Quick Summary

The CT-1610H35-1C is a compact, lightweight, and high-performance CPET airline meal tray designed for inflight catering, ready meals, and institutional foodservice. Its 160 × 105 × 35 mm structure and ultra-light 13 g weight provide excellent heat resistance, freezer stability, secure sealing, and consistent meal presentation for high-volume catering operations.

Introduction

Airline catering has evolved into a sophisticated industry where food safety, operational efficiency, and meal presentation must work seamlessly together. Airlines and catering companies must prepare meals that travel through multiple production stages—from cooking and chilling to freezing, storage, reheating, and final onboard service—while maintaining freshness and visual appeal.

The CPET airline meal tray CT-1610H35-1C is engineered to support these complex workflow requirements. With dimensions of 160 × 105 × 35 mm and a remarkably lightweight 13 g structure, this model provides an ideal balance of durability, thermal performance, and cost-efficiency. It is designed for small-portion inflight meals, side dishes, kids’ meals, desserts, and meal sets requiring compact and reliable packaging.

Made from Crystallized Polyethylene Terephthalate (CPET), this tray delivers excellent heat tolerance, low-temperature stability, high barrier protection, and food-contact safety. As a result, the CT-1610H35-1C is widely used not only in aviation catering, but also in railway foodservice, frozen ready meals, hospitals, and central kitchens.

Technical Specifications

-

Model: CT-1610H35-1C

-

Material: CPET

-

Size: 160 × 105 × 35 mm

-

Weight: 13 g

-

Temperature Resistance: –40°C to +220°C

-

Color Options: Black / White

-

Compartment: Single

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

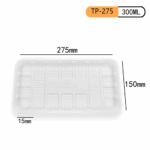

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

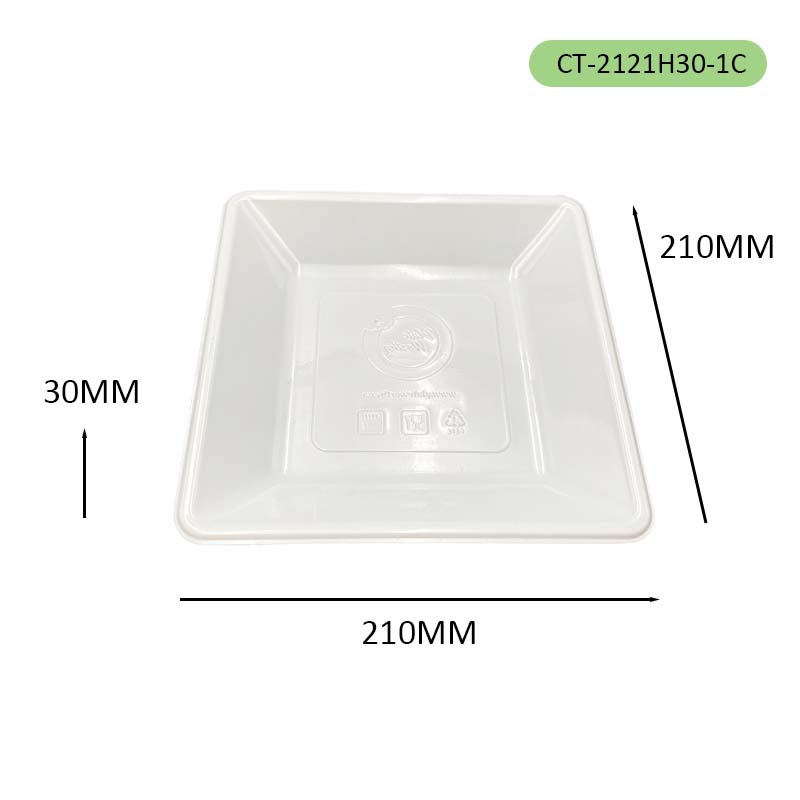

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

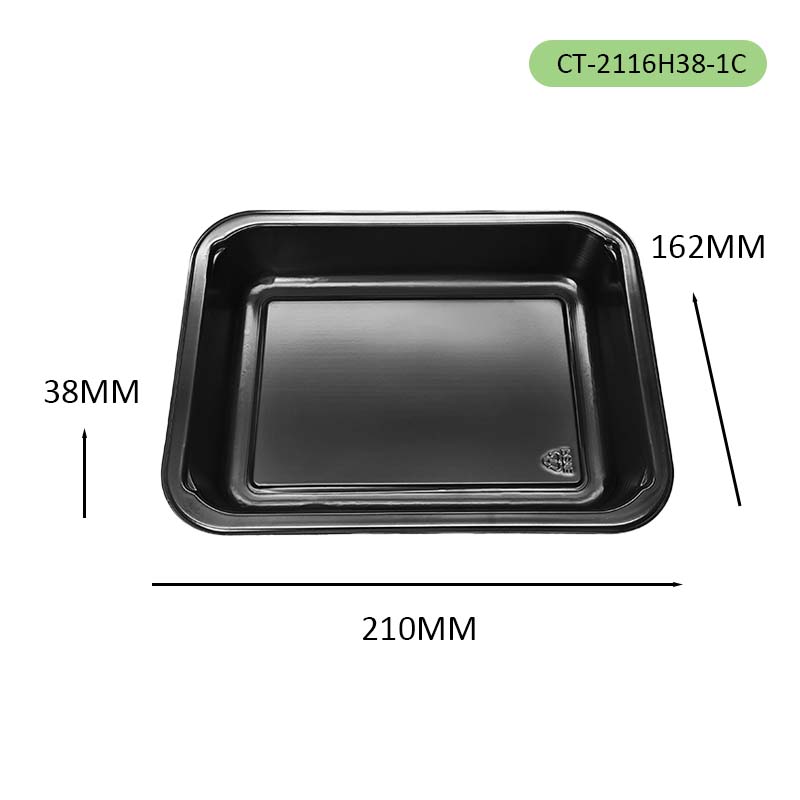

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

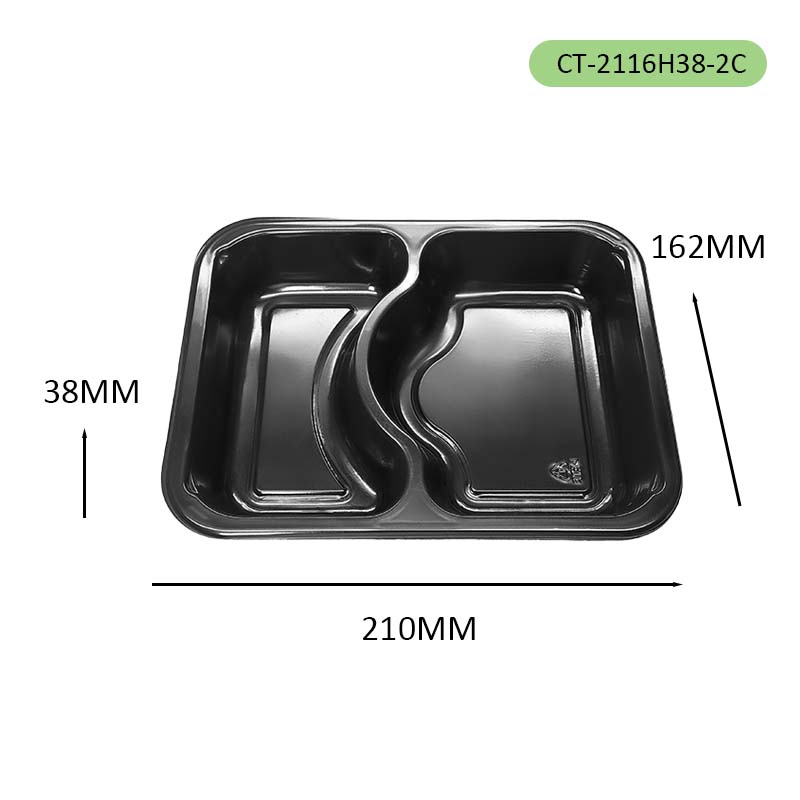

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

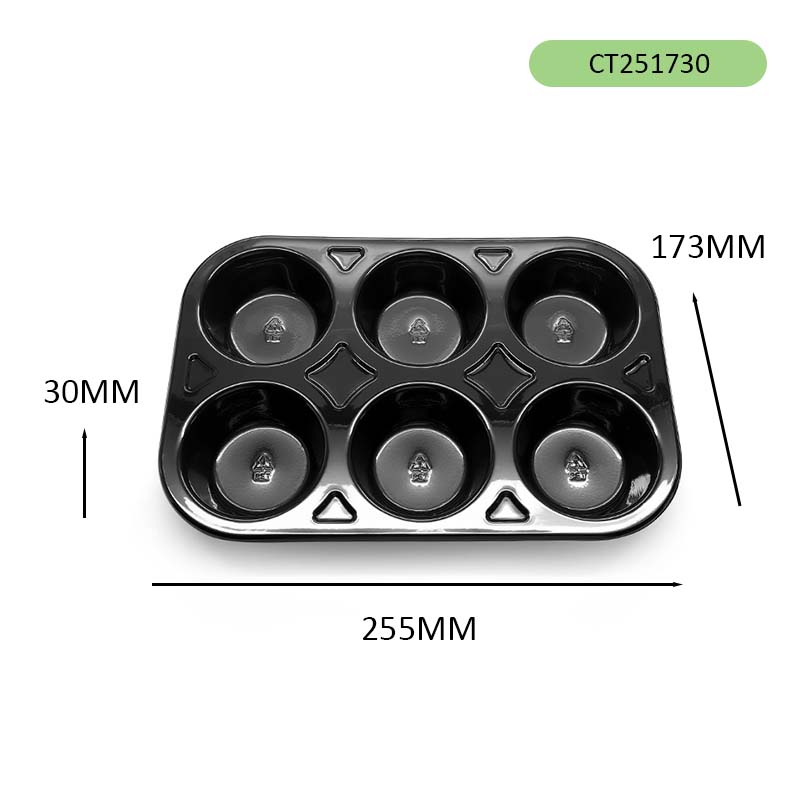

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Exceptional Temperature Resistance

One of the most important characteristics of CPET trays is their ability to withstand extreme temperature conditions. The CT-1610H35-1C tray is engineered for:

-

Blast freezing at –40°C

-

Long-term frozen storage

-

Chilled distribution

-

Oven reheating up to +220°C

-

Microwave reheating

This wide temperature range allows caterers to use a single tray throughout the entire production and delivery chain. The tray will not deform, warp, crack, or release odors—even under high heat cooking environments commonly used in airline convection ovens.

This durability makes the tray particularly valuable for frozen ready-meal producers who rely on packaging that maintains structural integrity throughout ice crystal formation, handling, and reheating cycles.

Food Safety and Material Integrity

The CT-1610H35-1C tray is produced using food-grade, BPA-free, non-toxic CPET resin that complies with global food safety regulations. CPET’s semi-crystalline structure ensures superior resistance to:

-

Grease

-

Sauces

-

Oils

-

Acidic or salty foods

This prevents chemical migration and maintains food purity, even during high-temperature reheating.

Because the tray remains clean and visually appealing after use, it is suitable for premium food programs and international airlines that place strong emphasis on passenger dining experience.

High Barrier Performance for Meal Preservation

The CT-1610H35-1C tray provides excellent barrier properties, protecting meals from external contaminants, oxygen, and moisture. These barrier characteristics help extend the shelf life of:

-

Frozen meals

-

Chilled ready meals

-

Pre-packaged inflight food components

-

Hospital or institutional meal sets

The tray’s surface allows secure sealing with:

-

Heat-seal films

-

Aluminum foil lids

-

CPET rigid lids

-

MAP (Modified Atmosphere Packaging) films

Sealing reliability ensures hygiene, flavor retention, and leak-resistant performance—especially critical in transportation environments such as airline cabins or meal carts.

Optimized for Airline Catering Workflows

The compact 160 × 105 × 35 mm design makes the CT-1610H35-1C ideal for side dishes, snacks, desserts, and portions served alongside main entrées in airline meal programs.

Operational advantages include:

1. Perfect fit for ATLAS trolley systems

Its standardized footprint supports efficient storage and stacking inside airline meal carts.

2. Lightweight structure for fuel efficiency

At only 13 g, the tray helps airlines reduce overall meal weight, contributing to lower fuel consumption and sustainable aviation goals.

3. Stable stacking for secure transport

The tray maintains rigidity even when stacked in bulk, minimizing the risk of crushing or deformation during meal production and handling.

4. Automation-friendly sealing rim

The tray is engineered with consistent tolerances for compatibility with automatic sealing machines, reducing production downtime and improving sealing accuracy.

Enhanced Food Presentation

Despite its small size, the CT-1610H35-1C delivers excellent food presentation benefits:

-

Maintains glossy, clean appearance after reheating

-

Prevents oil staining or surface dulling

-

Provides consistent color options for airline branding

-

Ensures uniform reheating, enhancing taste and texture

This ensures that inflight meals—especially premium desserts, appetizers, and sides—arrive to passengers in visually appealing condition.

Versatile Applications Beyond Airline Catering

1. Frozen Ready Meals

Ideal for compact meal components, side dishes, or children’s meals.

2. Railway and High-Speed Rail Catering

Handles vibration, reheating, and long storage cycles without deformation.

3. Hospital and Institutional Foodservice

Supports hygienic portioning and controlled meal distribution.

4. Central Kitchens and Meal Delivery Programs

Reliable for large-scale production requiring consistent packaging quality.

5. Cruise and Maritime Catering

Performs well in freezing–reheating cycles found in long-distance food preparation.

Customization Options

The CT-1610H35-1C tray can be tailored to fit specific operational or branding needs:

-

Customized colors (black, white, or special tone)

-

Embossed airline or company logos

-

Tailored carton packing for automated loading systems

-

Matching sealing film and lid solutions

This allows caterers and manufacturers to create cohesive branding across their meal programs.

Why CPET Is the Preferred Material

✔ Withstands extreme heat without deformation

✔ Excellent freezer stability

✔ High barrier protection for longer shelf life

✔ Rigid structure for clean meal presentation

✔ Recyclable in many regions

✔ Safe, stable, and globally compliant

These advantages position CPET as the most reliable and professional-grade material for airline and ready-meal packaging.

FAQ

1. Is the CT-1610H35-1C tray oven-safe?

Yes, it can be safely used in convection and steam ovens up to +220°C.

2. Can this tray be used for frozen storage?

Absolutely. It remains stable at –40°C and is ideal for long-term frozen meals.

3. What sealing options are compatible?

Heat-seal film, aluminum foil lids, and CPET rigid lids.

4. Is the tray recyclable?

In many countries, CPET is accepted in standard plastic recycling streams.

5. What types of meals is this tray best for?

Small entrées, side dishes, desserts, and children’s meal components.

Conclusion

The CT-1610H35-1C CPET airline meal tray offers a compact, lightweight, and high-performance solution for inflight catering, frozen ready meals, and institutional foodservice. Its reliable thermal resistance, exceptional food safety, secure sealing compatibility, and premium presentation make it ideal for high-volume meal producers. Whether used for side dishes, desserts, or small complete meals, this CPET tray ensures efficient production, stable storage, and excellent dining presentation across all stages of the catering process.