Quick Summary

RPET food packaging can significantly reduce plastic waste and support circular recycling — but only when purchased correctly. Buyers must verify documentation, understand heat limitations, avoid misleading claims, and choose reliable suppliers with traceable, food-safe production. Selecting RPET based on application, not marketing, prevents costly performance and compliance issues.

Recycled PET (RPET) has rapidly become one of the most discussed materials in food packaging. Governments are tightening plastic regulations, brands are under pressure to reduce carbon footprints, and consumers increasingly expect sustainable choices.

On paper, RPET seems like the perfect answer: recycled, resource-efficient, and widely recyclable.

But the reality is more complex.

The RPET market varies significantly in quality, safety, source control, and price integrity. Buyers who rely only on claims like “100% recycled” or “eco-friendly” can face product failures, compliance risks, and reputational damage.

This guide explains how RPET works, the most common pitfalls, and how to purchase RPET packaging in a safe, practical, and truly sustainable way.

1. What Exactly Is RPET?

RPET is polyethylene terephthalate that has been collected, sorted, cleaned, reprocessed, and converted back into packaging.

Typical raw materials include:

-

post-consumer plastic bottles

-

food trays collected through recycling streams

-

industrial PET scrap

Unlike virgin PET, which comes directly from fossil-based feedstock, RPET reduces reliance on new petrochemicals and supports circularity.

Where RPET works well

RPET is particularly suited to:

-

cold cups and lids

-

bakery containers and clamshells

-

fruit, salad, and deli boxes

-

product display packaging requiring clarity

Where RPET does NOT perform well

Because RPET softens at higher temperatures, it is generally unsuitable for:

-

very hot meals

-

microwaving

-

oven heating

-

steam environments

In these applications, safer options include PP, CPET, or certain fiber-based solutions.

Understanding these limits is the first step to avoiding costly mistakes.

2. Common Pitfalls When Buying RPET

2.1 “Greenwashing” and misleading claims

Some suppliers oversell RPET benefits:

-

“100% RPET” without documentation

-

fake recycling symbols

-

vague sustainability statements

-

inconsistent PCR (post-consumer recycled) percentage

If sustainability cannot be proven, it becomes a marketing liability rather than an advantage.

2.2 Inconsistent color and clarity

Poorly sorted feedstock or weak cleaning processes create:

-

yellow or bluish tint

-

visible specks

-

loss of transparency

-

batch-to-batch inconsistency

This affects product appearance and brand perception.

2.3 Odor contamination

Improperly cleaned material may retain odors from detergents, chemicals, or prior contents. In food packaging, this is unacceptable and potentially unsafe.

2.4 Heat misrepresentation

Some sellers position RPET as “heat resistant.”

In reality, deformation and warping occur when temperatures exceed recommended limits. Misuse leads to:

-

customer complaints

-

food spills

-

safety questions

A correct material-to-application decision is critical.

2.5 Food safety risks

Recycled plastic may carry contaminants. Without strict processing controls, migration risks can occur.

Missing or outdated compliance documents are a serious red flag.

2.6 Focusing only on price

Ultra-low pricing often indicates:

-

unstable raw material sources

-

low cleaning standards

-

inconsistent PCR content

-

minimal testing and QC

The hidden costs show up later through returns, reputational loss, or re-sourcing.

3. Tests and Certifications Buyers Should Request

Not all paperwork is equal. Request clear documentation, not vague promises.

Important verification includes:

-

food contact safety (FDA / EU-compliant reports)

-

specific migration testing

-

heavy metals and contaminant testing

-

PCR percentage verification

-

traceability documentation per batch

-

mechanical and performance test results

If a supplier cannot provide traceability from raw RPET flakes to final product, risk exposure is high.

4. How to Evaluate a Reliable RPET Supplier

A trustworthy RPET packaging manufacturer demonstrates the following:

Transparent sourcing

Clear explanation of where the recycled feedstock comes from and how it is processed.

Stable supply channels

Not dependent on random brokers or fluctuating scrap markets.

Batch testing systems

Every production run should have lot records and QC documentation.

Complaint and recall procedures

Professional suppliers know how to handle quality issues systematically.

Compliance expertise

They understand your destination market and provide appropriate documents proactively.

Sampling before mass production

Real-world testing on your menu, logistics route, and temperature conditions is essential.

5. Matching Applications to RPET — Correctly

Ideal uses

-

cold beverages

-

salads and fruit

-

bakery packaging

-

retail presentation packaging

Use with caution

-

warm but not hot foods

-

delivery situations with temperature exposure

Avoid RPET for

-

microwaving

-

reheating

-

hot soups or curries

-

oven meals

Alternative materials to consider

-

PP – excellent for hot foods and microwaving

-

CPET – reheatable and oven-safe meal trays

-

Bagasse – plant fiber options for specific formats

-

PLA – certain cold applications where compostable branding matters

Choosing the right material is a performance decision, not just a sustainability label.

You can learn more by watching the video.

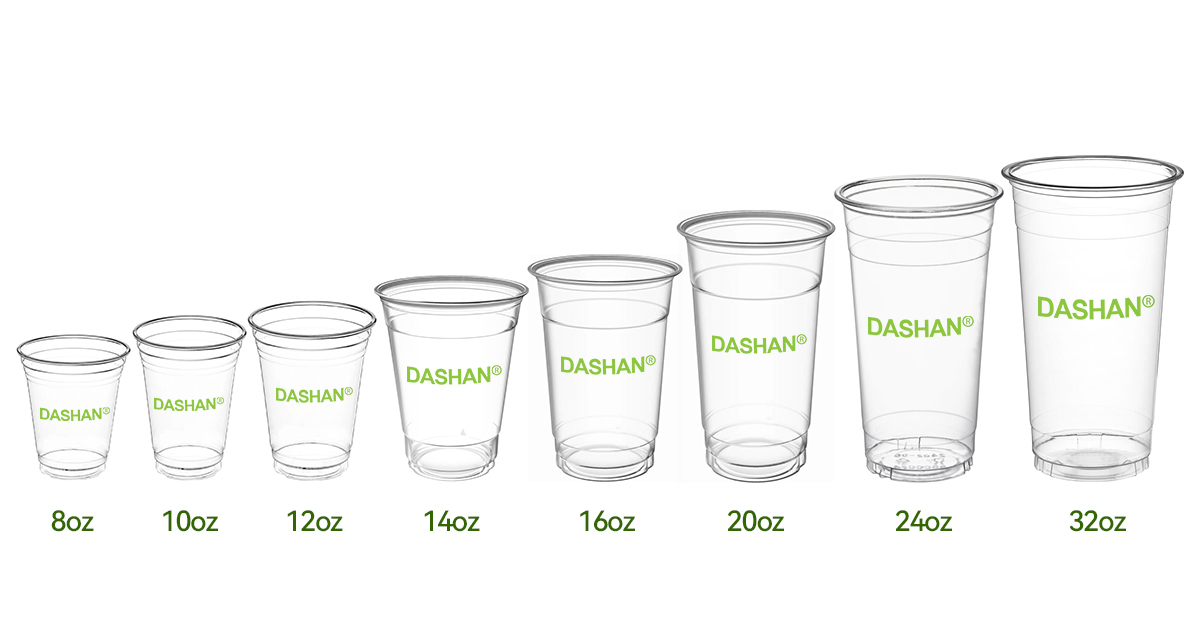

In practice, one clear example is DASHAN’s RPET anti-fog lid solution. It is designed for cold foods and beverages where visibility matters, while the anti-fog treatment helps prevent condensation from clouding the lid during storage or transport. The product is manufactured using traceable RPET and tested for food-contact safety, allowing buyers to benefit from recycled material without compromising product presentation or hygiene.

6. Cost vs. Value: Smart RPET Procurement

Looking beyond unit price yields better long-term value.

Consider:

-

breakage, leakage, and complaint rates

-

consistency across multiple shipments

-

sustainability claims that withstand audit

-

brand trust and compliance safety

-

lead time reliability

The cheapest RPET is rarely the lowest-cost solution.

7. Practical Buyer Checklist

Before confirming any order, ask suppliers:

-

What is the verified PCR percentage?

-

Do you provide batch-level traceability?

-

Are food contact and migration reports available and current?

-

Where are your recycled flakes sourced?

-

What is your cleaning and decontamination process?

-

How do you control yellowing or odor?

-

Can you provide samples for testing?

-

How stable is your production schedule?

-

What markets and regulations are your products compliant with?

-

What after-sales quality procedures do you follow?

Red flags

-

no documentation

-

unclear sourcing

-

inconsistent pricing

-

refusal to provide samples

-

overpromised heat performance

8. How DASHAN Supports Buyers (Light, Non-Sales)

At DASHAN, we work with RPET — but we do not position it as a “magic solution.”

Instead, we help buyers choose the right material for each scenario.

Our approach includes:

-

RPET, PET, PP, CPET, PLA, bagasse and other materials available for comparison

-

batch-level testing and traceable documentation

-

focus on application-based recommendations rather than single-material pushing

-

sample programs for real delivery testing

-

long-term, stable supply programs

This reduces risk, protects brand reputation, and supports sustainability goals in a practical way.

FAQ

1. Is RPET safe for direct food contact?

Yes — but only if produced under controlled processes and supported by valid food-contact and migration testing. Always request current documentation from your supplier.

2. Can RPET be used for hot meals or microwaving?

Generally no. RPET is better suited for cold and room-temperature foods. For hot meals, materials like PP or CPET are usually safer choices.

3. What does “PCR percentage” mean?

PCR (Post-Consumer Recycled) indicates how much of the material comes from collected and recycled products. Higher PCR content supports sustainability — but it must be verified.

4. Why does RPET sometimes look yellow or cloudy?

Color variation often results from mixed feedstock or insufficient cleaning. Consistent clarity requires strict sorting and quality control.

5. Is RPET always more sustainable than virgin PET?

Not automatically. Poorly recycled or low-quality RPET may lead to breakage, waste, and returns. Verified, traceable RPET is what truly supports sustainability.

6. How can I avoid “greenwashing” when buying RPET?

Request test reports, PCR verification, and traceability records. Avoid suppliers who only make claims without documentation.

7. When should I avoid RPET entirely?

Avoid RPET in applications involving high heat, ovens, microwaves, or prolonged steam exposure.

Conclusion

RPET offers real environmental value — when sourced, validated, and applied correctly.

Buyers who look beyond marketing statements and evaluate documentation, performance, and supplier capability gain both sustainability credibility and packaging reliability.

Smart procurement is not about buying “recycled.”

It is about buying safe, consistent, and verifiable recycled packaging.

References

-

European Commission – Food Contact Materials

https://food.ec.europa.eu/safety/chemical-safety/food-contact-materials_en -

U.S. FDA – Food Contact Substances

https://www.fda.gov/food/packaging-food-contact-substances-fcs -

Plastics Recyclers Europe – PET Recycling Guidelines

https://www.plasticsrecyclers.eu -

Ellen MacArthur Foundation – Circular Economy and Plastics

https://www.ellenmacarthurfoundation.org -

WRAP – Recycled Content and Packaging Guidance

https://wrap.org.uk

Copyright Statement

© 2026 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.