✅ Quick Summary

This article provides an in-depth scientific explanation of the seven Resin Identification Codes (RICs) found on plastic containers. It explores the chemical characteristics, heat resistance, safety implications, and common applications of each plastic type, helping consumers make informed decisions about daily food-contact usage. The guide also covers environmental concerns, practical safety tips, and the limitations of recycling systems, offering a comprehensive framework for safer and more sustainable plastic use.

Plastic containers are everywhere in modern life—from bottled water to takeaway lunch boxes to baby bottles—yet most consumers have only a vague idea of what the numbers on the bottom of these containers actually mean. These numbers, printed inside a triangle of chasing arrows, are called Resin Identification Codes (RICs). They provide important information about the chemical composition, heat resistance, and potential safety risks of plastic products. Understanding these codes empowers individuals and businesses to make safer and more sustainable choices for daily use.

This article offers a clear and comprehensive explanation of the seven major resin codes, how to evaluate safety, and what consumers should avoid when using plastic food containers. It also discusses environmental considerations, recycling limitations, and the rise of alternative eco-friendly materials.

I. What Are Resin Identification Codes?

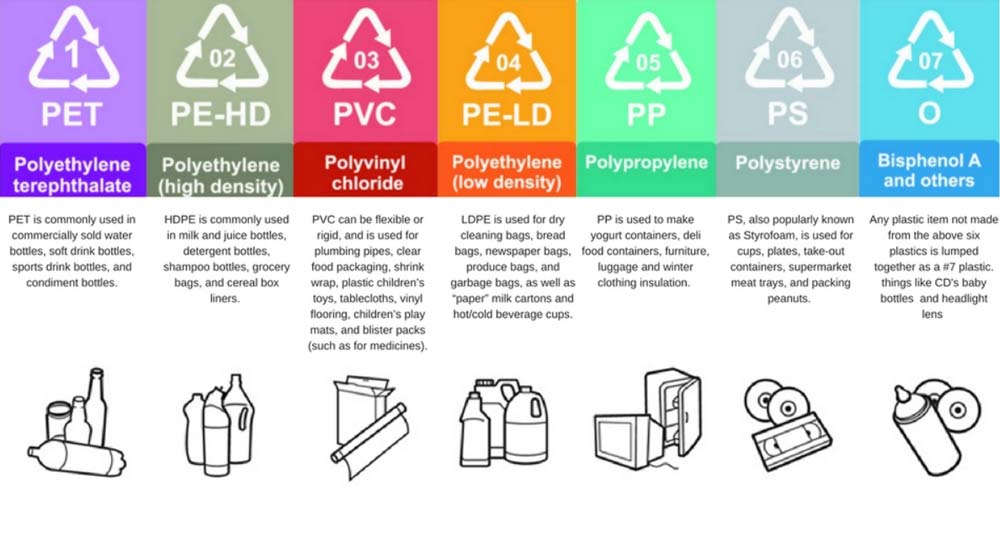

The Resin Identification Code system was introduced in 1988 by the Society of the Plastics Industry (SPI) to standardize plastic waste sorting in recycling facilities. Although the triangular symbol resembles the recycling icon, the RIC system does not necessarily mean that a product is recyclable. Instead, the number inside the triangle identifies the type of polymer used in the product.

The codes range from 1 to 7:

| Code | Material | Common Name |

|---|---|---|

| 1 | PET | Polyethylene Terephthalate |

| 2 | HDPE | High-Density Polyethylene |

| 3 | PVC | Polyvinyl Chloride |

| 4 | LDPE | Low-Density Polyethylene |

| 5 | PP | Polypropylene |

| 6 | PS | Polystyrene |

| 7 | Others | PC and miscellaneous plastics |

These codes serve as a quick guide for recyclers, regulators, manufacturers, and consumers. They help determine safe temperatures, chemical stability, microwave or dishwasher suitability, and proper disposal methods.

II. Code 1 — PET (Polyethylene Terephthalate)

1. Material Characteristics

PET is known for its high clarity, lightweight properties, excellent tensile strength, and outstanding barrier performance against carbon dioxide. These qualities make it ideal for carbonated beverages and bottled water. Originally used in synthetic fibers (such as polyester clothing), PET began being used for bottles and containers in the 1970s.

2. Common Applications

-

Water bottles

-

Carbonated drink bottles

-

Juice or sports drink packaging

-

Edible oil bottles

-

Food-grade thermoformed containers

3. Heat Limitations & Safety Concerns

PET has a maximum heat resistance of about 70°C. When exposed to hot water or high temperatures, PET containers may deform or release trace chemicals. Although PET is safe for single use, it should not be repeatedly refilled, especially with hot liquids.

4. Usage Recommendations

-

Do not use PET bottles for hot beverages.

-

Avoid long-term storage of acidic or alcoholic liquids.

-

Do not reuse PET bottles as water cups or kitchen storage.

-

Recycle after use to support PET-to-PET and PET-to-fiber circular systems.

III. Code 2 — HDPE (High-Density Polyethylene)

1. Material Profile

HDPE is a tough, chemically resistant, and moisture-proof plastic. It does not absorb water and is widely used for containers that must withstand rough handling. The material is durable and provides excellent protection for both food and non-food products.

2. Where It’s Found

-

White pharmaceutical bottles

-

Detergent jugs and cleaning containers

-

Shampoo and body wash bottles

-

Milk jugs

-

Chemical and pesticide containers

-

Grocery bags (thin HDPE film)

3. Heat Resistance & Safety

HDPE can tolerate about 110°C, which is higher than PET. However, the internal surfaces of HDPE bottles are more difficult to clean due to their semi-crystalline structure. Residues inside reused containers may harbor chemicals or bacteria.

4. Consumer Safety Tips

-

Avoid reusing HDPE containers that previously stored detergents or chemicals.

-

Do not use HDPE bottles as cups for hot liquids.

-

Food-grade HDPE bags may safely store food but should not be heated.

IV. Code 3 — PVC (Polyvinyl Chloride)

1. Material Traits

PVC is inexpensive, versatile, and highly formable. However, it requires plasticizers (like phthalates) and stabilizers (which may contain heavy metals), creating potential health concerns.

2. Common Applications

-

Water pipes

-

Flooring and building materials

-

Window frames

-

Raincoats, soft toys

-

Electrical cable insulation

3. Food Safety Concerns

PVC can only tolerate around 80°C, and heating significantly increases the risk of chemical migration. As a result, PVC is rarely used for food-contact packaging today. Residual monomers and plasticizers can enter food, particularly in oily environments.

4. Recommendation

-

Avoid purchasing foods packaged in PVC.

-

Never use PVC containers for hot or microwaved items.

V. Code 4 — LDPE (Low-Density Polyethylene)

1. Material Behavior

LDPE is highly flexible, transparent, and easy to process. It is widely used in thin films and soft packaging materials. Its melting point is lower than HDPE.

2. Common Uses

-

Plastic bags

-

Food wraps and cling films

-

Squeezable condiment bottles

-

Packaging films

3. Temperature Concerns

LDPE begins to melt at about 110°C. When heated, it may release additives that are not digestible by the human body.

4. Practical Advice

-

Remove plastic wrap before microwaving food.

-

Do not place LDPE film in direct contact with hot oils or boiling liquids.

-

Avoid reheating food in LDPE bags.

VI. Code 5 — PP (Polypropylene)

1. Key Properties

PP is considered one of the safest plastics for food contact. It is odorless, chemically stable, and has a high melting point of 160–170°C, making it suitable for hot foods and microwave use (when labeled accordingly).

2. Where You’re Likely to See PP

-

Microwave-safe lunch boxes

-

Yogurt cups

-

Food storage containers

-

Reusable water pitchers

-

Baby products

3. Heat & Safety

PP withstands steam sterilization and boiling water, making it ideal for reusable food containers. It does not leach harmful chemicals under normal household conditions.

4. Reuse Guidelines

-

Safe to reuse after thorough cleaning

-

Suitable for microwave reheating

-

Avoid direct flame or oven use beyond heat ratings

VII. Code 6 — PS (Polystyrene)

1. Material Overview

PS is a rigid, lightweight plastic available in two forms:

-

Regular PS (hard, brittle)

-

Expanded polystyrene (EPS), commonly known as foam

2. Typical Uses

-

Disposable cups and food trays

-

Instant noodle bowls

-

Takeout boxes

-

Cutlery for fast-food restaurants

3. Safety Considerations

PS can release styrene, a chemical that may pose health risks when exposed to high temperatures, acids, or oils. Foam bowls used to hold hot soup can accelerate this release.

4. Usage Recommendations

-

Do not microwave polystyrene containers.

-

Avoid using foam bowls for boiling foods.

-

Transfer takeout meals to ceramic or glass dishes before reheating.

VIII. Code 7 — PC and Other Plastics

1. What “7” Really Means

Code 7 covers all plastics not included in Codes 1–6. These can include:

-

Polycarbonate (PC)

-

ABS

-

Nylon

-

Acrylic

-

PLA (bioplastics)

-

Advanced polymer blends

2. Polycarbonate (PC) Focus

PC is extremely strong and transparent. It is used in:

-

Baby bottles (older types)

-

Reusable water jugs

-

Sports bottles

-

Safety goggles and face shields

However, PC may release Bisphenol A (BPA) when exposed to heat or sunlight. BPA is associated with potential hormonal effects.

3. Safety & Temperature Limitations

-

Avoid filling PC bottles with boiling water.

-

Do not expose PC containers to long periods of sunlight.

-

Prefer BPA-free alternatives whenever possible.

4. Safer Substitutes

-

PP baby bottles

-

Tritan (BPA-free copolyester)

-

Stainless steel

-

Glass bottles

IX. Evaluating the Safety of Plastic Containers

Choosing the right food container is not simply a matter of avoiding certain codes. Consumers should consider:

1. Food-Contact Certification

Look for symbols indicating:

-

Food-safe approval

-

Microwave-safe certification

-

Oven or dishwasher suitability

2. Intended Use

Containers designed for one-time use (like PET bottles) should not be repurposed repeatedly.

3. Heat Exposure

Never assume a plastic is microwave-safe unless explicitly labeled.

4. Condition of the Plastic

Scratched, cloudy, or discolored plastics should be discarded because surface damage may accelerate chemical migration.

5. Avoid Repurposing Chemical Containers

Even after washing, chemical residues can be difficult to fully remove.

X. Environmental Considerations

Plastic waste has become a global challenge. Understanding resin codes also helps consumers make environmentally responsible choices.

1. Recycling Limitations

A plastic marked “recyclable” is not always recycled. Factors include:

-

Local recycling infrastructure

-

Cleaning and sorting requirements

-

Contamination from food residues

2. Global Recycling Rates

Despite widespread use, only about 15% of plastic waste is recycled globally.

3. The Push for Alternative Materials

Businesses and governments are increasingly adopting:

-

Bagasse fiber products

-

PLA bioplastics

-

Recycled PET (rPET)

-

Compostable materials

These materials reduce reliance on fossil-fuel plastics.

4. Consumer Responsibility

-

Reduce single-use plastics

-

Separate waste properly

-

Support companies offering sustainable packaging

✅ FAQ

1. What do the numbers on the bottom of plastic bottles mean?

They are Resin Identification Codes (RICs) indicating the type of plastic used, providing guidance on heat resistance, recyclability, and food-contact safety.

2. Which plastic is safest for hot food or microwave heating?

PP (Code 5) is the safest plastic for hot foods and microwaving when the container is labeled microwave-safe.

3. Can PET water bottles (Code 1) be reused?

PET bottles are designed for single use only and should not be reused for hot drinks or long-term storage.

4. Is PVC (Code 3) safe for food packaging?

PVC can release plasticizers and residual monomers under heat or oily conditions, so it is rarely recommended for food contact.

5. Why is polystyrene (Code 6) not suitable for microwaving?

PS can release styrene when exposed to heat, acids, or oils, making it unsafe for microwaving or holding boiling liquids.

6. What is the concern with plastics labeled “7”?

Category 7 includes various materials, including polycarbonate (PC), which may release BPA under heat. These should not be used with hot liquids.

7. Are all plastics with recycle symbols actually recyclable?

No. Recycling depends on local facilities, contamination levels, and economic feasibility, not just the resin code.

Conclusion

The numbers on the bottom of plastic containers represent far more than recycling categories—they provide essential information about safety, temperature limits, and chemical properties. PET bottles are ideal for single-use cold beverages, PP is the safest choice for microwaving food, and PVC and PS should be kept away from heat. Polycarbonate products require cautious use, especially regarding exposure to hot liquids.

Understanding these resin codes helps consumers reduce health risks, make smarter purchasing decisions, and contribute to a more sustainable packaging ecosystem. With growing awareness and the rise of eco-friendly alternatives such as bagasse fiber and biodegradable materials, both individuals and industries can take meaningful steps toward safer and cleaner daily living.

References

-

Plastics Industry Association. Resin Identification Code System Overview.

https://en.wikipedia.org/wiki/Resin_identification_code

-

U.S. Food and Drug Administration (FDA). Food Contact Substances Regulations.

https://www.foamequipment.com/blog/bid/38348/plastic-recycling-resin-identification-codes

-

European Food Safety Authority (EFSA). Safety of BPA in Polycarbonate Plastics.

-

American Chemistry Council. Plastic Materials and Applications.

-

Environmental Protection Agency (EPA). Plastics: Material-Specific Data.