⚡ Quick Summary

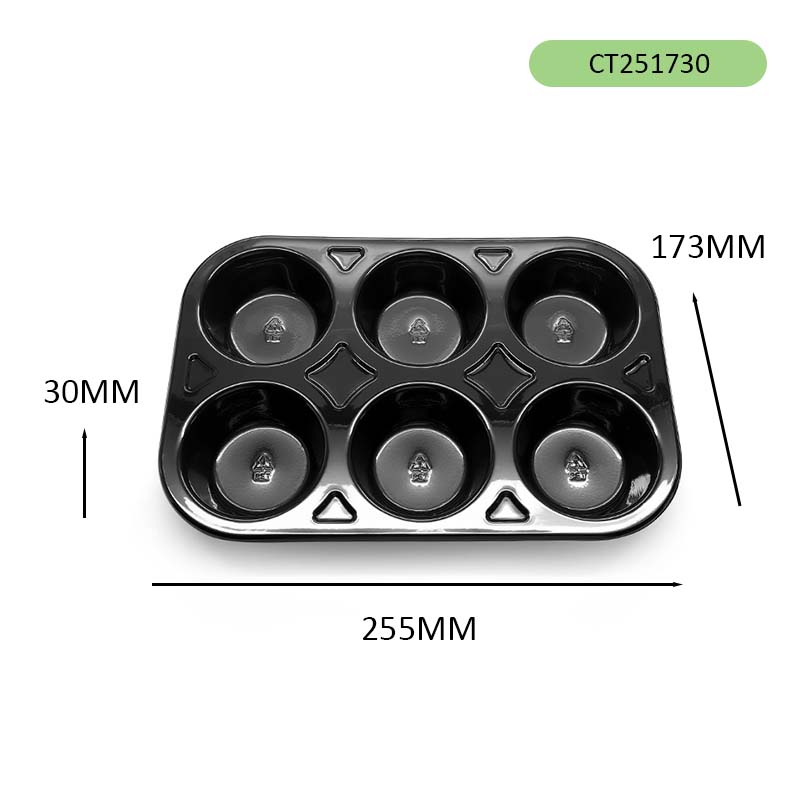

The CT251730 CPET tray is a 6-cavity dessert and cake tray (255×173×30 mm, 31.8 g) built for airline catering, bakeries, and frozen-ready dessert programs. Its CPET construction enables safe oven/microwave reheat, blast-freeze stability, easy food release, and reliable sealing—ideal for portioned pastries and in-flight dessert assortments.

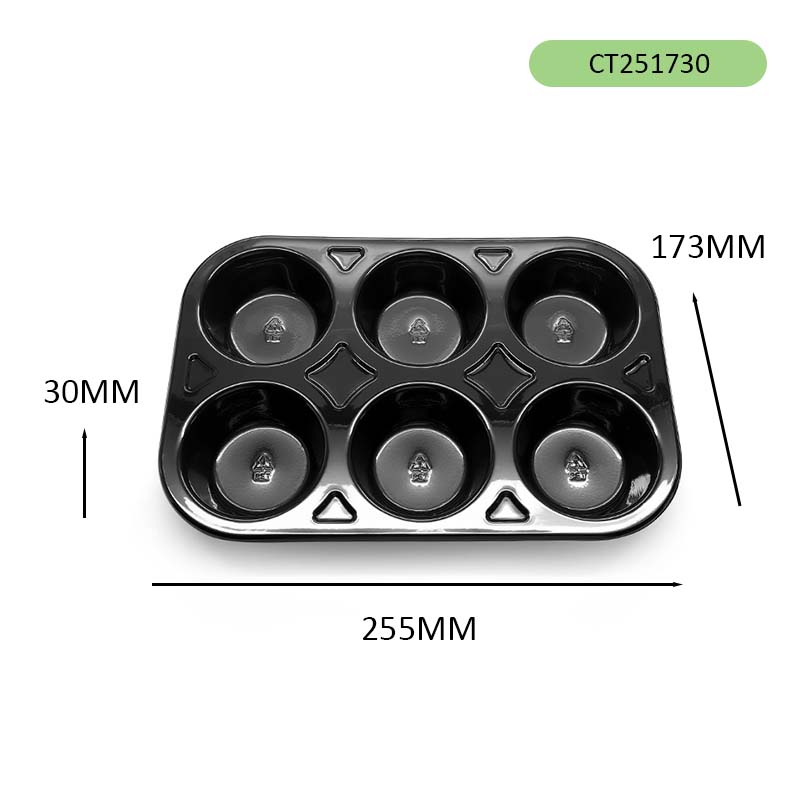

The CT251730 CPET Cake Airline Tray is a premium, high-performance packaging solution engineered for the demanding environments of airline catering, large-scale food production, and high-efficiency hot meal distribution. With a dimension of 255 × 173 × 30 mm and a lightweight yet durable 31.8 g structure, this tray is specifically crafted for applications that require stability, food safety, elegant presentation, and excellent heat resistance. Whether used for cakes, desserts, pastries, baked items, or specialty portions, this tray provides reliability from industrial kitchen preparation to in-flight serving.

Designed with six evenly distributed round cavities, the CT251730 model ensures consistent portioning, controlled baking performance, and an appealing presentation that enhances the passenger dining experience. Its glossy black finish elevates the visual quality of food plating while maintaining the professional standards required by airline caterers worldwide.

Technical Specifications

Model: CT251730

Material: CPET

Structure: Two compartments

Size: 255 × 173 × 30 mm

Weight: 31.8 g

Temperature Resistance: –40°C to +220°C

Color Options: Black / White

Applications: Airline catering, railway meals, frozen foods, central kitchens, hospital meals, ready-meal programs

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

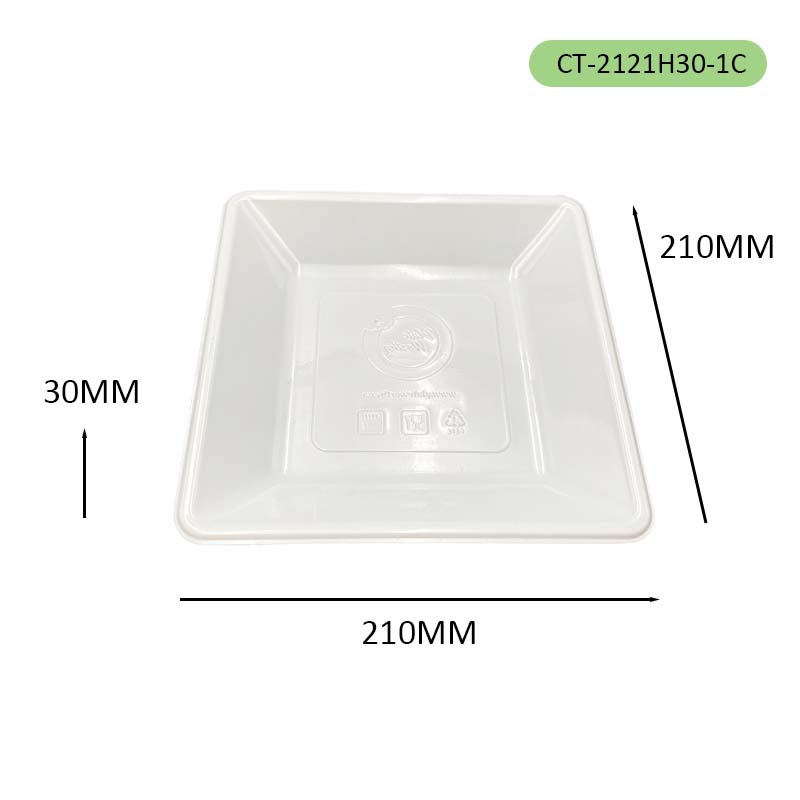

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

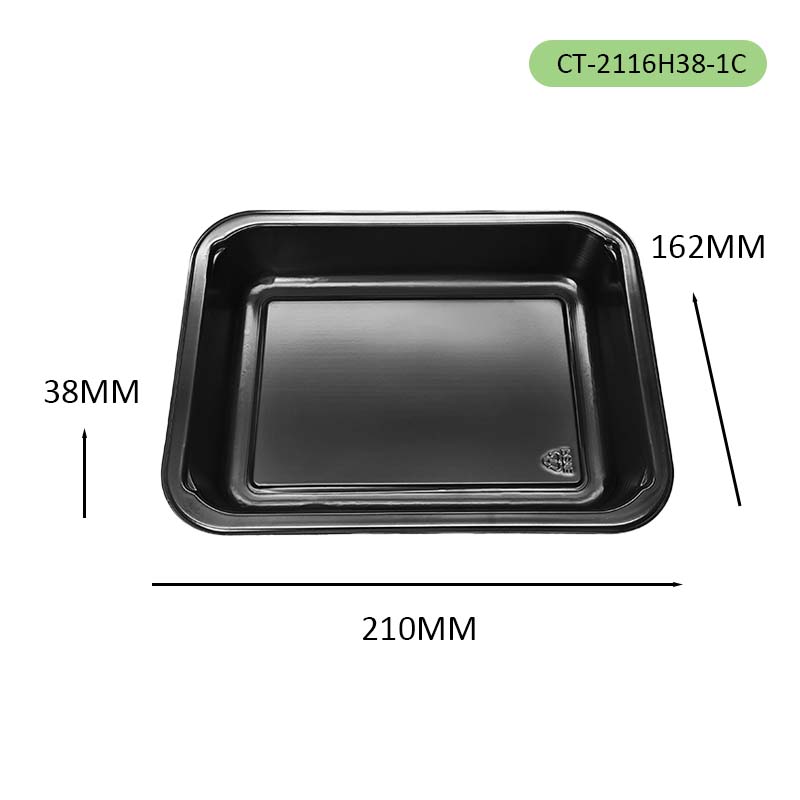

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

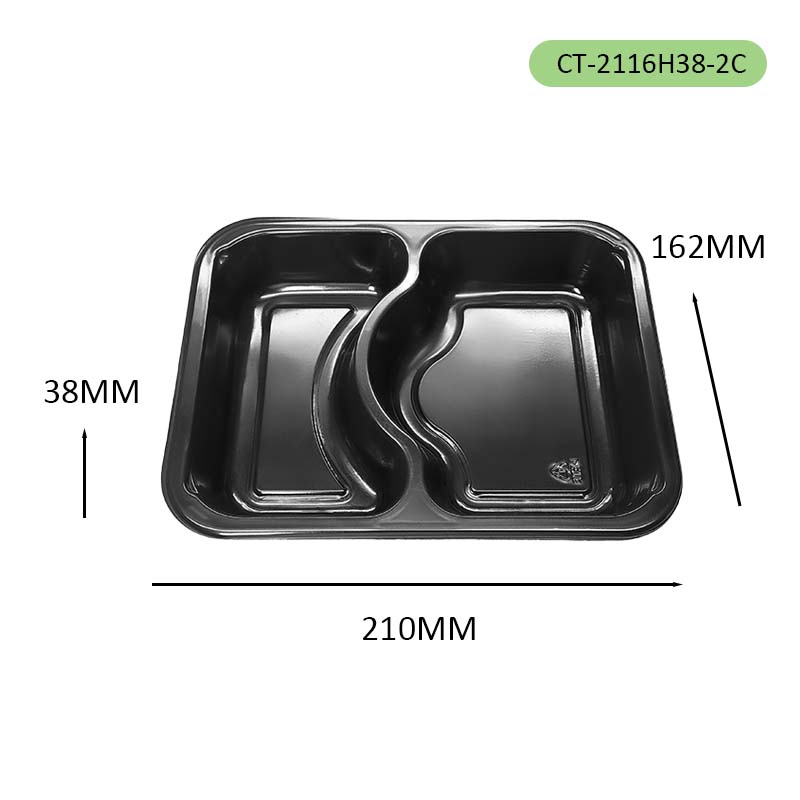

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Material Advantage — Why CPET is the Ideal Choice

CPET (Crystalline Polyethylene Terephthalate) is recognized globally for its superior thermal stability, strength, and barrier properties. The CT251730 tray leverages the full potential of CPET to deliver performance across the entire temperature spectrum required by modern foodservice systems:

-

Oven-safe up to 220–230°C, suitable for baking cakes, muffins, tarts, and hot desserts directly in the tray.

-

Microwave-safe, maintaining structural integrity under reheating.

-

Freezer-ready down to –40°C, enabling long-term frozen storage without brittleness.

-

Excellent grease, moisture, and oxygen barrier, protecting food freshness.

-

Recyclable under category “#1 PET”, supporting airline sustainability goals.

This combination of heat stability and food compatibility makes CPET one of the most trusted materials in airline meal production, where menus frequently shift between frozen storage, reheating, and service.

Purpose-Built Design for Airline Catering

The CT251730 tray is specifically engineered to support the entire workflow of airline food production and service. Every detail—from cavity depth to tray rigidity—reflects practical considerations from airline kitchens worldwide.

Six-Cavity Structure for Perfect Portion Control

Each of the six circular cavities is shaped to:

-

Hold individual cakes, muffins, mini cheesecakes, or pastries

-

Support even heat distribution during baking

-

Maintain food shape during freezing and transportation

-

Ensure neat portioning without excess movement or breakage

This format is ideal for:

-

Airline dessert assortments

-

Breakfast bakery items

-

Mini cake tasting menus

-

Mixed pastry sets

-

Children’s meals requiring smaller food units

Smooth Interior for Easy Food Release

The glossy cavity design minimizes sticking, making it perfect for:

-

Direct baking

-

Easy demolding

-

Maintaining clean edges and shapes

-

Reducing breakage during packing

Reinforced Edges and Base for Stability

Even with a lightweight 31.8 g structure, the tray remains rigid enough for:

-

High-speed filling lines

-

Conveyor systems

-

Freezer storage stacking

-

Heated trolley retherming

-

In-flight handling by cabin crew

Compatibility with Airline Meal Systems

The CT251730 CPET Cake Tray is engineered for seamless integration into global airline catering facilities.

Works with Most Sealing Films and Lidding Options

Compatible with:

-

CPET sealing films

-

PET-lids

-

Aluminum-foil seals

-

Laminated sealing materials

This allows the tray to be fully sealed for hygiene, freshness, and spill prevention.

Suitable for All Standard Heating Systems

Including:

-

Hot air ovens

-

Steam ovens

-

Microwave ovens

-

Dry-heat retherming carts

Efficient Frozen Logistics

The tray maintains shape without warping or cracking, even under:

-

Blast freezing

-

Deep-freeze storage

-

Long-haul airline loading schedules

Applications

The CT251730 tray is versatile across multiple food categories:

Airline Catering

-

Muffin assortments

-

Pastry samplers

-

Fruit tarts

-

Mini sponge cakes

-

Snack-box desserts

-

Premium mixed dessert sets

Commercial Bakeries

-

Tray-baked mini cakes

-

Pre-portioned batter baking

-

Retail multipack dessert sets

Food Manufacturers

-

Frozen ready-to-bake desserts

-

Institutional catering

-

Private-label airline food production

Benefits for Airlines & Caterers

Operational Efficiency

-

Supports automated filling lines

-

Stackable for reduced storage footprint

-

Withstands temperature shocks

-

Reduces food waste through portion control

Enhances Passenger Experience

-

Stylish black tray with clean cavity design

-

Maintains dessert shape even after heating

-

Professional presentation suitable for all cabin classes

Eco-Friendly and Compliant

-

Made from recyclable material

-

Meets global food-contact safety standards

-

Helps airlines meet sustainability initiatives

Why Choose DASHAN’s CT251730 CPET Tray

DASHAN specializes in food-grade packaging for aviation, rail, and large-scale catering industries. Our CPET trays, including the CT251730 model, are known for:

-

Stable and consistent molding quality

-

Fully automated production for uniform thickness

-

Strict quality control for food safety

-

Competitive pricing with reliable global supply

Whether you are supplying international airlines, railway food services, or commercial dessert bakeries, this tray provides performance you can rely on.

❓ FAQ

1. Is the CT251730 tray oven-safe?

Yes — made from CPET, the tray is oven-safe up to typical commercial temperatures (suitable for baking and reheating) and also microwave-safe for rapid service.

2. Can this tray be used for frozen storage?

Absolutely. The CT251730 remains stable at deep-freeze conditions (down to −40°C), making it suitable for blast freezing and long-term frozen storage.

3. Will cakes and pastries stick to the cavities?

The tray’s glossy, smooth cavity finish is optimized for easy release; for sticky batters you can still use a light release spray or liner, but in most cases products demold cleanly after cooling.

4. What sealing and packaging options are compatible?

It is compatible with heat-seal films, laminated sealing films, PET lids, and foil seals—allowing hygienic sealing, MAP applications, and secure transport.

5. Is the material food-safe and recyclable?

Yes. The tray is produced from food-grade CPET (BPA-free), compliant with international food-contact standards, and recyclable where PET/CPET recycling streams exist.

Conclusion

The CT251730 CPET 6-cavity cake tray offers a durable, heat-ready, and visually clean solution for airline desserts and industrial bakery packaging. With strong rigidity, excellent temperature resistance, and reliable sealing performance, it ensures consistent quality from production to inflight service. It is an efficient, professional choice for muffins, cakes, and premium dessert assortments.