Quick Summary

PET and rPET cups dominate the beverage packaging industry due to their strength, clarity, and recyclability. PET offers unmatched transparency, while rPET supports circular economy requirements and sustainability mandates. This article provides a detailed comparison of performance, cost, food safety, and global regulations to help buyers choose the most suitable material. DASHAN supplies both PET and rPET cups with advanced manufacturing, certified materials, and global export experience.

1. Introduction: Why PET and rPET Matter in Today’s Packaging Market

In the global food packaging industry, transparency, safety, and sustainability are no longer optional—they are mandatory expectations shaped by consumer behavior, government regulations, and brand commitments. Among all plastic materials, PET (Polyethylene Terephthalate) and rPET (Recycled PET) dominate the cold beverage cup market thanks to their clarity, strength, and recyclability.

However, procurement teams, brand owners, and packaging distributors frequently ask:

-

What is the real difference between PET and rPET?

-

Is rPET always the better environmental choice?

-

Do PET and rPET cups perform the same in real-world applications?

-

Which one is more suitable for cost-sensitive versus eco-driven markets?

This article provides a professional, data-backed, expert-level comparison, with a special focus on PET and rPET cups, helping international buyers make the right sourcing decisions.

2. What Is PET? (Material Science Overview)

PET is a thermoplastic polyester polymer formed by polymerizing ethylene glycol and terephthalic acid. Its structure provides several advantages:

Key Material Properties of PET

| Property | Description |

|---|---|

| Clarity | Excellent transparency (up to 92% light transmission) |

| Strength | High impact resistance and structural rigidity |

| Barrier Performance | Good barrier to oxygen, moisture, and aroma |

| Chemical Resistance | Stable against acids and beverages |

| Heat Resistance | Suitable for -70°C to 120°C |

| Recyclability | Fully recyclable worldwide |

PET is widely used for:

-

Cold drink cups

-

Salad containers

-

Bakery packaging

-

Water bottles

-

Fresh produce packaging

Why it matters: PET is the global standard material for transparent food packaging and the backbone of many recycling systems.

3. What Is rPET? (Recycled PET Explained)

rPET is produced by recycling post-consumer PET bottles, flakes, and preforms. After washing, sorting, and pelletizing, the material is remanufactured into food-grade products such as cups and containers.

Environmental Advantages

-

Up to 79% reduction in CO₂ emissions

-

66% lower energy consumption

-

Diverts PET waste from landfills and oceans

-

Supports circular economy commitments

Common rPET Grades Used in Cups

| rPET Grade | Characteristics | Typical rPET % |

|---|---|---|

| rPET-Clear | Highest clarity, near-PET appearance | 30–50% |

| rPET-Natural | Slight gray/blue tint | 50–70% |

| rPET-Dark | Visible color variation | 80–100% |

Why it matters: rPET enables brands to meet legislative requirements such as the EU’s 30% recycled content mandate by 2030.

4. PET vs rPET: A Technical Comparison for Cup Buyers

4.1 Optical Clarity

PET is 100% virgin and therefore consistently crystal-clear.

rPET clarity depends on feedstock quality.

| Feature | PET Cup | rPET Cup |

|---|---|---|

| Appearance | Crystal-clear | Slight tint (gray/blue) |

| Consumer Perception | Premium | Eco-friendly |

| Best For | Cafés, beverages, retail packaging | Eco-focused brands |

4.2 Strength & Durability

Both PET and rPET provide strong impact resistance.

| Feature | PET | rPET |

|---|---|---|

| Strength | Excellent | Very Good |

| Structural consistency | High | Depends on blending ratio |

| Cup cracking risk | Very low | Low |

4.3 Food Safety & Compliance

PET and rPET comply with global food-contact standards:

-

FDA 21 CFR 177.1630

-

EU Regulation 10/2011

-

EFSA approval for recycled inputs

-

LFGB (Germany)

However, rPET requires EFSA or FDA No Objection Letter to ensure safety.

4.4 Cost Comparison

PET prices follow crude oil.

rPET prices follow global recycling availability.

| Region / Market | Virgin PET Resin Price | rPET Resin / Flake Price | Notes |

|---|---|---|---|

| Global Avg (2024–25) | $1,200–1,400 / ton | $900–1,200 / ton | rPET cost depends on quality and supply (pmarketresearch.com) |

| Europe (2023–24) | ~€1,050 / ton | €1,600–1,800 / ton | High-quality food-grade rPET commands premium (reportsanddata.com) |

| USA (2025 Q2) | — | $1,238 / ton | Spot price for rPET flakes (imarcgroup.com) |

| Asia (2025) | ~RMB 6,400 / ton (~$860–950) | ~$900–1,100 / ton | Price varies with local supply & resin purity (jushiplastic.com) |

Explanation / Key Points:

-

rPET is not always cheaper than virgin PET, particularly in developed markets due to certification and processing costs.

-

Price differences reflect collection, cleaning, food-grade compliance, transportation, and local market conditions.

-

For applications such as cups, trays, and food containers, buyers should consider total cost, quality, regulatory compliance, and recycling infrastructure, not just raw material price.

4.5 Environmental Impact

A lifecycle assessment (LCA) from the Swiss Federal Institute of Technology shows:

| Material | CO₂ Emissions (per ton) |

|---|---|

| PET | ~2.15 tons CO₂ |

| rPET | ~0.45 tons CO₂ |

rPET reduces carbon impact by over 70%.

5. PET & rPET Cup Applications (Global Market Insights)

PET and rPET cups dominate several industries:

-

Bubble tea & beverage shops

-

Café chains

-

Airlines (cold drinks)

-

Fruit tea & smoothies

-

Salad bars

-

Bakery shops

-

Supermarket deli sections

A survey found:

-

62% of brands prefer PET for clarity

-

38% prefer rPET for sustainability branding

-

rPET adoption rate increases 22% annually in Europe

6. Global Policy Push Toward rPET Usage

European Union

-

Mandates 30% recycled content in PET bottles by 2030

-

Encourages rPET packaging through EPR fees

-

Several countries tax virgin plastics

United States

-

California requires 25% recycled content by 2025

-

New Jersey and Washington enforce minimum rPET standards

South America

-

Chile Plastic Law & EPR

-

Colombia plastic tax exemptions for compostable and recyclable materials

Asia

-

Japan and Korea have strong recycling systems

-

Increasing demand for food-grade rPET cups

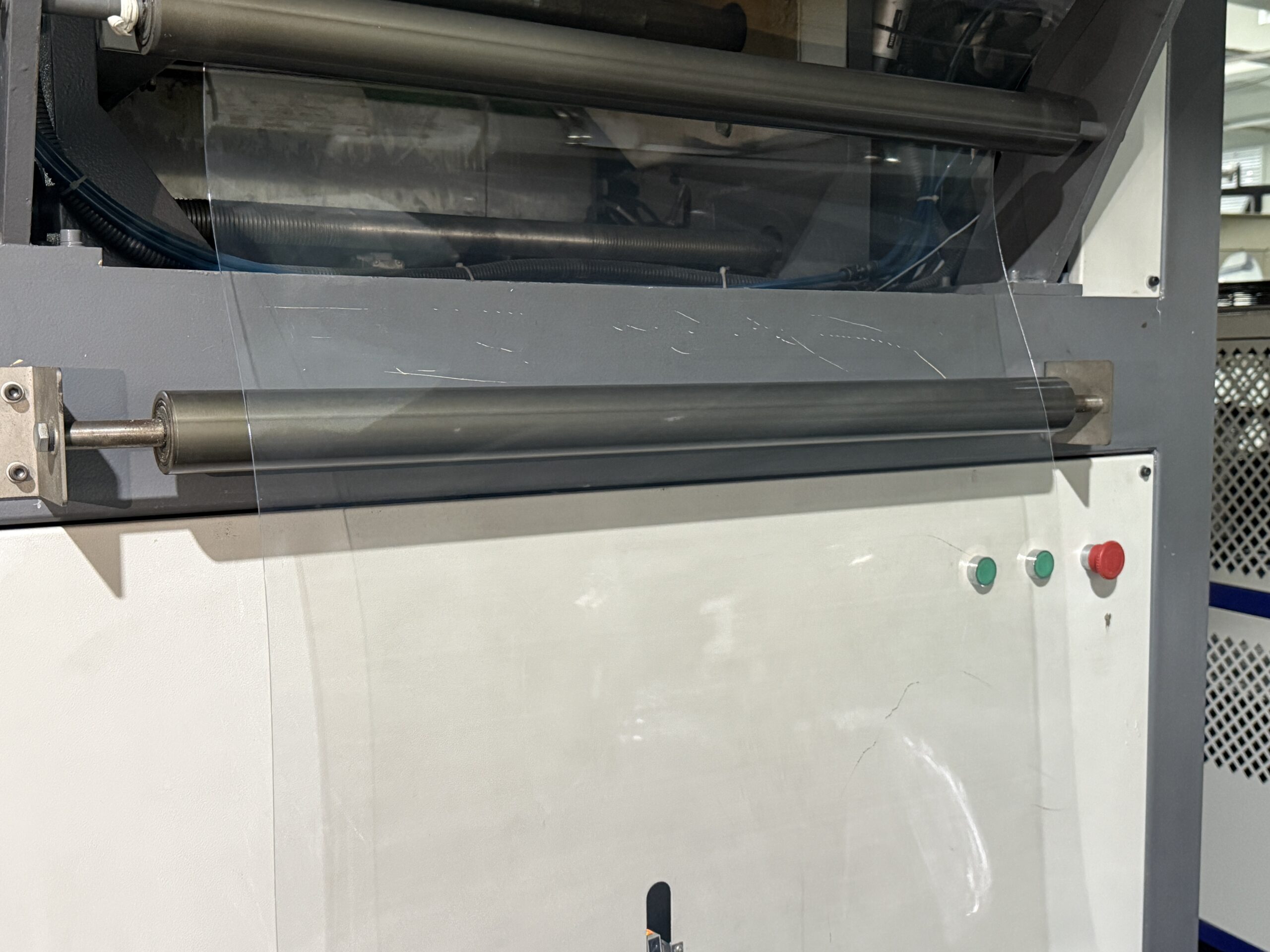

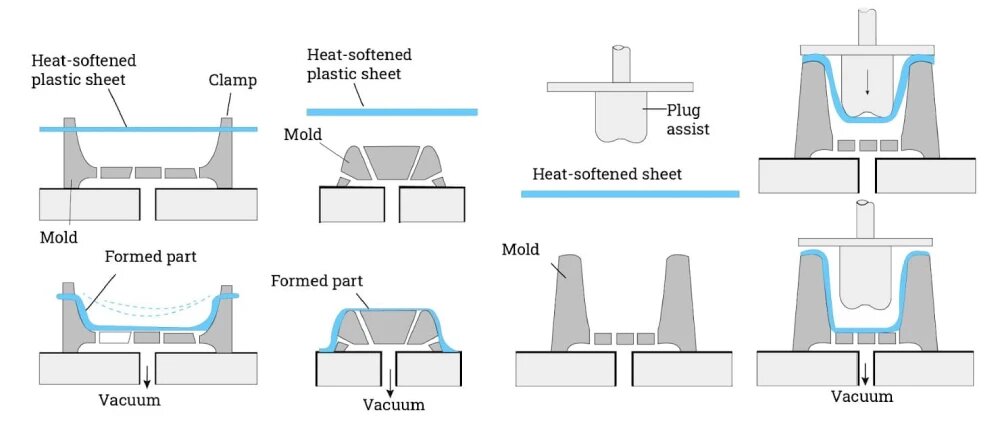

7. How PET & rPET Cups Are Manufactured (Thermoforming Overview)

Process

-

Extrusion into sheet

-

Thermoforming using mold tools

-

Trimming

-

Inspection

-

Stacking & packing

Why This Matters for Buyers

-

Thermoforming determines wall thickness

-

Affects transparency

-

Impacts cup stacking accuracy

-

Determines lead time & MOQ

8. Choosing Between PET and rPET Cups: Buyer Decision Matrix

| Buyer Priority | Best Choice | Reason |

|---|---|---|

| Maximum transparency | PET | Premium clarity |

| Eco-branding | rPET | Sustainability commitments |

| Cost sensitivity | PET | Lower price |

| Europe/UK compliance | rPET | Regulation-driven |

| High-volume beverages | PET or rPET blend | Stability + cost control |

9. Why Choose DASHAN for PET & rPET Cups?

DASHAN is a professional food packaging manufacturer specializing in PET and rPET cups for global markets. With years of export experience and strong manufacturing capabilities, DASHAN ensures:

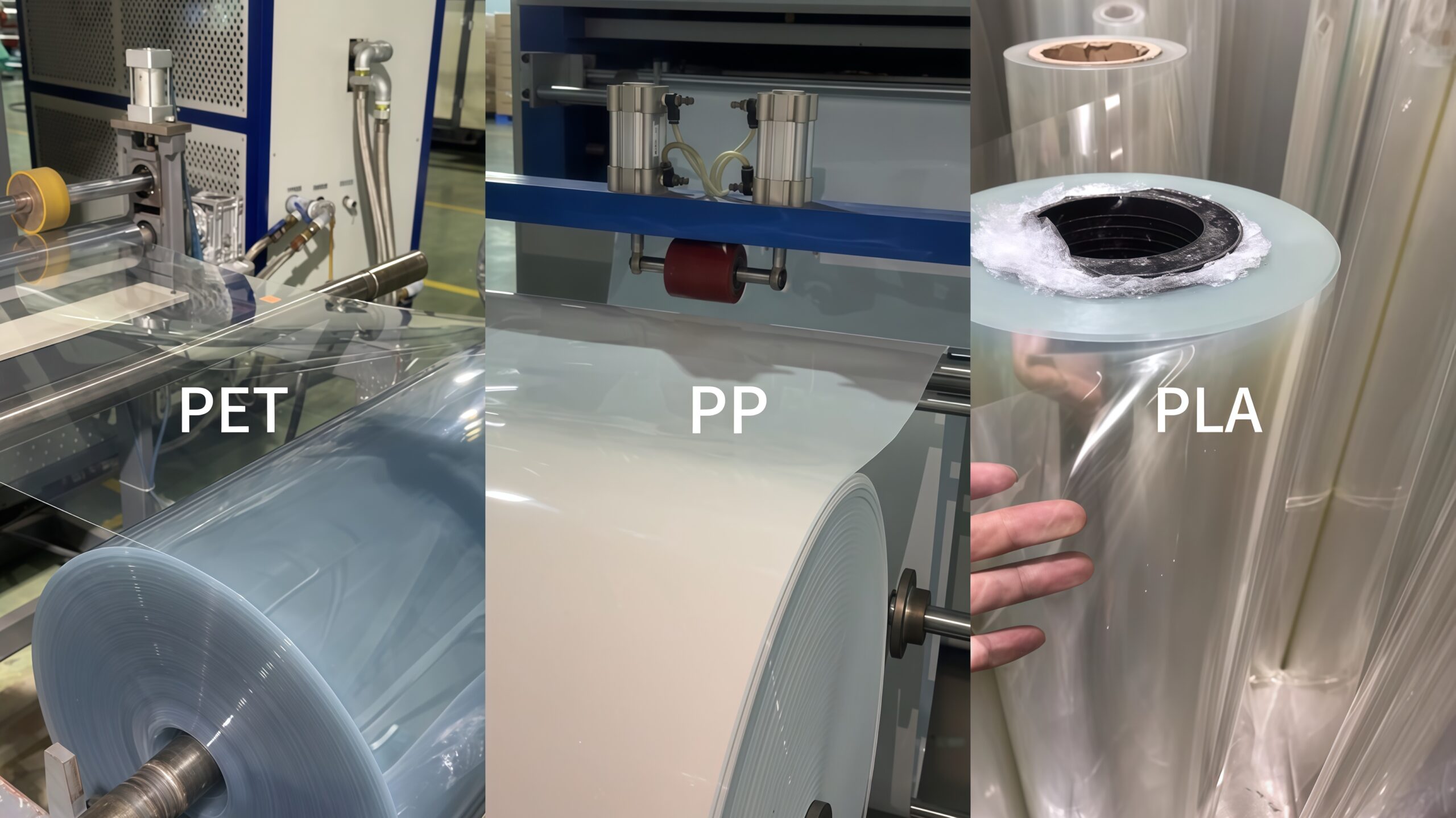

✔ High-Quality Raw Materials

-

Uses certified food-grade PET and rPET

-

Complies with FDA, EU, LFGB, and ISO standards

✔ Advanced Production Equipment

-

Fully automated thermoforming lines

-

Precise mold design for stable cup shape

-

Strict QC at every step (clarity test, impact test, stacking test)

✔ Sustainable Options

-

rPET cups from 25%–100% recycled content

-

Supports brands with EU sustainability requirements

-

Helps customers achieve carbon reduction goals

✔ Global Exhibition Experience

DASHAN has participated in international trade fairs in:

-

Dubai

-

Russia

-

Malaysia

-

Thailand

✔ Proven Export Record

Products shipped to:

-

Europe

-

South America

-

Middle East

-

Southeast Asia

-

North America

DASHAN provides stable supply, competitive pricing, and strong technical support for global buyers looking for PET and rPET solutions.

10. Data Table: PET vs rPET Technical Comparison

| Attribute | PET Cup | rPET Cup |

|---|---|---|

| Transparency | ★★★★★ | ★★★★☆ |

| Food Safety | FDA/EU/LFGB | FDA/EU/LFGB + EFSA recycling approval |

| Strength | ★★★★★ | ★★★★☆ |

| Heat Resistance | -70°C to 120°C | -70°C to 120°C |

| Cost | Medium | Medium–High |

| Environmental Impact | Moderate | Low |

| Recycled Content | 0% | 25–100% |

| Consumer Perception | Premium | Sustainable |

| Availability | Global | Region-dependent (EU demand high) |

FAQs

1. Is rPET safe for food-contact cups?

Yes. Food-grade rPET must meet FDA or EU 10/2011 standards and obtain EFSA or FDA approval.

2. Why do some rPET cups look slightly tinted?

The recycling process may introduce color variations, especially with higher recycled content.

3. Are PET and rPET cups fully recyclable?

Yes. Both PET and rPET can be recycled through standard PET recycling systems.

4. Is rPET more expensive than PET?

Generally yes, due to collection, washing, and pelletizing processes.

5. Does DASHAN offer customized PET and rPET cups?

Yes. DASHAN supports custom sizes, printing, and recycled content levels.

Conclusion

PET and rPET cups are key materials in the global food packaging market. PET offers unmatched clarity, strength, and cost-efficiency, ideal for premium beverage brands. rPET supports sustainability goals with lower carbon emissions and compliance with recycled-content regulations, especially in the EU, UK, and U.S. Both materials are safe, recyclable, and reliable. Understanding their differences in clarity, performance, and environmental impact helps buyers make informed decisions. Suppliers like DASHAN provide stable, compliant, and customizable solutions, enabling brands to balance quality, sustainability, and market competitiveness.

References

-

Plastics Recyclers Europe — https://www.plasticsrecyclers.eu

-

European Commission Circular Economy — https://environment.ec.europa.eu

-

FDA Food Contact Substances — https://www.fda.gov/food/food-ingredients-packaging

-

Petcore Europe Reports — https://www.petcore-europe.org

-

Swiss Federal Institute of Technology LCA Study — https://ethz.ch

-

Why PET Packaging Remains the Global Standard: Performance, Technology, and the Future of Sustainable Food Packaging–DASHAN Blog

opyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.