging. Specializing in biodegradable sugarcane bagasse products, we provide sustainable solutions for restaurants, retailers, and catering distributors worldwide.

Our commitment includes:

-

Internationally recognized certifications: FDA, EU 10/2011, OK Compost, SGS

-

OEM & ODM customization available

-

Expertise in sustainable packaging logistics

-

Proven reliability across over 30 export markets

With DASHAN, you get more than a plate—you get a partnership built on quality, sustainability, and trust.

🌍 DASHAN at Global Exhibitions

Showcasing Sustainable Packaging Worldwide

DASHAN has proudly participated in several international trade fairs, bringing our biodegradable and compostable tableware to a global audience. From Malaysia to Dubai and Russia, we’ve shared our vision of a cleaner, greener future for food packaging.

Connecting with Global Partners

Through these exhibitions, DASHAN has built strong relationships with distributors, restaurant chains, and retailers who value sustainable innovation. Each event provides an opportunity to exchange insights, explore new market trends, and present our certified, high-quality bagasse products to the world.

FAQ

1. What materials are these trays made of?

They are made from 100% food-grade polypropylene (PP), known for its excellent safety, durability, and heat resistance.

2. Are the trays microwave-safe?

Yes. PP material withstands microwave reheating without warping or releasing odors, making it ideal for ready meals.

3. Can these trays be sealed with film?

Absolutely. The trays are compatible with heat-sealing film, MAP sealing, and various automatic sealing machines.

4. What is the main difference between models 2617H70 and 2618H110?

2617H70 is a deep 1800 ml tray suitable for fresh meat, seafood, and large meal portions.

The 2618H110 is a deeper 2900ml large-capacity tray, perfect for holding large portions of cooked food.

5. Are these trays suitable for chilled food packaging?

Yes. PP performs well in cold-chain environments, making the trays ideal for meat, seafood, and prepared dishes stored in refrigerators.

6. Are PP trays recyclable?

Yes. PP is widely recyclable in many regions, supporting sustainability initiatives.

7. Can the trays be customized?

DASHAN offers OEM/ODM services, allowing customization of weight, color, thickness, or printing to meet specific market needs.

Conclusion

The DASHAN PP Tray Series—represented by models 2617H70 and 2618H18—provides a highly adaptable, safe, and efficient packaging solution suitable for fresh foods, ready-to-eat meals, bakery products, and food processing applications. The combination of food-grade PP material, excellent sealing performance, structural durability, and customizable sizing makes these trays an ideal choice for businesses seeking to improve product presentation, operational efficiency, and food safety.

Whether used in supermarket displays, central kitchen distribution, chilled meal production, or retail packaging, DASHAN PP trays deliver consistent performance and a strong return on investment. Their compatibility with sealing machines and modern processing systems ensures that food stays fresh, protected, and visually appealing—from production to end-consumer.