Quick Summary

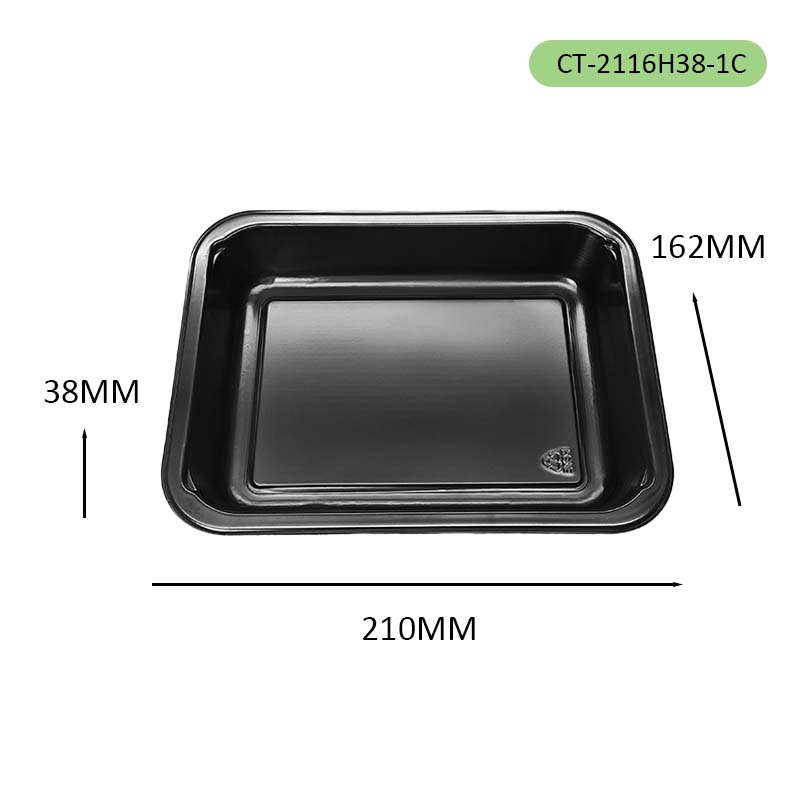

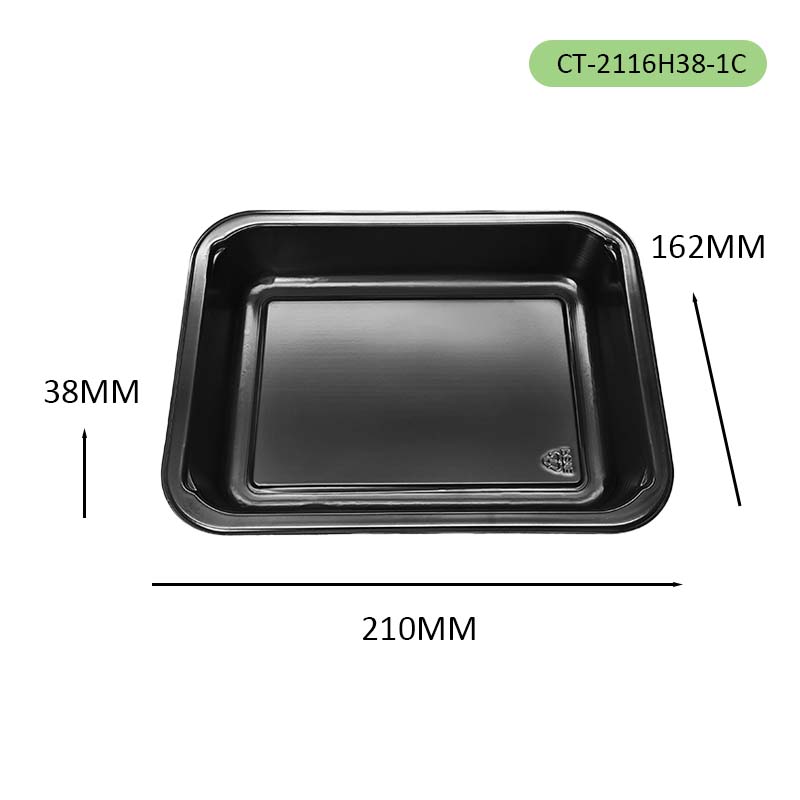

The CT-2116H38-1C CPET airline meal tray is a durable, oven-safe, and freezer-ready food container designed for aviation catering, ready meals, and large-scale foodservice. With a 210 × 162 × 38 mm structure and lightweight 30 g body, it offers superior heat resistance, food safety, sealing compatibility, and long-term storage performance.

Introduction

In modern airline catering, consistency, safety, and efficiency are the foundations of every successful inflight meal service. Airlines and aviation catering companies face increasing pressure to deliver meals that not only taste fresh but also maintain their visual appeal after long preparation cycles that involve freezing, storage, reheating, and distribution. The CPET airline meal tray CT-2116H38-1C is purpose-built to meet these operational challenges. With a dimension of 210 × 162 × 38 mm and a lightweight 30 g structure, this model offers an ideal balance between durability, performance, thermal resistance, and cost efficiency. It is designed for global airline catering systems and optimized for automated production environments where precision is crucial.

CPET (Crystallized Polyethylene Terephthalate) has become the gold-standard material for premium ready-meal trays because of its excellent heat resistance, food safety performance, and barrier properties. The CT-2116H38-1C tray leverages the full advantages of CPET, making it suitable not only for inflight catering but also for railway meal services, frozen meal manufacturers, hospital catering, and large-scale institutional kitchens.

Technical Specifications

Model:CT-2116H38-1C

Material:CPET

Size:210 × 162 × 38 mm

Weight:30g

Temperature Resistance:–40°C to +220°C

Color Options:Black / White

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

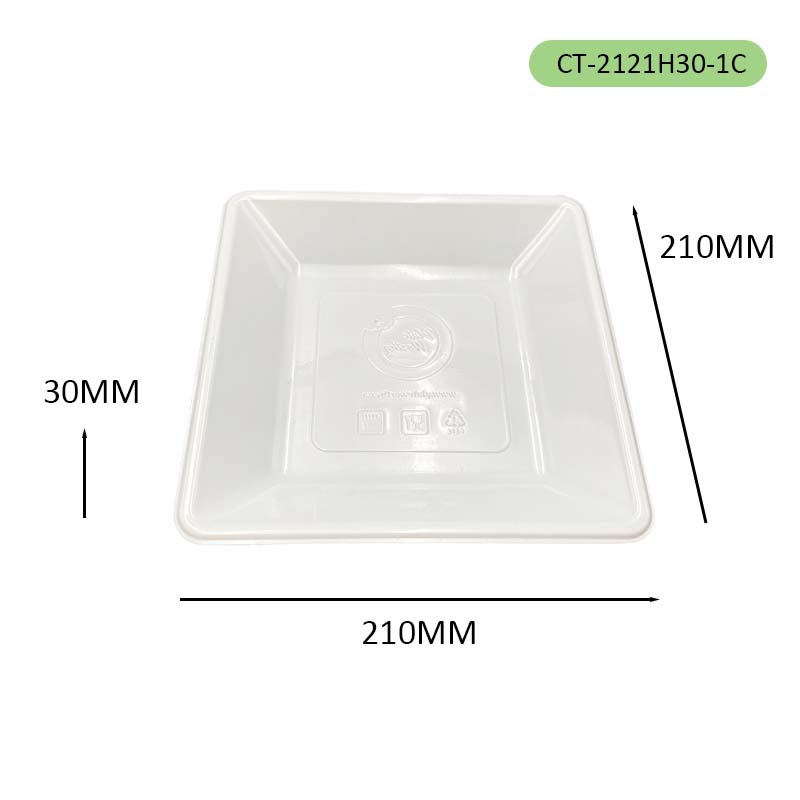

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

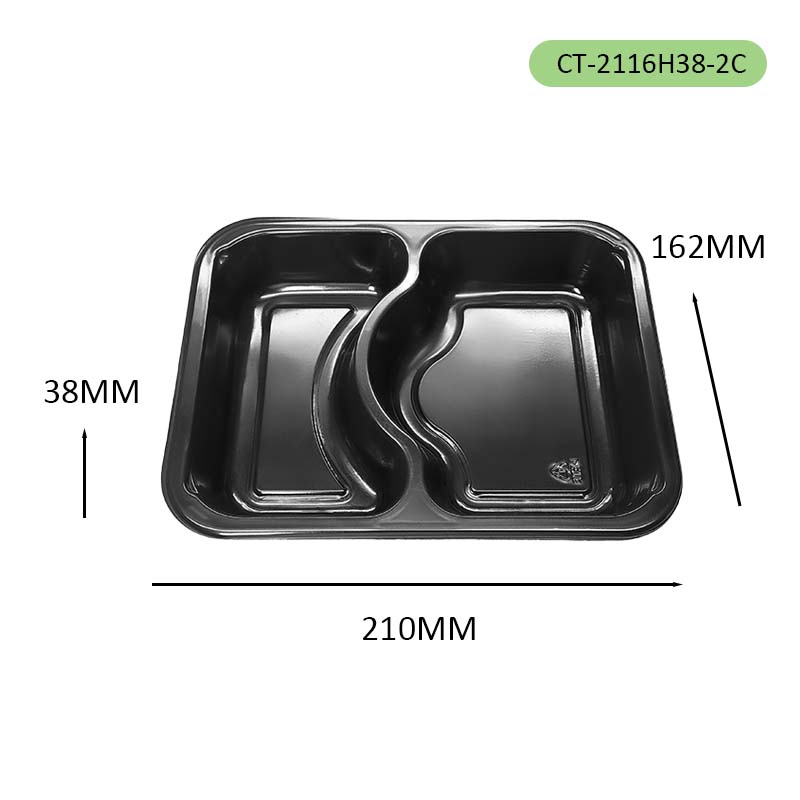

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

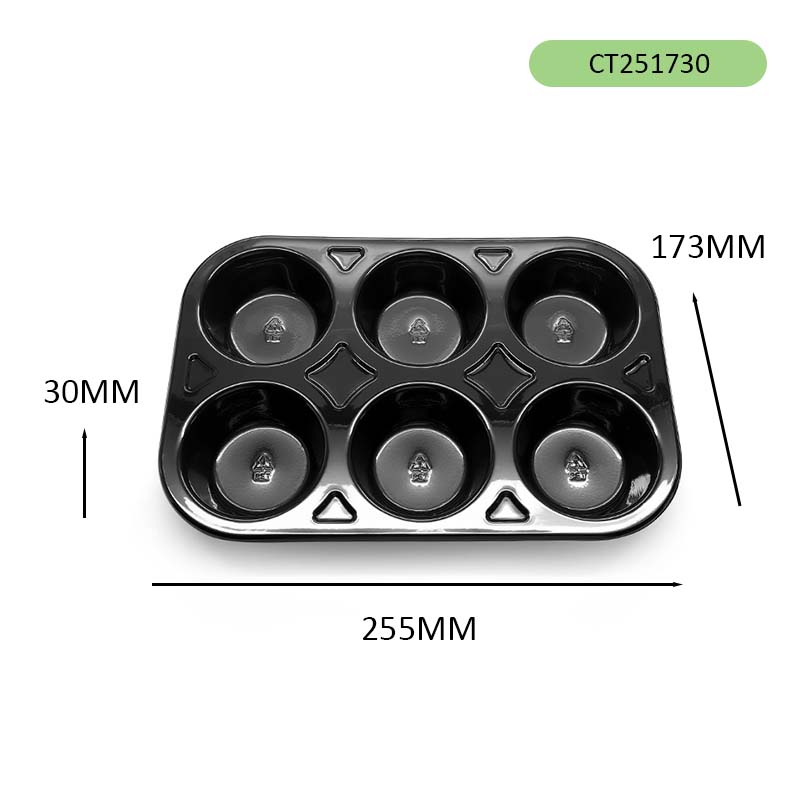

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Outstanding Temperature Performance

One of the most remarkable attributes of the CT-2116H38-1C tray is its wide temperature tolerance. CPET is engineered to tolerate environments ranging from –40°C to +220°C, which allows the tray to transition seamlessly from blast freezers to high-temperature reheating equipment. For airline caterers, this flexibility is essential.

Airline meals often undergo multiple temperature cycles:

-

Initial cooking in industrial kitchens

-

Rapid cooling or freezing to stabilize freshness

-

Storage in low-temperature warehouses

-

Transport in cold-chain conditions

-

Reheating inside convection ovens or steam ovens before service

-

Final presentation onboard the aircraft

The CT-2116H38-1C tray maintains structural stability throughout these processes. It does not warp, crack, deform, or release odor under extreme temperatures, ensuring a consistent and predictable performance that airlines depend on. Its oven-safe and microwave-safe capabilities make it ideal for both dry-heat and steam-based reheating systems used by major international caterers.

Food Safety and Material Integrity

The tray is manufactured using certified food-grade CPET resin, ensuring complete safety for direct food contact. It is BPA-free, non-toxic, and compliant with international safety standards used across Europe, Asia, and North America. CPET is chemically stable even under high heating temperatures, which minimizes the risk of chemical migration — a concern common with lower-grade plastics.

Additionally, CPET’s semi-crystalline structure provides resistance against grease, acids, oils, and salty foods. This makes the tray suitable for all types of inflight meals, from saucy pasta and curries to grilled meats, vegetables, and desserts. It also prevents staining and maintains a clean, appealing look even after reheating.

High Barrier Performance for Longer Shelf Life

The CT-2116H38-1C tray features excellent barrier properties against oxygen, moisture, and contaminants, significantly extending the shelf life of chilled or frozen ready meals. For airline catering, especially long-haul flights or regions where food must be prepared days in advance, this barrier strength is essential.

The tray’s surface is compatible with:

-

Standard lidding films

-

Aluminum foil lids

-

Sealable CPET rigid lids

-

MAP (Modified Atmosphere Packaging) films

Secure sealing ensures that the food stays fresh, hygienic, and stable throughout storage and transportation. It also makes the tray suitable for high-pressure handling and stacking inside airline meal carts, meal trolleys, and storage compartments.

Designed for Airline Catering Operations

The 210 × 162 × 38 mm size of the CT-2116H38-1C tray conforms to common airline meal tray dimensions used by major carriers. This compatibility is critical for efficient workflow integration.

Key operational advantages:

1. Compatibility with automated sealing machines

The tray is engineered to ensure smooth sealing with both manual and fully automated lidding systems. Whether using heat-seal film, foil, or rigid lids, the fit remains consistent, helping minimize sealing errors and production stoppages.

2. Optimized for stacking and trolley loading

The tray’s structural rigidity ensures that stacked trays do not deform under load, allowing caterers to maximize space inside airline trolleys or cold-storage racks.

3. Leak-resistant design for sauced dishes

Its stable walls and secure sealing compatibility help minimize leakage during transport and reheating, preserving both hygiene and food presentation.

4. Lightweight yet durable

Weighing only 30 g, the tray contributes to fuel-saving strategies. Airlines increasingly seek lightweight packaging solutions to reduce fuel consumption and carbon emissions, making this tray a sustainable and operationally efficient choice.

Enhanced Food Presentation

Passenger satisfaction increasingly depends on the visual appeal of meals, especially in premium cabins. CPET trays maintain a clean and glossy appearance even after reheating. The CT-2116H38-1C model supports:

-

Uniform heat distribution, ensuring even reheating of the meal

-

No melting or oil penetration, keeping meals visually attractive

-

Customizable colors, such as classic airline black or white

High-quality food presentation enhances the passenger dining experience and supports airline brands that prioritize service excellence.

Applications Across Multiple Foodservice Sectors

While the CT-2116H38-1C tray is primarily designed for airlines, its performance makes it suitable for many other industries:

1. Railway and High-Speed Rail Catering

Meals served on trains require containers that can handle reheating, storage, and transport vibration. CPET trays maintain food integrity and resist deformation.

2. Frozen Ready Meal Production

Frozen meal manufacturers rely on CPET trays due to their long-term cold storage stability and reheating performance.

3. Central Kitchens and Institutional Catering

Hospitals, schools, corporate cafeterias, and military kitchens benefit from CPET trays for their hygiene, durability, and convenience.

4. Cruise Lines and Marine Catering

Meal preparation on ships often involves freezing and reheating cycles similar to airline catering, making CPET the ideal packaging choice.

Customization Options

To meet diverse operational requirements, the CT-2116H38-1C tray can be customized in several ways:

-

Embossed airline logo or branding

-

Color customization (black, white, blue, or special tones)

-

Multi-compartment versions for entrée and side dish separation

-

Tailored carton packing for automated loading systems

-

Coordinated sealing film and lid supply

These customization options help large catering companies create a unified brand presence and streamline workflow.

Why CPET Is the Best Material for Premium Meal Trays

CPET offers several advantages over PP, PS, and aluminum:

✔ Extreme heat resistance

No deformation during oven or microwave heating.

✔ Strong barrier performance

Extends shelf life and protects against contamination.

✔ Excellent structural rigidity

Maintains the shape of the meal and supports attractive food plating.

✔ Recyclable in many regions

CPET is accepted in recycling streams in numerous countries, supporting sustainability initiatives.

✔ Safe, stable, and versatile

Suitable for all major global markets and food types.

FAQ

1. Is the CT-2116H38-1C tray safe for oven heating?

Yes. Made from CPET, it is safe for use in convection ovens and steam ovens up to 220°C without deformation.

2. Can this tray be frozen for long-term storage?

Absolutely. It remains stable at temperatures as low as –40°C, making it ideal for frozen ready meals.

3. What sealing options are compatible with this tray?

It supports heat-seal films, aluminum foil lids, and CPET rigid lids for secure sealing and leak prevention.

4. Is the tray recyclable?

In many regions, CPET is accepted in standard plastic recycling streams, supporting sustainability goals.

5. What industries commonly use this CPET tray?

Airline catering, railway foodservice, hospital kitchens, cruise catering, and frozen ready-meal manufacturers.

Conclusion

The CPET airline meal tray CT-2116H38-1C is a high-performance solution specifically engineered for the demanding conditions of airline and frozen meal catering. With outstanding thermal resistance, food-grade safety, strong sealing compatibility, and a lightweight yet durable structure, this tray ensures consistent results across cooking, freezing, reheating, and onboard service. Its reliability and versatility make it a preferred choice for airlines, catering companies, ready-meal producers, and institutional kitchens seeking professional and efficient meal packaging solutions.