Introduction: The Global Packaging Waste Challenge

Packaging waste is one of the fastest-growing types of waste worldwide, with plastics being a major contributor to the problem. Over 300 million tons of plastic are produced annually, a large portion of which ends up as waste. Improper disposal and inefficiency in recycling systems have created long-lasting environmental damage. Closed-loop systems offer a sustainable solution to packaging waste by providing a method for effective waste management and material recycling that supports the circular economy.

This article will explore how closed-loop systems work in the context of packaging, their potential to reduce resource waste, and their contribution to achieving a sustainable circular economy. Through detailed analysis, this article will highlight how businesses and governments can use closed-loop systems to effectively manage packaging waste, recover valuable materials, and prevent environmental degradation.

1. Understanding Closed-Loop Systems: A Definition and Overview

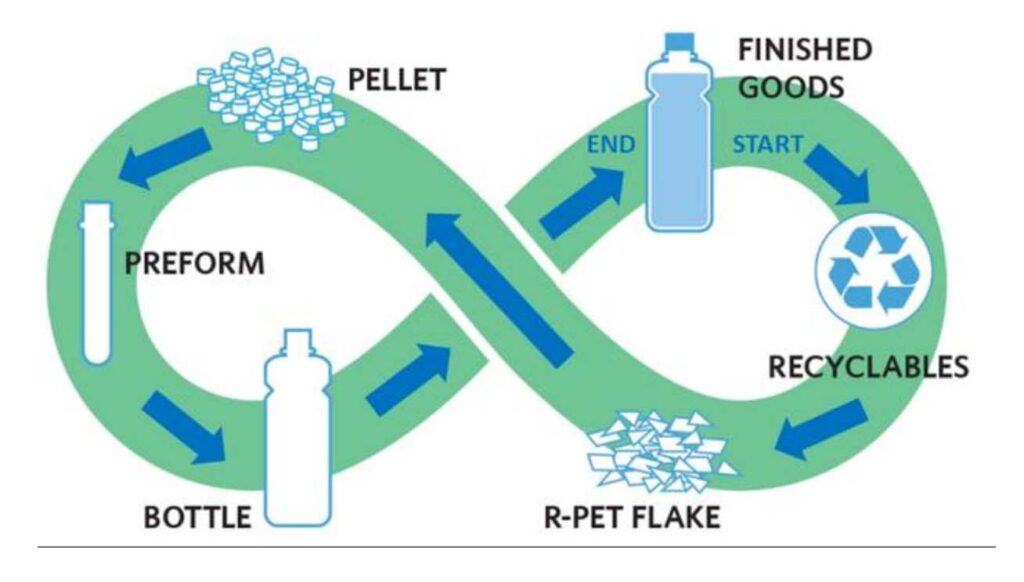

Closed-loop systems refer to processes where waste products are reintroduced into the production cycle to create new products of equal or higher quality. In packaging, this means that used materials like plastic, paper, and glass can be recycled, remade, and reused without significant loss of value or quality. In comparison to open-loop recycling, where materials may lose their original qualities and require downcycling, closed-loop systems allow for a continuous, circular flow of material reuse.

Closed-loop recycling ensures that packaging materials retain their value and can be continually used in the production process. For example, PET bottles are recycled and remade into new bottles, reducing the need for virgin plastic production and preventing waste. This system is essential for a circular economy because it limits the extraction of new resources and minimizes environmental impact.

2. The Key Components of a Closed-Loop Packaging System

2.1 Design for Recyclability

The foundation of a successful closed-loop system begins with designing packaging that can be easily recycled. Packaging should be made from single-materials rather than composite materials, which are difficult to separate and recycle. For example, PET bottles are easier to recycle than multi-layered packaging with different materials.

The design process also includes ensuring packaging is easy to disassemble, clean, and reintroduce into the recycling system. Design for recyclability ensures that packaging doesn’t just end up as waste but is properly recycled back into the production cycle.

2.2 Efficient Collection and Sorting

For closed-loop systems to work efficiently, proper collection and sorting of waste materials are crucial. The success of recycling depends on whether materials are sorted correctly and without contamination. Investments in smart collection systems, where materials are sorted at the point of collection or through advanced sorting technologies, can greatly improve recycling rates.

3. The Role of Consumers in Closed-Loop Systems

Consumers are a vital part of the recycling process. For closed-loop systems to function, consumers must be educated on proper waste segregation. By encouraging responsible waste disposal, communities can ensure that valuable recyclable materials like plastic, paper, and glass are separated and sent for recycling.

Programs such as deposit return schemes (where consumers return empty containers for a refund) can incentivize better recycling practices. In some regions, public awareness campaigns and extended producer responsibility (EPR) schemes encourage businesses to take responsibility for the recycling of their products.

4. Real-World Applications of Closed-Loop Systems in Packaging

4.1 Plastic Packaging and Closed-Loop Recycling

Plastic is one of the most common and difficult-to-recycle materials in packaging. However, PET (polyethylene terephthalate) plastic, often used in bottles, is well-suited for closed-loop recycling. Companies like Coca-Cola and PepsiCo have committed to using 100% recycled PET (rPET) in their bottles, which can be recycled infinitely without degradation in quality.

Challenges: The main challenges for closed-loop PET recycling include contamination during collection and the lack of infrastructure in some regions to process recycled materials efficiently.

4.2 Paper Packaging and Recycling

Paper packaging (such as cartons and boxes) has a higher recycling rate compared to plastics but still faces challenges in closed-loop systems. High-quality paper used in packaging can be reused multiple times before degradation. Programs like paper-based beverage cartons in Europe show the potential of closed-loop systems in paper recycling, where paper products are made from 100% recycled paper fibers.

4.3 Glass and Metal Packaging

Both glass and metal (such as aluminum cans) have well-established closed-loop recycling systems. Glass can be recycled indefinitely without losing its quality, and aluminum, in particular, is one of the most recycled materials worldwide due to its high value in closed-loop systems. Brands like Heineken and Coca-Cola have adopted aluminum cans and glass bottles, which are easily returned to the production cycle after use.

5. Circular Economy: How Closed-Loop Systems Drive Sustainability

The core principle of a circular economy is to eliminate waste and keep products and materials in use for as long as possible. Closed-loop systems are critical to realizing this vision, as they promote the continuous reuse and recycling of packaging materials, which in turn conserves natural resources.

By adopting closed-loop systems, businesses reduce the demand for virgin materials, such as petroleum-based plastics, and promote the use of recycled materials, thus reducing their carbon footprint. Additionally, closed-loop systems contribute to sustainability goals, such as achieving zero-waste targets and minimizing environmental impact.

5.1 Reducing Carbon Footprint

Closed-loop recycling has the potential to significantly lower carbon emissions compared to the extraction and production of virgin materials. For instance, producing new plastic from recycled PET uses up to 60% less energy than manufacturing plastic from raw petroleum.

6. Challenges and Barriers to Implementing Closed-Loop Systems

Despite the benefits of closed-loop systems, several challenges need to be addressed to make them more widespread:

6.1 Technological Limitations

Currently, many closed-loop recycling technologies are limited by the need for sophisticated sorting and cleaning systems. Mixed-material packaging can be challenging to recycle in a closed-loop manner, and technological advances are required to better separate and process these materials.

6.2 Economic Challenges

While closed-loop systems are environmentally beneficial, they can sometimes be more expensive than traditional linear systems. Recycling infrastructure can be costly to develop, and businesses may face higher costs in the initial phase of switching to closed-loop systems. However, over time, these costs can be offset by reduced raw material expenses and compliance with regulations.

6.3 Consumer Participation

Effective consumer participation is essential for the success of closed-loop systems. Education campaigns and incentives are necessary to encourage responsible consumer behavior, such as sorting waste and returning packaging materials.

7. Global Examples of Successful Closed-Loop Systems

7.1 Sweden’s Recycling Success

Sweden is one of the leaders in closed-loop packaging recycling. The country has a high recycling rate for plastics, with 98% of PET bottles being recycled through a closed-loop system. The Swedish government supports recycling through strict extended producer responsibility (EPR) regulations.

7.2 Germany’s Green Dot System

Germany’s Green Dot system is an example of a highly successful closed-loop system that has been implemented for packaging. The Green Dot symbol on packaging signifies that the manufacturer is responsible for ensuring its packaging is recycled. This system has significantly reduced packaging waste and increased recycling rates.

8. The Future of Closed-Loop Systems in Packaging

The future of closed-loop systems looks promising, with advancements in technology, policy development, and consumer engagement driving improvements. Key trends include:

-

The integration of AI and robotic sorting technologies to enhance recycling efficiency.

-

The adoption of chemical recycling to close the loop on complex materials.

-

Government incentives to encourage businesses to adopt circular economy practices.

9. Conclusion: The Path Forward for Sustainable Packaging

Closed-loop systems are a crucial part of packaging waste management and will play a significant role in transitioning towards a circular economy. By promoting recycling, reusing, and reducing waste, these systems can help companies lower their environmental impact while improving economic performance. Through continued innovation and investment in recycling infrastructure, the potential for closed-loop systems to become the norm in the packaging industry is immense.

FAQ

1. What is the difference between closed-loop and open-loop recycling?

Closed-loop recycling refers to recycling materials that can be reused to create the same product, while open-loop recycling often leads to downcycling or turning materials into lower-value products.

2. How can businesses implement closed-loop systems?

Businesses can design recyclable packaging, invest in advanced recycling technologies, and partner with recycling organizations to collect and process materials.

3. What are the environmental benefits of closed-loop recycling?

Closed-loop recycling reduces the demand for virgin materials, lowers energy consumption, and decreases carbon emissions.

4. Can all packaging materials be recycled in a closed-loop system?

Not all materials can be recycled in a closed-loop system. Materials like multi-layer packaging or complicated composites are harder to recycle effectively.

5. How can consumers participate in closed-loop recycling?

Consumers can ensure they properly sort and dispose of packaging materials, participate in recycling programs, and return recyclable packaging to the collection system.

References

-

Circular Economy: Principles and Applications

Ellen MacArthur Foundation. (2015). Towards a Circular Economy: Business Rationale for an Accelerated Transition. Ellen MacArthur Foundation.

URL: https://www.ellenmacarthurfoundation.org/publications/towards-a-circular-economy-business-rationale-for-an-accelerated-transition -

Global Plastic Production, Use, and Waste

Geyer, R., Jambeck, J. R., & Law, K. L. (2017). Production, use, and fate of all plastics ever made. Science Advances, 3(7), e1700782.

DOI: 10.1126/sciadv.1700782 -

The Role of Packaging in Sustainable Waste Management

United Nations Environment Programme (UNEP). (2018). Single-Use Plastics: A Roadmap for Sustainability.

URL: https://www.unep.org/resources/report/single-use-plastics-roadmap-sustainability

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.