Introduction

Packaging plays a critical role in the food industry, serving more than just a protective function. The right packaging material not only ensures the food’s safety and preservation but also enhances brand image, supports sustainability goals, and meets regulatory standards. In this article, we will discuss how to select the most suitable packaging materials for food, based on factors such as food characteristics, material properties, cost-efficiency, sustainability, and consumer preferences.

1. Understanding the Characteristics of the Food

The first step in selecting packaging materials is understanding the specific needs of the food product itself. Each type of food has unique characteristics that influence its ideal packaging.

Temperature Sensitivity

Different foods have varying temperature requirements. For example:

-

Hot Foods: Foods like ready meals or hot soups require packaging materials that can withstand high temperatures. CPET (Crystallized PET) is an excellent choice for this purpose because it can be heated safely in the microwave or oven.

-

Cold Foods: Items such as salads or fresh fruits need to be stored in materials that maintain their freshness without reacting to temperature changes. PET is commonly used here due to its high clarity and strong barrier properties, which keep products fresh longer.

-

Frozen Foods: Foods that need freezing, such as frozen vegetables or meats, require packaging materials with a low-temperature tolerance. PP (Polypropylene) and CPET are ideal for these applications.

Moisture Requirements

Certain foods, such as fresh vegetables or baked goods, need to be kept dry to avoid spoilage. Conversely, wet products like meats or fish require moisture-resistant packaging.

-

Permeable Packaging: Packaging materials like PET or PLA (Polylactic Acid) can provide controlled humidity levels. PP is also commonly used for moisture protection, particularly in food trays and containers.

Weight and Shape

The weight and shape of food products impact the strength and design of packaging. Heavier items, such as large meats or multiple-serving meals, require sturdier materials. For instance, CPET trays are commonly used for heavier meals, while lighter snacks can be packaged in PLA or PP containers.

Odor and Freshness Preservation

Some foods, such as meats or dairy, are sensitive to air and oxygen, and require airtight packaging to preserve their flavor and shelf life.

-

Modified Atmosphere Packaging (MAP): This technology uses barrier films or containers to extend shelf life by reducing oxygen and moisture levels. It is ideal for products like meats, cheeses, and fresh produce.

2. Types of Packaging Materials and Their Characteristics

Choosing the right material depends on its properties, such as durability, transparency, and sustainability.

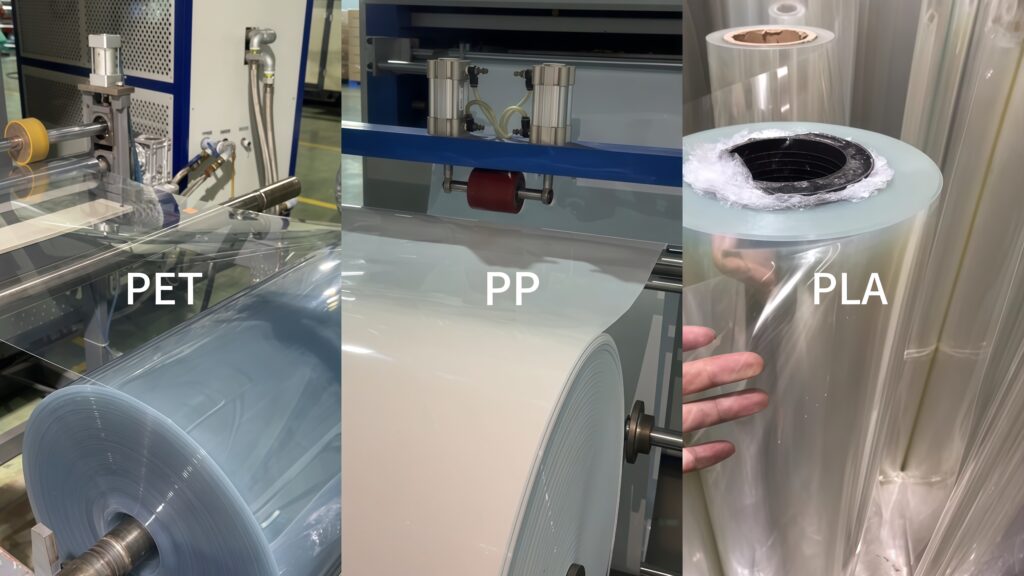

PET (Polyethylene Terephthalate)

-

Pros: High clarity, strong barrier properties, lightweight, and widely recyclable. Ideal for beverages, fruits, and salads.

-

Cons: Low heat tolerance, unsuitable for high-temperature applications.

PLA (Polylactic Acid)

-

Pros: Biodegradable, made from renewable resources like corn starch or sugarcane, suitable for eco-friendly products, and commonly used for cold food and drink packaging.

-

Cons: Not heat-resistant and easily affected by humidity, limiting its use to low-temperature products.

CPET (Crystallized Polyethylene Terephthalate)

-

Pros: Heat-resistant, suitable for microwave and oven use, widely used for ready-to-eat meals and baked foods.

-

Cons: Less transparent compared to PET, and its recyclability can be challenging.

PP (Polypropylene)

-

Pros: Strong, heat-resistant, and moisture-resistant. Commonly used in containers for microwaving and for freezer-safe applications.

-

Cons: Less transparent than PET, which may not be suitable for premium products requiring a clear display.

Paper-Based Materials (e.g., Sugarcane Bagasse, Cornstarch)

-

Pros: Eco-friendly, biodegradable, and compostable. Often used for single-use items like food containers, plates, and cutlery.

-

Cons: Relatively weaker than plastic, not suitable for moist or liquid foods.

3. Cost-Efficiency Analysis

When selecting packaging, cost is always a significant factor. The overall cost includes the raw material cost, production cost, and transportation cost.

Raw Material Costs

-

PET and PP tend to be more affordable than biodegradable materials like PLA and paper-based materials. However, costs can vary depending on local markets and availability.

-

PLA materials are more expensive due to their production from renewable sources, which may increase costs for companies that prioritize cost savings.

Production and Transport Costs

-

Packaging design complexity, material weight, and packaging size affect production and transport costs. For instance, lightweight PLA packaging can help reduce shipping costs.

-

PET packaging, while affordable, can sometimes increase transportation costs due to its bulkier design.

Recycling and Environmental Costs

-

Recyclable Materials: Choosing recyclable materials, like PET and PP, can reduce waste disposal costs. Many markets offer incentives for businesses that use recyclable packaging.

-

Biodegradable Materials: Although PLA and paper-based options are more expensive upfront, they are often preferred in markets with strong environmental regulations and consumer demand for sustainable options.

4. Sustainability and Environmental Impact

As consumers increasingly demand environmentally friendly products, sustainability is becoming a key factor in packaging material selection.

Recyclability

-

PET and PP are highly recyclable and support a circular economy by being reused in new products.

-

PLA, while biodegradable, is not always accepted in traditional recycling systems, which can limit its overall environmental benefits.

Biodegradability

-

PLA and paper-based packaging (like sugarcane bagasse) are biodegradable and compostable, making them ideal for eco-conscious brands.

-

PET and PP take longer to break down and can accumulate in landfills if not properly recycled.

Certifications and Standards

-

Packaging materials should comply with local environmental certifications, such as BPI (Biodegradable Products Institute) for compostable packaging or FSC (Forest Stewardship Council) for paper-based materials.

5. Consumer Preferences and Branding

Consumer preferences for packaging can significantly influence purchasing decisions. Transparent, visually appealing packaging is more likely to attract attention in the marketplace.

Transparency and Aesthetics

-

PET provides excellent clarity and allows consumers to see the product clearly, making it a popular choice for beverages and fresh foods.

-

PLA is often transparent but lacks the same visual appeal as PET due to its matte finish.

Convenience and Functionality

-

Easy-to-open packaging and resealable options enhance the consumer experience. PP containers, for example, offer airtight seals that keep food fresh, while PLA may not offer the same level of protection.

Eco-Conscious Branding

-

Brands with a focus on sustainability should prioritize PLA, paper-based, or other biodegradable packaging to align with their environmental values. These materials appeal to consumers who value sustainability and eco-consciousness.

6. Regulatory and Market Requirements

Packaging materials must comply with food safety regulations, which vary by region and market.

International and Regional Standards

-

FDA in the U.S., EFSA in Europe, and other regulatory bodies require food packaging materials to meet specific safety standards. This includes testing for chemical leaching, migration, and overall food safety.

-

Certain regions have strict guidelines on the use of non-recyclable plastics, pushing manufacturers toward more sustainable options.

Market Preferences

-

Some markets, like Europe, have stringent requirements for recyclable or biodegradable packaging, whereas others, like the U.S., may prioritize functionality and convenience over environmental factors.

Conclusion

Selecting the right packaging material for food is a multifaceted decision that requires careful consideration of food characteristics, material properties, cost, sustainability, and consumer preferences. By balancing these factors, food manufacturers can choose packaging that ensures product safety, appeals to consumers, supports brand values, and meets regulatory standards. As the packaging industry evolves, staying ahead of trends in sustainability and material innovation will be crucial for long-term success.

FAQ

-

Does packaging material affect the shelf life of food?

-

Yes, packaging materials significantly impact the shelf life. For example, Modified Atmosphere Packaging (MAP) helps extend shelf life by reducing oxygen levels.

-

-

What types of food are best suited for PLA packaging?

-

PLA packaging is ideal for cold foods and beverages but should not be used for hot or high-temperature foods.

-

-

How do I know if a packaging material is environmentally friendly?

-

Look for certifications such as BPI, FSC, or compostability labels to confirm that the material is biodegradable or recyclable.

-

-

Why is transparency important in food packaging?

-

Transparency enhances product appeal by allowing consumers to see the quality of the food inside, which is crucial for products like fresh produce or beverages.

-

-

Can biodegradable packaging materials be recycled?

-

Some biodegradable materials, like PLA, are not accepted in conventional recycling systems and should be composted instead.

-

References

-

Smith, J. (2021). Food Packaging Trends and Innovations: A Comprehensive Overview. Journal of Food Packaging Technology, 45(3), 102-115.

Available at: www.foodpackagingjournal.com -

Jones, A., & Williams, P. (2020). Sustainable Packaging Materials: Impact on Consumer Behavior and Environmental Practices. Packaging Science and Technology, 36(4), 78-90.

Available at: www.packagingresearch.org -

Liu, Y., & Zhang, H. (2019). Biodegradable and Eco-Friendly Packaging: The Future of Sustainable Food Packaging. International Journal of Environmental Science and Technology, 56(2), 45-59.

DOI: 10.1007/s12345-019-01004-1 -

European Commission. (2018). Circular Economy Action Plan: For a Cleaner and More Competitive Europe. Brussels: European Commission.

Available at: www.ec.europa.eu

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.