Quick Summary

The CT-1610H35-1C CPET airline meal tray is a compact, oven-safe, and freezer-ready food container designed for inflight catering, frozen meal production, and high-volume foodservice systems. With its 160 × 105 × 35 mm size, lightweight 14.5 g structure, and durable single-compartment design, it provides excellent heat resistance, long-term cold-storage stability, strong sealing compatibility, and premium presentation for small entrées, sides, desserts, and pre-portioned meals.

Introduction

In modern airline catering, efficiency, consistency, and food safety are essential to ensuring high-quality inflight service. Airlines rely on packaging that can maintain food quality throughout an intensive operational cycle—from industrial cooking and rapid chilling to frozen storage, reheating, and final delivery onboard. Small-format meal components such as sides, appetizers, bread, desserts, and child-meal portions require containers that deliver excellent thermal performance, food protection, and compact storage efficiency.

The CT-1610H35-1C CPET tray is specifically designed for these requirements. Its compact footprint of 160 × 105 × 35 mm fits seamlessly into airline service trays, galley trolleys, and multi-dish meal layouts. Despite its small size, the tray offers exceptional durability, structural rigidity, and thermal stability. Weighing only 14.5 g, it reduces overall catering weight, contributing to fuel-efficiency goals without compromising strength or safety.

Constructed from CPET (Crystallized Polyethylene Terephthalate)—one of the most reliable materials for ready-meal applications—the tray delivers proven performance in extreme temperature environments, making it ideal not only for airlines but also for frozen meal manufacturers, institutional kitchens, railway catering, and central kitchens worldwide.

Technical Specifications

Model: CT-1610H35-1C

Material: CPET

Structure: Single compartment

Size: 160 × 105 × 35 mm

Weight: 14.5 g

Capacity: 350 ml

Temperature Resistance: −40°C to +220°C

Color Options: Black / White

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

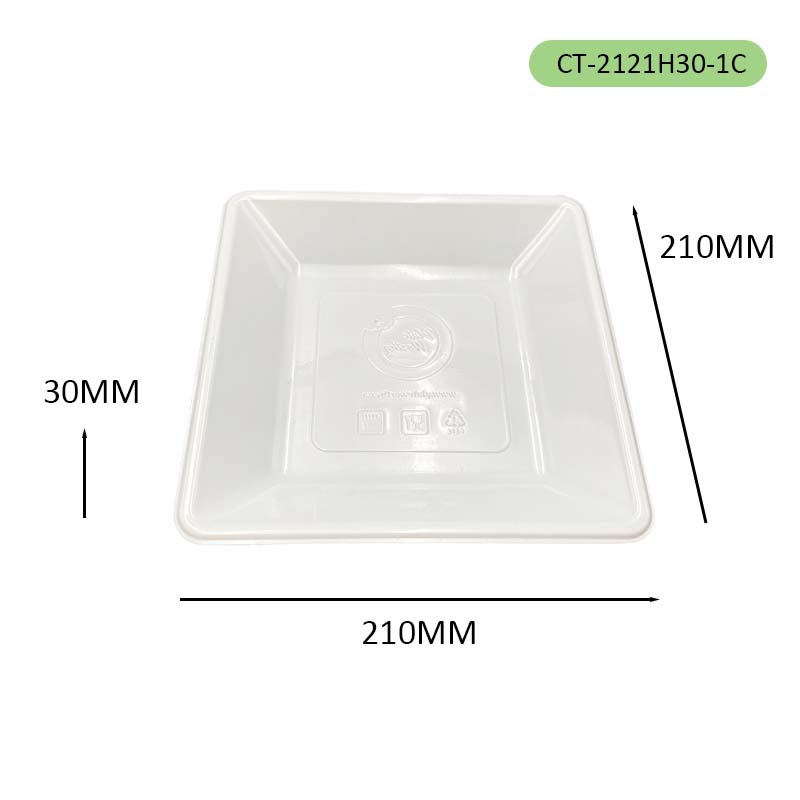

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

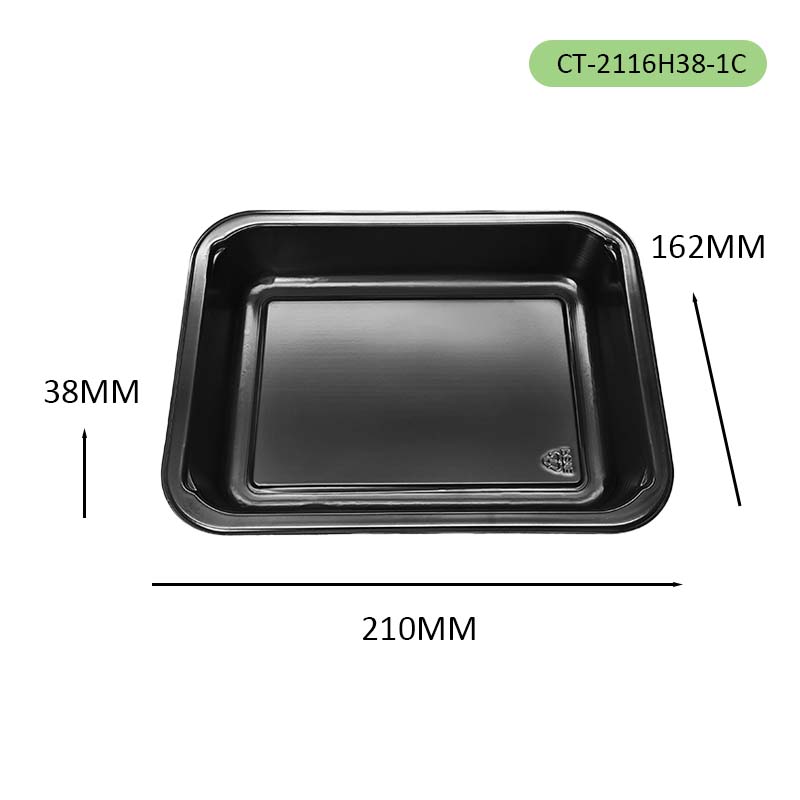

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

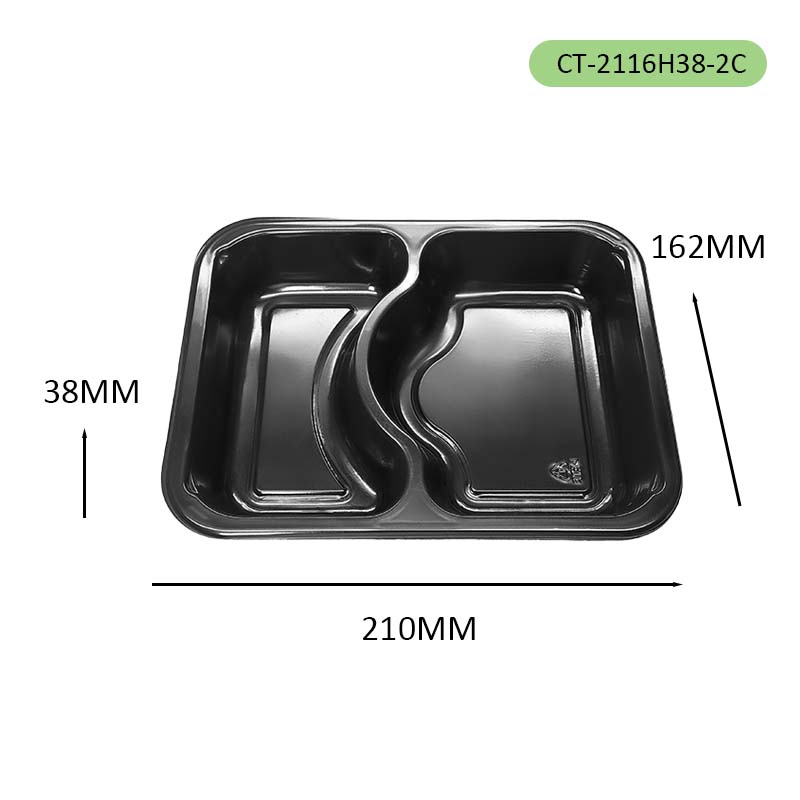

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

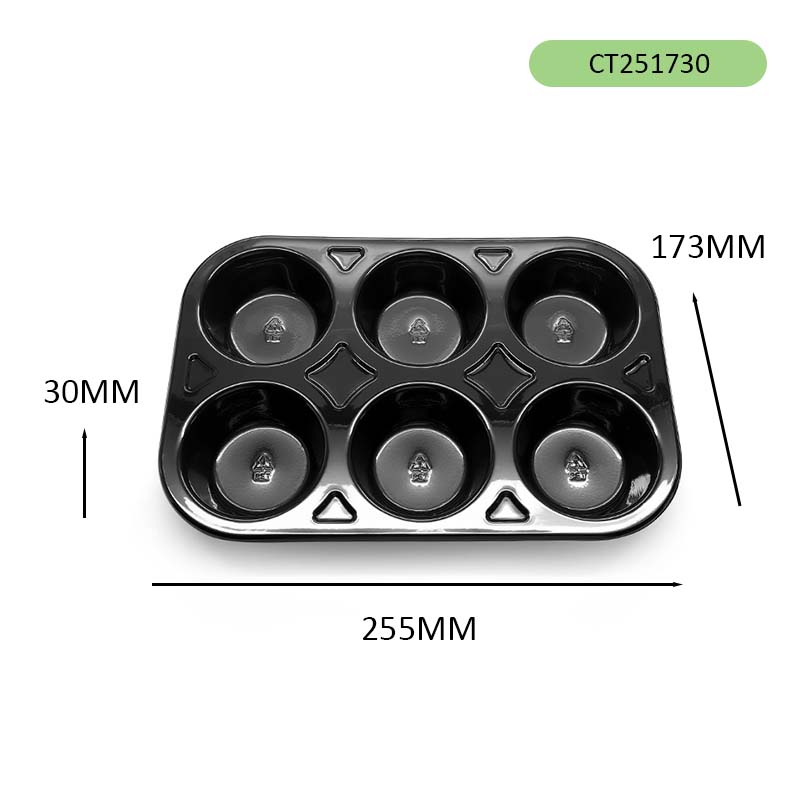

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Outstanding Temperature Performance

The CT-1610H35-1C tray delivers the same high-level thermal stability seen in larger CPET trays. It performs reliably across the full temperature spectrum of foodservice operations:

-

Industrial cooking and baking

-

Rapid chilling or quick-freeze processing

-

Cold-chain storage

-

Long-distance catering logistics

-

Reheating in convection or steam ovens

-

Final inflight presentation

With a resistance range from −40°C to +220°C, the tray transitions smoothly from freezer to oven without warping, cracking, or releasing odors.

Even though small trays often face structural stress during rapid temperature changes, CPET’s semi-crystalline structure maintains rigidity and ensures meals remain visually appealing after reheating. Its oven-safe and microwave-safe performance makes it universally compatible with global airline catering equipment.

Food Safety and Material Integrity

The CT-1610H35-1C is manufactured from high-grade, food-safe CPET resin that meets international food-contact standards. It is:

-

BPA-free

-

Odorless and non-toxic

-

Chemically stable under high heat

-

Resistant to oils, acids, tomato-based sauces, and spices

Its smooth interior surface prevents staining and flavor migration, ensuring meals taste fresh and retain their intended aroma. Since small meal portions often contain desserts, fruit, side vegetables, bread, or sauces, material stability is crucial for preserving quality.

CPET’s superior strength also prevents deformation—an important factor when trays are stacked densely inside airline trolleys, cold rooms, or freezer racks.

High Barrier Performance for Longer Shelf Life

Strong barrier properties are essential for pre-prepared airline meals or frozen entrées that may remain in storage for days or weeks. The CT-1610H35-1C provides excellent resistance to:

-

Oxygen penetration

-

Moisture

-

External contaminants

-

Temperature-related degradation

The tray is fully compatible with:

-

Standard heat-seal films

-

Aluminum foil lids

-

Rigid CPET lids

-

MAP (Modified Atmosphere Packaging) systems

These sealing options are essential for preventing leaks, extending shelf life, and preserving both taste and aroma during storage and transport.

Designed for Airline Catering Operations

Every aspect of the CT-1610H35-1C tray is engineered to integrate seamlessly with global airline catering systems.

Key operational advantages:

1. Perfect fit for automated sealing lines

Its dimensions are optimized for stable sealing performance, reducing sealing defects and improving efficiency in high-volume assembly lines.

2. Strong rigidity for stacking and transport

The compact shape and durable CPET walls withstand stacking pressure inside meal carts and freezer units.

3. Leak-resistant design for sauces and moist foods

The tray maintains its shape even under heat, preventing spills during reheating or vibration during flight.

4. Lightweight design for cost and fuel savings

At 14.5 g, it supports airline sustainability initiatives by reducing total catering weight.

Enhanced Food Presentation

Even in small portions, presentation is critical for passenger satisfaction. The CT-1610H35-1C enhances visual appeal through:

-

A clean, premium surface finish

-

Stable shape after reheating

-

Uniform heat distribution

-

Availability in black or white for branding consistency

This tray is ideal for:

-

Side dishes

-

Bread and pastry portions

-

Desserts

-

Children’s meals

-

Appetizers

-

Fruit portions

-

Small hot meals

Its compact, elegant design enhances inflight dining while supporting efficient compartmentalized meal layouts.

Applications Across Multiple Foodservice Industries

Although originally designed for airlines, the CT-1610H35-1C is widely used in various industries:

1. Railway Catering

Ideal for side dishes or compact entrées requiring reheating while resisting vibration during travel.

2. Frozen Ready Meals

Supports long-term cold-storage stability without losing shape.

3. Central Kitchens & Institutional Meal Programs

Used in schools, hospitals, military facilities, and corporate canteens.

4. Cruise Lines & Marine Catering

Functions well in environments where frozen-to-oven meal cycles are common.

Customization Options

The CT-1610H35-1C supports a wide range of customization possibilities:

-

Embossed airline or brand logos

-

Custom colors

-

Tailored sealing films

-

Customized carton packaging for automated production lines

This allows the tray to meet diverse branding and operational needs across global foodservice markets.

Why CPET Is the Ideal Material for Airline Meal Trays

Compared with PP, PS, and aluminum, CPET offers:

✔ Heat resistance up to 220°C

✔ Excellent freezer stability

✔ Strong rigidity for stacking

✔ Compatibility with MAP sealing

✔ Premium appearance after reheating

✔ Recyclability in many regions

✔ Full compliance with global food-contact standards

For airlines and ready-meal producers, CPET provides unmatched reliability and performance.

FAQ

1. Is the CT-1610H35-1C tray oven-safe?

Yes, it is oven-safe up to 220°C and can be used in convection or steam ovens.

2. Is it suitable for frozen storage?

Absolutely. It performs reliably down to −40°C, making it ideal for frozen meals.

3. What sealing options does it support?

Heat-seal film, aluminum lids, and CPET lids.

4. Is the tray recyclable?

Yes, CPET is recyclable in many PET-accepted recycling systems.

5. Which industries most commonly use this tray?

Airlines, railway services, frozen meal factories, hospitals, cruise lines, and central kitchens.

Conclusion

The CT-1610H35-1C CPET airline meal tray is a high-performance packaging solution designed for small-portion meals in modern airline catering and industrial foodservice operations. With its exceptional heat resistance, food-safe material composition, strong sealing compatibility, and compact design, it ensures meals remain visually appealing, safe, and delicious throughout the entire preparation-to-service cycle. Lightweight, efficient, and durable, it is an ideal choice for airlines and ready-meal producers seeking professional, reliable, and thermally versatile packaging.