🟩 Quick Summary

The one-piece PET sushi box offers a modern, efficient, and sustainable packaging solution for the global foodservice industry. Made from crystal-clear, recyclable PET, it combines durability, moisture resistance, and excellent presentation. Through precision thermoforming, the tray integrates base and lid into a single structure — simplifying operations, preventing leaks, and enhancing stackability. Certified to ISO, FDA, and EU standards, PET box ensure food safety and brand trust. With DASHAN’s commitment to rPET development and automation-friendly design, these trays represent the future of sustainable sushi packaging — balancing functionality, visual appeal, and environmental responsibility.

Introduction

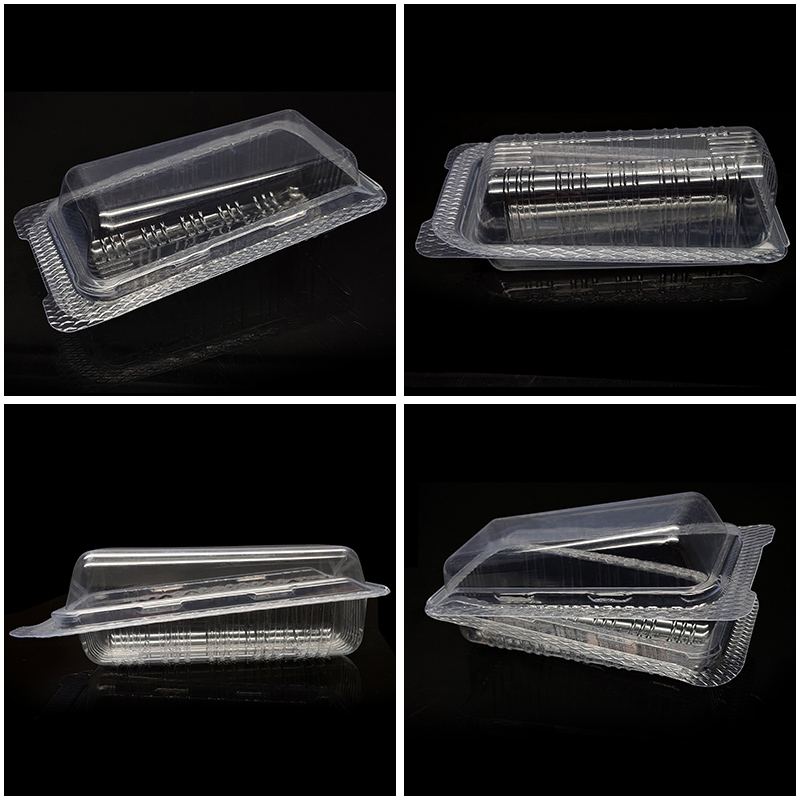

In today’s competitive food packaging market, PET sushi box have become a go-to solution for restaurants, supermarkets, and food delivery brands seeking packaging that combines clarity, durability, and sustainability. Sushi, as a high-value ready-to-eat product, requires packaging that not only protects freshness but also enhances visual appeal.

Among various packaging options, the one-piece PET sushi box stands out. Unlike traditional two-piece containers, this innovative design integrates the base and lid into a single structure — simplifying packaging operations while maintaining a premium presentation. For international buyers, understanding how these boxes are designed, manufactured, and evaluated is crucial for making the right procurement decisions.

This article serves as a comprehensive procurement guide for businesses seeking high-quality PET sushi trays, covering material science, production processes, design functionality, and selection criteria.

1.Understanding PET Material: The Foundation of High-Quality Packaging

PET (Polyethylene Terephthalate) is a widely used plastic material known for its exceptional clarity, strength, and chemical stability. It is commonly used in the food packaging industry due to its non-toxic nature and ability to preserve the quality of food for extended periods. PET packaging is popular for a wide range of products, including beverages, snacks, and, of course, sushi.

Clarity & Visual Appeal: One of the most significant benefits of PET sushi trays is their transparency. Customers can easily see the fresh sushi, making it an excellent choice for grab-and-go meals. Transparent trays also help customers assess the quality and freshness of the product before purchasing, which is essential for food businesses aiming to build consumer trust.

-

Strength & Durability: PET trays are not only clear but also highly durable. They can withstand the rigors of transport and storage without breaking, ensuring that your sushi arrives at its destination intact. The durability of PET also helps prevent damage during stacking and display, providing a secure and reliable packaging solution.

-

Moisture & Oil Resistance: PET trays are designed to resist moisture and oil, both of which are critical considerations when packaging sushi. Sushi rolls can release moisture or oils, which can damage packaging. PET’s moisture-resistant properties ensure that the tray remains strong, even when exposed to humidity or oily foods like eel or tempura rolls.

-

Recyclability: PET is 100% recyclable and is accepted by most recycling programs worldwide under resin code #1. This makes it an eco-friendly choice for businesses looking to reduce their environmental impact. Recycling PET trays contributes to the circular economy by reducing plastic waste and encouraging responsible material use.

2.Lid Design & Functionality: Key Features of One-Piece PET Sushi Boxes

One of the standout features of the PET sushi box in question is its one-piece design, which integrates both the tray and the lid into a single, seamless unit. This innovative design offers several advantages in terms of convenience, security, and aesthetics, making it an ideal choice for businesses looking for practical, reliable, and visually appealing sushi packaging.

1. One-Piece Design: Streamlined Convenience

-

The one-piece design eliminates the need for separate lids and trays, making the packaging easier to handle, store, and transport.

-

This feature reduces the likelihood of misalignment or incomplete sealing, which can be a concern with multi-piece designs. The integrated lid ensures that the food is securely enclosed in a single, tamper-evident unit.

-

Since the lid and tray are molded together, there is less risk of leakage, making this design particularly ideal for sauces or sushi rolls with moisture.

2. Clear, Transparent Lid for Maximum Visibility

-

The transparent PET lid allows consumers to see the freshness and quality of the sushi, enhancing the appeal of the product. The clarity of the material is a significant selling point, as it ensures the food inside is visible and protected without the need for additional packaging materials.

-

The transparency also allows sushi makers and sellers to present the dish in an elegant and professional manner, where the vibrant colors of sushi rolls, fish, and garnishes are clearly visible.

3. Secure Sealing and Leak-Resistance

-

Even though the design is one-piece, the lid still offers a secure, tight seal, ensuring that the contents are well-protected. The snug fit of the lid provides a protective barrier against contaminants and maintains food freshness.

-

The leak-resistant edges ensure that the sushi, sauces, or any additional accompaniments (such as wasabi or soy sauce) remain securely contained, preventing spillage during transit or storage.

4. Ease of Use and Consumer Convenience

-

The one-piece tray design simplifies the packaging process. There’s no need for additional lid fittings or assembly, making it quicker for food businesses to pack and prepare orders for delivery or takeout.

-

For consumers, the convenience of an easy-to-open, integrated packaging system adds to the positive user experience. The box can be easily opened, and the food is immediately accessible without having to separate multiple pieces of packaging.

5. Optimized for Stackability and Display

-

The flat, seamless design of the one-piece tray enhances its stackability, allowing multiple trays to be stacked securely for efficient storage and transportation.

-

The integrated lid ensures a smooth, clean surface for stacking, reducing the chance of the tray slipping or the lid becoming misaligned, a common issue with multi-part packaging.

-

From a retail perspective, the one-piece design makes it easier to organize and display sushi trays in refrigeration units or on store shelves.

3.Manufacturing Process of One-Piece PET Sushi Box

Understanding how one-piece PET sushi are boxes made can help buyers evaluate product quality, performance, and supplier reliability. The manufacturing process involves advanced thermoforming techniques that transform PET sheets into durable, transparent, and functional food packaging. Here’s how it works:

1. Material Preparation: PET Sheet Extrusion

The process begins with Polyethylene Terephthalate (PET) resin pellets — a food-safe, recyclable plastic known for its clarity and toughness.These pellets are melted and extruded into thin, uniform PET sheets, typically ranging from 0.3mm to 0.8mm in thickness, depending on the intended tray rigidity and size.During this stage, manufacturers may use recycled PET (rPET) content, which maintains sustainability without compromising mechanical strength or transparency.

Key quality controls:

-

Sheet thickness uniformity

-

Optical clarity (no haze or bubbles)

-

Food-grade certification (FDA, EU, LFGB compliance)

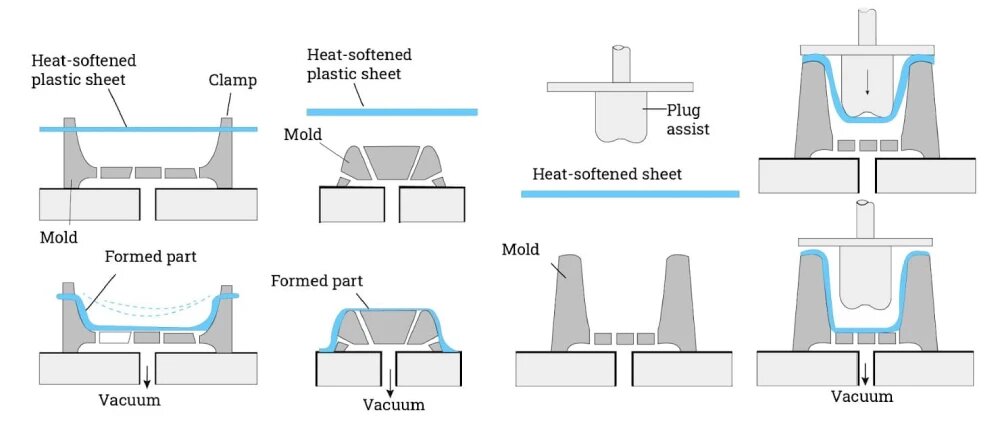

2. Thermoforming: Shaping the One-Piece Box

Once the PET sheet is ready, it is fed into a thermoforming machine, which uses heat and vacuum to shape the material into the desired sushi tray form.

-

The sheet is preheated to a pliable temperature (usually around 120–140°C).

-

It is then stretched over a precision mold that defines the tray’s structure — including the base, walls, and the raised dome lid (integrated in one piece).

-

A vacuum system pulls the material tightly against the mold surface, ensuring sharp edges, clean contours, and consistent wall thickness.

The result is a seamless, one-piece tray where the lid and base are connected by a thin flexible hinge. This hinge allows the lid to open and close repeatedly without cracking, eliminating the need for separate components.

3. Cooling and Trimming

After forming, the tray is rapidly cooled to retain its shape and clarity. Automated cutters then trim away excess PET from the sheet edges, producing smooth, uniform borders.The trimmed PET scrap is collected, ground, and often reintroduced into the extrusion line, creating a closed-loop recycling process that minimizes material waste.

4. Surface Finishing and Quality Inspection

Each tray undergoes a quality inspection to ensure:

-

Clarity – no scratches, fogging, or contamination

-

Consistency – uniform dimensions and thickness

-

Seal Integrity – the hinge and closing area function properly

-

Food Contact Safety – compliance with international food packaging standards

Some trays are embossed with anti-slip textures or decorative patterns on the surface to enhance grip and presentation. These details are added directly during the thermoforming stage through patterned molds.

5. Packaging and Sterilization

Before shipment, the trays are often air-cleaned or UV-sterilized in a dust-free environment to meet hygienic packaging requirements. They are then stacked and wrapped in shrink film or cartons for export.

This controlled process ensures the trays remain clean, crystal-clear, and ready for direct food contact upon delivery.

4. How to Choose the Right PET Sushi Boxes: Key Factors for Businesses

Selecting the ideal PET sushi box involves balancing functionality, presentation, and sustainability. Below are essential factors procurement managers should evaluate:

4.1 Size and Capacity

Your tray’s size should match your menu portions:

-

Single-roll trays for individual servings or takeout sushi sets

-

Medium trays for combination meals

-

Large trays for supermarket family packs

The one-piece design ensures easy stacking and display, perfectly fitting retail shelves and refrigerated units.

4.2 Design and Functionality

Since one-piece PET boxes integrate the lid and base:

-

No assembly errors — the lid always aligns perfectly.

-

Leak-proof performance — reliable for moist or sauce-containing products.

-

User-friendly closure — customers can open and reseal easily.

For packaging operations, this structure means faster handling and reduced packaging costs.

4.3 Visual Appeal and Transparency

The crystal-clear PET surface showcases sushi freshness — essential in visual-driven retail.

-

Transparent packaging boosts consumer trust.

-

Smooth lid design supports stickers, labels, or QR codes.

This transparency is not just aesthetic — it directly influences purchase behavior in supermarkets.

4.4 Durability and Protection

PET is impact-resistant and moisture-proof, ensuring:

-

No deformation under stacking pressure

-

Safe long-distance transport

-

Excellent resistance to condensation in chilled display cases

For cold-chain logistics and restaurant takeout, durability translates into fewer returns and customer complaints.

4.5 Sustainability and Recycling

PET sushi boxes are 100% recyclable, aligning with global sustainability trends.

-

Using rPET reduces virgin plastic consumption.

-

Recycling networks in Europe, North America, and Asia widely accept PET packaging.

By choosing recyclable packaging, brands strengthen their ESG credentials and appeal to eco-conscious consumers.

4.6 Customization and Branding

For branding consistency, many suppliers offer:

-

Custom logo embossing or printing

-

Tray color customization (black, clear, smoky gray, or tinted)

-

Embossed brand name or pattern on lid or base

OEM/ODM customization helps build a recognizable brand identity, especially for chain restaurants or premium sushi brands.

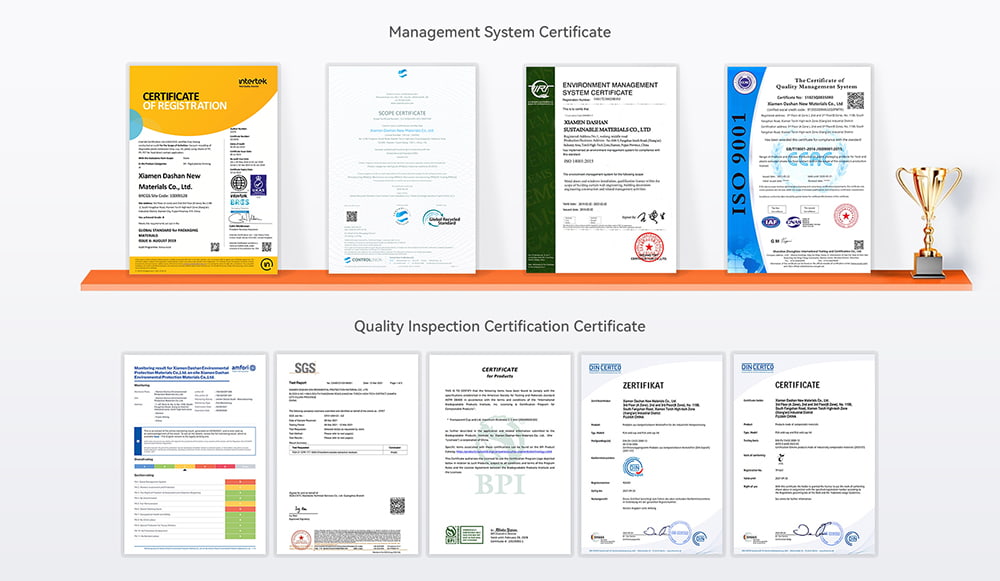

5. Common Quality Standards and Certifications

When sourcing from manufacturers, ensure compliance with international quality systems:

-

ISO 9001 / ISO 14001 – production quality and environmental management

-

FDA / EU 10/2011 / LFGB – food-contact material safety

-

BRC / HACCP – hygienic manufacturing environments

A reputable supplier like DASHAN maintains these certifications to ensure every batch meets export-grade requirements.

6. Cost Considerations for Procurement

Several factors influence PET sushi box pricing:

-

Material thickness – thicker PET increases cost but enhances rigidity.

-

Production method – one-piece designs are efficient but require precision molds.

-

Order quantity – larger volumes reduce unit cost through economies of scale.

-

Customization – printing and branding add small premiums but elevate perceived value.

For importers, considering total landed cost (including packaging density and shipping efficiency) provides a more accurate procurement strategy.

7. Future Trends: Sustainable Innovation in Sushi Packaging

The future of sushi packaging is shifting toward sustainability and smart design:

-

rPET integration (up to 70–100%)

-

Biodegradable coatings compatible with PET structure

-

Smart labels showing freshness and temperature history

-

Automation-friendly packaging for sushi production lines

Suppliers that invest in eco-materials and automated thermoforming are leading the next wave of packaging innovation.

💬 FAQ: One-Piece PET Sushi Boxes

1. What is the main advantage of a one-piece PET sushi box?

The one-piece design integrates the lid and base, reducing assembly time, preventing misalignment, and ensuring a secure seal — ideal for high-volume sushi packaging operations.

2. Are PET sushi boxes recyclable?

Yes. PET (Polyethylene Terephthalate) is 100% recyclable and widely accepted by global recycling systems. Many modern boxes also incorporate rPET content to reduce carbon footprint.

3. How does PET compare with PLA or bagasse in sustainability?

PET is recyclable and offers superior clarity, while bagasse and PLA are compostable options. DASHAN provides both types, allowing buyers to choose based on regional recycling or composting infrastructure.

4. Can one-piece PET boxes withstand cold storage?

Absolutely. PET maintains its clarity and strength in refrigerated environments, making it ideal for cold sushi display and takeaway applications.

5. Does the one-piece hinge weaken over time?

No. High-quality thermoforming ensures flexible, durable hinges that withstand repeated openings without cracking or deforming.

6. What certifications should suppliers have for PET sushi boxes?

Look for ISO 9001, ISO 14001, FDA, EU 10/2011, and LFGB compliance. DASHAN’s production lines are certified to meet international export standards.

7. Can these boxes be customized with brand logos or colors?

Yes. OEM/ODM customization is available — including embossed branding, color options (clear, black, smoky gray), and printable lids for labels or QR codes.

8. What are the latest innovations in sushi packaging?

Future trends include high-content rPET integration, biodegradable coatings, automation-compatible designs, and smart freshness labels — all areas DASHAN is actively developing.

Conclusion

Selecting the right PET sushi box is not only a design choice but a strategic business decision. The one-piece PET design simplifies operations, reduces waste, and enhances presentation — aligning perfectly with global trends toward sustainability and efficiency.

By understanding the manufacturing process, material properties, and key procurement factors, international buyers can confidently partner with professional suppliers like DASHAN, ensuring their packaging meets the highest standards of quality, hygiene, and market appeal.

From supermarket shelves to takeaway counters, the PET one-piece sushi box represents the ideal balance between functionality, transparency, and eco-conscious design — making it a smart investment for any forward-thinking food business.

📚 References & Further Reading

-

European Commission. Regulation (EU) No 10/2011 on Plastic Materials and Articles Intended to Come into Contact with Food.

https://eur-lex.europa.eu/legal-content/EN/TXT/ -

U.S. Food and Drug Administration (FDA). Food Contact Substances (FCS) and Food Packaging Regulations.

https://www.fda.gov/food/packaging-food-contact-substances-fcs -

ISO. ISO 9001:2015 Quality Management Systems & ISO 14001:2015 Environmental Management Systems.

https://www.iso.org/standards.html -

Ellen MacArthur Foundation. The Circular Economy in Plastic Packaging.

https://ellenmacarthurfoundation.org/topics/plastics/overview -

Plastics Europe. Polyethylene Terephthalate (PET): Properties, Applications and Recycling.

https://plasticseurope.org/materials/types-of-plastics/pet/ -

UNEP. Single-Use Plastic Product Guidelines and Global Packaging Sustainability Trends.

https://www.unep.org/resources -

DASHAN Packaging. Sustainable Food Packaging Solutions: PET and Bagasse Product Development.

https://www.dashanpacking.com/

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.