Quick Summary

The CT-2116H38-3C CPET meal tray is a durable, oven-safe, freezer-ready three-compartment food container designed for airline catering, frozen meals, and large-scale food production. With a 210 × 162 × 38 mm structure and 30 g lightweight design, it supports high-temperature reheating, long-term cold storage, food separation, and leak-resistant sealing for premium meal presentation.

Introduction

In the world of airline catering and frozen meal preparation, maintaining flavor integrity, food separation, and visual appeal is essential. Modern inflight meals must endure complex production cycles involving cooking, chilling or freezing, cold-chain logistics, long-term storage, reheating, and onboard service. The CT-2116H38-3C CPET meal tray is engineered to support this demanding workflow.

With dimensions of 210 × 162 × 38 mm and a total weight of 30 g, this three-compartment tray offers excellent structural rigidity and thermal performance. It is designed specifically for large-scale catering systems, automated sealing lines, and diversified meal layouts where entrées and side dishes must remain well separated. Its multi-compartment design is ideal for operators who value portion control, cross-flavor protection, and premium plating effects.

CPET (Crystallized Polyethylene Terephthalate) is widely recognized as the top-tier material for professional ready-meal trays. The CT-2116H38-3C leverages CPET’s full advantages—outstanding heat resistance, cold tolerance, food safety, and barrier performance—making it suitable for aviation, railway catering, frozen meal producers, hospitals, and institutional kitchens.

Technical Specifications

-

Model: CT-2116H38-3C

-

Material: CPET

-

Size: 210 × 162 × 38 mm

-

Weight: 30 g

-

Temperature Resistance: –40°C to +220°C

-

Color Options: Black / White

-

Compartments: Three (entrée + sides)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

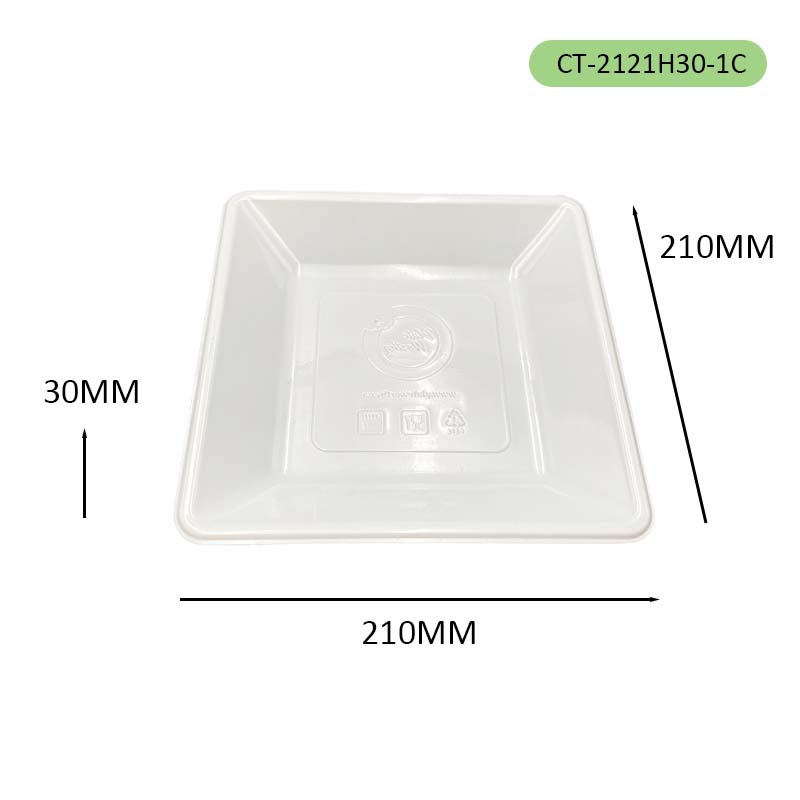

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

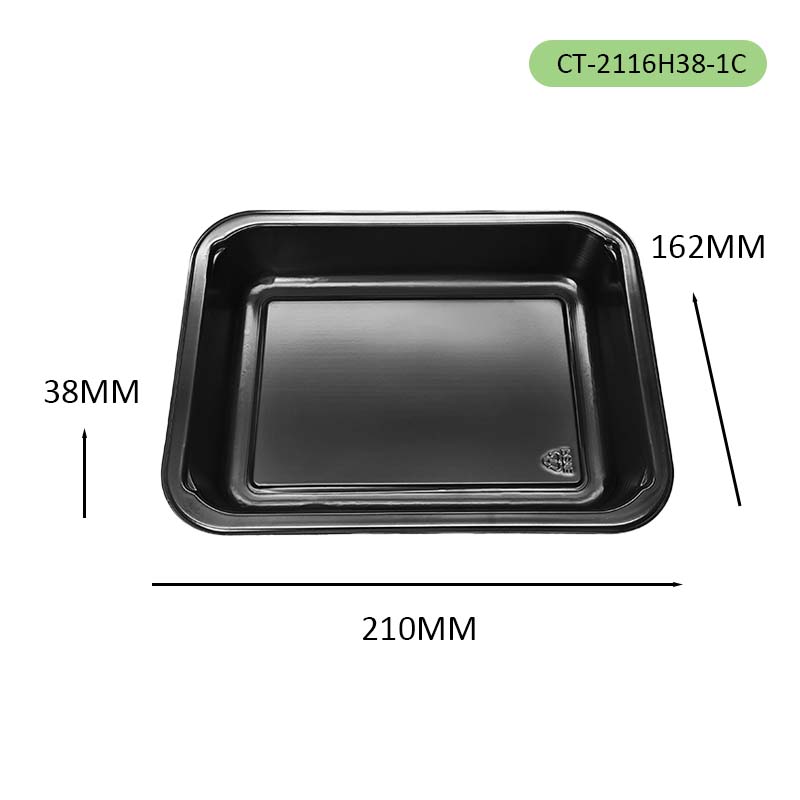

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

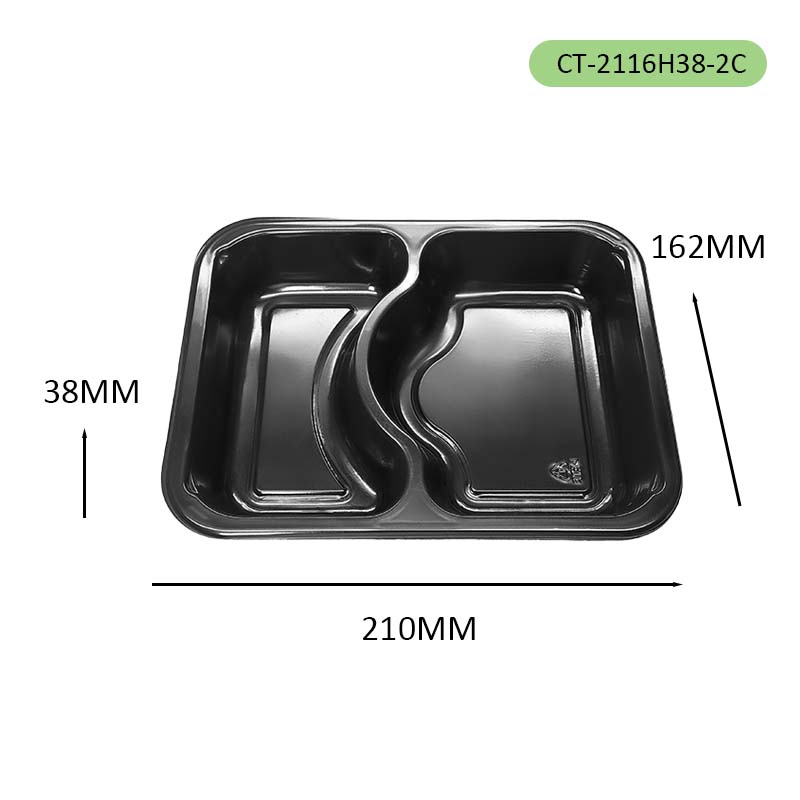

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

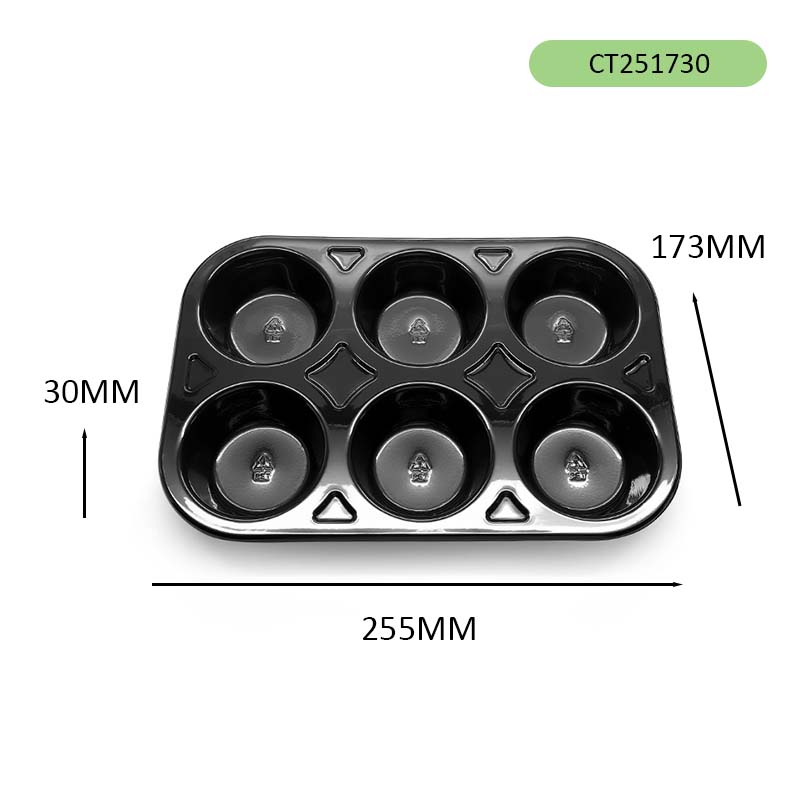

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Outstanding Temperature Performance

The CT-2116H38-3C tray is engineered to withstand extreme temperature conditions, allowing seamless transitions from freezing to reheating. With a stable operating range of –40°C to +220°C, the tray performs reliably in every stage of the catering process:

-

Industrial kitchen cooking

-

Rapid chilling or blast freezing

-

Low-temperature warehousing

-

Long-distance cold-chain distribution

-

Reheating in airline convection ovens or steam ovens

-

Final onboard meal service

The tray maintains shape, rigidity, and aesthetics throughout all thermal cycles. No warping, cracking, melting, or odor occurs, ensuring consistent performance for inflight meals or frozen meals requiring precise heating.

Its oven-safe and microwave-safe nature makes it compatible with the heating systems used globally by major airlines and catering centers.

Food Safety and Material Integrity

Manufactured with certified food-grade CPET resin, the CT-2116H38-3C provides absolute safety for direct food contact. It is:

-

BPA-free

-

Non-toxic

-

Resistant to grease, oil, acids, and sauces

-

Compliant with international food safety standards

Thanks to CPET’s semi-crystalline molecular structure, the tray offers excellent resistance to aggressive ingredients. This prevents staining and ensures the tray maintains a clean, professional appearance even after reheating. For airlines that prioritize passenger satisfaction, this high-quality presentation is a valuable advantage.

Multi-Compartment Design: Superior Food Separation

The CT-2116H38-3C’s three-compartment layout offers significant advantages for meal organization:

1. Prevents flavor mixing

Each compartment keeps entrées and side dishes separated, maintaining flavor integrity.

2. Enhances visual appeal

Multiple compartments help chefs design structured, attractive inflight meals.

3. Supports portion control

Standardized compartment sizes help maintain consistent meal output across production batches.

4. Reduces leakage and cross-contamination

The raised internal walls are engineered for secure sealing compatibility, protecting delicate ingredients.

This makes the tray perfect for meals that include proteins, vegetables, carbohydrates, desserts, or sauces.

High Barrier Strength for Longer Shelf Life

The CT-2116H38-3C tray offers outstanding protection against oxygen, moisture, and contaminants. These barrier properties significantly extend the shelf life of frozen and chilled ready meals. For airlines and frozen meal producers, this enables:

-

Longer pre-production windows

-

Reduced food waste

-

Stable quality during long storage cycles

The tray is compatible with:

-

Heat-seal lidding films

-

Aluminum foil lids

-

CPET rigid lids

-

MAP (Modified Atmosphere Packaging) sealing

Secure sealing ensures freshness, prevents leakage, and supports efficient stacking during storage and transport.

Designed for Airline and Industrial Catering

The CT-2116H38-3C tray meets global standard airline tray dimensions, ensuring compatibility with meal carts, ATLAS trolleys, and automatic sealing machines.

Operational advantages include:

1. Automation-friendly sealing design

Ensures precise sealing and reduces production errors.

2. Rigid structure for safe stacking

Maintains shape even under heavy stacking loads.

3. Leak-resistant geometry

Supports liquid-based dishes without spillage.

4. Lightweight and fuel-efficient

The 30 g weight helps airlines reduce fuel consumption—an important sustainability advantage.

Enhanced Meal Presentation

CPET maintains a glossy, clean appearance after reheating, making the CT-2116H38-3C suitable for premium meal programs. Benefits include:

-

Uniform heat distribution

-

No oil penetration

-

Attractive plating surface

-

Color customization options

For airlines seeking improved passenger experience, the tray helps deliver consistent, visually appealing meals.

Applications Across Foodservice Sectors

1. Airline catering

The primary market—ideal for multi-dish inflight menus.

2. Railway catering

Supports reheating, transport vibration, and long storage.

3. Frozen meal manufacturers

Reliable for –40°C storage and oven reheating cycles.

4. Hospitals and institutions

Enhances hygiene and meal organization.

5. Cruise and marine catering

Handles the harsh conditions of long-distance food logistics.

Customization Options

-

Embossed airline or brand logo

-

Custom colors (black / white / blue)

-

Modified compartment layouts

-

Optimized carton packing for automation

-

Matching sealing film or lid supply

These options support brand consistency and operational efficiency.

Why CPET Is the Ideal Material

✔ Excellent heat resistance

✔ Strong barrier performance

✔ High structural rigidity

✔ Recyclable in many regions

✔ Safe and food-contact compliant

✔ Suitable for global meal service systems

FAQ

1. Is the CT-2116H38-3C tray oven-safe?

Yes, it is safe up to 220°C in convection and steam ovens.

2. Can it be used for frozen meals?

Yes, it remains stable at –40°C and is ideal for long-term frozen storage.

3. What sealing options are compatible?

Heat-seal film, aluminum foil, and CPET rigid lids.

4. Is CPET recyclable?

In many countries, CPET is accepted in standard plastic recycling systems.

5. What industries use this tray?

Airlines, frozen meal producers, hospitals, rail catering, and cruise lines.

Conclusion

The CT-2116H38-3C three-compartment CPET meal tray provides a premium solution for inflight catering, frozen meals, and large-scale foodservice operators. With exceptional thermal resistance, food safety performance, structural durability, and compartmentalized design, it ensures consistent meal quality across production, storage, reheating, and service. Its reliability, lightweight build, and professional food presentation make it an ideal choice for global airlines, institutional kitchens, and ready-meal manufacturers seeking stable and efficient packaging solutions.