Quick Summary

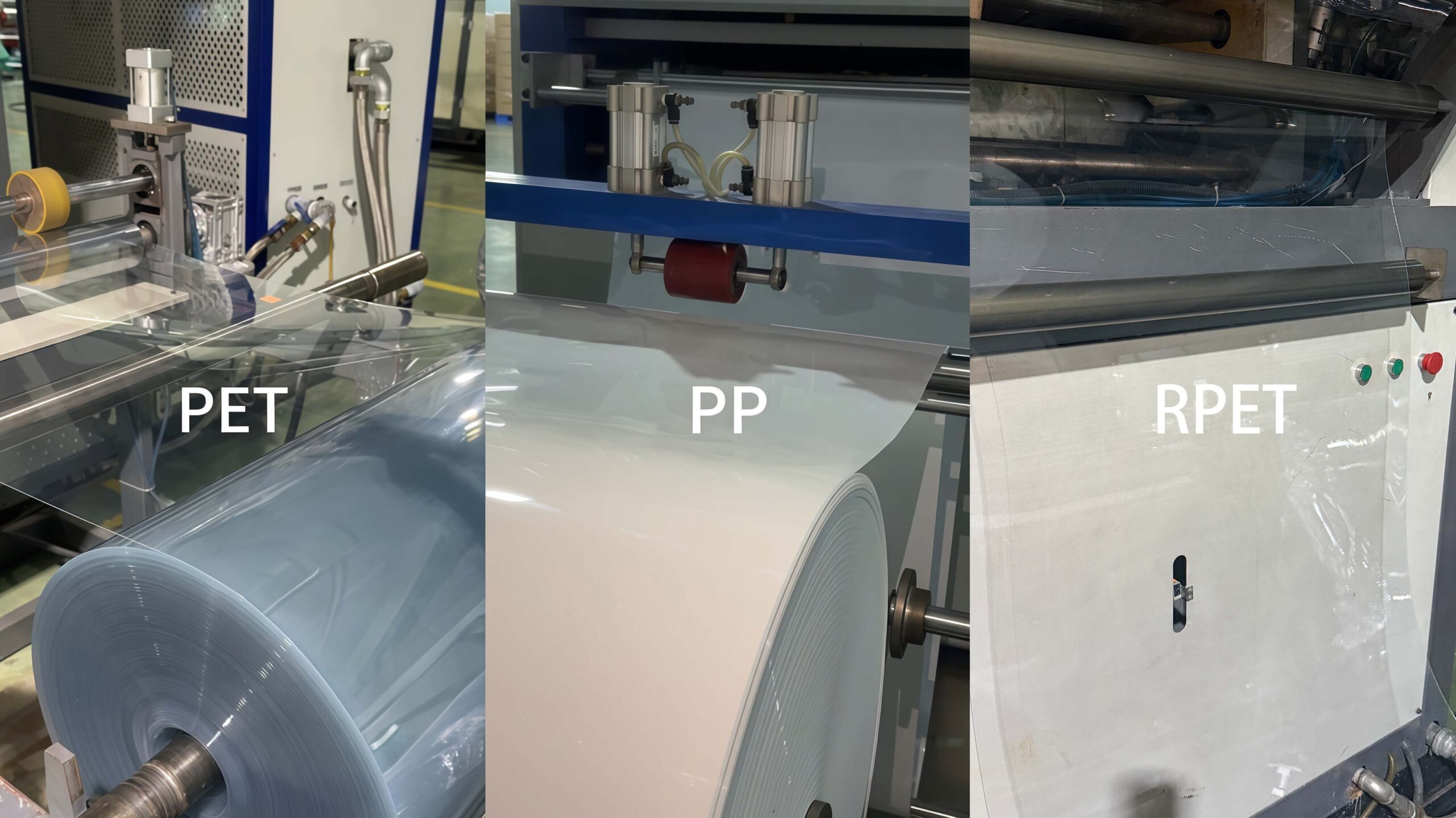

PET, rPET, and PP are three of the most commonly used plastics in global food packaging, yet they are frequently misunderstood or oversimplified. PET is prized for clarity and consistency, rPET is promoted for sustainability and circularity, while PP is favored for heat resistance and durability. In practice, none of these materials is universally superior. Their performance, safety, cost, and environmental impact depend heavily on processing methods, application scenarios, regulatory compliance, and local recycling infrastructure. This article provides an in-depth comparison of PET, rPET, and PP, examining how each material is made, where it performs best, common misconceptions, and what buyers should truly consider when selecting food packaging materials

Why PET, rPET, and PP Are Often Confused

From the perspective of end users and even some buyers, PET, rPET, and PP containers often appear interchangeable. They are lightweight, disposable, and widely used for takeaway, supermarket, and foodservice applications. This visual similarity creates the false impression that these materials behave similarly in real-world use.

Several factors contribute to this confusion:

First, appearance-driven assumptions. Clear plastic is often assumed to be PET or rPET, while slightly cloudy plastic is assumed to be lower quality. In reality, appearance has little to do with heat resistance, chemical stability, or recyclability.

Second, marketing-driven terminology. Terms such as “eco-friendly,” “green plastic,” “recyclable,” or “sustainable packaging” are frequently used without context. These labels rarely explain how or where recycling occurs, or under what conditions a material performs safely.

Third, global sourcing complexity. Buyers sourcing packaging internationally may encounter PET, rPET, and PP used interchangeably across regions, even though local regulations, waste systems, and usage habits differ significantly.

Understanding the real differences between these materials requires looking beyond surface-level claims.

What Is PET? (Virgin PET Explained)

Watch this video for more details.

How PET Is Made

PET (Polyethylene Terephthalate) is a thermoplastic polymer synthesized from purified terephthalic acid (PTA) and ethylene glycol (EG). The polymer chains formed during polymerization give PET its characteristic strength, clarity, and barrier properties.

For food packaging, PET is typically shaped through:

-

Thermoforming, used for trays, cups, and clamshell containers

-

Injection molding, used for thicker or more rigid items

Virgin PET refers to PET produced entirely from new petrochemical feedstocks, without recycled content.

Why PET Is Widely Used in Food Packaging

PET’s dominance in food packaging is not accidental. It offers a rare balance of properties that meet both functional and commercial requirements:

-

High transparency, allowing consumers to see the product clearly

-

Good gas and moisture barrier performance, suitable for many fresh foods

-

Lightweight structure, reducing transport and logistics costs

-

Dimensional stability, ensuring consistent performance at scale

-

Well-established food-contact safety history, accepted in most markets

For manufacturers and importers, PET also offers predictable processing behavior, which reduces production risks and quality variation.

Common Food Packaging Applications of PET

PET is primarily used for foods that are:

-

Cold or ambient temperature

-

Visually driven (appearance influences purchasing decisions)

-

Not intended for reheating

Typical applications include:

-

Fresh salads and fruit containers

-

Sushi and deli trays

-

Bakery and dessert packaging

-

Beverage cups and lids

-

Retail-ready display packaging

However, PET begins to deform at relatively low temperatures, making it unsuitable for hot-fill or microwave use.

What Is rPET? (Recycled PET in Reality)

How rPET Is Produced

rPET is produced by recycling post-consumer PET products, most commonly beverage bottles. The general process includes:

-

Collection and sorting

-

Washing and contamination removal

-

Shredding into flakes

-

Re-melting and pelletizing

For food-contact rPET, additional steps are required to remove potential contaminants absorbed during the product’s previous lifecycle.

This distinction is critical: not all rPET is food-grade, and food-grade rPET requires more advanced processing and control.

Is rPET Safe for Food Contact?

rPET can be safe for food contact only when strict conditions are met. Safety is determined by:

-

The quality and traceability of input materials

-

The effectiveness of decontamination technology

-

Compliance with food-contact regulations in the destination market

From a chemical standpoint, rPET is the same polymer as PET. The difference lies in process control, not molecular structure.

This is why food-grade rPET is often more expensive and less widely available than buyers expect.

Why rPET Costs More Than PET

Many buyers assume recycled materials should be cheaper. In practice, rPET often costs more than virgin PET due to several structural factors:

-

Limited availability of clean, food-grade recycled input

-

High operational costs for sorting and decontamination

-

Additional testing and compliance documentation

-

Supply volatility tied to collection systems and policy incentives

As demand for sustainable packaging increases, competition for high-quality rPET further drives price instability.

What Is PP? (Polypropylene for Food Containers)

Key Properties of PP

PP (Polypropylene) is a semi-crystalline thermoplastic known for:

-

Excellent heat resistance

-

High chemical stability

-

Good fatigue and impact resistance

-

Lower density than PET, contributing to lightweight designs

PP is generally translucent or opaque, with lower clarity than PET-based materials.

Why PP Is Common for Hot Food Packaging

PP’s ability to withstand higher temperatures makes it particularly suitable for:

-

Hot takeaway meals

-

Microwave reheating

-

Foods with high oil or fat content

Unlike PET, PP maintains shape and strength under heat stress, reducing leakage and deformation risks during use.

Typical PP Food Packaging Uses

PP is widely used in:

-

Takeaway and delivery containers

-

Microwaveable meal trays

-

Soup and noodle bowls

-

Ready-meal packaging

-

Airline and institutional catering trays

In these scenarios, functionality outweighs visual presentation.

PET vs rPET vs PP: Side-by-Side Comparison

| Aspect | PET | rPET | PP |

|---|---|---|---|

| Transparency | Very high | High, variable | Low–medium |

| Heat Resistance | Low | Low | High |

| Structural Rigidity | High | High | Medium |

| Food Safety | Highly consistent | Process-dependent | Highly stable |

| Environmental Claim | Recyclable | Recycled content | Recyclable |

| Recycling Reality | Widely collected | Limited by infrastructure | Lower collection rates |

| Cost Stability | High | Volatile | Moderate |

| Best Use | Cold & display foods | Sustainability-led packaging | Hot & microwave foods |

Environmental Impact: Which Is Actually More Sustainable?

PET and Recycling Reality

PET has one of the most mature recycling systems globally. However, real-world recycling rates vary widely depending on local infrastructure, policy incentives, and consumer behavior.

Recyclability does not guarantee recycling.

rPET and Circular Economy Claims

rPET supports circular economy models by reintroducing plastic into production cycles. Its real benefit depends on:

-

Closed-loop recycling systems

-

Stable collection streams

-

End-market demand

Without these conditions, rPET may function more as a symbolic sustainability claim than a systemic solution.

PP Recycling Challenges

Although PP is recyclable, it often faces:

-

Lower collection priority

-

Sorting challenges

-

Fewer food-grade recycling loops

As a result, PP’s environmental profile depends heavily on local waste management realities.

Food Safety & Regulations: What Really Matters

Food safety is influenced less by material name and more by:

-

Intended use conditions

-

Temperature exposure

-

Food type (acidic, fatty, hot)

-

Compliance with local regulations

Misapplication of a material is one of the most common causes of packaging-related food safety issues.

Common Myths About PET, rPET, and PP

-

“Recycled always means greener.”

Environmental impact depends on system efficiency, not labels. -

“PP is unsafe because it’s plastic.”

PP is widely used in medical and food applications due to stability. -

“Clear packaging is better packaging.”

Clarity is aesthetic, not functional. -

“All recyclable packaging gets recycled.”

Most does not.

Which Material Is Best for Different Food Packaging Scenarios?

Cold Food & Fresh Produce

PET or rPET due to clarity and barrier performance.

Hot Meals & Microwave Use

PP due to heat resistance and structural integrity.

Takeaway & Delivery

Material choice should match food temperature and handling conditions.

Supermarket & Retail Display

PET and rPET dominate due to visual merchandising advantages.

What Buyers Should Focus on When Choosing Plastic Packaging

Instead of focusing solely on material type, buyers should evaluate:

-

Actual usage conditions

-

Regulatory compliance

-

Supply chain consistency

-

End-of-life reality

Packaging decisions should balance performance, safety, cost, and environmental impact—not marketing claims.

FAQ

Is rPET safer than PET for food?

Safety depends on processing and regulatory compliance, not recycled content.

Can PP containers be recycled?

Yes, but recycling availability depends on local systems.

Why do some regions promote rPET more strongly?

Policy incentives and sustainability targets drive adoption.

Is PP microwave-safe?

PP is commonly used for microwave applications.

Does PET release chemicals when heated?

PET is not designed for high-temperature use and should not be heated.

Conclusion

PET, rPET, and PP each serve distinct roles in food packaging. No single material offers a universal solution. Understanding their real-world behavior—beyond surface-level sustainability claims—allows buyers to make informed, responsible decisions that align with functional needs, regulatory requirements, and realistic environmental outcomes.

References

-

U.S. Food & Drug Administration (FDA) – Food Contact Substances

https://www.fda.gov/food/food-ingredients-packaging/food-contact-substances-fcs -

European Food Safety Authority (EFSA) – Food Contact Materials

https://www.efsa.europa.eu/en/topics/topic/food-contact-materials -

PlasticsEurope – PET, rPET and PP Plastics Overview

https://plasticseurope.org/knowledge-hub/plastics-explained/ -

Ellen MacArthur Foundation – Plastics and the Circular Economy

https://ellenmacarthurfoundation.org/topics/plastics/overview -

European Commission – Plastics in Food Contact Applications

https://food.ec.europa.eu/safety/chemical-safety/food-contact-materials/plastics_en -

Association of Plastic Recyclers (APR) – PET Recycling Guidance

https://plasticsrecycling.org/pet

Copyright Statement

© 2026 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.