1. Introduction

The global push for sustainability in the packaging industry has led to an increased use of recycled materials in food packaging. Polyethylene terephthalate (PET) is one of the most commonly used materials for food packaging due to its strength, transparency, and recyclability. However, with rising concerns over plastic pollution and resource conservation, the packaging sector has also seen a significant shift towards the use of recycled PET (rPET). This trend aligns with the growing demand for eco-friendly packaging solutions that are both functional and safe for consumers.

PET is widely used in a variety of applications, from beverage bottles to trays and food containers. However, the inclusion of rPET in food packaging raises concerns regarding the potential migration of chemical contaminants into food products. In response, this article examines the risks associated with rPET in food packaging, focusing on the migration of chemicals, the application of functional barriers in packaging, and the role of ABA (A/B/A) technology in mitigating these risks. Additionally, the article will explore how Dashan’s PET products contribute to sustainable and safe food packaging solutions.

2. Migration Risks and the Safety of rPET in Food Packaging

A critical issue when incorporating rPET into food packaging is the potential for chemical migration from the recycled material into the food. Migration modeling is an essential tool to predict the transfer of contaminants, including hazardous substances such as solvents, plasticizers, and other chemicals, which may leach from the packaging into food. The study Assessment of chemical risks and circular economy implications of recycled PET in food packaging with functional barriers provides significant insight into how these chemicals migrate from non-decontaminated rPET when used in food-contact applications.

Table 1: Migration Modeling of Contaminants in rPET

| Contaminant | Molecular Weight (g/mol) | Toxicological Alert | Specific Migration Limit (mg/kg) | Maximum Migration Level in Food (mg/kg) |

|---|---|---|---|---|

| Acetaldehyde | 44 | None | 6 | 0.15 |

| Toluene | 92 | DNA binding alert | 6 | 0.15 |

| Chlorobenzene | 113 | DNA binding alert | 0.6 | 0.02 |

| Chloroform | 120 | None | 1.5 | 0.05 |

| Limonene | 136 | None | 30 | 0.45 |

| Methyl salicylate | 152 | None | 30 | 0.45 |

| Phenyl cyclohexane | 160 | DNA binding alert | 0.6 | 0.02 |

| Benzophenone | 182 | DNA binding alert | 0.6 | 0.02 |

| Lindane | 291 | DNA binding alert | 0.0025 | 0.000075 |

| Methyl stearate | 298 | None | 60 | 0.90 |

In the migration modeling conducted in the study, various chemicals were tested to evaluate their likelihood of migrating into food from rPET-based trays. The contaminants with lower migration limits, such as acetaldehyde and toluene, pose a higher risk, and strict monitoring is required to prevent these substances from exceeding safe levels.

3. ABA Technology: Barrier Layers and Food Safety

To mitigate the risks associated with the migration of contaminants from recycled PET, ABA technology has been developed. ABA technology involves the use of a multi-layered packaging structure, where a recycled PET (rPET) layer is sandwiched between two virgin PET layers. The virgin layers act as functional barriers, reducing the likelihood that contaminants from the rPET layer will migrate into the food. This innovation provides an added layer of safety, especially when using rPET that has not been fully decontaminated.

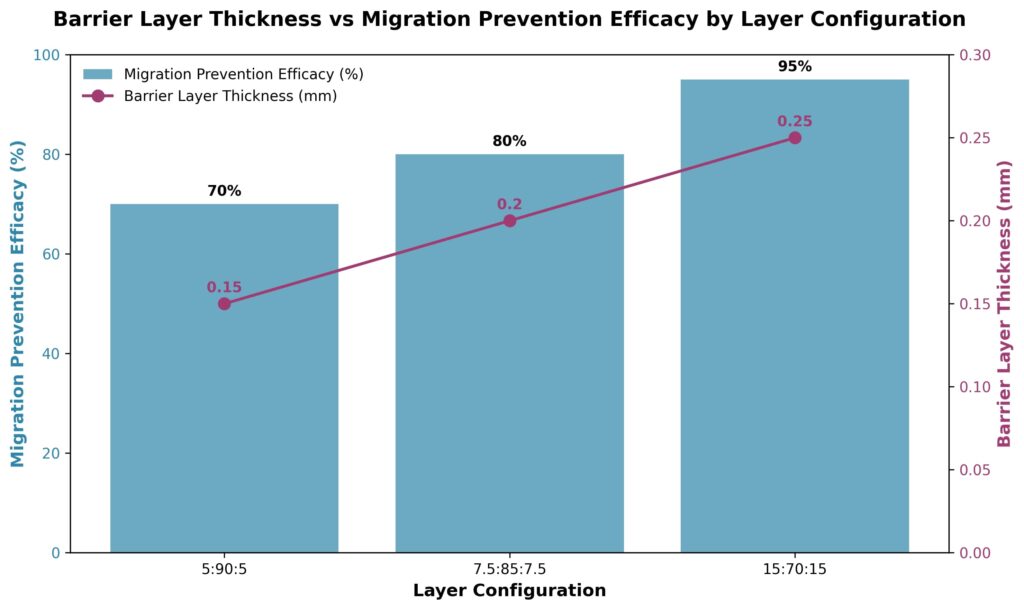

While ABA technology is effective in reducing chemical migration, the thickness of the barrier layer plays a significant role in its efficiency. The study highlights that thicker virgin PET layers provide better protection against migration, and the design of packaging structures should take this into consideration.

Table 2: Thickness of Barrier Layers and Migration Prevention

| Layer Configuration | Barrier Layer Thickness (mm) | Migration Prevention Efficacy (%) |

|---|---|---|

| 5:90:5 | 0.15 | 70 |

| 7.5:85:7.5 | 0.20 | 80 |

| 15:70:15 | 0.25 | 95 |

The data from the study indicates that increasing the thickness of the virgin barrier layer significantly enhances its ability to prevent the migration of contaminants from the rPET layer. This finding underscores the importance of optimizing the barrier properties of packaging materials in order to ensure consumer safety.

4. Circular Economy Implications of rPET

The shift toward using rPET in food packaging is part of a broader movement toward a circular economy, where materials are reused, recycled, and repurposed to reduce waste and conserve resources. However, while the environmental benefits of using rPET are clear, the challenges associated with its recycling are significant. The study discusses the potential for chemical contamination in rPET during the recycling process, especially in cases where sorting and decontamination processes are not sufficiently rigorous.

Table 3: rPET Recycling Streams and Contamination Levels

| Recycling Stream | Contamination Level (%) | Feedstock Origin | Average Decontamination Rate (%) |

|---|---|---|---|

| Historical rPET | 10 | Post-consumer packaging | 50 |

| First Extension rPET | 5 | Household plastic and bottles | 60 |

| Second Extension rPET | 2 | Sorted PET bottles only | 80 |

The table above demonstrates that with improved sorting and decontamination practices, contamination levels in rPET can be reduced, resulting in a safer product for food contact. Dashan follows best practices in sourcing rPET from high-quality, well-sorted streams to minimize contamination.

5. Advanced Chemical Analysis and Monitoring

Advanced chemical analysis methods are essential for monitoring the safety of rPET used in food packaging. These methods include gas chromatography (GC), high-performance liquid chromatography (HPLC), and mass spectrometry (MS), which are used to detect trace levels of contaminants in rPET. The study emphasizes the need for ongoing monitoring and testing to ensure that rPET meets safety standards for food contact.

Table 4: Chemical Analysis Methods for rPET Safety

| Analysis Method | Description | Detection Limit (mg/kg) | Purpose |

|---|---|---|---|

| Gas Chromatography (GC) | Identifies volatile organic compounds | 0.01 | Detects residual chemicals from prior use |

| High-Performance Liquid Chromatography (HPLC) | Detects non-volatile compounds like plasticizers and stabilizers | 0.05 | Assesses migration of plastic additives |

| Mass Spectrometry (MS) | Detects trace contaminants like pesticides and inks | 0.005 | Identifies potentially harmful residues |

Dashan’s rPET products are rigorously tested using these advanced techniques, ensuring that all potential contaminants are identified and migration levels remain within safe limits as defined by regulatory bodies.

6. Recommendations for Enhancing rPET Recycling Practices

The study offers several key recommendations to improve the safety and quality of rPET used in food packaging:

-

Improved Sorting: Increasing the effectiveness of sorting practices to ensure that only food-grade rPET is used in food packaging.

-

Advanced Decontamination Technologies: Developing and adopting more effective decontamination technologies to reduce harmful residues in rPET.

-

Ongoing Monitoring and Testing: Continuously monitoring the safety of rPET through rigorous testing to detect any harmful chemical migration.

-

Regulatory Oversight: Ensuring that all rPET materials comply with EU and other global safety standards for food packaging.

Dashan is committed to implementing these recommendations, ensuring that its rPET products meet the highest standards for safety and sustainability.

7. Regulatory Landscape and Future Directions

As the use of rPET in food packaging grows, so does the regulatory scrutiny. The European Union’s regulatory framework, including EU Regulation 2022/1616, now allows migration modeling as a valid method to demonstrate the safety of recycled materials. This regulatory shift highlights the importance of using advanced modeling and testing to ensure that rPET is safe for food contact.

Dashan follows all relevant regulations and standards, ensuring that its PET and rPET products are compliant with the latest safety requirements. We continue to invest in research and development to stay at the forefront of industry regulations.

8. Conclusion

Recycled PET (rPET) offers a sustainable solution to the growing demand for eco-friendly food packaging. However, to ensure that rPET is safe for food contact, it is crucial to address the risks of chemical migration and contamination during the recycling process. Through innovations like ABA technology, advanced decontamination processes, and ongoing monitoring, rPET can be safely incorporated into food packaging.

Dashan’s commitment to sustainable packaging practices ensures that our PET and rPET products meet both safety standards and environmental goals, making us a trusted partner for eco-conscious businesses worldwide.

9. FAQ Section

-

What is the difference between virgin PET and rPET in food packaging?

-

Virgin PET is made from new raw materials, while rPET is made from recycling post-consumer PET waste. rPET can be used for food packaging after decontamination.

-

-

How does ABA technology work to prevent contamination in food packaging?

-

ABA technology uses a recycled PET layer (B) sandwiched between two virgin PET layers (A), which act as barriers to prevent contaminants from migrating into food.

-

-

Are Dashan’s PET products safe for direct food contact?

-

Yes, all Dashan PET products, including those made from rPET, comply with international safety standards for food contact.

-

-

What is migration modeling, and how does it ensure rPET safety?

-

Migration modeling simulates the potential transfer of contaminants from the packaging to food. It is used to evaluate the safety of rPET by predicting migration levels under worst-case conditions.

-

-

How does Dashan ensure the sustainability of its PET and rPET packaging?

-

Dashan uses high-quality rPET, ensures rigorous testing for safety, and works to improve recycling practices, supporting the circular economy.

-

-

Can rPET be used in hot food applications?

-

rPET is suitable for cold and room temperature foods but may not be ideal for hot food applications unless properly processed and treated.

-

-

What are the environmental benefits of using rPET in food packaging?

-

Using rPET reduces the demand for virgin materials, decreases plastic waste, and promotes a circular economy by reusing materials.

-

-

How does Dashan maintain high standards for rPET decontamination?

-

Dashan works with advanced decontamination technologies to ensure that our rPET is safe for food contact, following international safety guidelines.

-

References

-

Assessment of chemical risks and circular economy implications of recycled PET in food packaging with functional barriers. ScienceDirect Article