✅ Quick Summary

Bagasse packaging offers a durable, heat-resistant, and eco-friendly alternative for modern foodservice operations. Made from renewable sugarcane fiber, bagasse products—including clamshell boxes, take-out boxes, plates, trays, and bowls—perform reliably with both hot and cold foods. Their strength, grease resistance, and microwave-safe properties make them suitable for restaurants, catering, supermarkets, and delivery services. DASHAN enhances this sustainability shift by providing high-quality molded bagasse solutions that balance performance, safety, and environmental responsibility. As global businesses seek greener packaging, bagasse stands out as a practical, scalable, and compliant choice.

Introduction

As global foodservice operators shift away from petroleum-based plastics, sugarcane bagasse food containers have become one of the most trusted eco-friendly alternatives for serving hot and cold meals. Driven by government regulations, sustainability commitments, and evolving consumer expectations, bagasse packaging has moved from a niche solution to a mainstream option used by restaurants, catering companies, supermarkets, hotels, and airlines.

However, many international buyers still ask the same questions:

How durable is bagasse tableware? Is it truly safe for hot foods, oily dishes, and liquids? Does it meet global food-contact standards? How does it compare with traditional plastics?

This article provides a professional, evidence-based, and engineering-level examination of bagasse tableware performance, backed by material science research, environmental data, and manufacturing expertise. It also explains how leading producers—such as DASHAN, a manufacturer of sustainable sugarcane bagasse products—engineer durable clamshell boxes, take-out boxes, plates, trays, and bowls for export markets worldwide.

1. What Is Sugarcane Bagasse? Understanding the Material

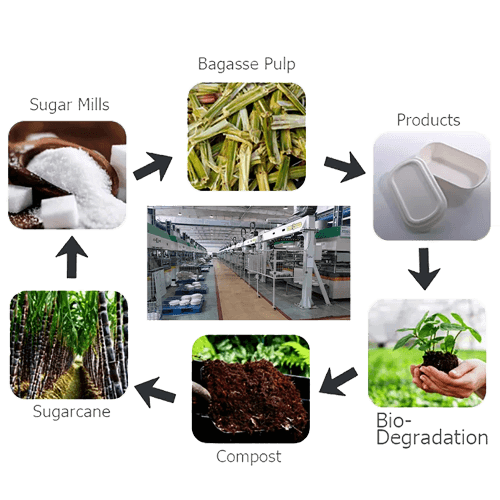

Sugarcane bagasse is the fibrous residue left after crushing sugarcane to extract juice. Instead of burning or disposing of it as agricultural waste, modern factories convert this renewable biomass into food-safe molded fiber packaging.

Key Material Properties

Scientific studies show that bagasse fibers possess:

-

High cellulose content (40–50%), similar to wood pulp

-

Low lignin levels, enabling easy pulping and molding

-

Excellent biodegradability, breaking down naturally in months under composting conditions

-

Strength and rigidity, comparable to high-grade molded paper pulp

Environmental Advantages

-

100% renewable agricultural by-product

-

Minimal carbon emissions compared with plastics

-

Converts waste into high-value goods

-

Suitable for composting (industrial and sometimes home composting)

-

Helps reduce dependence on fossil-based materials

Because of these characteristics, bagasse is widely recognized by NGOs and regulators as a low-impact, circular-economy packaging material.

2. How Are Bagasse Food Containers Manufactured?

A Detailed Engineering Overview

The manufacturing process is critical to product quality, durability, and food safety. Modern factories follow a multi-stage thermoforming pulp molding system, which can be summarized as:

Step 1: Raw Material Preparation

Sugarcane bagasse fibers are:

-

Washed

-

Refined and filtered

-

Converted into pulp through mechanical pulping

-

Mixed with clean water and optional natural binders (no toxic plastics)

Quality producers like DASHAN use fully closed-loop water recycling to minimize waste.

Step 2: Pulp Forming (Wet Vacuum Suction)

A forming mold creates the basic shape of the product. A vacuum system draws pulp fibers tightly onto the surface of the mold, ensuring:

-

Even fiber distribution

-

Consistent wall thickness

-

Structural strength

This is one of the core steps that determines durability.

Step 3: Hot Pressing (Thermoforming)

After initial shaping, products are placed between heated molds. Hot pressing:

-

Removes moisture

-

Enhances density and rigidity

-

Creates smooth surfaces

-

Improves oil and water resistance

-

Ensures dimensional accuracy

Different temperatures are used depending on the product type—plates, bowls, clamshell boxes, etc.

Step 4: Trimming and Quality Inspection

Products undergo:

-

CNC trimming

-

Edge finishing

-

Weight and dimension inspection

-

Water and oil resistance testing

Factories exporting globally (e.g., DASHAN) apply stricter QC to meet FDA, EU 10/2011, LFGB, and GB standards simultaneously.

Step 5: Sterilization and Packaging

Final products are sterilized using high-temperature drying, UV treatment, or ozone chamber cleaning before packing in dust-controlled rooms.

3. Durability Performance: Can Bagasse Serve Hot, Oily, and Liquid Foods?

Bagasse containers are engineered to withstand real foodservice conditions—not just dry foods. Here is a performance analysis:

Heat Resistance

Research consistently finds bagasse maintains structural integrity at:

-

100°C (212°F) for 30–40 minutes for liquids

-

Up to 120–150°C (248–302°F) for dry food heating

-

Microwave-friendly (without plastic lining)

-

Oven-safe (up to 200°C depending on thickness)

This makes bagasse suitable for:

-

Hot rice, noodles, pasta

-

Fried dishes

-

Curries and soups

-

Baked goods

DASHAN’s bagasse plates and take-out boxes are hot-pressed at higher temperatures to enhance thermal stability for export catering markets.

Cold & Freezer Resistance

Bagasse fibers remain stable at low temperatures:

-

Down to –20°C (–4°F) for freezer storage

-

No cracking or fiber separation

-

Maintains rigidity when chilled

Ideal for salads, sushi, cold desserts, and ready-to-eat meals.

Oil & Water Resistance

Hot-pressed bagasse naturally forms a semi-crystalline structure with excellent resistance:

Tests show:

-

No leakage for 3–4 hours with oily foods

-

No softening with hot soups

-

Superior to paper bowls without coating

-

No synthetic PE lining required

High-density bagasse bowls and trays from DASHAN pass both water penetration and oil soak tests suitable for export to EU and North America.

Mechanical Strength

Because bagasse has long cellulose fibers, it performs well in:

-

Stack compression

-

Bending resistance

-

Impact absorption

Bagasse clamshells and take-out boxes can handle heavy meals (500–1200 g) without sagging.

4. Food Safety: Is Bagasse Safe for Direct Food Contact?

Bagasse products from reputable manufacturers meet international safety standards:

Compliance Typically Includes:

-

FDA 21 CFR (USA)

-

EU Regulation 10/2011 (overall migration limits)

-

LFGB (Germany Food and Feed Law)

-

GB 4806 series (China food contact materials)

-

BPA-free, PFAS-free options

-

No heavy metals (lead, cadmium, chromium)

-

No fluorescent whitening agents

DASHAN implements batch-level migration testing, guaranteeing safety across all markets.

5. Advantages of Bagasse Over Traditional Plastic Tableware

Below is an analytical comparison relevant for international buyers:

1. Renewable vs. Fossil-based Raw Material

-

Bagasse comes from agricultural biomass.

-

Plastics come from petroleum or natural gas.

2. Production Energy Consumption

-

Bagasse molding typically requires 140–160°C.

-

Plastics (PP, PET, PS) require 170–280°C, significantly higher.

3. End-of-Life Impact

-

Bagasse can decompose into CO₂, water, and organic matter.

-

Plastics persist for centuries, fragmenting into microplastics.

4. Health and Safety

-

Bagasse contains no harmful additives.

-

Plastics may include stabilizers, softeners, pigments, or PFAS.

5. Foodservice Versatility

Bagasse tableware is suitable for:

-

Hot meals

-

Cold dishes

-

Greasy food

-

Soups

-

Microwave heating

-

Oven heating

Plastic products struggle with heat and often cannot be microwaved.

6. Where Are Bagasse Products Used?

Bagasse packaging is popular across industries, including:

-

Restaurants and cafés

-

QSR and fast-food chains

-

Airline catering

-

School and corporate canteens

-

Supermarkets and deli counters

-

Hotel buffets

-

Home parties and small events

DASHAN distributes bagasse packaging to Europe, North America, the Middle East, and Southeast Asia, adapting specifications to different regulatory and cultural dining expectations.

7. DASHAN’s Bagasse Product Portfolio

DASHAN manufactures a complete range of molded fiber foodservice items:

1. Bagasse Clamshell Boxes

Ideal for burgers, rice meals, pasta, and hot entrées. Strong locking design and high rigidity.

2. Bagasse Take-Out Boxes

Two- or three-compartment options for bento-style meals or international lunchboxes.

3. Bagasse Plates

Available in round, oval, and divided formats. Suitable for catering and events.

4. Bagasse Trays

Used for sushi, chilled meals, desserts, or display.

5. Bagasse Bowls

Perfect for soups, noodles, salads, or grain bowls.

All products follow DASHAN’s high-density thermoforming process, ensuring durability and compliance with export standards.

8. How to Choose High-Quality Bagasse Tableware

For international buyers, consider:

1. Check for Certifications

Ensure compliance with:

-

FDA

-

EU 10/2011

-

LFGB

-

Compostability certifications (where applicable)

2. Inspect Surface Quality

Look for:

-

Smooth surface

-

Consistent color

-

No fiber lumps

-

No oil stains

-

No cracks or deformities

3. Test Durability

Evaluate:

-

Hot liquid resistance

-

Oil resistance

-

Stack compression

-

Microwave/oven performance

4. Evaluate Manufacturer Capability

A reliable supplier should offer:

-

Modern pulp molding machines

-

Clean production environment

-

Strong QC systems

-

Export experience

-

OEM/ODM capability

DASHAN fulfills all of these criteria with long-established thermoforming expertise.

9. Environmental Benefits: Bagasse in the Global Circular Economy

Using bagasse supports:

-

SDG 12 “Responsible Consumption and Production”

-

Low-carbon manufacturing

-

Reduced landfill waste

-

Reduced deforestation (vs. wood pulp)

-

Reduced plastic dependency

Studies show bagasse products can reduce carbon emissions by 50–80% compared with similar plastic items.

✅ FAQ — Bagasse Tableware Durability & Safety

1. Are bagasse plates and containers safe for hot food?

Yes. High-quality bagasse products can typically withstand temperatures of up to 120°C (248°F) without deforming. They remain stable with hot meals, soups, fried items, and freshly cooked dishes.

2. Can bagasse tableware handle cold or refrigerated foods?

Absolutely. Bagasse maintains its structure under cold storage and is suitable for salads, desserts, chilled meals, and refrigerated display items.

3. Are bagasse trays and bowls microwave-safe?

Yes. Most bagasse tableware is microwave-safe, usually for 2–3 minutes depending on the wattage. Because the material contains no plastic lining, it does not release harmful chemicals when heated.

4. Do bagasse products resist oil and moisture?

Bagasse fibers naturally provide excellent grease and liquid resistance, making them suitable for oily, saucy, or juicy foods without leaking or collapsing.

5. Is bagasse tableware strong enough for heavy meals?

Yes. Properly molded bagasse containers have high structural rigidity. Plates, clamshell boxes, and trays can support full meals, dense proteins, and loaded dishes without bending.

6. Are bagasse containers biodegradable and compostable?

Yes. Bagasse is fully biodegradable and compostable, breaking down in commercial composting within 45–90 days under ideal conditions.

7. Does bagasse contain harmful chemicals?

No. Bagasse products are made from natural sugarcane fiber and are typically free from PFAS, plastics, and toxic additives when produced by reputable manufacturers.

8. Are bagasse products suitable for food delivery and takeaway?

Yes. Their durability, heat resistance, and leak-resistant structure make bagasse ideal for take-out, catering, and delivery.

9. Can bagasse replace all traditional plastic food containers?

For most hot and ready-to-eat foods, yes. For extremely liquid-heavy or long-storage items, PET or PP may still be used—but bagasse covers 90%+ of typical foodservice needs.

10. What makes DASHAN’s bagasse products different?

DASHAN uses refined sugarcane fiber, precision molding, and strict QC systems to produce durable, food-safe, and export-grade clamshell boxes, take-out containers, plates, trays, and bowls. The products maintain stronger structure, smoother surface, and more consistent performance than standard bagasse items.

Conclusion

Sugarcane bagasse tableware is a durable, safe, and environmentally responsible solution for serving both hot and cold meals. With excellent heat resistance, structural strength, and natural biodegradability, it outperforms traditional plastic options in sustainability while meeting modern foodservice needs.

Manufacturers like DASHAN enhance these advantages with advanced pulp molding technology, strict quality control, and a full product range including clamshell boxes, take-out boxes, plates, trays, and bowls—making bagasse packaging an ideal choice for global restaurants, retailers, and catering businesses seeking performance without environmental compromise.

References

-

-

ASTM International. ASTM D6400-23 — Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities.

https://www.astm.org/d6400-23.html ASTM International | ASTM -

ASTM International. ASTM D6400-04 — Standard Specification for Compostable Plastics.

https://www.astmestandards.com/standards/ASTM-D6400-04/ ASTM Digital Standards -

Washington State Department of Ecology. Biobased, Biodegradable, Compostable Information Guide.

https://apps.ecology.wa.gov/publications/UIPages/documents/2307021.pdf apps.ecology.wa.gov -

ASTM International. ASTM D6400-21 — Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities.

https://webstore.ansi.org/standards/astm/astmd640021 webstore.ansi.org -

ASTM International / BPC Instruments. Designation: D6400-12 — Standard Specification for Labeling of Plastics Designed to be Aerobically Composted.

https://www.bpcinstruments.com.cn/wp-content/uploads/2020/05/ASTM_D6400-Standard-Specification-for-Labeling-of-Plastics-Designed-to-be-Aerobically-Composted-in-Municipal-or-Industrial-Facilities.pdf

-

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.