Quick Summary

Polypropylene (PP) packaging remains a core material in global foodservice because it performs reliably where it matters most. Designed for microwave heating, durable enough for repeated use, and consistent at scale, PP supports real-world food operations better than many trend-driven alternatives. This article explains why PP continues to play a practical role in modern packaging systems.

Polypropylene (PP) packaging is rarely described as exciting. It does not dominate sustainability headlines, nor is it marketed as a revolutionary material. Yet across foodservice, ready meals, and takeaway systems worldwide, PP remains one of the most trusted and widely used packaging materials.

This is not an accident. PP packaging has survived decades of material innovation because it consistently solves real operational problems—especially in environments where food must be heated, handled repeatedly, and delivered reliably.

To understand the true value of PP packaging, it is useful to step away from labels and focus on how packaging is actually used. In daily life and commercial food systems, PP’s strength can be summarized in three words: microwave, reuse, repeat.

Why PP Packaging Has Endured While Other Materials Come and Go

Packaging materials often rise and fall with trends. Some gain attention due to regulatory changes, others because of consumer perception. PP, however, has remained stable across markets and decades because it meets a fundamental requirement: predictable performance under stress.

Food packaging is exposed to a combination of challenges:

-

Heat and temperature fluctuations

-

Oils, moisture, and acidic ingredients

-

Mechanical pressure during stacking and transport

-

Repeated opening, closing, and handling

PP performs consistently across these conditions. Its molecular structure provides flexibility without brittleness, allowing containers to retain shape under heat and pressure. This balance of toughness and stability is difficult to replicate at scale with many alternative materials.

For food brands and operators, reliability matters more than novelty.

Microwave Use: One of the Toughest Tests for Food Packaging

Microwave heating places unique demands on packaging. Unlike conventional ovens, microwaves heat unevenly, creating localized hot spots and rapid steam buildup. Packaging materials that are not designed for these conditions may warp, soften, or fail.

Why microwave compatibility is critical

-

Consumers increasingly expect reheatable packaging

-

Ready meals and takeaway often require reheating at home

-

Safety risks arise if containers deform or leak

PP is inherently suited for microwave use within typical food reheating temperature ranges. It maintains structural integrity, resists melting, and does not release odors or compromise food quality.

This is why PP is commonly used for:

-

Hot takeaway meals

-

Ready-to-eat meals

-

Institutional foodservice (schools, hospitals, offices)

Microwave performance comparison

| Material | Microwave Safety | Heat Stability | Typical Limitation |

|---|---|---|---|

| PP | High | Stable | Lower transparency |

| PET / RPET | Limited | Moderate | Deformation risk |

| PLA | Low | Poor | Softens easily |

| Bagasse | Moderate | Limited | Moisture absorption |

In real-world foodservice operations, these differences translate directly into fewer spills, fewer complaints, and better user experience.

Reuse: An Often Overlooked Sustainability Advantage

While PP packaging is often categorized as “disposable,” actual consumer behavior tells a different story. Many PP containers are reused multiple times before disposal, particularly in household and workplace settings.

This reuse is enabled by PP’s:

-

Mechanical strength

-

Resistance to cracking

-

Compatibility with washing and refrigeration

Common reuse scenarios

-

Storing leftovers

-

Packing lunches

-

Freezing food

-

Dry food storage

From a sustainability perspective, reuse significantly lowers the environmental impact per use. Even without compostability, extending the functional life of packaging can reduce total material demand and waste generation.

This practical reuse behavior is one reason PP remains relevant in modern sustainability discussions, especially in regions where composting infrastructure is limited.

Repeat Performance: Why Consistency Is Essential for Food Businesses

For foodservice operators, packaging is not evaluated one unit at a time. It is evaluated across thousands or millions of uses.

PP packaging supports repeat performance in:

-

Automated filling and sealing

-

Transport and stacking

-

Temperature changes

-

Storage and handling

Consistency reduces operational risks and hidden costs.

Operational advantages of PP

-

Predictable lid fit

-

Stable stacking during transport

-

Reduced leakage and deformation

-

Compatibility with existing equipment

Many restaurants and food manufacturers prioritize materials that perform reliably every time. In this context, PP’s repeatability becomes a strategic advantage.

Cost Efficiency Without Compromising Performance

Beyond technical performance, PP offers cost stability. It is widely produced, globally available, and compatible with high-speed manufacturing.

This allows:

-

Competitive unit pricing

-

Stable supply chains

-

Scalable production

For large-volume foodservice and retail operations, these factors are critical. Packaging decisions must balance sustainability goals with economic reality.

Where PP Clearly Outperforms Other Materials

PP is not universal, but it excels in specific applications.

Best-fit applications

| Application | PP Advantage |

|---|---|

| Hot food takeaway | Heat and oil resistance |

| Microwave reheating | Structural stability |

| Reusable food containers | Durability |

| Central kitchens | Process consistency |

| High-volume foodservice | Cost efficiency |

In these use cases, alternative materials often introduce compromises—either in performance or cost.

Where PP Is Not the Best Choice

A balanced discussion must acknowledge limitations.

PP may not be ideal for:

-

Premium retail display requiring high clarity

-

Markets focused exclusively on compostable solutions

-

Single-use-only applications with no reuse potential

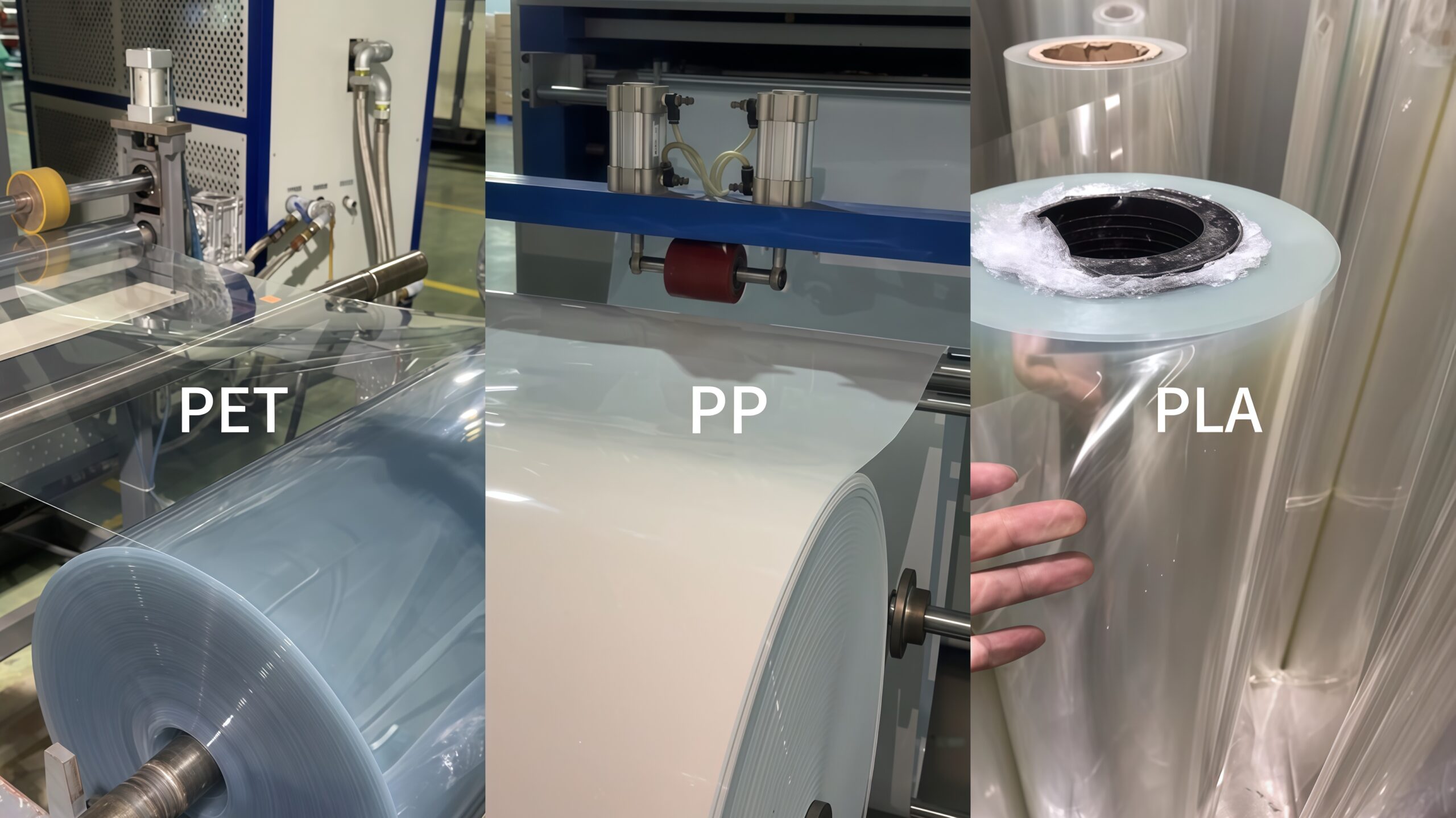

In such cases, PET, RPET, PLA, or fiber-based packaging may offer better alignment with goals.

The key principle is application-driven material selection.

PP Packaging and the Reality of Sustainability

Sustainability cannot be assessed by material type alone. It must consider:

-

Actual use patterns

-

Infrastructure availability

-

Functional lifespan

PP is widely recyclable in many regions, and its durability encourages reuse. In practice, a PP container reused several times may have a lower overall footprint than a compostable container that is landfilled due to lack of composting facilities.

This does not make PP “the most sustainable” material—but it makes it a realistic and effective option in many systems.

Why PP Continues to Play a Central Role in Modern Packaging

PP packaging persists because it aligns with how food is prepared, transported, consumed, and reheated in real life.

It supports:

-

Microwave heating

-

Repeated use

-

Consistent operational performance

In an industry where failure is costly and reliability matters, PP remains a practical solution.

The future of packaging is not about choosing a single “best” material. It is about matching materials to applications thoughtfully and honestly. PP continues to earn its place by doing exactly that—quietly, consistently, and effectively.

FAQ

1. Why is PP packaging commonly used for microwave food?

PP maintains structural stability under typical microwave reheating temperatures, reducing the risk of warping, leakage, or container failure during heating.

2. Is PP packaging reusable?

Yes. PP is mechanically durable and resistant to cracking, which allows many containers to be reused multiple times for food storage, refrigeration, and reheating.

3. How does PP compare to compostable materials?

PP offers better heat resistance and durability, while compostable materials may be better suited for cold food or short-term use when composting infrastructure is available.

4. Is PP packaging recyclable?

PP is recyclable in many regions where appropriate recycling systems exist, though recycling availability varies by market.

5. When is PP not the best packaging choice?

PP may not be ideal for premium retail display requiring high transparency or in applications where compostability is a strict requirement.

6. Why do many foodservice operators still rely on PP?

Because PP delivers predictable performance at scale, supports automated operations, and minimizes packaging-related failures in daily use.

Conclusion

Polypropylene packaging continues to play a central role in modern food systems not because it follows trends, but because it performs reliably in real-world conditions. From microwave reheating to repeated handling and large-scale foodservice operations, PP delivers consistency where failure is not an option.

As sustainability discussions become more nuanced, material choices must move beyond labels and focus on how packaging is actually used. PP may not be the right solution for every application, but in scenarios that demand heat resistance, durability, and operational stability, it remains one of the most practical and dependable options available.

The future of packaging will not be defined by a single “best” material. Instead, it will be shaped by thoughtful material selection—matching performance, infrastructure, and real-life use. In that context, PP packaging continues to earn its place through microwave readiness, reuse potential, and repeatable performance.

References

-

European Food Safety Authority (EFSA)

Safety of Polypropylene Used in Food Contact Materials

https://www.efsa.europa.eu/en/topics/topic/food-contact-materials -

PlasticsEurope

Polypropylene (PP) – Properties and Applications

https://plasticseurope.org/knowledge-hub/polypropylene-pp/ -

U.S. Food & Drug Administration (FDA)

Food Contact Substances and Microwave Use

https://www.fda.gov/food/packaging-food-contact-substances-fcs -

World Packaging Organisation (WPO)

Packaging Materials and Performance in Food Systems -

WRAP UK

Packaging Durability, Reuse and Environmental Impact

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.