Quick Summary

The CT161035 CPET airline meal tray with a matching 10 g CPET lid is a compact, heat-resistant, and freezer-ready solution designed for inflight catering, frozen meals, and institutional kitchens. Its 163 × 102 × 35 mm structure, 14 g lightweight tray, and secure-fit lid provide excellent sealing performance, strong rigidity, and reliable oven and cold-chain compatibility. Ideal for desserts, side dishes, and small entrées that require premium presentation and industrial food-safety standards.

The CT161035 CPET airline meal tray is a compact, high-performance food packaging solution engineered for inflight catering, large-scale meal production, frozen food processing, and institutional kitchen operations. With a size of 163 × 102 × 35 mm, a tray weight of 14 g, and a matching 10 g CPET lid, this model delivers superior reliability across freezing, reheating, sealing, and transportation environments—ensuring consistent food quality from preparation to final service.

This tray-lid set is specially designed to support modern catering workflows where efficiency, food safety, visual consistency, and temperature performance are crucial. The CT161035 set is widely adopted for breakfast items, dessert dishes, side meals, snacks, and child portions on airlines and railways due to its small footprint, lightweight build, and professional-grade heat resistance.

Introduction

In today’s global aviation and ready-meal industries, packaging must withstand extreme temperature changes while maintaining structural strength and attractive presentation. Many meal components—such as small entrées, desserts, sauces, rice portions, or specialty items—require compact but durable trays that can survive industrial preparation processes.

The CT161035 CPET tray offers a practical combination of size, rigidity, and flexibility. Its freezer-to-oven performance, compatibility with automated sealing lines, and high barrier protection make it a reliable choice for industrial catering teams. The addition of a 10 g tight-fitting CPET lid increases product value, allowing operators to use it for full sealing workflows or as a premium display-ready packaging option.

CPET (Crystallized Polyethylene Terephthalate) is recognized as one of the most advanced materials for hot-serve and frozen meal packaging. It allows the CT161035 to safely handle temperatures between –40°C and +220°C, making it ideal for airline ovens, steam ovens, microwave systems, and cold storage environments.

Technical Specifications

-

Model: CT161035

-

Material: CPET

-

Structure: Single compartment

-

Size: 163 × 102 × 35 mm

-

Weight: 14 g

-

Color Options: Black / White

-

Temperature Resistance: –40°C to +220°C

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

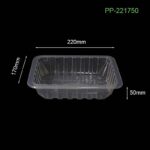

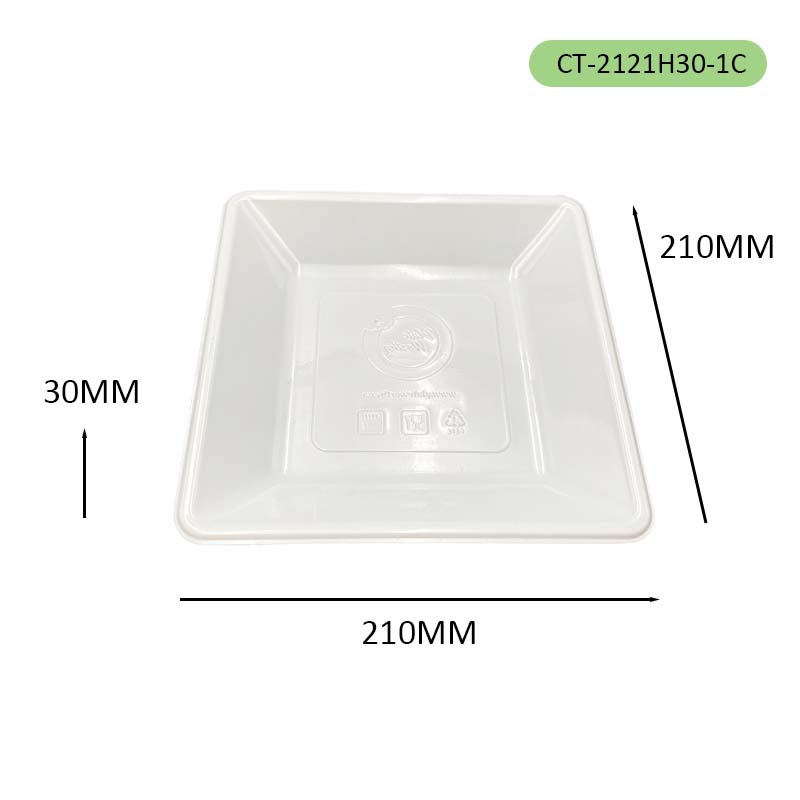

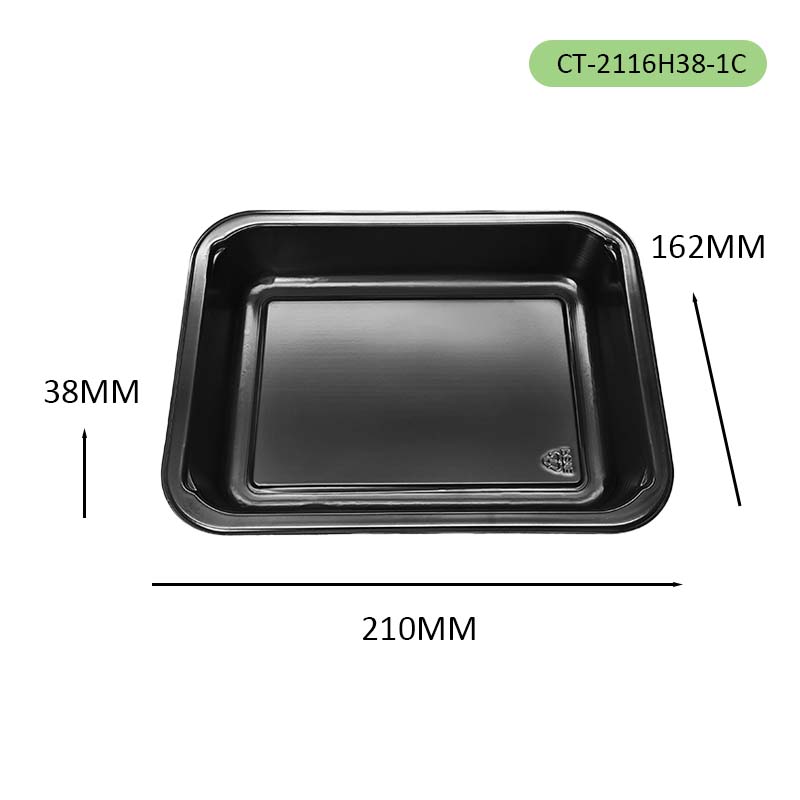

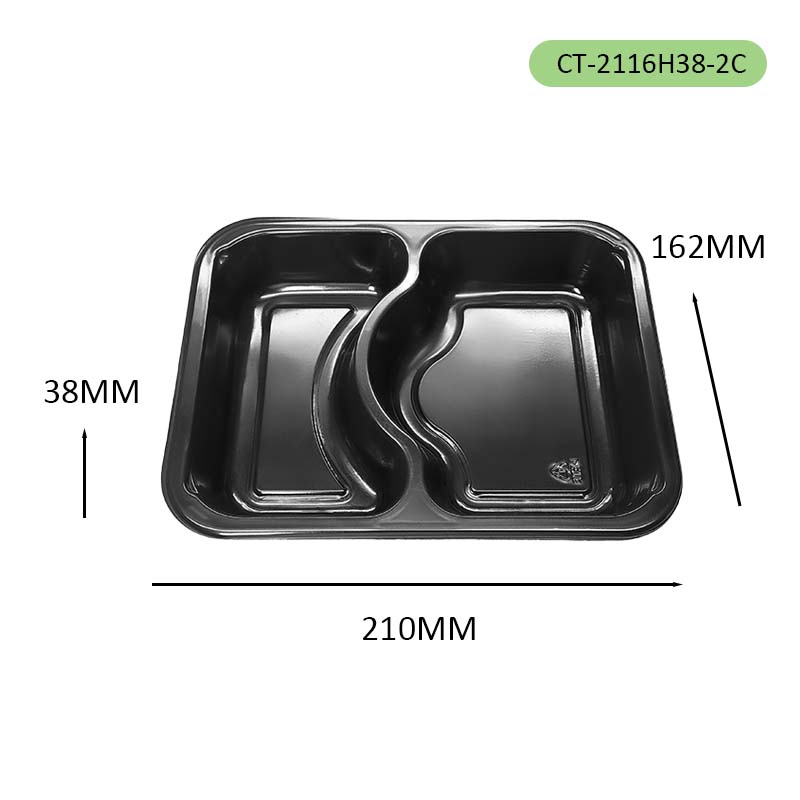

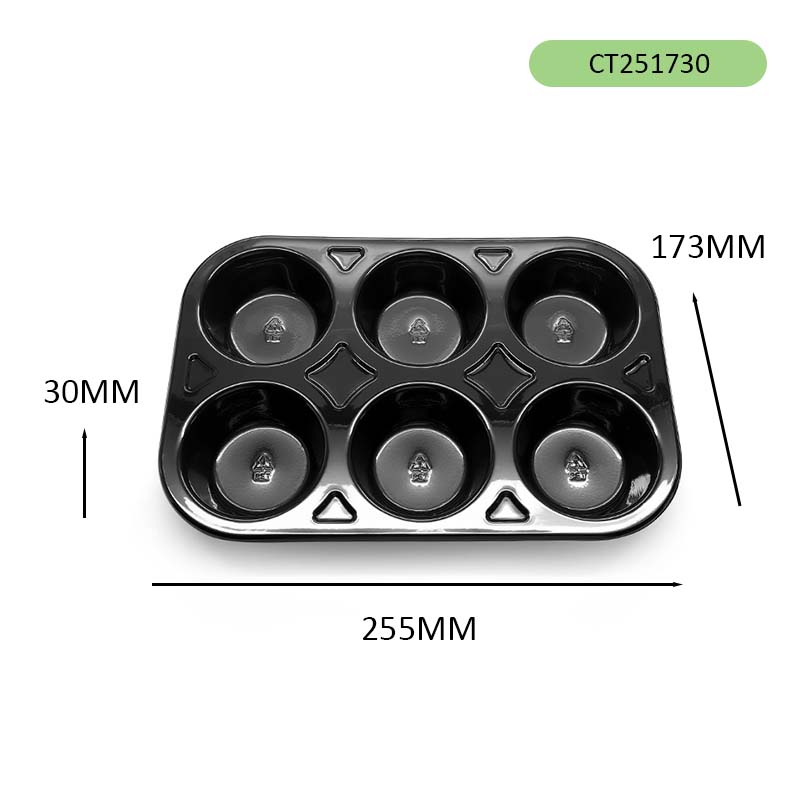

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Outstanding Temperature Resistance

The CT161035 CPET tray performs reliably across the entire industrial food preparation chain:

-

Industrial cooking

Suitable for pre-cooked or semi-cooked meals prepared in central kitchens. -

Rapid chilling & freezing

Maintains structural integrity at –40°C without cracking or deforming. -

Cold-chain storage & transportation

Ideal for long-term frozen stock, intercontinental shipment, and vibration-prone logistics. -

Reheating before service

Withstands up to 220°C, making it compatible with:-

Airline convection ovens

-

Steam ovens

-

Microwave systems

-

-

Inflight or on-site serving

Maintains shape, rigidity, and food presentation even after reheating.

Its resistance to extreme temperatures ensures that the tray and lid remain stable through multiple handling stages, improving the operational reliability for catering companies worldwide.

Food Safety & Material Reliability

The tray and lid are produced with food-grade CPET, compliant with global food-contact standards. Key advantages include:

-

BPA-free

-

Odorless & non-toxic

-

Resistant to oils and acidic foods

-

Chemically stable during heating

-

No flavor transfer or staining

-

Durable during hot and cold storage

The smooth interior surface prevents residue buildup and staining from sauces, curries, tomato-based foods, and high-fat meals. This enhances visual appeal and ensures food safety for long-term storage.

The matching CPET lid is engineered for secure locking and excellent clarity (if ordered transparent), offering improved display value for desserts, airline snacks, or premium ready meals.

Sealing Compatibility & Barrier Performance

The CT161035 tray-lid system is optimized for industrial sealing workflows. It works with:

-

Standard heat-seal films

-

Aluminum sealing foil

-

Snap-on CPET lids

-

MAP (Modified Atmosphere Packaging) systems

-

Travel-safe cold-chain storage

Key advantages:

-

Leak resistance for sauced foods

-

High oxygen and moisture barrier

-

Reduced contamination risks

-

Stable stacking in airline trolleys and cold rooms

These performance advantages make it ideal for meals requiring extended shelf life, such as frozen entrées, bakery items, and pre-sealed desserts.

Operational Benefits for Airline Catering

-

Lightweight for fuel and shipping efficiency

At only 14 g + 10 g, the tray and lid reduce logistics costs and help airlines meet sustainability targets. -

Optimized for automated lines

Fits high-speed sealing machines used in central kitchens and aviation catering facilities. -

Stackable and space-efficient

Maximizes trolley and freezer storage capacity. -

Presentable for inflight meal service

Ensures a clean, professional appearance even after reheating. -

Versatile for many meal types:

-

Desserts

-

Salads

-

Kids’ meals

-

Rice or pasta sides

-

Bakery items

-

Breakfast components

-

Enhanced Food Presentation

The CT161035 tray, with its sharp lines and smooth CPET finish, provides clean food presentation suitable for premium meal services. Benefits include:

-

Attractive black/white visual effect

-

Uniform heating for appealing textures

-

Well-shaped structure after reheating

-

Crystal-clear lid option for pre-display items

-

No warping or collapsing under heat

For airlines that emphasize presentation, this tray is ideal for side dishes and premium desserts served on international flights.

Applications Across Multiple Industries

Although originally designed for aviation catering, the CT161035 is widely used in:

1. Railway Catering

Durable and leak-resistant for shaking and vibration during transport.

2. Frozen Ready Meal Manufacturers

Supports long storage cycles without deformation or cracking.

3. Institutional Catering

Used by hospitals, corporate cafeterias, military bases, and school kitchens.

4. Bakery & Dessert Packaging

Ideal for cheesecakes, puddings, tiramisu, jelly desserts, and pastries requiring a clear lid.

5. Central Kitchens

Efficient for daily meal distribution and portion control.

Customization Options

To meet diverse branding and operational needs, the CT161035 supports:

-

Customized colors

-

Airline logo embossing

-

Special lid options

-

Custom print sealing films

-

Carton packaging tailored for automation

FAQ

1. Can the CT161035 tray be used in airline ovens?

Yes. The CPET material withstands up to 220°C and is safe for convection and steam ovens commonly used in airline catering.

2. Is the tray suitable for frozen storage?

Absolutely. It performs well at –40°C, making it ideal for long-term frozen meals and cold-chain logistics.

3. Does the tray come with a compatible lid?

Yes. It includes a 10 g CPET lid designed for secure fit, sealing stability, and enhanced presentation.

4. What types of meals is this tray suitable for?

Side dishes, desserts, children’s meals, bakery items, breakfast servings, and small entrées.

5. Is CPET recyclable?

In many regions, CPET is accepted in recycling systems due to its high-quality food-grade composition.

Conclusion

The CT161035 CPET airline meal tray with its 10 g matching lid is a compact, durable, freezer-to-oven safe packaging solution designed for modern catering demands. With strong heat resistance, excellent sealing compatibility, stable structure, and professional presentation, it supports efficient workflows from central kitchen preparation to inflight service. This tray-lid combination ensures safety, freshness, and an appealing food experience across airline, railway, frozen meal, and institutional applications.