Quick Summary

Dubai’s comprehensive ban on single-use plastics, effective January 1, 2026, prohibits plastic cutlery, plates, cups, lids, and disposable food containers across import, manufacturing, and local trade. To comply and remain competitive, businesses must transition to sustainable alternatives such as bagasse, corn starch materials, PLA, RPET, CPET, and PP. Understanding the performance, compliance, and real-world application of each material helps brands and buyers choose packaging that meets regulatory requirements while supporting operational needs. Partnering with experienced suppliers ensures supply stability, certification support, and material selection tailored to your product formats.

Dubai’s full ban on single-use plastics, taking effect on January 1, 2026, is reshaping how brands, importers, and foodservice operators select packaging. This initiative is not merely a symbolic environmental move. It is a structural regulatory change that touches procurement strategy, product design, compliance documentation, logistics, and customer expectations across the entire value chain.

Businesses supplying food packaging into Dubai must rethink their material portfolio — replacing conventional disposable plastics with alternatives that are both compliant and operationally viable. The ability to make the right material choices today will determine whether companies can operate seamlessly in the market tomorrow.

This article provides a practical, business-focused guide to navigating the transition: what is banned, why the regulation matters, what alternative materials actually work, and how suppliers such as DASHAN help importers and brands implement change with minimal disruption.

1. Understanding Dubai’s 2026 Single-Use Plastic Ban

The 2026 phase targets some of the most widely used disposable food-contact articles. The restriction applies to items that are typically used once and discarded, especially those made from conventional fossil-based plastics.

Covered categories include:

-

plastic knives, forks, spoons, and chopsticks

-

plastic plates, dishes, and small tableware

-

plastic beverage cups and plastic lids

-

takeaway food containers made of traditional single-use plastics

This restriction applies across:

-

import activities

-

local manufacturing

-

wholesale trade and retail

-

foodservice operations such as restaurants, catering companies, cafés, and delivery operators

If a product is intended to circulate within Dubai’s market, it must be aligned with the policy.

What happens if companies do not transition

Organizations that rely on prohibited materials may face:

-

shipment delays or returns at customs

-

financial penalties and compliance notices

-

temporary business interruptions

-

forced replacement programs that increase procurement costs

-

reputational risk with customers and government agencies

Therefore, transitioning early is not simply “good practice” — it is risk management and market protection.

2. Why Dubai Is Eliminating Single-Use Plastics

Dubai’s initiative is rooted in long-term environmental and economic policy priorities.

Key strategic motivations include:

-

Reducing persistent plastic waste

Many disposable plastics break down slowly and accumulate in land and marine environments. -

Supporting circular economy objectives

The ban encourages reusable, recyclable, or compostable systems rather than one-way disposal models. -

Enhancing resource efficiency

Materials derived from renewable or recyclable sources reduce dependence on virgin fossil inputs. -

Strengthening global sustainability positioning

Dubai is positioning itself as a leader among regions that are actively moving away from single-use plastics.

For businesses, this means the transition is structural and permanent — not temporary and not optional.

3. How Businesses Should Evaluate Replacement Materials

Choosing “anything labeled eco-friendly” is not sufficient. A rational framework is required to balance compliance, performance, and cost.

A. Regulatory compliance

-

Does the material fall outside restricted categories?

-

Does it comply with food-contact and hygiene regulations?

-

Can the supplier provide supporting technical documentation?

B. Performance in real operating conditions

-

resistance to heat, moisture, and grease

-

rigidity and impact resistance during transport

-

suitability for microwave, oven, or freezing environments

-

stackability and storage efficiency

C. End-of-life profile

-

recyclable, compostable, or biodegradable pathways

-

realistic infrastructure availability in the region

-

accurate labeling that avoids misleading claims

D. Cost and supply reliability

-

stable procurement channels

-

predictable lead times

-

scalable production capacity

Businesses that evaluate alternatives across all four factors are more likely to build packaging systems that are both compliant and sustainable.

4. Sustainable Material Options That Work in Dubai

Several categories of alternative materials are emerging as practical, scalable replacements for single-use plastics. Each has unique strengths and limitations; therefore, the right choice depends on application scenarios.

Bagasse (Sugarcane Pulp)

Bagasse is produced from sugarcane fibers left after juice extraction. It is molded into rigid packaging formats and has become one of the most widely adopted eco-friendly materials.

Advantages

-

renewable agricultural by-product

-

excellent rigidity and structural stability

-

strong heat tolerance suitable for hot meals

-

natural fiber appearance that communicates sustainability

Typical uses

-

clamshell boxes

-

plates and bowls

-

trays for takeaway meals

Bagasse serves as a near one-to-one replacement for many plastic plates and containers, especially in foodservice applications.

Corn Starch Materials

Corn starch–based materials create bioplastic formulations that resemble traditional plastic, but utilize plant-derived feedstocks.

Advantages

-

plant-based raw material origin

-

relatively lightweight

-

formable into cutlery and smaller containers

Considerations

-

lower heat resistance than bagasse or PP

-

best suited to low-temperature or short-term applications

They are ideal when customers require an alternative to plastic utensils or lightweight trays.

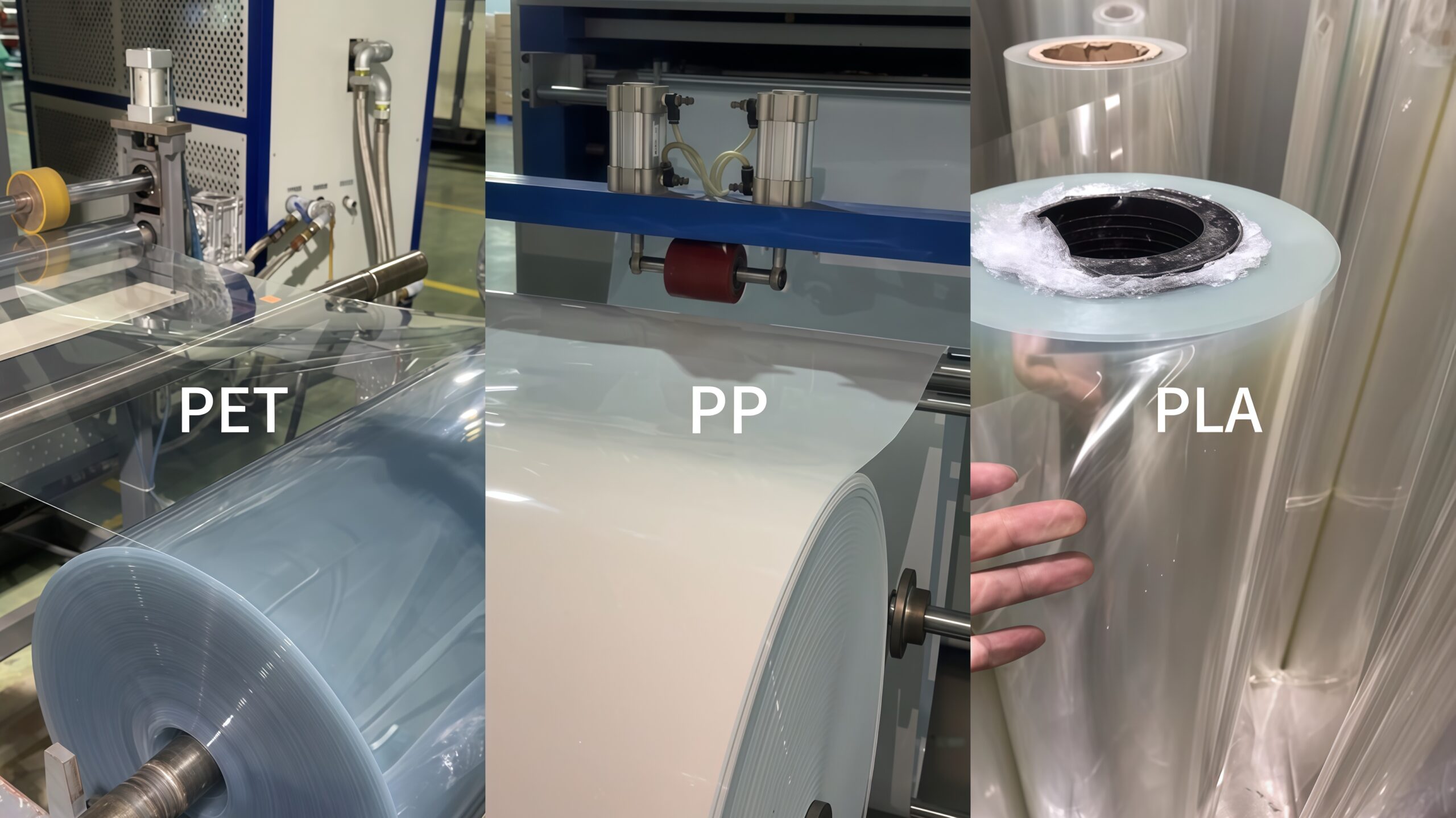

PLA (Polylactic Acid)

PLA is derived from fermented plant sugars and is widely used in cold-food packaging.

Advantages

-

smooth, high-quality appearance

-

good clarity for product display

-

plant-origin material perception

Limitations

-

limited thermal resistance

-

primarily suitable for cold applications

PLA is commonly used for cups, salad containers, lids, and bakery packaging.

RPET (Recycled PET)

RPET is produced from post-consumer PET recycling streams.

Advantages

-

maintains transparency and rigidity

-

encourages circular resource loops

-

familiar to manufacturers and consumers

Use cases

-

clear clamshells

-

cold-food containers

-

bakery, fruit, and salad packs

RPET is suitable when visibility is essential yet sustainability messaging must be preserved.

CPET (Crystallized PET)

CPET is engineered to withstand heat.

Advantages

-

compatible with microwave and oven reheating

-

retains shape at elevated temperatures

-

strong and durable for prepared meals

Common applications

-

airline meal trays

-

ready-to-heat containers

-

catering trays

It offers high functionality where performance and safety are critical.

PP (Polypropylene)

PP remains one of the most versatile recyclable plastics when designed responsibly.

Advantages

-

heat-resistant

-

microwave-safe in many formats

-

robust mechanical strength

Key management principle

PP should be implemented in systems that encourage reuse and recycling, rather than short-term disposal.

5. Selecting Materials by Application Scenario

A practical decision framework matches each material to its most suitable use case:

Hot meals, oily foods, and main courses

Bagasse, CPET, PP

Cold foods, salads, bakery, desserts

PLA, RPET

Utensils and accessories

Corn starch-based cutlery, bagasse cutlery

Ready-to-heat or prepared meals

CPET, PP

In many operations, the best strategy is not to select one material for everything, but to deploy a portfolio aligned to each functional requirement.

6. Implementation Challenges — and How to Manage Them

Businesses often experience several issues when transitioning away from single-use plastics:

1) Cost sensitivity

Some sustainable materials appear more expensive per unit. However, savings can be realized through optimized design, reduced material thickness, and improved logistics planning.

2) Misleading environmental claims

Certain suppliers exaggerate “biodegradable” or “compostable” claims. Buyers must request technical documentation and clear labeling guidance.

3) Operational adaptation

Packaging changes may require staff training, revised storage practices, or switching to different lid and container combinations.

A structured transition plan minimizes these risks.

7. How DASHAN Helps Buyers Navigate Dubai’s Transition

DASHAN supports customers through a comprehensive, consultative approach.

Product portfolio

Service capabilities

-

specification recommendations based on menu types and temperatures

-

documentation to support compliance and product qualification

-

customization and branding options

-

export logistics, packing optimization, and stable supply planning

Rather than simply supplying products, DASHAN works with customers to design packaging systems that are sustainable, practical, and aligned with Dubai’s evolving regulations.

8. Key Takeaways for Decision-Makers

-

Dubai’s 2026 regulation marks a permanent structural change in packaging markets.

-

Businesses must evaluate alternatives with respect to compliance, performance, environmental impact, and cost.

-

No single material solves every problem — portfolios built around application scenarios perform best.

-

Transitioning early reduces risk, avoids supply disruption, and positions brands as sustainability leaders.

Moving from conventional plastics to sustainable materials is not just regulatory compliance. It is an opportunity to modernize procurement strategy, enhance brand credibility, and build a future-ready supply chain.

FAQ

Q1: What products are banned in Dubai from January 1, 2026?

A: The ban covers plastic cutlery (spoons, forks, knives, chopsticks), plastic plates and dishes, plastic cups and lids, and single-use plastic food containers across import, manufacture, and local trading activities.

Q2: Why is Dubai banning single-use plastics?

A: The ban supports environmental protection, reduction of persistent waste, and the promotion of circular economy principles. It aligns the market with regional sustainability goals and global expectations.

Q3: Are materials like PLA and corn starch truly compliant with the ban?

A: Yes, plant-based materials such as PLA and corn starch can be compliant alternatives when properly certified and matched to application needs. Buyers should verify performance and certification.

Q4: How do materials like RPET and CPET fit into sustainable packaging strategies?

A: RPET supports circular recycling systems and is ideal for transparent cold-food packaging. CPET offers high heat resistance and is suitable for ready-to-heat meals, aligning with compliance and performance criteria.

Q5: What should buyers consider when choosing packaging for Dubai’s market?

A: Evaluate regulatory fit, performance under real-use conditions (heat, moisture, structural strength), sustainability credibility (recyclability or compostability), and supply reliability.

Q6: Will branding or custom printing still be possible with sustainable packaging?

A: Yes — many sustainable alternatives support custom branding and printing, enabling businesses to maintain brand aesthetics while complying with regulations.

Q7: Is switching to sustainable packaging more expensive?

A: Material cost varies, but total cost should consider logistics efficiency, reduced waste, and brand value. Early transition planning often reduces overall expense compared to last-minute sourcing.

Conclusion

Dubai’s 2026 ban marks a decisive shift away from single-use plastics. To stay compliant and competitive, businesses need to transition early to proven, scalable materials such as bagasse, PLA, corn starch, RPET, CPET, and PP — selecting each material based on real application needs. The companies that plan ahead, validate certifications, and work with experienced suppliers will reduce risk, protect brand reputation, and align with the region’s sustainability expectations.

References

-

Dubai Municipality — awareness and guidance on single-use plastics regulation

https://www.dm.gov.ae/2025/12/24/dubai-to-enforce-final-phase-of-single-use-plastic-ban-from-2026/ -

Government announcements on the final phase of single-use plastic ban effective 2026

-

Environmental policy coverage on UAE plastic restriction implementation

-

Industry analysis on sustainable packaging adoption in regulated markets

Copyright Statement

© 2026 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.