Quick Summary

The CT-1813H45-1C CPET airline meal tray is a durable, oven-safe, and freezer-ready food container designed for inflight catering, frozen ready meals, and high-volume institutional foodservice. With dimensions of 185 × 135 × 45 mm and a weight of 23 g, this tray offers excellent temperature resistance, sealing compatibility, and clean food presentation.

Introduction

In global airline catering, food packaging must endure intense production workflows, long-distance logistics, and precise service requirements. From industrial cooking and rapid chilling to frozen storage, reheating, and onboard presentation, every container must perform flawlessly. The CT-1813H45-1C CPET tray is specifically engineered to meet these rigorous demands.

With a versatile 185 × 135 × 45 mm design and a 23 g lightweight profile, this single-compartment CPET tray is widely used for main dishes, side dishes, desserts, baked meals, and premium ready-made products. It is compatible with automated tray-sealing systems and supports efficient, stable, and hygienic food production at industrial scale.

Manufactured using Crystallized Polyethylene Terephthalate (CPET)—the leading material for airline and ready-meal packaging—the CT-1813H35-1C delivers exceptional thermal stability, chemical resistance, structural strength, and food-safety performance. Whether used in airline catering facilities, frozen entrée factories, hospitals, or central kitchens, this tray ensures reliable performance and professional presentation.

Technical Specifications

| Specification | Details |

|---|---|

| Model | CT-1813H45-1C |

| Material | CPET |

| Structure | Single compartment |

| Size | 185 × 135 × 45 mm |

| Weight | 23 g |

| Temperature Resistance | –40°C to +220°C |

| Colors | Black / White |

| Applications | Airline catering / frozen meals / central kitchens / railway catering |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

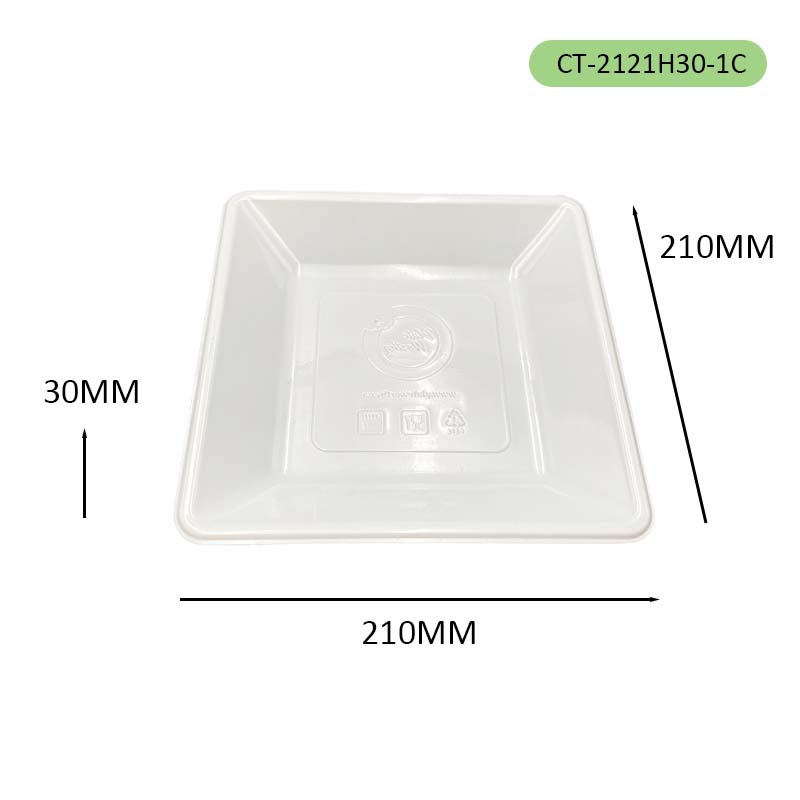

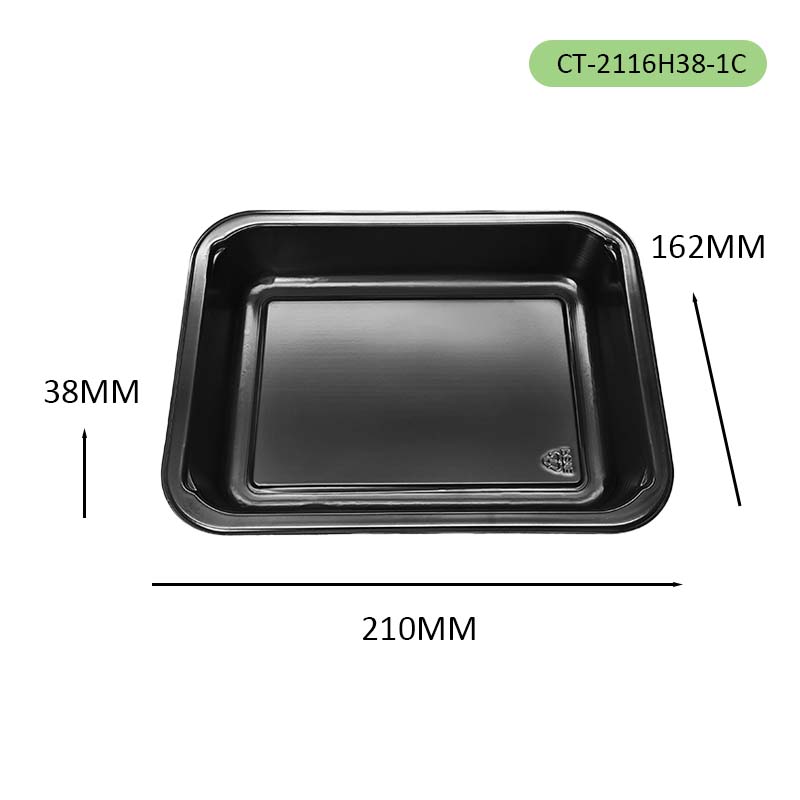

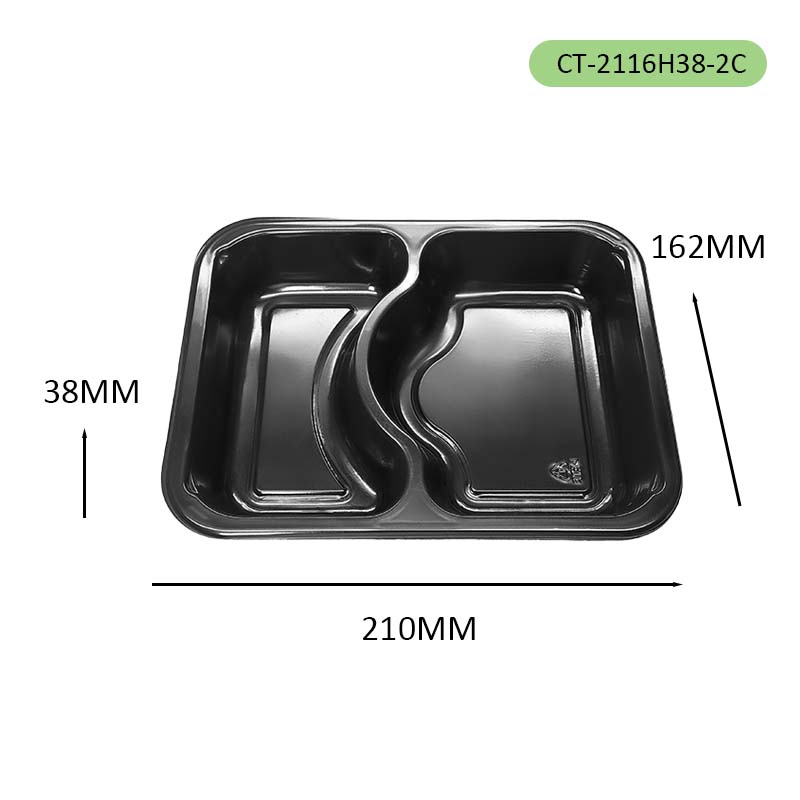

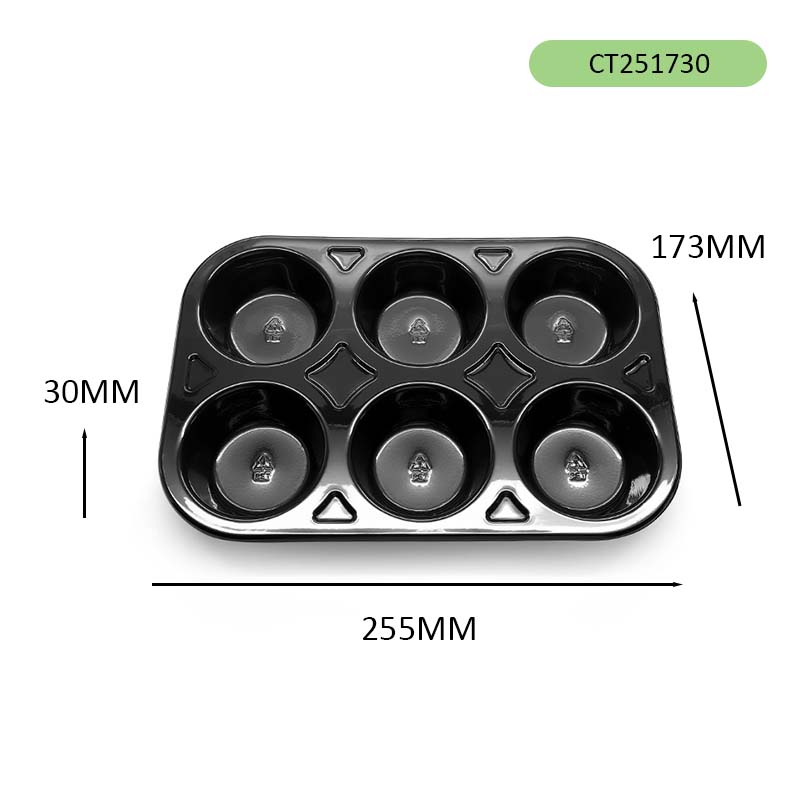

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Outstanding Temperature Performance

The exceptional temperature performance of CPET makes the CT-1813H45-1C ideal for all stages of airline meal production:

1. Industrial Cooking

Meals can be filled while hot, or cooked directly in the tray in batch ovens.

2. Blast Chilling & Rapid Freezing

The tray maintains rigidity even under rapid temperature changes.

3. Long-Term Frozen Storage

CPET protects meals from freezer burn and moisture loss.

4. Reheating (Up to 220°C)

The tray is compatible with:

-

Convection ovens

-

Steam ovens

-

Microwave systems

It does not warp, crack, or release harmful chemicals during heating.

5. Final Inflight Service

Its rigidity ensures safe handling during turbulence and frequent transport.

This wide temperature range—from –40°C to +220°C—makes it ideal for cold-chain logistics and high-volume reheating systems used by international airline caterers.

Food Safety and Hygiene

The CT-1813H45-1C is manufactured from fully food-grade CPET resin and is:

✔ BPA-free

✔ Odorless

✔ Non-toxic

✔ Safe for acidic, oily, and high-fat foods

✔ Resistant to staining and flavor transfer

The semi-crystalline CPET structure offers strong resistance to:

-

Tomato sauces

-

Curry bases

-

Cheese and cream-based dishes

-

High-temperature oils

This ensures that meals remain safe, clean, and visually appealing throughout handling, reheating, and consumption.

Superior Barrier Properties for Extended Shelf Life

The tray’s high-barrier performance protects food against:

-

Oxygen intrusion

-

Moisture loss

-

Contamination

-

Flavor migration

This is particularly important for frozen meals and long-haul airline catering operations.

Compatible sealing options include:

-

Heat-seal films

-

CPET rigid lids

-

Aluminum foil lids

-

MAP (Modified Atmosphere Packaging) systems

These sealing choices help extend shelf life and improve stacking stability in cold-storage facilities and airline trolley systems.

Strong Structural Integrity

The CT-1813H45-1C tray is engineered to remain rigid even when filled with heavy or sauced dishes. It resists compression in:

-

Airline trolleys

-

Storage racks

-

Freezer rooms

-

Transport crates

This structural strength ensures that meals retain shape and integrity during international transport and cabin service.

Enhanced Food Presentation

Presentation is critical for passenger satisfaction. The tray features:

-

Smooth interior surfaces

-

Clean edges for premium sealing

-

Black or white color options for strong food contrast

-

A flat bottom for even heat distribution

-

A single-compartment layout ideal for larger entrée portions

Meals reheated in this tray maintain an attractive, appetizing appearance—essential for high-quality inflight service.

Optimized for Industrial and Airline Catering Operations

The CT-1813H45-1C tray is designed for compatibility with automated, high-efficiency meal production systems:

1. Fully Compatible with Sealing Machines

Its uniform rim ensures a consistent and leak-resistant seal.

2. Stackable for Efficient Logistics

Ideal for large-scale production and storage.

3. Lightweight for Reduced Transportation Costs

At only 23 g, it reduces fuel consumption in airline operations.

4. Leak-Resistant Design

Perfect for sauced meals, stews, or moist ingredients.

5. Reliable During Turbulence

The tray maintains rigidity during service in flight.

Applications Across Foodservice Industries

Although designed for airline catering, the CT-1813H45-1C is widely used in:

1. Airline Catering

Entrées, side dishes, breakfast components, desserts.

2. Railway Catering

Meals requiring vibration-resistant and reheatable packaging.

3. Frozen Meal Production

Ideal for mass-market retail ready meals.

4. Central Kitchens

Corporate canteens, hospitals, military bases.

5. Cruise Line Catering

Meals handled under rigorous temperature cycles.

Its versatility and professional appearance make it one of the most used CPET tray formats globally.

Customization Options

DASHAN provides customizable features for brand-specific requirements:

-

Custom colors

-

Embossed airline or company logos

-

OEM/ODM tray molds

-

Tailored carton packaging

-

Compatible sealing film supply

This allows seamless integration into any operational or branding strategy.

Why Choose CPET Over Other Materials

Compared with PP, PS, and aluminum packaging, CPET provides:

✔ Seamless shift from freezer to oven

✔ Premium rigidity

✔ Excellent sealing performance

✔ Safe food-contact certification

✔ High-barrier protection

✔ Enhanced presentation quality

Its performance and reliability make CPET the material of choice for the world’s leading airline caterers.

FAQ

1. Is the CT-1813H45-1C tray suitable for airline oven reheating?

Yes. The tray withstands temperatures up to 220°C, making it ideal for standard airline convection ovens.

2. Can this CPET tray be used for frozen meal storage?

Absolutely. It is safe down to –40°C and remains crack-resistant during long-term freezing and transportation.

3. What kind of foods fit best in this single-compartment design?

It is suitable for entrées such as rice meals, pasta, meats, vegetables, and sauces, offering flexible plating space.

4. Is the tray compatible with sealing film?

Yes. It supports heat sealing with CPET-compatible films, aluminum lids, and snap-on CPET covers.

5. Is CPET recyclable?

Yes. CPET is a recyclable material, helping airlines and foodservice operators meet sustainability goals.

Conclusion

The CT-1813H45-1C CPET airline meal tray is a high-performance, professional-grade packaging solution designed for modern airline, railway, and large-scale foodservice industries. Its outstanding thermal resistance, superior structural integrity, sealing reliability, and food safety make it ideal for ready meals undergoing freezing, transport, reheating, and final service.

Compact, durable, and visually clean, this tray ensures meals remain fresh, stable, and appealing from production to the passenger’s table. For caterers seeking an efficient and dependable CPET packaging solution, the CT-1813H45-1C is a proven and trusted choice.