Quick Summary

RPET (Recycled Polyethylene Terephthalate) is one of the most commercially viable circular packaging materials available today. Technically, RPET can be recycled more than once because PET is a thermoplastic. However, real-world outcomes depend on collection systems, sorting infrastructure, contamination levels, economics, and regulations.

With thoughtful product design, verified recycled content, and collaboration across the supply chain, businesses can significantly improve the probability that RPET is collected and recycled again. As a responsible manufacturer, Dashan focuses on mono-material structures, food-contact safety, and traceable recycling streams to support genuine circularity rather than marketing claims alone.

For many food and beverage brands, sustainability has shifted from a “nice-to-have” marketing angle to a strategic requirement. Governments are regulating, retailers are setting packaging targets, and consumers increasingly want to understand what happens to packaging after they throw it away.

Within this conversation, RPET (Recycled Polyethylene Terephthalate) has become one of the most widely promoted “circular” packaging materials. You see it in bottles, bakery clamshells, deli containers, dessert cups, salad bowls, and protective trays across supermarkets worldwide. It is often presented as the sustainable alternative to virgin PET — and in many ways, it is.

However, as companies begin using RPET, a very reasonable question arises:

“If this packaging is already recycled… can it be recycled again?”

At first glance, the answer seems intuitive — if PET can be recycled once, surely it can be recycled multiple times. But the reality is more nuanced. The technical possibility, the infrastructure, the economics, and the way packaging is designed all influence the true end-of-life outcome.

In this article, we take a practical look at what happens to RPET after its first life cycle. We will separate technical facts from wishful thinking, highlight both opportunities and limitations, and provide actionable guidance for brands, importers, and packaging buyers.

As a packaging manufacturer working closely with global customers, DASHAN has seen how expectations and reality often diverge — not because RPET is ineffective, but because systems and decisions around it are not always aligned.

Let us begin with the basics.

1. What Exactly Is RPET?

RPET stands for Recycled Polyethylene Terephthalate, the same polymer used in water bottles, soft-drink bottles, and clear thermoformed packaging. It is derived from recycled PET materials that have gone through collection, sorting, cleaning, and reprocessing.

Typical inputs include:

-

post-consumer PET bottles

-

post-industrial PET sheet waste

-

trays, clamshells, and lids in regions with advanced sorting systems

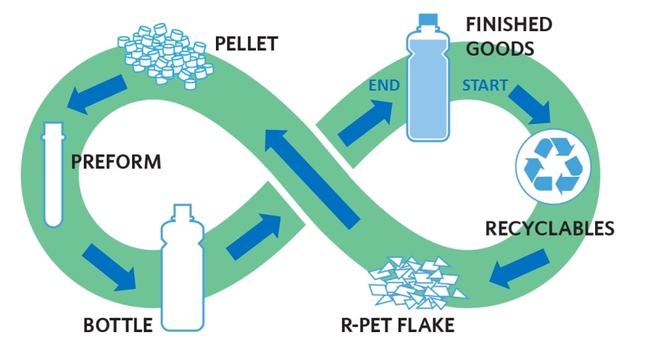

The journey of RPET typically looks like this:

-

Collection – bottles and packaging enter recycling bins or deposit systems.

-

Sorting – optical scanners and manual sorting separate PET from other plastics.

-

Washing & Flaking – items are washed, labels removed, then shredded into flakes.

-

Decontamination – flakes undergo high-temperature, vacuum, or SSP systems to remove contaminants.

-

Extrusion – flakes are melted and extruded into sheets or pellets.

-

Forming – finished sheets are thermoformed into new packaging.

When done correctly, RPET enables closed-loop material circulation: yesterday’s bottle becomes tomorrow’s cup or tray. This is what makes RPET such an attractive material in sustainability conversations.

But that brings us back to the big question.

2. In Theory: Yes, RPET Can Be Recycled Multiple Times

From a purely technical standpoint, PET is a thermoplastic polymer. That means it can be melted and reshaped repeatedly.

So, technically:

RPET can be recycled again. And again — at least several cycles.

Laboratory tests and industrial trials have shown that, with proper controls, recycled PET can pass through multiple reprocessing cycles. Chemical recycling technologies (such as depolymerization back into monomers) even allow PET to theoretically return to near-virgin quality repeatedly.

In theory, if collection systems worked perfectly and contamination was minimal, the loop could look like this:

RPET tray → collection → recycling → RPET tray again.

However, real-world systems rarely perform under perfect conditions.

This is where expectations begin to diverge from reality.

3. In Practice: Why RPET Is Not Always Recycled Again

Although RPET is recyclable, the probability that it will actually be recycled again depends on several conditions — and these conditions are not always met.

3.1 Contamination

After use, RPET packaging is often contaminated with:

-

food residues

-

sauces and oils

-

paper labels and adhesives

-

inks, stickers, or sleeves

-

mixtures of non-PET plastics (PP, PS, PLA, PVC)

Contamination increases cost and reduces yield. If recyclers determine that cleaning RPET waste is too expensive or complicated, it may be diverted to incineration or landfill instead of being recycled.

3.2 Collection Systems and Infrastructure

Not every region has effective sorting infrastructure. While some countries separate PET bottles, trays and lids are sometimes treated differently because:

-

sorting machines are optimized for bottles

-

trays often contain multilayer structures

-

labeling and food contamination reduce value

So even though RPET is recyclable, it may not enter the recycling stream at all.

3.3 Economics and Market Incentives

Recycling is a business. If virgin PET becomes cheaper than recycled PET due to oil prices, recyclers may struggle to operate profitably.

Factors that influence the decision include:

-

price volatility

-

demand for high-grade recycled pellets

-

transportation and labor costs

-

contamination losses

In certain markets, recyclers prioritize bottle-to-bottle loops because they are more valuable, while thermoformed trays receive less attention.

3.4 Consumer Behavior

Even in regions with good systems, disposal behavior matters. If packaging is thrown into general waste instead of the correct bin, it leaves the recycling loop permanently.

From DASHAN’s conversations with customers, we observe that many brands assume recyclability automatically guarantees recycling — but collection design, labeling, and education are equally important.

4. Quality Degradation Over Multiple Cycles

While PET can theoretically be recycled multiple times, material properties change with each cycle.

During reprocessing:

-

polymer chains shorten (chain scission)

-

mechanical strength gradually decreases

-

clarity may reduce

-

processability can become more challenging

To compensate, recyclers often:

-

blend RPET with virgin PET

-

use chain extenders and additives

-

carefully control heat and processing conditions

This is why you often see claims such as:

-

“30% recycled content”

-

“50% RPET”

-

“up to 100% depending on application”

The choice depends on required clarity, strength, and food-contact safety. RPET can still be recycled, but maintaining premium quality requires balancing engineering constraints.

5. RPET vs Other Materials: A Reality Check

Understanding recyclability means comparing RPET to other packaging options.

5.1 RPET vs PET

-

PET: Stable, clear, widely recyclable.

-

RPET: Lower carbon footprint, supports circular economy, slightly more sensitive to processing.

Both are recyclable — but RPET reduces dependency on virgin petrochemical resources.

5.2 RPET vs PLA

PLA is compostable in industrial facilities, not widely recyclable.

RPET is recyclable in existing systems but depends on infrastructure.

5.3 RPET vs PP and PS

PP and PS recycling infrastructure is less developed in many countries. This gives RPET a practical advantage.

Key takeaway:

“Recyclable” does not automatically mean “will be recycled” — but RPET has one of the best chances among plastics.

6. What Businesses Can Do to Improve RPET Recyclability

Packaging design decisions have real downstream effects.

Here is what brands can do.

6.1 Choose Mono-Material Designs

Avoid unnecessary layers combining PET with other plastics.

6.2 Avoid Dark Coloring and Complex Printing

Clear RPET has higher recycling value. Opaque or dark tones often become downcycled.

6.3 Use Recognized Recycling Symbols

Clear labeling helps consumers dispose correctly.

6.4 Work With Transparent Suppliers

Serious manufacturers provide:

-

recycled content statements

-

traceability documentation

-

migration and food-contact testing

-

quality consistency records

At DASHAN, many customers request RPET for lids, clamshells, and trays. We have seen that when product design prioritizes recyclability, recyclers treat the material more favorably.

6.5 Educate Consumers

Short, honest disposal messaging (on-pack or online) increases recovery rates.

7. Regulations and Market Drivers Supporting RPET

Government and corporate commitments are accelerating RPET usage:

-

recycled content mandates in certain markets

-

Extended Producer Responsibility programs

-

large retailers requiring minimum recycled content

-

corporate sustainability reporting

These forces gradually improve infrastructure and market value for RPET.

8. Managing Expectations: Communicating Honestly About RPET

Brands must avoid overstating claims.

Recommended phrasing:

-

“Made with recycled content”

-

“Recyclable where facilities exist”

-

“Supports circular packaging initiatives”

Over-promising creates distrust. Realistic communication builds credibility — and this is something we emphasize when supporting our customers at DASHAN.

9. Final Perspective: Reality vs Expectations

Expectations

-

RPET is always recycled.

-

Packaging moves endlessly in a closed loop.

-

Quality remains identical forever.

Reality

-

RPET can be recycled again — technically — but depends on systems.

-

Quality management and blending may be required.

-

Infrastructure, economics, and design affect final outcomes.

Even with these constraints, RPET remains one of the most realistic, scalable pathways for reducing virgin plastic use in food packaging today.

When manufacturers design for recyclability, recyclers invest in better technology, and consumers are educated — RPET performs its intended role in the circular economy.

And in our experience at DASHAN, customers who understand these nuances make smarter buying decisions, achieve sustainability goals more honestly, and avoid unrealistic expectations.

FAQ

1. Can RPET really be recycled again?

Yes — in theory, RPET can re-enter the recycling stream multiple times. In practice, it depends on whether the packaging is properly collected, sorted, and processed without excessive contamination.

2. Does RPET lose quality after several recycling cycles?

Polymer chains may shorten after repeated processing, which can affect clarity, strength, and processability. That is why many converters blend RPET with a percentage of virgin PET to stabilize performance.

3. Is RPET safer than ordinary PET for food contact?

RPET can be food-contact compliant when it is produced under certified processes and meets applicable regulations. Reputable suppliers (including Dashan partners) provide test reports, migration testing, and traceability.

4. Why is some “recyclable” packaging never recycled?

“Recyclable” means the material can be recycled under the right conditions. Whether it will be recycled depends on infrastructure, consumer behavior, market prices, and regional policies.

5. Is RPET better than PLA or PP?

Each material has advantages. RPET often performs better in clarity, barrier properties, and global recycling acceptance. PLA requires composting facilities, and PP sometimes faces sorting limitations depending on region.

6. Can businesses improve the recyclability of their RPET packaging?

Yes. Choose mono-material designs, avoid unnecessary colors, minimize inks, clearly mark the recycling symbol, and work with certified suppliers who document recycled content and processing integrity.

7. Does RPET cost more than virgin PET?

Sometimes yes — when recycled feedstock is scarce. However, regulations, brand commitments, and sustainability goals increasingly justify the investment and help stabilize long-term supply.

8. What is Dashan’s approach to RPET packaging?

Dashan prioritizes clean material streams, reliable thickness control, food-grade compliance, and collaboration with certified recyclers. The goal is not only to “use recycled plastic,” but to strengthen circular value chains.

Conclusion

RPET represents one of the most realistic and scalable pathways toward lower-impact plastic packaging. While the material can technically be recycled repeatedly, real outcomes are shaped by systemic factors — infrastructure, policy, consumer participation, and responsible product design.

The gap between expectations and reality narrows when brands choose transparent labeling, verifiable recycled content, and mono-material solutions designed for recovery. Working with manufacturers such as Dashan enables buyers to balance sustainability ambitions with operational reliability and compliance.

In short, RPET is not a perfect solution — but it is one of the most practical tools available today for advancing circular packaging without compromising product performance.

References

-

Ellen MacArthur Foundation — Global Commitment & Circular Economy

https://www.ellenmacarthurfoundation.org/our-work/activities/global-commitment -

Plastics Recyclers Europe — PET & RPET Guidance

https://www.plasticsrecyclers.eu/pet -

U.S. Environmental Protection Agency — Plastics Recycling Overview

https://www.epa.gov/recycle/recycling-basics -

European Food Safety Authority (EFSA) — Recycled Plastics for Food Contact

https://www.efsa.europa.eu/en/topics/topic/food-contact-materials -

Association of Plastic Recyclers (APR) — Design for Recyclability Guidelines

https://plasticsrecycling.org/technical-resources/design-guide -

National Renewable Energy Laboratory — Plastic Recycling Research

https://www.nrel.gov/news/features/2019/how-chemical-recycling-could-change-the-plastics-economy.html -

UN Environment Programme — Single-Use Plastics and Circularity

https://www.unep.org/resources/report/single-use-plastics-roadmap-sustainability

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.