Cornstarch clamshell boxes offer an eco-friendly, biodegradable alternative to traditional plastic food containers. Made from renewable corn starch, they are safe, durable, and suitable for both hot and cold meals. Their innovative design and material technology help reduce plastic waste, align with global sustainability initiatives, and meet the growing demand for environmentally responsible packaging.

The Rise of Cornstarch Packaging

Plastic packaging has long dominated the foodservice and takeaway industry due to its affordability and convenience. However, global plastic pollution has become a serious environmental concern. Over 300 million tons of plastic are produced each year, with most ending up in landfills or oceans, where they can take centuries to decompose. This so-called “white pollution” threatens ecosystems worldwide.

In response, corn starch-based packaging emerged as a promising alternative. Corn is abundant and renewable, making it an ideal raw material. After extracting starch from harvested corn, manufacturers use it as the foundation for creating biodegradable clamshell boxes. Compared to conventional plastic boxes, cornstarch clamshells decompose much faster—typically within 6–12 months under natural conditions—offering a truly sustainable solution for the catering, takeaway, and food delivery industries.

Material Innovation: How Cornstarch Becomes Functional Packaging

While corn starch is renewable and biodegradable, it has natural limitations, such as poor water resistance. Overcoming these challenges has been key to producing reliable food containers.

Advanced Material Modification

Modern cornstarch clamshell boxes use advanced chemical techniques to enhance performance:

-

Esterification: Introduces water-resistant chemical groups to corn starch molecules, forming a protective “coat” that prevents swelling and erosion.

-

Cross-Linking: Creates strong molecular bonds, improving tensile strength and overall structural integrity.

These modifications allow cornstarch clamshells to maintain their shape and strength even in humid or high-temperature environments. Lab tests show that modified cornstarch can withstand 40°C for 24 hours without deforming, with tensile strength reaching up to 80MPa—about 70% of traditional polypropylene.

Structural Design: The Clamshell Advantage

Cornstarch clamshell boxes are designed with a unique bionic structure inspired by natural clams. The design features include:

-

Double-Petal Hinge: Enables easy one-handed opening, with a maximum 180° angle for convenient access.

-

Sealing Edges: Protects food from moisture and maintains freshness even in high-humidity conditions.

-

Food-Grade Coating: FDA-approved coatings ensure that materials remain safe for direct contact with food, even at temperatures up to 120°C.

This thoughtful engineering combines functionality with environmental responsibility, ensuring that the boxes are both practical for everyday use and safe for consumers.

Applications in the Catering and Food Industry

Sustainable Takeaway Solutions

Restaurants and takeaway services face growing consumer demand for eco-friendly packaging. Cornstarch clamshell boxes provide a practical, green alternative:

-

Cafés and Restaurants: Offer sustainable packaging for salads, sandwiches, and hot meals.

-

Food Delivery: Leak-proof and heat-resistant boxes maintain food quality during transit.

-

Catering Services: Simplify cleanup at large-scale events while reducing plastic waste.

Case Example – Eco-Catering in London

A mid-sized catering company in London switched all takeaway packaging to cornstarch clamshell boxes. Within six months, they reduced plastic waste by 32%, while customer feedback highlighted increased brand loyalty due to their sustainability initiatives.

Cross-Industry Innovation

Cornstarch clamshell boxes are increasingly used beyond food packaging:

-

Medical Device Packaging: Their structural stability and sterility compliance make them suitable for ISO 11607-certified medical packaging.

-

Electronics and Consumer Goods: Some brands now use cornstarch clamshells to package premium headphones, creating an eco-friendly unboxing experience and boosting perceived brand value.

Overcoming Technical Challenges

Improving Oil Resistance

Corn starch-based materials naturally absorb oil, which can compromise structural integrity. By adding a nano-silicon dioxide coating, manufacturers have extended the material’s oil resistance from 2 to 6 hours. This makes cornstarch clamshell boxes suitable for oily foods such as fried items or curries.

Scaling Production

Early production faced high costs and inefficiencies. The introduction of fluidized bed drying technology improved efficiency by rapidly drying materials with hot air in a fluidized state, lowering production costs from $0.35/piece to $0.22/piece. This advancement enables cornstarch clamshell boxes to compete with traditional PP packaging in price, promoting wider adoption.

Environmental Benefits

Cornstarch clamshell boxes align with sustainability goals on multiple fronts:

-

Biodegradability: Break down within 6–12 months, diverting waste from landfills.

-

Carbon Footprint Reduction: Manufacturing emits significantly fewer greenhouse gases than conventional plastics.

-

Renewable Resources: Made from plant-based corn starch, reducing reliance on fossil fuels.

-

Support for Circular Economy: Can be composted industrially or, in some cases, at home, returning nutrients to the soil.

Policy and Market Trends

Government policies, such as the EU’s Single-Use Plastics Directive, are driving the global shift toward sustainable packaging. The bio-based packaging market is projected to exceed $28 billion by 2026, highlighting the strong demand for green alternatives. Cornstarch clamshell boxes, with their combination of eco-friendliness, practicality, and commercial viability, are leading this market transformation.

Future Outlook

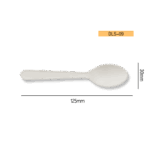

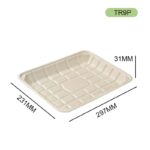

With advancements in bio-fermentation and production technologies, cornstarch packaging is becoming increasingly sustainable and cost-effective. Derived series of tableware, trays, and containers are now entering international markets, making corn starch a versatile material platform.

As consumers prioritize environmental responsibility, companies offering cornstarch clamshell boxes can achieve a balance between commercial value and sustainability, creating a positive impact across the entire supply chain.

FAQs

Q1: What is a cornstarch clamshell box made of?

A1: They are made from modified corn starch and biodegradable polymers, providing a plant-based alternative to conventional plastic containers.

Q2: Are cornstarch clamshell boxes compostable?

A2: Yes, they are compostable in industrial facilities, typically decomposing within 90–180 days under optimal conditions.

Q3: Can they handle hot and oily foods?

A3: Yes, high-quality cornstarch clamshells are heat-resistant and leak-proof, suitable for hot meals and greasy foods.

Q4: How do they differ from bagasse containers?

A4: Cornstarch clamshells are smoother and slightly transparent, while bagasse is fibrous, made from sugarcane fiber.

Q5: Are they microwave-safe?

A5: Some are microwave-safe for short durations; always check labeling for temperature limits.

Q6: How do they support sustainability goals?

A6: They reduce fossil fuel dependence, lower carbon emissions, and divert packaging waste from landfills.

Q7: Who benefits most from using cornstarch clamshell boxes?

A7: Restaurants, cafés, catering businesses, and takeaway services benefit, appealing to eco-conscious consumers.

Conclusion

Cornstarch clamshell boxes are more than just a packaging innovation—they are a revolution in sustainable materials. Combining material science, structural design, and environmental responsibility, they offer a practical, safe, and eco-friendly alternative to traditional plastics. By adopting these boxes, businesses and consumers alike can contribute to a greener future while maintaining convenience and quality in daily foodservice operations.

Disclaimer & Copyright Notice

This article is created by the Dashan Packing editorial and research team.

All information presented here is for educational and industry reference purposes only.

Some data and standards cited in this article are sourced from publicly available materials,

official regulatory documents, or third-party publications, which are properly credited where applicable.

All rights to third-party trademarks, images, and content belong to their respective owners.

If any copyrighted material has been used inadvertently, please contact us at angel@chndashan.com.

We respect intellectual property rights and will promptly remove or revise any material upon verification.