Quick Summary

This guide explains how businesses can lower packaging costs without sacrificing performance or food safety. By optimizing materials, design, logistics, and supplier collaboration, companies reduce total cost of ownership while protecting product quality and brand value.

Across retail, foodservice, e-commerce, and FMCG, one truth is universal: packaging is essential — but it can also be expensive.

When margins tighten, many companies instinctively push suppliers to “make it cheaper.” Unfortunately, that often leads to thinner, weaker, and riskier packaging that causes leaks, product damage, customer complaints, and ultimately higher costs.

The smarter question is:

How do we reduce packaging costs without sacrificing performance, safety, or brand value?

This article introduces a practical framework used by many global buyers and manufacturers, including our engineering and production teams at DASHAN. Instead of focusing on price per piece alone, we examine materials, design, logistics, and lifecycle economics to cut cost — sustainably and intelligently.

1. Understand Your True Packaging Cost

Most buyers look only at the per-unit price. But true cost includes everything that happens before and after the packaging leaves the factory.

1.1 Direct costs

-

Raw materials

-

Molding, forming, or thermoforming

-

Labor and production overhead

-

Printing, labeling, and finishing

-

Tooling or mold amortization

1.2 Hidden (indirect) costs

-

Freight weight and volume

-

Warehouse storage space

-

Damaged goods, leakage, breakage

-

Returns and refund processing

-

Regulatory non-compliance risks

-

Replacement orders and emergency shipments

A lower unit price can still cost more overall if:

-

more items break,

-

transport volume increases,

-

or the packaging causes food contamination or leakage.

1.3 Shift thinking: cost per unit → cost per use

If a slightly stronger tray reduces returns by 20%, it is cheaper over the long term.

If a better stacking design cuts shipping volume by 25%, the total landed cost drops.

The right benchmark is:

total cost of ownership — not just unit price.

2. Choose the Right Material for the Application

Selecting material is one of the most powerful ways to control cost without compromising quality.

2.1 Avoid “over-engineering”

Sometimes buyers specify:

-

unnecessarily thick walls

-

high heat resistance for cold foods

-

complex multilayers that are difficult to recycle

All of this increases cost without adding value.

2.2 Smart material substitutions

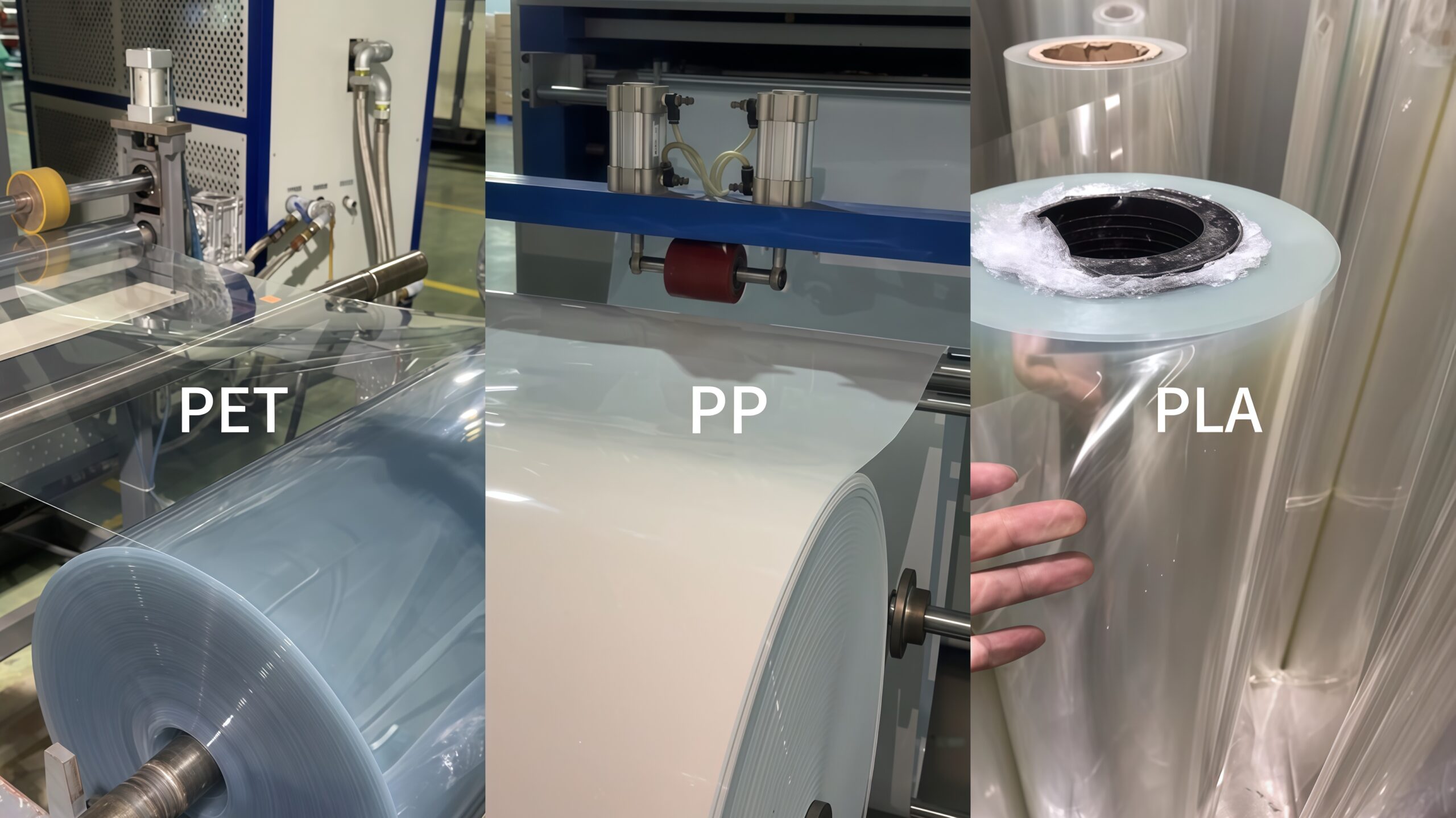

Depending on the product and temperature range, consider:

-

PP (Polypropylene): economical, heat-resistant, flexible.

-

PET / RPET: good clarity for display, rigid, recyclable.

-

Bagasse: strong, compostable under industrial conditions, heat-tolerant.

-

PLA: plant-based for specific compostable programs.

-

CPET: for ovenable and airline meals.

In many applications, switching to the correct technology delivers equal performance at lower cost.

2.3 Evaluate trade-offs carefully

Consider:

-

strength vs. weight

-

clarity vs. sustainability

-

heat resistance vs. price

-

recyclability vs. compostability

At DASHAN, our engineers typically start by understanding the food type, temperature, logistics route, and storage scenario — then recommend the material with the best balance of cost and performance.

3. Optimize Design to Save Cost

Design decisions can reduce cost dramatically while keeping quality stable.

3.1 Lightweighting

Reducing grams without compromising structural integrity saves:

-

resin

-

energy

-

shipping weight

Re-engineering ribs, curves, and stacking height can maintain strength even at lower weight.

3.2 Nesting and stackability

Better nesting means:

-

more units per carton

-

more cartons per pallet

-

lower freight per unit

A 10–30% logistics saving is common.

3.3 Standardize parts where possible

Using common lids, bases, or dimensions:

-

reduces tooling

-

lowers MOQ

-

simplifies inventory management

3.4 Functional enhancements reduce losses

Anti-fog lids, leak-proof seams, and snap-lock closures may cost slightly more — but prevent returns, spills, and food waste.

4. Reduce Waste Across the Supply Chain

Every percentage of scrap or breakage is hidden money lost.

4.1 Production waste

Better mold design, stable processing parameters, and material utilization reduce scrap.

4.2 Packing and boxing compatibility

Matching product dimensions to outer cartons prevents crushing and improves pallet efficiency.

4.3 Pallet optimization

Well-designed pallet layouts reduce:

-

crushed boxes

-

tilt risk

-

transport damage

4.4 Quality control

Routine drop tests, stacking tests, and sealing tests protect your margins.

5. Spend Smart on Printing and Branding

Branding matters — but overspending does not.

5.1 Simplify inks and colors

Reducing colors or eliminating metallic inks saves cost and improves recyclability.

5.2 Use labels instead of full-surface printing

Labels or sleeves are cheaper to adjust than reprinting entire packaging runs.

5.3 Consider embossing or debossing

Logo in tooling instead of ink = strong branding + long-term savings.

5.4 Minimalist design communicates sustainability

Consumers increasingly associate clean, simple packaging with environmental responsibility.

6. Logistics and Inventory Optimization

Packaging that travels better costs less across its lifecycle.

6.1 Flat-pack and nesting advantages

More units per container = lower landed cost.

6.2 Forecasting and MOQ planning

Work with suppliers to plan production and avoid expensive urgent orders.

6.3 Phased shipments

Staggered shipments maintain supply while reducing storage burdens.

6.4 Shared data reduces waste

Collaborative forecasting helps factories prepare materials efficiently.

7. Work With the Right Supplier

Not all factories operate the same way.

7.1 Capabilities and certifications

Look for food-contact compliance, traceability, and material testing.

7.2 Engineering support

Suppliers that co-design and prototype help optimize cost, not just price.

7.3 Transparent pricing

Understand what drives cost:

-

material choice

-

tooling

-

shipping

-

inspection

-

packaging methods

7.4 Co-development mindset

Instead of asking, “Make it cheaper,” ask:

“How can we redesign together to reduce total cost?”

This is the approach our team at DASHAN uses across PET, RPET, CPET, PP, PLA, bagasse, and cornstarch programs — focusing on lifecycle performance rather than shortcuts.

8. Case-Style Examples (Illustrative)

-

Lightweight redesign → 12–18% cost reduction

-

Improved stackability → 20–30% freight savings

-

Better leak control → returns reduced significantly

The lesson: engineering beats cost-cutting.

9. Buyer Checklist: Where to Find Savings

Ask yourself:

-

Is this material over-specified?

-

Can weight be reduced without weakening performance?

-

Are there standardized sizes that fit our needs?

-

Do our products stack efficiently?

-

Are logistics costs higher than they should be?

-

Are we paying for unnecessary printing processes?

-

Do we experience leakage or breakage?

-

Are certifications and testing up to date?

-

Are we forecasting and planning inventory well?

-

Can a supplier help redesign instead of just quoting?

If the answer to any question is unclear, there is probably saving potential.

FAQ

1) Does cheaper packaging always increase risk?

Not always. When cost reductions come from engineering optimization (lightweighting, nesting, standardization), you can save money without performance loss.

2) What is the biggest hidden cost in packaging?

Logistics: freight volume, warehouse space, and breakage-related returns often exceed the unit price impact.

3) Which materials help balance cost and performance?

PP, PET/RPET, bagasse, PLA, and CPET — the right choice depends on heat, clarity, food type, and sustainability goals.

4) Will lightweighting weaken my packaging?

Done improperly, yes. Done correctly with structural reinforcement, it reduces grams while maintaining strength.

5) How can suppliers help reduce cost?

Through redesign, testing, pallet optimization, and part standardization — not only by cutting thickness.

6) Is printing the best place to save money?

Often. Fewer colors, sleeves instead of full prints, or embossing can significantly reduce cost.

Conclusion

Reducing packaging cost does not mean sacrificing quality.

It requires thoughtful engineering, smarter material choices, logistics optimization, and strong supplier collaboration. Companies that treat packaging as a system — not a line item — consistently achieve lower total cost and higher customer satisfaction.

References

https://www.epa.gov/smm/sustainable-management-materials

https://www.oecd.org/environment/plastic-pollution/

https://www.fda.gov/food/packaging-food-contact-substances

https://www.iso.org/standard/76592.html

https://www.wrap.org.uk/resources/guide/packaging-design

Copyright Statement

© 2026 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.