Introduction

In the competitive packaging industry, businesses often prioritize lowering costs by opting for packaging materials with the lowest unit prices. However, this approach may not always lead to lower total costs, as various other factors such as logistics efficiency, damage rates, and container utilization significantly influence the overall cost. Even though a material might have a lower unit price, these hidden factors can increase the total cost, making cheaper options more expensive in the long run.

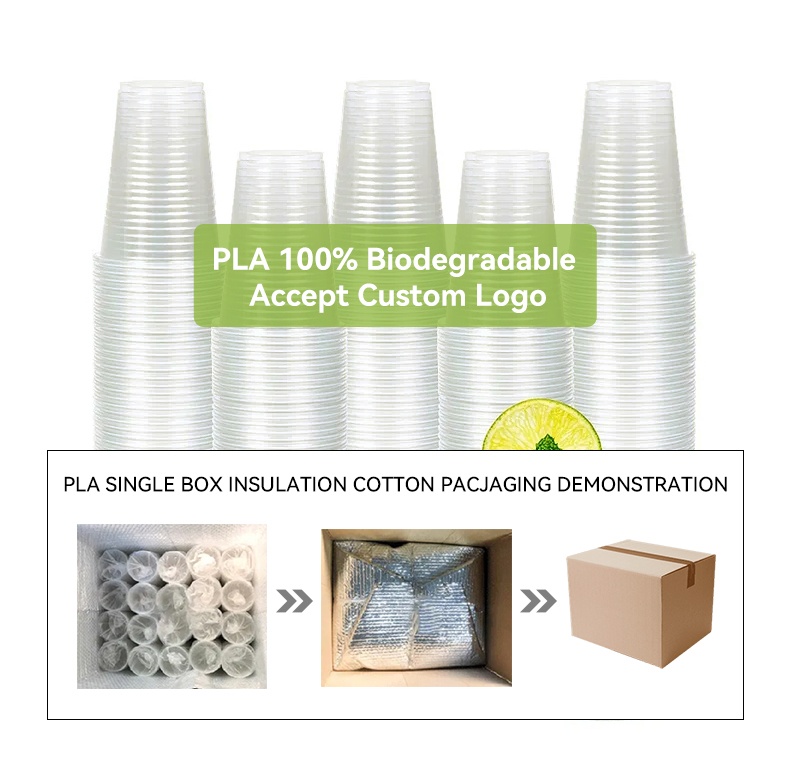

DaShan, as a leading provider of high-quality packaging solutions, specializes in manufacturing custom packaging from PET, CPET, RPET, PLA, and PP materials. By optimizing product design and considering all aspects of the packaging lifecycle, DaShan helps businesses achieve not only reduced packaging costs but also enhance sustainability and logistical efficiency.

Section 1: Understanding Unit Price vs. Total Cost

1.1 What is Unit Price?

Unit price refers to the cost of a single unit of packaging material. It’s the most commonly used metric for comparing prices across different suppliers and is often the basis for purchasing decisions. However, while unit price can give an idea of affordability, it only represents a fraction of the overall cost. A lower unit price does not necessarily result in a lower total cost.

1.2 Total Cost Breakdown

Total cost refers to the complete cost of acquiring and using a product. This includes not only the unit price but also additional expenses like logistics, damages during transit, storage costs, and container utilization. Compared to unit price, total cost provides a much more comprehensive view of the true expense involved in packaging. Businesses need to evaluate the full lifecycle costs of packaging, from procurement to handling and disposal, to get an accurate picture of the total expenditure.

Section 2: Key Factors Affecting Total Cost

2.1 Logistics Efficiency

Transportation Costs

Shipping packaging materials globally adds significant costs depending on the weight and volume of the packaging. Cheaper packaging materials may take up more space or be heavier, requiring more shipping capacity and thus increasing overall freight costs. Poorly optimized packaging can lead to higher transportation costs, negating any savings made from lower unit prices.

Efficient Logistics Management

At DaShan, we focus on optimizing our packaging solutions to improve logistical efficiency, reducing unnecessary shipping costs. By offering lightweight, compact PET packaging, businesses can reduce the volume and weight of their shipments, ultimately lowering transportation costs while ensuring product safety during transit.

2.2 Damage Rates

Packaging Durability and Protection

Low-unit price packaging often means lower quality, leading to higher damage rates during shipping. Packaging that doesn’t provide adequate protection results in damaged products, which increases replacement costs, as well as the cost of returns and customer dissatisfaction.

Impact on Total Costs

Damaged goods not only raise direct costs due to replacements but can also result in significant indirect costs like customer complaints, returns, and loss of brand reputation. On the other hand, DaShan provides packaging solutions made from durable materials such as CPET and RPET, which reduce the likelihood of damage and lower overall costs.

2.3 Container Utilization

Space Efficiency in Shipping Containers

The size and design of packaging play a critical role in how effectively it utilizes available space in shipping containers. Low-cost packaging may not be optimized for space, resulting in inefficient use of shipping containers and higher shipping costs. By offering custom-sized PET food containers, DaShan ensures that packaging maximizes space in shipping containers, reducing the overall transportation cost.

Volume and Weight Optimization

Efficiently designed packaging can significantly reduce the number of shipments required to transport products. Our lightweight PET containers are designed to make the most of available space and minimize the number of shipments needed. This efficiency leads to reduced shipping costs and a lower total cost for businesses.

2.4 Customization and Adaptability

Tailored Packaging Solutions

Customization is another factor that can affect total cost. Packaging that is tailored to fit the specific dimensions of products reduces wasted space and ensures that products are transported safely. Customized packaging solutions are often more efficient than generic packaging, as they can be specifically designed to minimize material waste and maximize space usage during shipping.

DaShan’s Custom Solutions

At DaShan, we offer custom packaging options designed to meet the specific needs of businesses, improving both logistical efficiency and product safety. Our ability to customize packaging helps customers reduce waste, lower storage costs, and improve transportation efficiency, ultimately reducing total costs.

Section 3: The Hidden Costs of Low-Unit Price Packaging

3.1 Quality vs. Price Trade-Offs

Quality vs. Price

Opting for low-unit-price packaging often comes at the expense of quality. While the initial purchase may seem more affordable, poor-quality packaging can lead to higher costs in the long run. Packaging that fails to meet safety or durability standards can result in damaged goods, increased waste, and a negative customer experience, all of which add hidden costs.

The Long-Term Impact of Low-Quality Packaging

For example, low-quality PLA cups may not be able to hold hot beverages, leading to leaks, burns, or spillage during use. These issues create long-term costs in terms of customer complaints, returns, and lost sales. In contrast, higher-quality packaging materials, though initially more expensive, can save money in the long term by reducing damage and maintaining customer satisfaction.

3.2 Brand Image and Consumer Trust

The Importance of Packaging in Brand Perception

Packaging does more than just protect products; it represents a company’s brand. Low-cost packaging may not only fail to protect the product effectively but may also affect the brand’s image negatively. If products arrive damaged due to poor-quality packaging, it erodes customer trust and harms the company’s reputation, which leads to long-term financial losses.

DaShan’s Brand Value

At DaShan, we understand that high-quality packaging is integral to maintaining a strong brand image. By offering premium PET containers and other high-quality packaging materials, we help businesses uphold their brand reputation and customer loyalty, minimizing the costs associated with poor brand perception and product damage.

Section 4: The Role of Sustainability in Total Cost

4.1 Sustainable Packaging Materials

Environmental and Economic Benefits

While sustainable materials like RPET and PLA may have a higher unit price, they can reduce long-term costs by minimizing waste, lowering carbon footprints, and providing better recyclability. Businesses that opt for sustainable packaging are also less likely to face regulatory fines or compliance costs associated with using non-compliant materials.

Long-Term Savings with Sustainable Packaging

For example, RPET packaging offers environmental and economic benefits by utilizing recycled materials, reducing overall environmental impact, and potentially lowering waste management costs. DaShan’s sustainable packaging solutions align with the growing demand for eco-friendly products, providing both cost savings and sustainability for businesses.

4.2 The Cost of Compliance with Regulations

Regulatory Compliance

Many regions around the world are introducing stricter packaging regulations, particularly related to environmental sustainability. Failure to comply with these regulations can result in penalties or additional costs for redesigning packaging. By investing in higher-quality, sustainable materials, businesses can avoid the costs associated with non-compliance.

DaShan’s Compliance with Global Standards

DaShan ensures that all our packaging products meet global environmental regulations, helping our clients avoid regulatory risks and hidden costs associated with non-compliant packaging.

Conclusion

In conclusion, while a lower unit price for packaging materials may seem like an effective way to cut costs, it is essential to consider the broader picture. Logistics efficiency, damage rates, container utilization, and sustainability all contribute significantly to the total cost of packaging. Businesses that only focus on unit price without considering these factors may end up spending more in the long run.

By choosing high-quality packaging and working with trusted suppliers like DaShan, businesses can strike the right balance between cost, quality, and sustainability, ensuring they get the best value for their packaging needs.

FAQ – Frequently Asked Questions

-

What factors affect the total cost of packaging beyond the unit price?

-

Logistics efficiency, damage rates, and container utilization are key factors that significantly influence the total cost. Even if the unit price of packaging materials is low, these factors can increase the total cost by adding shipping fees, replacement costs for damaged goods, and wasted storage space.

-

-

How can logistics efficiency affect packaging costs?

-

Packaging that is poorly designed or inefficient can take up more space, increasing freight and transportation costs. Optimized packaging can reduce the number of containers required, thus reducing overall shipping and logistics costs.

-

-

Why does packaging damage rate matter in total cost?

-

When packaging materials fail to protect the product during transportation, it results in damaged goods, which increases replacement costs, and the return process becomes more expensive. It also affects customer satisfaction and brand reputation, leading to long-term financial losses.

-

-

How does container utilization impact packaging costs?

-

Low-cost packaging often does not optimize the use of available space in shipping containers. Poor utilization can lead to additional trips, wasted shipping space, and increased transportation costs. Efficiently designed packaging helps maximize container space, reducing the number of containers needed and thus lowering shipping costs.

-

-

Is sustainable packaging more expensive in the short term?

-

While sustainable packaging materials (like RPET or PLA) often have a higher initial cost, they can provide long-term savings by reducing waste, improving recyclability, and helping businesses meet regulatory compliance. In addition, sustainable practices can enhance brand reputation and customer loyalty, providing indirect financial benefits.

-

-

How can a company assess the total cost of packaging?

-

To assess the total cost, businesses should consider factors such as logistics, damages during transport, storage efficiency, and environmental impact. It is important to calculate not just the unit price, but the overall cost of handling, transportation, and potential waste or inefficiency.

-

-

Can customized packaging solutions reduce total cost?

-

Yes, customized packaging solutions that are tailored to specific product sizes can help reduce space waste, improve logistics efficiency, and prevent damage during transit. This can lower overall costs by optimizing both transportation and storage.

-

-

How does packaging affect brand image and consumer trust?

-

High-quality packaging protects the product, ensuring it arrives safely and in perfect condition, which is vital for maintaining customer trust and loyalty. Poor packaging can lead to product damage, negative reviews, and a damaged reputation, which results in long-term financial losses.

-

References

-

“The Economics of Packaging” – Packaging Digest.

This report explores the economic implications of packaging decisions, comparing the cost of low-price packaging to high-quality alternatives and analyzing how factors like logistics and damage rates influence the final cost.

Link to Packaging Digest -

“Reducing Costs in Supply Chain with Optimized Packaging” – Journal of Supply Chain Management, 2021.

This academic article provides data and case studies on how optimizing packaging can reduce shipping and storage costs. It emphasizes the importance of using properly designed, efficient packaging for long-term savings.

Link to Journal of Supply Chain Management -

“Sustainable Packaging: A Guide to Green Packaging Solutions” – The Sustainable Packaging Coalition.

This guide outlines the environmental benefits of using sustainable materials in packaging and discusses how businesses can balance the upfront costs with the long-term economic and ecological benefits.

Link to SPC

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.