Quick Summary

The CT170935 CPET airline meal tray is a compact, lightweight, and high-temperature-resistant food container designed for aviation catering, frozen meals, and institutional foodservice. With dimensions of 171 × 97 × 35 mm and a weight of just 12.6 g, it provides reliable durability, excellent heat-resistance, and consistent sealing performance for large-scale meal production and inflight service.

Introduction

In the fast-paced world of inflight catering and industrial meal preparation, packaging must withstand rigorous operational conditions—from rapid chilling and long-term freezer storage to high-temperature reheating and onboard service. The CT170935 CPET airline meal tray is engineered precisely for these professional requirements.

Designed with a compact footprint of 171 × 97 × 35 mm and a lightweight 12.6 g structure, the CT170935 tray serves as an ideal solution for side dishes, desserts, bread portions, small entrées, snacks, and premium meal components. Airlines and ready-meal producers rely on this size class for its versatility, stacking stability, and compatibility with automated sealing systems.

Made from Crystallized Polyethylene Terephthalate (CPET), the tray offers exceptional thermal performance, structural rigidity, food safety, and aesthetic appeal. Whether it is used in airline service carts, frozen meal production lines, or mass-production central kitchens, the CT170935 delivers consistent results with a professional finish.

This product detail document covers its specifications, technical advantages, performance characteristics, operational benefits, and multi-industry applications—showing why the CT170935 remains one of the most trusted compact CPET airline trays.

Technical Specifications

| Item | Details |

|---|---|

| Model | CT170935 |

| Material | CPET (Crystallized Polyethylene Terephthalate) |

| Structure | Single compartment |

| Product Size | 171 × 97 × 35 mm |

| Weight | 12.6 g |

| Temperature Resistance | –40°C to +220°C |

| Color Options | Black / White |

| Reheating Methods | Oven, microwave, steam oven |

| Sealing Options | Heat-seal film / Aluminum foil lids / CPET rigid lids |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

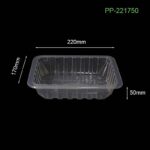

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

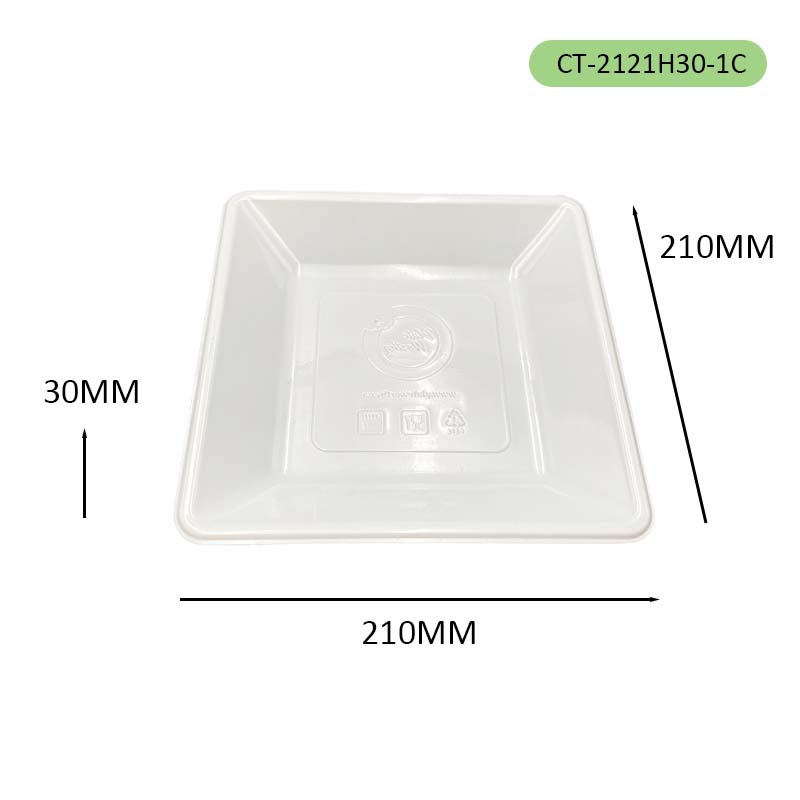

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

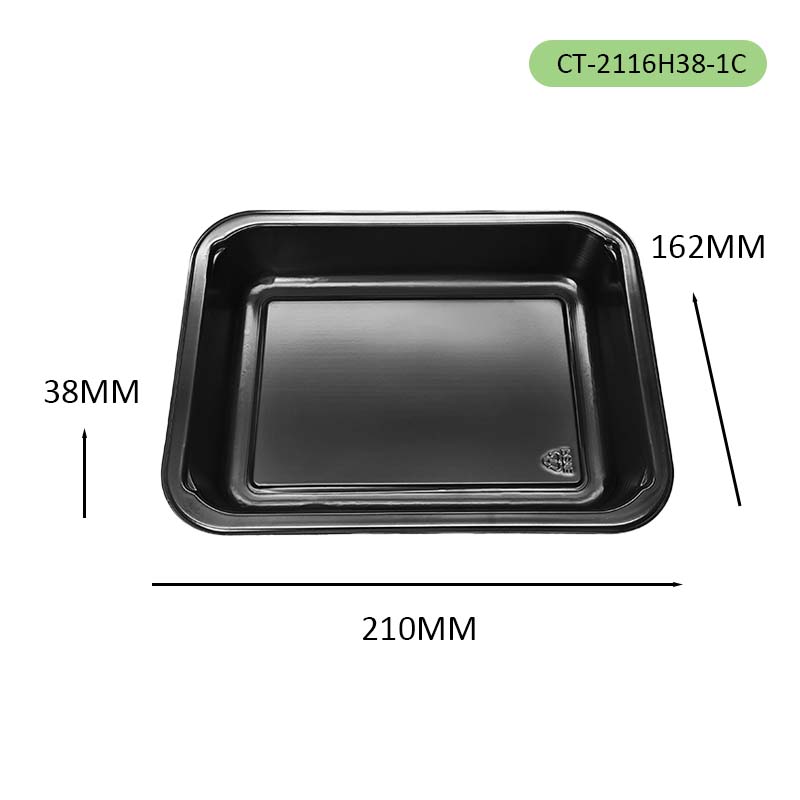

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

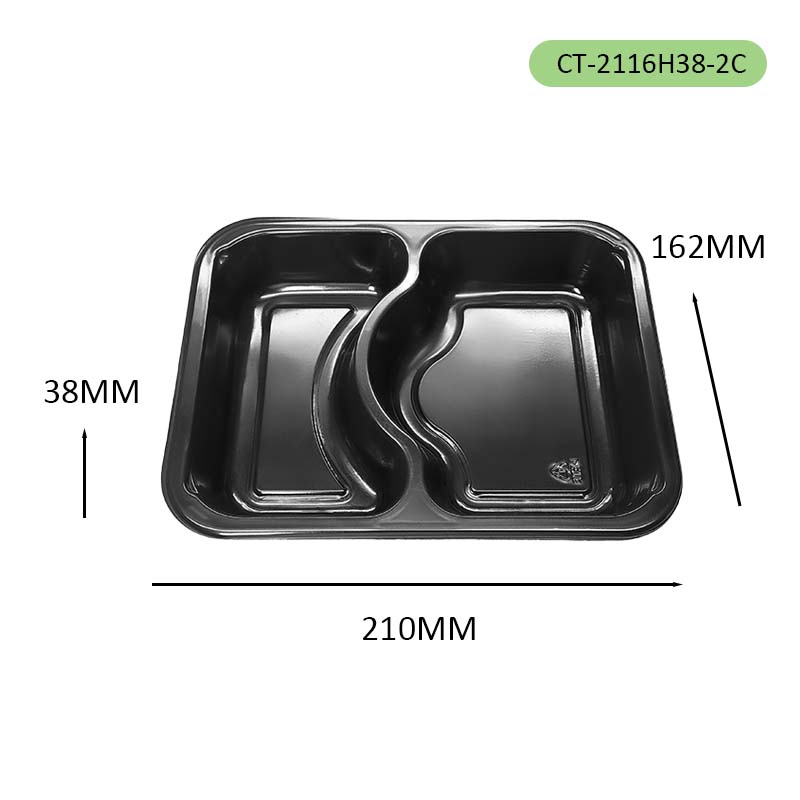

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

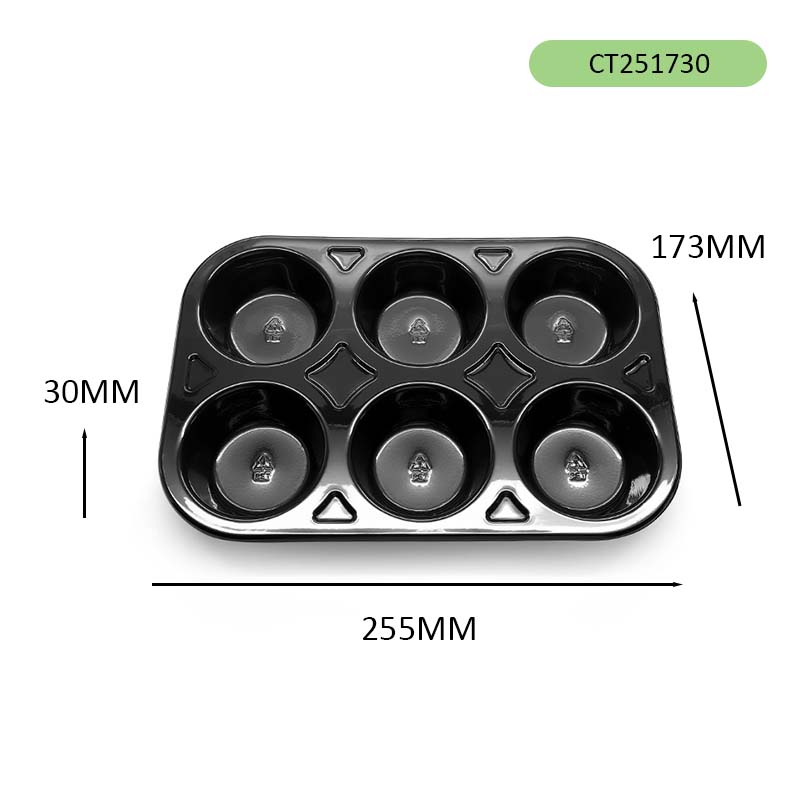

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Outstanding Temperature Performance

One of the most important characteristics of CPET is its wide temperature tolerance. The CT170935 tray performs reliably in conditions ranging from –40°C freezing to +220°C oven heating, making it suitable for every step of the airline catering workflow:

1. Industrial Cooking

The tray can be filled with hot dishes or freshly cooked sides without softening or deforming.

2. Blast Chilling and Freezing

Professional meal suppliers depend on CPET because it maintains structural integrity even under rapid temperature drops and long frozen storage periods.

3. Long-Term Frozen Storage

Meals remain sealed, stable, and well-presented for weeks or months in cold-chain distribution.

4. Reheating Before Service

The CT170935 is fully compatible with:

-

Convection ovens

-

Steam ovens

-

Microwave reheating systems

It does not warp, crack, or emit odors during reheating. Heat is evenly distributed, ensuring consistent food quality onboard.

5. Final Inflight Service

CPET maintains its rigidity during service, preventing bending and ensuring safe handling by airline crew.

Food Safety and Hygienic Performance

The CT170935 tray meets global food-contact safety standards and is manufactured using certified food-grade CPET resin. It is:

✔ BPA-free

✔ Non-toxic

✔ Odorless

✔ Resistant to oils, acids, and sauces

✔ Chemically stable during heating

CPET’s semi-crystalline structure ensures excellent resistance to:

-

Tomato-based sauces

-

High-fat foods

-

Acidic marinades

-

Oily dressings

This prevents staining, flavor transfer, and material weakening. Even after being heated to high temperatures, the tray retains its shape and rigidity.

Superior Barrier Properties

Airline meals often undergo long preparation cycles—from factory kitchens to international airports to inflight service. The CT170935 tray features strong barrier performance that helps:

• Preserve aroma

• Prevent moisture loss

• Maintain freshness

• Protect meals from external contaminants

The tray is compatible with multiple sealing formats:

-

Standard heat-seal lidding films

-

Aluminum foil lids

-

Rigid CPET lids

-

MAP (Modified Atmosphere Packaging) systems

This flexibility makes it suitable for both short-haul and long-haul inflight catering operations.

Compact, Efficient Design for Airline Catering

The 171 × 97 mm footprint is widely used in airline meal service trays, trolley setups, and multi-component meal designs. Key operational benefits include:

1. Fits perfectly into airline service trays

Its size is ideal for side dishes, desserts, bread portions, snacks, and hot or cold accompaniments.

2. Lightweight for reduced fuel and logistics costs

At just 12.6 g, it supports airline efficiency goals.

3. Strong rigidity for stacking

The tray resists compression inside catering carts and freezers.

4. Fast and clean sealing

Its uniform edge structure ensures sealing consistency during high-speed production.

5. Leak-resistant

Ideal for items containing sauces, creams, stews, or moist desserts.

Enhanced Food Presentation

A clean, professional food appearance is essential in premium airline catering. The CT170935 tray supports:

-

Smooth interior surfaces to enhance plating

-

Uniform heating for visually pleasing results

-

Black or white colors for strong food contrast

-

High-gloss CPET finish for a premium look

Whether used for desserts, vegetables, appetizers, or specialty items, the tray ensures consistent and attractive presentation.

Applications Across Multiple Industries

Although primarily used for airline meals, the CT170935 is also widely applied in:

1. Airline Catering

Small hot dishes, desserts, sides, or snacks.

2. Railway Catering

Compact meal components for high-speed rail and long-distance trains.

3. Frozen Meal Manufacturing

Ideal for single-serve components.

4. Industrial Central Kitchens

Hospitals, schools, and corporate dining services.

5. Institutional Catering

Military, cruise ships, offshore operations, correctional facilities.

Its compact design makes it extremely versatile and cost-effective across all foodservice segments.

Customization Options

To support branding and operational needs, the CT170935 tray can be customized with:

-

Embossed company or airline logos

-

Custom colors

-

Tray edge designs for automated sealing

-

Packaging carton formats optimized for assembly lines

Custom OEM/ODM solutions allow foodservice companies to integrate the tray seamlessly into their production systems.

Why CPET is the Preferred Material for Airline Meal Trays

Compared to PP, PS, or aluminum, CPET offers unique advantages:

✔ Withstands –40°C to +220°C

✔ Can go directly from freezer to oven

✔ Rigid and durable for stacking

✔ Supports beautiful presentation

✔ Safe for direct food contact

✔ Recyclable in many regions

For airlines and industrial kitchens requiring reliability and food safety at scale, CPET remains the gold standard.

FAQ

1. Is the CT170935 tray oven-safe?

Yes, the tray can withstand heating up to 220°C, making it suitable for convection, steam, and microwave systems.

2. Can the tray be frozen for long-term storage?

Absolutely. The CT170935 performs reliably at –40°C and is ideal for frozen meals and cold-chain distribution.

3. What types of sealing films are compatible with this tray?

It supports heat-seal films, aluminum foil lids, and CPET rigid lids commonly used in airline and industrial kitchens.

4. Is the tray safe for direct food contact?

Yes, it is made from food-grade CPET resin that is BPA-free, odorless, and compliant with international food safety standards.

5. What applications is the CT170935 best suited for?

It is ideal for airline catering, desserts, side dishes, frozen meal sets, railway catering, and institutional foodservice.

Conclusion

The CT170935 CPET airline meal tray is a compact, reliable, and high-performance packaging solution engineered for today’s demanding foodservice environments. Its excellent thermal stability, lightweight construction, sealing compatibility, and professional presentation make it ideal for side dishes, desserts, snacks, and premium meal components in airline catering, frozen meal production, and institutional foodservice.

With superior CPET material properties and a proven track record in global inflight catering systems, the CT170935 tray delivers consistent results from production to final service—making it one of the most versatile small-format trays available.