Quick Summary

Packaging material decisions in today’s global foodservice and retail environments are often clouded by common myths. Believing there is a single “best” material, or that sustainable packaging always costs more, can lead to poor performance, higher operational costs, or compliance risk. In reality, materials such as PET, RPET, CPET, PP, PLA, bagasse, and cornstarch each have specific strengths tied to application needs, temperature conditions, and regulations. Professional buyers evaluate packaging based on food type, use conditions, and market requirements, not marketing labels. Understanding material fits, regulations, and real-world performance leads to better cost control, compliance, and operational success.

In today’s global foodservice and retail markets, packaging decisions have become more complex than ever. Buyers are expected to balance food safety, cost control, sustainability commitments, logistics efficiency, and regulatory compliance—often across multiple countries and use cases.

Yet despite this complexity, many packaging decisions are still influenced by simplified assumptions and persistent myths. These misconceptions can lead to material mismatches, operational inefficiencies, regulatory risk, and unnecessary cost increases.

This article aims to clarify the most common packaging myths and explain what professional buyers, brand owners, and importers truly need to understand when selecting food packaging materials in 2025 and beyond.

Why Packaging Myths Persist in the Industry

Packaging myths do not arise from ignorance alone. They are often the result of fragmented information, marketing-driven narratives, and the understandable desire for simple answers in a complex environment.

Sustainability campaigns may highlight one material as a universal solution. Regulatory discussions are sometimes summarized into headlines that overlook nuance. Suppliers may promote their strongest category without emphasizing its limitations.

Over time, these partial truths solidify into “rules” that are rarely questioned. However, real-world packaging performance is shaped by factors far more practical: temperature exposure, food composition, logistics duration, disposal systems, and local regulations.

Understanding packaging requires moving beyond slogans and focusing on application-based reality.

Myth 1: “There Is One Best Packaging Material”

Many buyers begin their search hoping to identify a single material that can replace all others across their product range. From a procurement perspective, this seems efficient—fewer SKUs, simpler supplier management, and unified sustainability messaging.

In practice, however, food packaging operates under highly variable conditions.

Hot meals generate steam and internal pressure. Cold beverages create condensation. Oily foods migrate fats into container walls. Acidic foods stress chemical stability. Long-distance delivery introduces stacking pressure and vibration. No single material can address all these challenges without compromise.

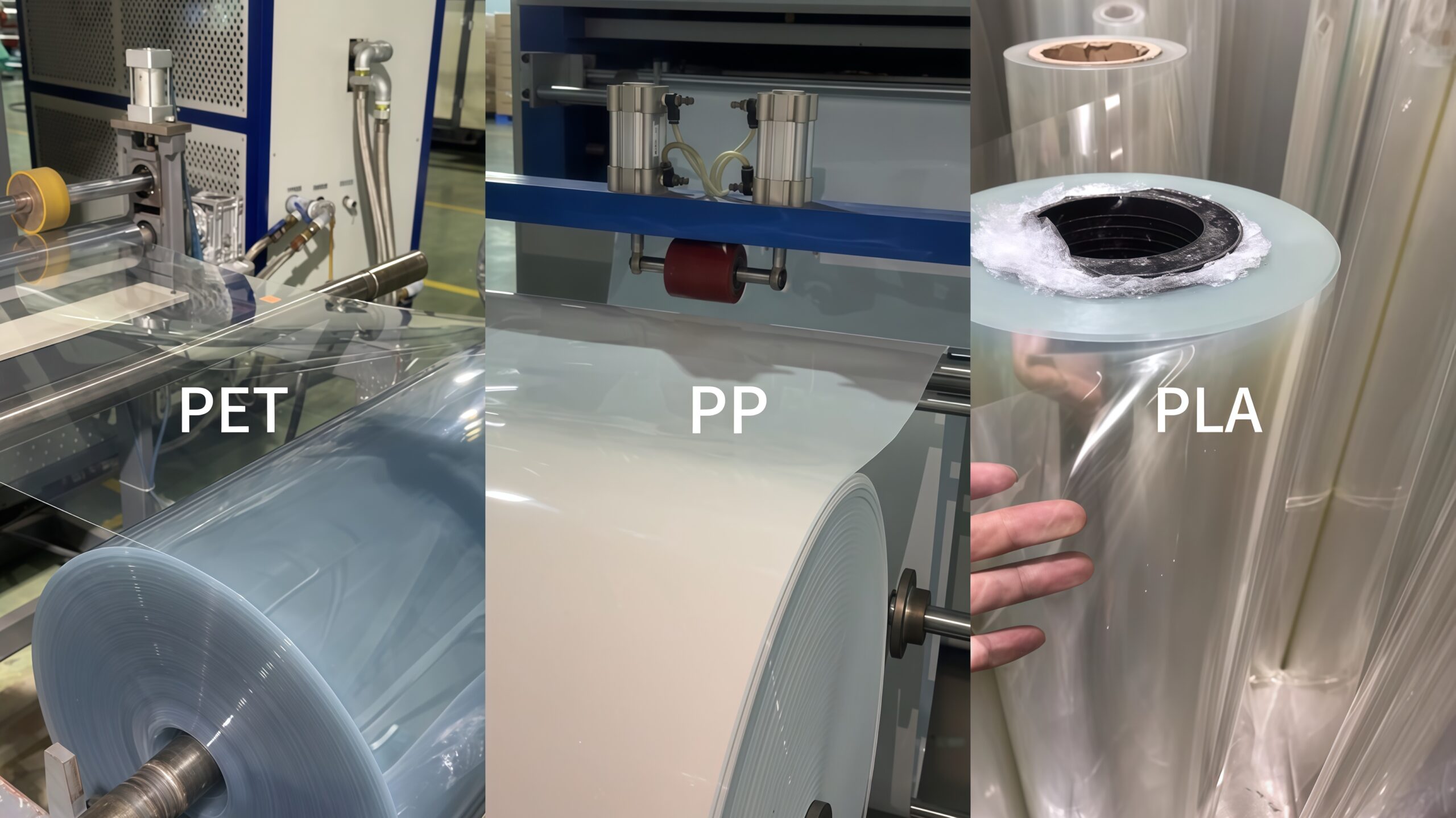

For example, PET and RPET offer excellent clarity and rigidity, making them ideal for cold food and beverage applications. CPET excels in high-temperature environments such as airline meals or oven reheating but lacks transparency. PP provides flexibility and microwave resistance, while PLA performs well for cold drinks where plant-based sourcing and visual appeal are priorities. Fiber-based materials such as bagasse and cornstarch serve takeaway and short-use scenarios where natural appearance and compostability are valued.

Each material exists because it solves a specific problem. Treating materials as competitors rather than tools often leads to overstandardization—and ultimately to performance failures.

Myth 2: “Sustainable Packaging Always Costs More”

One of the most persistent beliefs in packaging procurement is that sustainability inevitably increases cost. This assumption is usually based on direct unit price comparisons.

While it is true that some sustainable materials carry a higher per-unit cost, unit price alone rarely reflects the full economic impact of packaging.

Poorly matched packaging can result in deformation, leakage, cracking, or seal failure. These issues lead to food waste, customer complaints, refunds, re-deliveries, and brand damage. Each incident adds hidden costs that quickly outweigh initial savings.

For instance, a low-cost container that warps during microwave reheating may lead to spilled meals during delivery. Even a small failure rate can significantly increase cost per successful order.

Conversely, materials such as PP, CPET, or well-engineered RPET often reduce breakage and improve stacking efficiency. Over time, their durability lowers overall operational cost despite a higher initial price.

Sustainable packaging does not automatically increase cost. When evaluated through total cost of ownership, it often improves cost stability and reduces risk.

Myth 3: “Compostable Packaging Breaks Down Anywhere”

Compostability is one of the most misunderstood concepts in packaging.

Marketing narratives often suggest that compostable packaging will naturally decompose in any environment. In reality, compostable materials behave very differently depending on disposal conditions.

PLA typically requires industrial composting facilities with controlled heat and humidity. Without these conditions, it may persist in landfills similarly to conventional plastics. Bagasse and cornstarch products degrade more naturally but still rely on appropriate moisture, oxygen, and waste separation.

The challenge arises when compostable packaging is introduced into regions without suitable infrastructure. In such cases, the environmental benefits may not materialize, and improper disposal can create compliance or reputational risks.

Responsible buyers evaluate compostable packaging based on local waste systems, not just material classification. Compostability should complement an existing waste strategy rather than replace it.

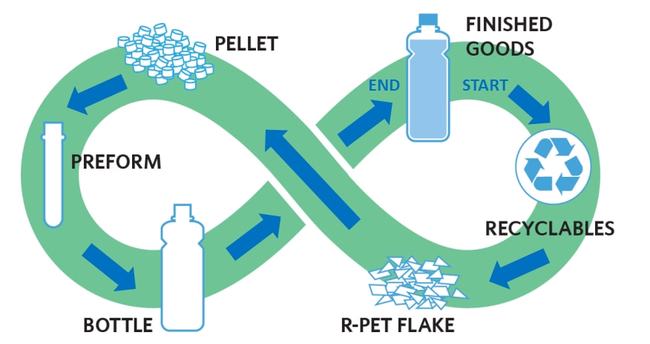

Myth 4: “Recycled Plastic Is Lower Quality”

Recycled plastic, particularly RPET, has undergone significant technological improvement over the past decade.

Modern food-grade RPET offers high clarity, stable rigidity, and reliable sealing performance. In cold food and beverage applications, RPET often performs comparably to virgin PET while reducing reliance on fossil resources.

The key factor is controlled sourcing and processing. When recycling streams are well managed, RPET delivers consistent quality suitable for demanding foodservice and retail environments.

This evolution has made RPET a viable mainstream solution rather than a compromise.

Myth 5: “Clear Packaging Is Only About Appearance”

Transparency is often viewed as a purely aesthetic choice. In reality, it plays a functional role in food packaging.

Clear packaging allows consumers to visually assess freshness and portion size, reducing unnecessary handling and improving trust. In retail environments, clarity directly influences purchasing decisions.

Features such as anti-fog lids, stable sealing, and clarity retention under refrigeration further enhance product performance. Transparency is therefore part of both product protection and consumer communication.

Myth 6: “Packaging Regulations Are the Same Everywhere”

Global buyers frequently underestimate regulatory fragmentation.

While sustainability goals may appear aligned globally, regulations differ significantly in execution. The European Union emphasizes recyclability, recycled content, and extended producer responsibility. The UK applies separate labeling and reporting requirements. The United States operates under state-level frameworks. Asia-Pacific markets vary widely in maturity and enforcement.

As a result, a packaging solution compliant in one market may require redesign or relabeling in another.

This reality makes single-material strategies increasingly impractical for export-oriented brands. Instead, many companies adopt multi-material portfolios, selecting materials based on destination market and application.

Why Regulations Encourage Multiple Solutions

Modern packaging regulations focus on outcomes rather than prescribing materials. Legislators aim to reduce environmental impact, improve waste recovery, and protect food safety, while leaving room for innovation.

This approach allows recyclable plastics, plant-based materials, and fiber-based solutions to coexist—each addressing specific challenges.

Rather than forcing uniformity, regulations encourage adaptability. Companies that maintain flexible material strategies are better positioned to respond to regulatory changes without disrupting supply chains.

How Professional Buyers Actually Choose Packaging

Experienced procurement teams follow a structured evaluation process:

-

Food type and composition

-

Temperature exposure during use

-

Distribution and logistics model

-

Target market regulations

-

Total cost of ownership

Typical Material–Application Overview

| Material | Primary Applications | Key Strength |

|---|---|---|

| PET | Cold food, beverages | High clarity, rigidity |

| RPET | Retail & takeaway | Recycled content, transparency |

| CPET | Hot meals, airline catering | Heat resistance |

| PP | Microwave & hot food | Flexibility, durability |

| PLA | Cold drinks, display | Plant-based, clear |

| Bagasse | Takeaway meals | Natural fiber, compostable |

| Cornstarch | Lightweight foodservice | Plant-based simplicity |

What Buyers Should Focus on in 2025–2026

Looking ahead, effective packaging strategies will prioritize:

-

Application-specific performance

-

Regulatory adaptability

-

Stable supply chains

-

Scalable manufacturing

-

Clear sustainability communication

Rather than chasing trends, buyers benefit from understanding the strengths and limits of each material category.

FAQ

1. Why is there no single “best” packaging material?

Packaging performance depends on specific application requirements such as temperature, food type, barrier needs, and logistics. A material that works for cold drinks may fail for hot meals.

2. Does sustainable packaging always cost more?

Not necessarily. Initial unit prices can be higher, but total costs often decrease when durability, reduced waste, and operational reliability are factored in.

3. Are compostable materials truly biodegradable everywhere?

No. Many compostable materials such as PLA require industrial composting facilities to break down properly; they do not degrade quickly in natural environments or landfills.

4. Is recycled plastic lower quality than virgin plastic?

Modern RPET can match the clarity and performance of virgin PET in many applications when sourced and processed under controlled conditions.

5. What role does transparency play in packaging?

Beyond aesthetics, clarity helps consumers assess freshness, builds trust, and supports retail sales.

6. Are packaging regulations uniform across markets?

No. Different countries and regions have varied requirements for recyclability, compostability claims, labeling, and food-contact safety. This requires flexible material strategies.

7. What should buyers focus on when choosing packaging?

Buyers should prioritize material fit for the product’s use case, regulatory compliance, supply stability, and total cost effectiveness rather than material popularity.

Conclusion

There is no perfect packaging material.

Every material represents a balance between performance, cost, sustainability, and compliance. Packaging myths simplify a complex decision—but often at the expense of real-world results.

The most successful packaging strategies are built on practical understanding, not assumptions. By selecting materials based on real use cases, businesses can reduce risk, control costs, and meet sustainability goals with confidence.

Reference

-

European Commission – Packaging and Packaging Waste Regulation (PPWR)

https://environment.ec.europa.eu/publications/proposal-packaging-and-packaging-waste_en -

European Bioplastics – Materials Overview (PLA and Bioplastics)

https://www.european-bioplastics.org/bioplastics/materials/ -

European Food Safety Authority (EFSA) – Food Contact Materials

https://www.efsa.europa.eu/en/topics/topic/food-contact-materials -

U.S. Food & Drug Administration – Food Contact Materials Guidance

https://www.fda.gov/food/packaging-food-contact-substances-fcs -

ASTM International – ASTM D6400 Compostability Standard

https://www.astm.org/d6400

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.