Quick Summary

This article delves into the critical role of heat-resistant packaging in maintaining temperature integrity during cold chain logistics. It covers key materials like CPET and PP, which help preserve food safety and freshness for perishable goods such as seafood, frozen foods, and fresh produce. By analyzing the various packaging materials used in the industry, the article highlights how effective packaging solutions prevent spoilage, extend shelf life, and ensure the safe transportation of temperature-sensitive food products. Real-world examples and innovative packaging trends are also explored, showcasing the evolving role of packaging in the cold chain industry.

I. Introduction

In the global food Packaging industry, cold chain logistics plays a vital role in ensuring the freshness and safety of temperature-sensitive products. It involves the transportation, storage, and handling of goods at consistent low temperatures to preserve their quality and prevent spoilage. Fresh produce, seafood, frozen foods, and other perishable items require an intact cold chain to maintain their optimal conditions from origin to destination. Packaging materials, especially those with heat resistance, are a critical component in maintaining the required temperature and preventing the effects of heat exposure during transport.

This article explores the relationship between heat-resistant packaging and its applications in cold chain logistics, examining how materials can maintain temperature integrity, preserve food safety, and extend product shelf life.

II. Heat Resistance of Packaging Materials

Heat resistance refers to the ability of a material to withstand high temperatures without deteriorating, deforming, or losing its functionality. This property is essential for packaging materials used in cold chain logistics, as they help protect perishable items from temperature fluctuations during transport and storage.

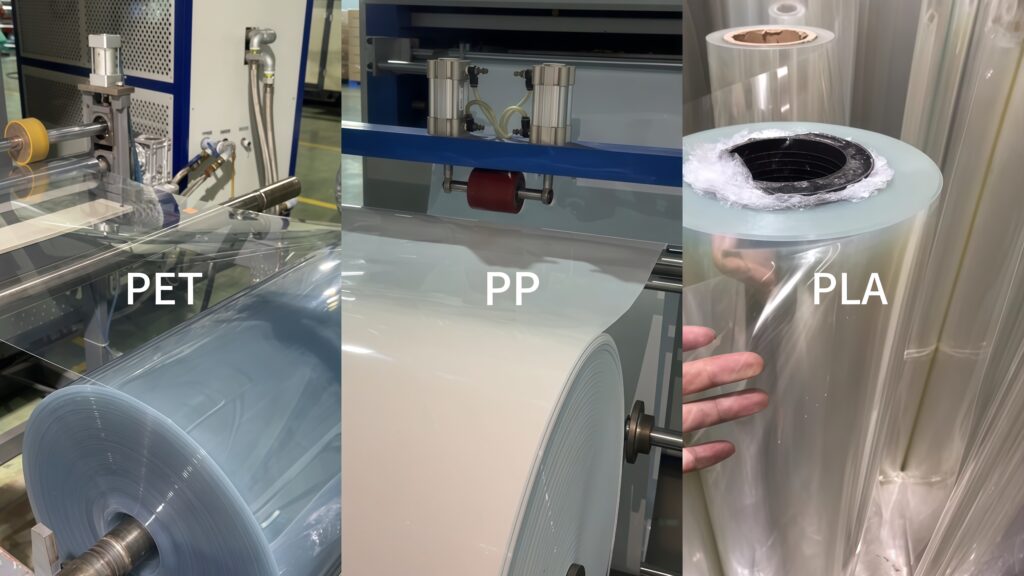

Key Packaging Materials with Heat Resistance

-

CPET (Crystallized PET): CPET is a modified version of PET (Polyethylene Terephthalate) that exhibits superior heat resistance compared to regular PET. It can withstand high temperatures without warping or melting, making it ideal for applications such as microwaveable food trays and high-temperature food containers. CPET is commonly used in the cold chain logistics of ready-to-eat meals, where the packaging must endure both freezing and heating processes.

-

Polypropylene (PP): PP is another widely used material in food packaging, known for its excellent heat tolerance. It is often used in packaging frozen foods and microwavable meals. PP can withstand temperatures up to 100°C, making it a suitable choice for heat-resistant packaging solutions in cold chain logistics.

-

CPET vs. PET: While PET is commonly used for food packaging, CPET provides enhanced performance in terms of thermal stability. This makes CPET more suitable for situations where the food is exposed to a wide range of temperatures, such as during microwave heating or freezing. PET, on the other hand, is more often used for applications where heat resistance is less critical.

-

Other Materials (e.g., PLA, PS): Biodegradable materials such as PLA (Polylactic Acid) and PS (Polystyrene) are sometimes used in cold chain logistics but have limitations in heat resistance. PLA is more sensitive to temperature changes and is better suited for cold beverages or short-term food storage, while PS provides some heat resistance but is typically less durable than CPET or PP.

III. The Role of Heat-Resistant Packaging in Cold Chain Logistics

Heat-resistant packaging plays a key role in ensuring the temperature integrity of perishable goods during cold chain logistics. By preventing temperature fluctuations, heat-resistant materials help preserve food quality, minimize spoilage, and prevent contamination.

Maintaining Temperature Integrity

Effective packaging helps maintain the required temperature during transportation and storage by providing thermal insulation. For example, CPET containers can withstand the high temperatures of microwave ovens while keeping the food intact during freezing or cooling processes. Additionally, PP materials protect frozen foods from temperature increases that could lead to partial thawing and loss of product quality.

Preserving Food Safety

Temperature fluctuations can lead to bacterial growth and foodborne illnesses. Heat-resistant packaging reduces the risk of food safety issues by preventing external heat from affecting the food product. For instance, CPET trays used in airline catering ensure that meals remain safe for consumption by maintaining consistent temperatures during long-haul flights. Frozen seafood can be similarly protected by packaging that prevents heat exposure during transit.

Extended Shelf Life

Proper heat-resistant packaging can significantly extend the shelf life of temperature-sensitive products. By maintaining an optimal environment for products like fresh produce, seafood, and frozen foods, packaging materials help reduce spoilage and waste. For example, CPET and PP packaging prevent temperature fluctuations that could cause food to spoil, keeping it fresh for longer periods.

IV. Types of Cold Chain Products and Their Packaging Needs

Fresh Produce (e.g., Fruits, Vegetables)

Fresh produce is highly sensitive to temperature fluctuations, which can accelerate ripening and cause spoilage. Heat-resistant packaging solutions such as breathable trays and insulated wraps are commonly used to keep fruits and vegetables fresh during transport. These materials allow for proper ventilation while protecting against external heat.

Seafood

Seafood products are particularly vulnerable to temperature changes, as they are highly perishable. Heat-resistant packaging helps maintain the cold chain and keeps seafood at a safe temperature during transportation. Packaging materials like CPET trays and insulated bags are ideal for preserving the freshness and quality of seafood products.

Frozen Foods

Frozen foods, including ready-to-eat meals and frozen vegetables, require heat-resistant packaging to ensure they remain at sub-zero temperatures throughout the supply chain. PP containers and CPET trays are commonly used for frozen foods, as they provide excellent thermal stability and can withstand low temperatures without cracking or warping.

V. Case Studies: Real-World Examples

-

Case Study 1: CPET in Airline Catering

CPET trays are widely used in the airline industry to package meals that need to be heated in microwaves. The material’s heat resistance ensures that the meals remain safe and intact during both freezing and heating processes, making it ideal for airline catering. -

Case Study 2: Frozen Food Packaging for Global Distribution

Frozen foods shipped internationally often rely on PP packaging to maintain temperature stability during transport. For example, PP containers are commonly used for frozen meals and vegetables, ensuring the food stays at the desired temperature and remains safe for consumption. -

Case Study 3: Seafood Cold Chain in the Asian Market

In the seafood industry, CPET and PP packaging are widely used to ensure freshness and food safety during the long transportation of seafood across Asia. These materials provide excellent thermal insulation to maintain the cold chain, ensuring that the seafood remains at safe temperatures during transit.

VI. Innovations in Heat-Resistant Packaging for Cold Chain Logistics

Technological Advancements

The development of new heat-resistant materials is helping improve the performance of cold chain packaging. Innovations such as smart packaging, which includes temperature indicators and sensors, provide real-time tracking of temperature changes during transportation, ensuring that the product remains within safe temperature ranges.

Sustainability Considerations

As the demand for eco-friendly packaging grows, many companies are exploring sustainable heat-resistant materials such as biodegradable plastics and recyclable materials. This shift is not only beneficial for the environment but also helps reduce the overall carbon footprint of cold chain logistics.

VII. Challenges and Solutions

Challenges in Heat Resistance for Cold Chain Packaging

One of the major challenges in cold chain logistics is the variability in temperature fluctuations. Packaging materials must be able to handle temperature extremes and prevent product spoilage. Another challenge is the cost of advanced heat-resistant packaging, which may increase packaging costs.

Solutions to Overcome These Challenges

To overcome these challenges, companies are exploring ways to balance cost, performance, and sustainability. Investing in high-quality packaging materials like CPET and PP can help ensure food safety and reduce the risk of spoilage, making them a valuable investment for long-term cold chain operations.

VIII. Conclusion

In conclusion, heat-resistant packaging plays a crucial role in the successful operation of cold chain logistics. By maintaining temperature integrity, preserving food safety, and extending shelf life, materials like CPET and PP are essential for the transportation and storage of perishable goods. As the demand for sustainable packaging grows, the development of eco-friendly and innovative heat-resistant solutions will continue to shape the future of the cold chain industry.

IX. Frequently Asked Questions (FAQ)

1. Why is heat resistance important in cold chain packaging if products are kept cold?

Even in cold chain logistics, products are often exposed to temperature fluctuations during loading, unloading, customs clearance, or unexpected delays. Heat-resistant packaging prevents deformation, leakage, and material failure when external temperatures rise, ensuring food safety and packaging integrity throughout the supply chain.

2. Which packaging material offers the best balance between heat resistance and cold chain performance?

Among commonly used materials, CPET packaging offers the best balance. It performs well under freezing, refrigeration, and reheating, making it ideal for frozen meals, airline catering, and ready-to-eat foods. PP packaging is also widely used for frozen foods due to its flexibility and thermal stability.

3. Is PET suitable for cold chain logistics involving frozen foods?

Standard PET packaging is suitable for chilled foods and short-distance cold chain transportation. However, it has limited heat resistance compared to CPET or PP, making it less suitable for applications that involve reheating or wide temperature variations.

4. How does heat-resistant packaging contribute to food safety?

Heat-resistant packaging helps maintain a stable internal temperature, reducing the risk of bacterial growth, moisture condensation, and packaging deformation. This is particularly critical for seafood, fresh food, and frozen food products, where even slight temperature abuse can compromise food safety.

5. Can heat-resistant packaging be sustainable and recyclable?

Yes. Materials such as CPET and PP are widely recyclable in many markets. In addition, manufacturers are increasingly developing recycled-content CPET (rCPET) and lightweight packaging designs to support sustainable cold chain logistics while maintaining high thermal performance.

6. What happens if non–heat-resistant packaging is used in cold chain logistics?

Using packaging with poor heat resistance can lead to warping, cracking, seal failure, leakage, and even contamination. This not only causes product loss but also increases logistics costs, customer complaints, and food safety risks.

X. References

-

Food and Agriculture Organization of the United Nations (FAO).

Cold Chain Management for Perishable Foods.

https://www.fao.org/home/en -

World Health Organization (WHO).

Food Safety and Temperature Control in the Supply Chain.

https://www.who.int/teams/nutrition-and-food-safety/food-safety -

International Institute of Refrigeration (IIR).

Cold Chain Technology and Logistics for Food Products.

https://iifiir.org

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.