Quick Summary

There is no single “best” packaging material for foodservice and takeaway applications. PET, RPET, CPET, PP, PLA, bagasse, and cornstarch each serve different functional needs depending on food type, temperature, logistics, and regulatory requirements. In practice, successful brands adopt a multi-material strategy, selecting the right material for each application rather than relying on one universal solution. Understanding material fit—not trends—is the key to long-term packaging decisions.

In global foodservice and takeaway markets, one question appears again and again:

Which packaging material is the best?

It is a reasonable question—but also a misleading one.

Packaging does not operate in a vacuum. A material that performs perfectly for cold beverages may fail entirely in hot food delivery. A solution that works well in retail may be impractical for real-time foodservice operations. As a result, the idea of a single “best” packaging material oversimplifies a decision that is, in reality, highly situational.

Across international markets, experienced buyers are moving away from material rankings and toward application-driven selection. The goal is no longer to find the most talked-about material, but the one that performs reliably under specific conditions.

Why the Search for a “Best” Material Never Works

Every packaging material represents a balance between performance, cost, appearance, compliance, and availability. Improving one attribute often means compromising another.

For example, materials with excellent transparency may struggle with heat resistance. Fiber-based packaging offers a natural look but may not deliver the same barrier performance as plastic. High-heat materials tend to sacrifice visual clarity.

This is why packaging decisions rarely fail because of “wrong materials” in general. They fail because of wrong matches between material and application.

The industry’s current transition is not about replacing one dominant material with another. It is about learning where each material works best—and where it does not.

The Real Factors That Define the “Right” Packaging Material

When professional buyers evaluate packaging, sustainability claims are only part of the picture. Day-to-day decisions are shaped by operational realities, including:

-

Food composition: liquid, solid, oily, acidic, or mixed-content foods

-

Temperature exposure: cold-fill, hot-fill, reheating, or frozen storage

-

Handling and logistics: stacking strength, transport distance, delivery time

-

User experience: ease of use, sealing performance, visual presentation

-

Regulatory compliance: market-specific rules and labeling requirements

-

Cost control: unit price stability and long-term supply consistency

No material delivers top performance across all these factors. Each one solves certain problems while introducing others.

How Different Packaging Materials Solve Different Problems

Understanding materials through their strengths—not their labels—leads to better decisions.

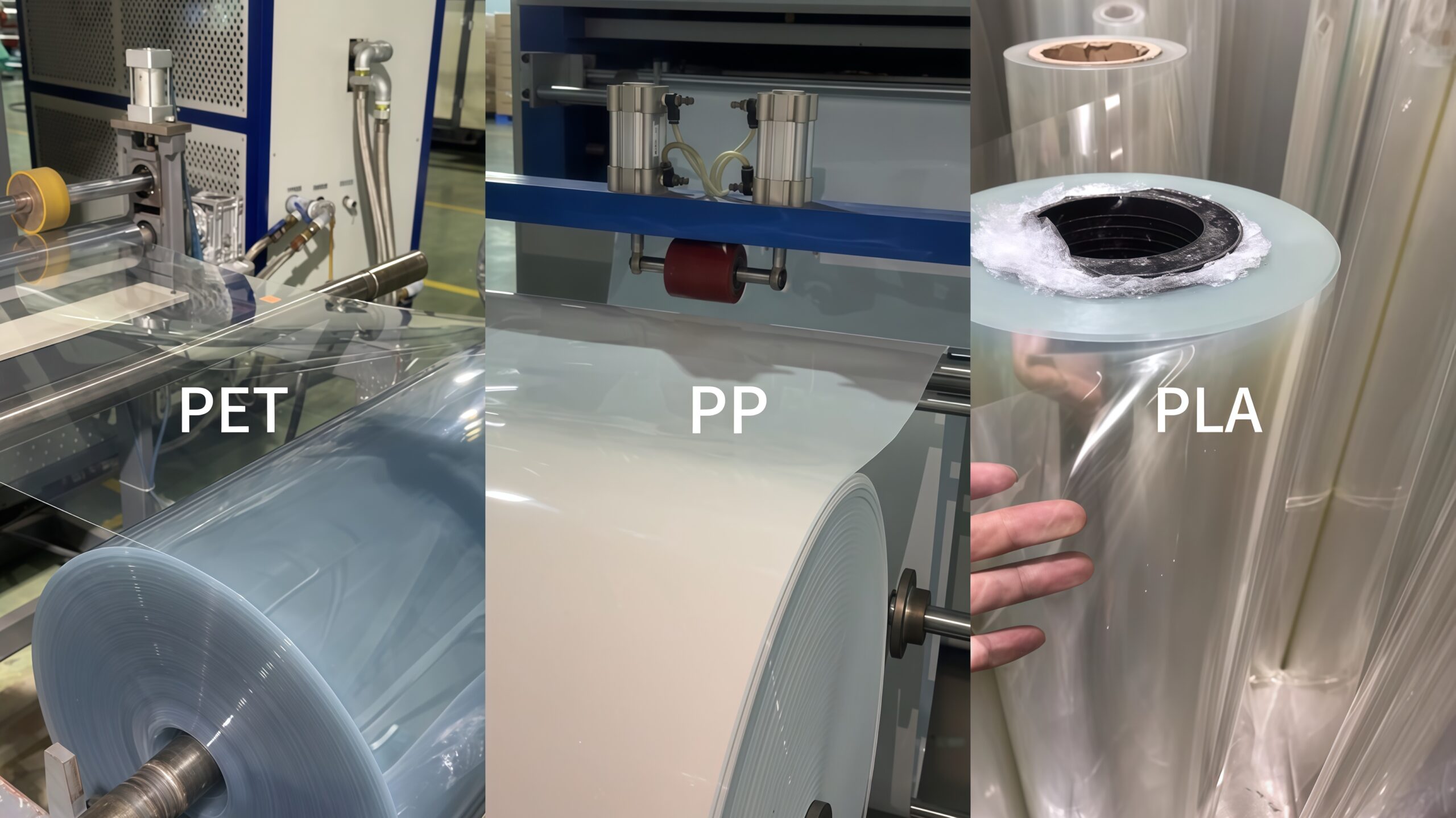

PET and RPET: Clarity and Consistency

PET remains one of the most widely used materials for cold food and beverage packaging. Its clarity enhances product visibility, which is critical for retail displays and branded beverage cups. RPET builds on this performance while supporting recycled-content goals.

However, PET-based materials are not designed for high-temperature use. Their value lies in appearance, strength, and consistency rather than heat resistance.

CPET: Built for Heat

CPET is engineered for thermal stability. It retains shape and strength under oven or microwave conditions, making it a reliable option for airline catering, ready meals, and hot food packaging.

In exchange for this performance, CPET sacrifices transparency. Buyers choose CPET not for aesthetics, but for functional reliability.

PP: Versatility and Durability

PP sits between PET and CPET in terms of performance. It handles moderate heat well, resists oil and moisture, and performs reliably in daily foodservice operations.

Its flexibility makes it one of the most commonly used materials for takeaway containers, bowls, and reusable-style food packaging.

PLA: Plant-Based, Cold-Use Focused

PLA is derived from renewable resources and is widely adopted for cold beverage cups, salad containers, and dessert packaging. Its clarity and plant-based origin make it attractive for sustainability-oriented branding.

That said, PLA is application-sensitive. It is not designed for high temperatures, and its performance depends heavily on correct use.

Bagasse: Fiber-Based Functionality

Bagasse packaging offers a different value proposition. Made from sugarcane residue, it delivers solid performance for hot and cold foods while offering a natural, paper-like appearance.

It is commonly used where a molded, sturdy structure is needed without relying on plastic aesthetics.

Cornstarch-Based Materials: Lightweight Simplicity

Cornstarch materials are typically chosen for lightweight disposable tableware and simple food packaging. They perform well in short-use scenarios and support plant-based material strategies.

They are not designed for demanding barrier or heat applications, but they serve specific needs efficiently.

How Buyers Compare Materials in Practice

Rather than ranking materials, buyers often compare them across practical criteria to find the best fit for each product.

| Material | Visual Appeal | Heat Performance | Barrier Strength | Cost Stability | Typical Use |

|---|---|---|---|---|---|

| PET | Very High | Low | Medium | Stable | Cold drinks, desserts |

| RPET | Very High | Low | Medium | Stable | Beverages, retail |

| CPET | Low | Very High | High | Medium | Airline meals |

| PP | Medium | Medium–High | High | Very Stable | Takeaway meals |

| PLA | High | Low | Medium | Medium | Cold cups, salads |

| Bagasse | Low | Medium | Medium | Medium | Hot food containers |

| Cornstarch | Low | Low–Medium | Low | Medium | Disposable tableware |

This type of comparison reflects decision-making reality, not marketing preference.

Why Regulations Encourage Multiple Solutions

1. Regulations Set Targets, Not a Single Material

Most packaging regulations define what must be achieved, not what material must be used.

For example, many EU policies focus on reducing packaging waste and increasing recycling rates, rather than banning all plastics outright. As a result, PET and RPET remain widely accepted in beverage and retail packaging because they fit existing recycling systems.

2. Different Applications Are Regulated Differently

Packaging rules often change depending on how the product is used.

-

Cold beverage cups are commonly assessed based on recyclability or recycled content, which is why PET and RPET are still widely used.

-

Hot food and reheatable meals must meet strict heat-resistance and food-contact requirements, making materials like PP and CPET difficult to replace.

-

Takeaway containers and plates may allow fiber-based options such as bagasse, especially where organic waste collection exists.

Each application favors a different material under the same regulatory framework.

3. Local Infrastructure Influences What Is Allowed

A material’s regulatory acceptance is closely linked to local waste management systems.

-

In markets with strong plastic recycling infrastructure, PET and RPET are often encouraged.

-

Where composting or organic waste collection is available, bagasse and some bioplastics are more practical.

-

PLA is typically approved for specific cold-use applications but requires clear labeling to avoid disposal confusion.

This infrastructure dependence naturally supports multiple compliant solutions rather than one universal option.

4. Why Importers Use More Than One Material

Because regulations vary by region and application, importers rarely rely on a single material.

Using a mix of PET, PP, fiber-based, and plant-based packaging allows brands to stay compliant across markets while maintaining product performance.

How Brands Actually Build Packaging Strategies

Successful foodservice brands rarely standardize on one material. Instead, they segment packaging by product line:

-

Cold beverages use PET, RPET, or PLA

-

Hot meals rely on PP, CPET, or fiber-based materials

-

Takeaway and delivery mix durability with cost efficiency

This layered strategy reduces operational risk and allows brands to adapt to changing regulations and consumer expectations.

DASHAN’s Perspective: Matching Materials to Real Applications

DASHAN’s product portfolio reflects how packaging works in practice. By offering PET, RPET, CPET, PP, PLA, bagasse, and cornstarch solutions, DASHAN supports customers in selecting packaging based on use case, not trend.

Each material exists to solve a specific problem. The role of the supplier is to help customers identify the right match.

FAQ

1. Why isn’t there one best packaging material for food packaging?

Because packaging performance depends on many variables, including heat exposure, food composition, shelf life, cost, and compliance. No single material performs best in all scenarios.

2. Is plastic always worse than plant-based materials?

Not necessarily. Materials like PET, RPET, PP, and CPET often provide superior durability, barrier performance, or heat resistance, which can reduce food waste and operational risk.

3. When is PLA the right choice?

PLA works best for cold applications such as beverage cups, salad containers, and dessert packaging, where clarity and plant-based sourcing are priorities.

4. Are fiber-based materials like bagasse suitable for hot food?

Yes. Bagasse performs well for hot and warm foods, especially in takeaway and casual dining, but may not offer the same barrier properties as plastic for long shelf life.

5. Why do many brands use multiple packaging materials?

Using different materials for different product lines allows brands to balance performance, cost, sustainability goals, and regulatory compliance across markets.

6. How should importers choose the right packaging material?

Importers should evaluate materials based on application requirements first—food type, temperature, usage scenario—before considering sustainability claims or trends.

Conclusion: Stop Looking for the Best—Choose the Right One

The future of food packaging is not about crowning a single winner. It is about understanding materials deeply enough to apply them correctly.

There is no perfect packaging material. There is only the material that fits the job at hand. Brands that recognize this will make better decisions, reduce risk, and build more resilient packaging strategies.

References

-

European Commission – Packaging and Packaging Waste Directive

https://environment.ec.europa.eu/topics/waste-and-recycling/packaging-waste_en -

PlasticsEurope – Plastics and Packaging Applications

https://plasticseurope.org/knowledge-hub/plastics-and-packaging/ -

European Bioplastics – Materials Overview (PLA and Bioplastics)

https://www.european-bioplastics.org/bioplastics/materials/ -

U.S. Food & Drug Administration – Food Contact Materials

https://www.fda.gov/food/food-ingredients-packaging/food-contact-materials -

World Packaging Organisation – Global Packaging Trends

https://worldpackaging.org/knowledge-hub/

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.