Quick Summary

PLA (Polylactic Acid) has become one of the most widely adopted bioplastics in global foodservice packaging. Made from renewable plant-based resources, PLA offers strong visual clarity, food safety compliance, and a lower carbon footprint compared to traditional plastics. In 2026, PLA cups and lids are especially popular for cold beverage applications, helping brands reduce fossil-plastic use while meeting sustainability expectations. Although PLA requires industrial composting and is not suitable for all use cases, it remains a practical, scalable solution when applied in the right packaging scenarios.

Why PLA Is Getting So Much Attention Again

Over the past few years, sustainability has moved from a “nice-to-have” to a real business requirement. Governments are tightening plastic regulations, brands are setting carbon reduction targets, and consumers are paying closer attention to what packaging is made of.

In this changing environment, bioplastics are no longer a niche topic. Among them, PLA (Polylactic Acid) has returned to the spotlight—especially in foodservice and beverage packaging. Once questioned for its limitations, PLA is now being reconsidered with more realistic expectations and better technology.

So the key question in 2026 is not “Is PLA perfect?”

It is: Is PLA good enough—and in the right situations, is it one of the best options available?

This article looks at PLA in a practical, easy-to-understand way, focusing on how it actually performs in real markets.

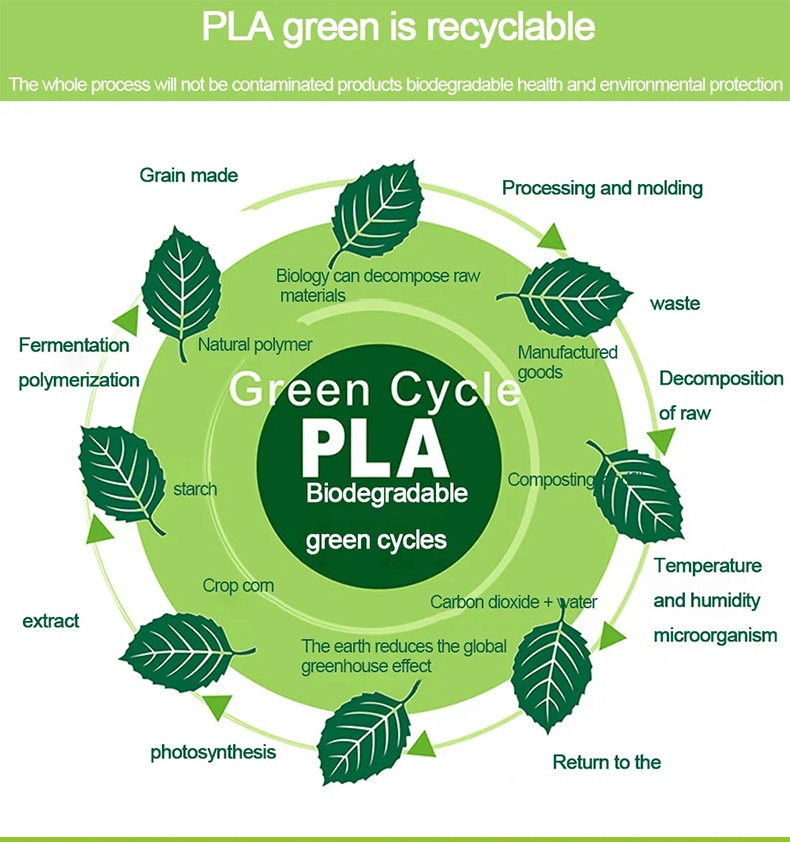

What Is PLA, Simply Explained

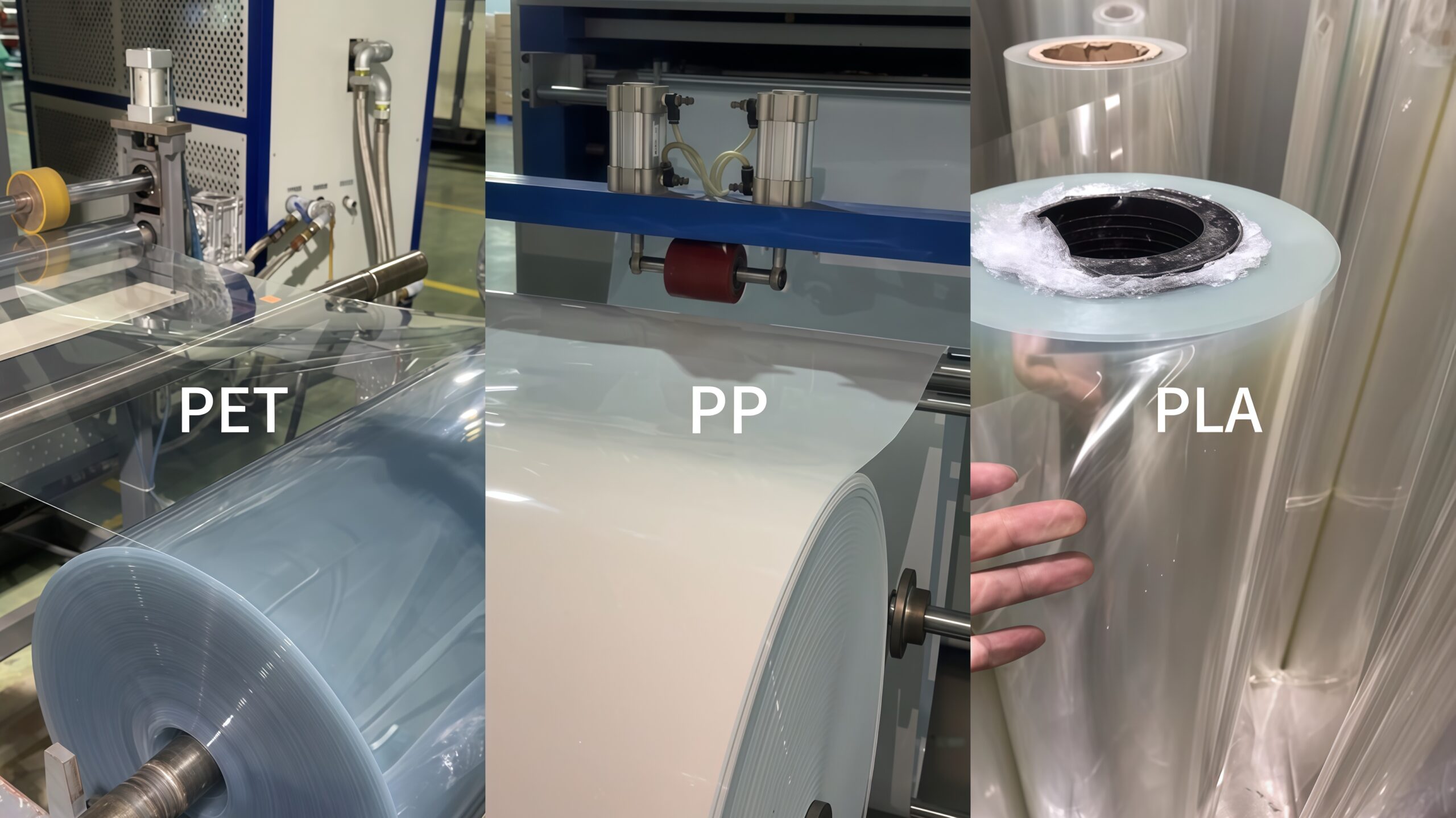

PLA is a plastic made from plants instead of fossil oil. Most PLA comes from renewable crops such as corn or sugarcane. These plants absorb CO₂ while growing, which is why PLA is often described as a lower-carbon material.

From a production point of view, PLA behaves much like traditional plastic. It can be molded, thermoformed, and shaped into cups, lids, containers, and packaging. This makes it attractive for manufacturers who want to switch materials without rebuilding their entire production line.

However, one important thing must be clarified:

PLA is biobased, but it is not “naturally biodegradable everywhere.”

PLA is designed to break down in industrial composting facilities, not in the ocean or in nature. Understanding this point is essential for using PLA responsibly.

Is PLA Really More Sustainable Than Traditional Plastics?

When people ask whether PLA is sustainable, they are usually thinking about carbon emissions and environmental impact.

According to multiple life cycle studies, PLA generally produces significantly lower carbon emissions than traditional plastics like PET or PP. The main reason is simple: PLA avoids fossil fuel extraction and uses renewable raw materials instead.

In addition, PLA usually requires less non-renewable energy during production. This makes it attractive for brands that are trying to reduce their overall carbon footprint, especially Scope 3 emissions.

That said, PLA is not “impact-free.” Agriculture uses land, water, and energy. This is why PLA works best as part of a balanced material strategy—not as a one-size-fits-all solution.

Compostability: What PLA Can and Cannot Do

PLA is certified as compostable under standards such as EN 13432 (EU) and ASTM D6400 (US). Under industrial composting conditions—high temperature and controlled humidity—PLA products can break down within a reasonable timeframe.

But here is the reality many blogs avoid mentioning:

-

PLA does not break down quickly in nature

-

PLA does not work well in home composting

-

PLA requires proper waste sorting and composting systems

This does not make PLA a bad material. It simply means PLA must be used where composting infrastructure exists, or where its carbon reduction benefits justify its use.

Clear labeling and honest communication are critical to avoid confusion or greenwashing.

How PLA Performs in Real Food and Beverage Packaging

One reason PLA has gained popularity is its performance in everyday foodservice applications.

PLA is especially strong in:

-

Cold drink cups

-

Smoothie and juice cups

-

Clear lids

-

Short-life food packaging

It offers excellent transparency, neutral taste, and good rigidity—qualities that are very important for beverages and takeaway food.

Heat resistance is still a limitation for standard PLA. Hot beverages require special grades or alternative materials. For cold and room-temperature applications, however, PLA performs very reliably.

This is why PLA cups and lids have become one of the most common bioplastic products worldwide.

PLA Compared with Other Sustainable Materials

PLA is not the only sustainable option on the market. Each material has its strengths:

-

RPET works best in strong recycling systems

-

Bagasse and molded fiber work well for compostable food containers

-

Paper-based packaging is familiar but often needs plastic coatings

PLA sits somewhere in the middle. It combines:

-

Plastic-like performance

-

Renewable raw materials

-

Certified industrial compostability

For applications where clarity, strength, and appearance matter—such as beverage cups—PLA often offers a better balance than fiber-based alternatives.

Is PLA Accepted by Global Regulations?

By 2026, PLA is widely accepted in major markets.

-

In the EU, compostable plastics are regulated under clear standards

-

In the US, PLA used for food contact complies with FDA requirements

-

International certifications help importers verify compliance

What regulators are focusing on now is accuracy of claims. Words like “biodegradable” and “eco-friendly” must be used carefully and supported by proper certification.

For importers and brands, documentation matters as much as the material itself.

Why More Brands Continue to Choose PLA

Despite ongoing discussions, PLA adoption continues to grow. The reasons are practical:

-

Clear sustainability story (plant-based, lower carbon)

-

Good performance in cold foodservice

-

Improved cost stability compared with previous years

-

Strong consumer acceptance

For companies working on ESG goals, PLA provides a measurable improvement without sacrificing functionality.

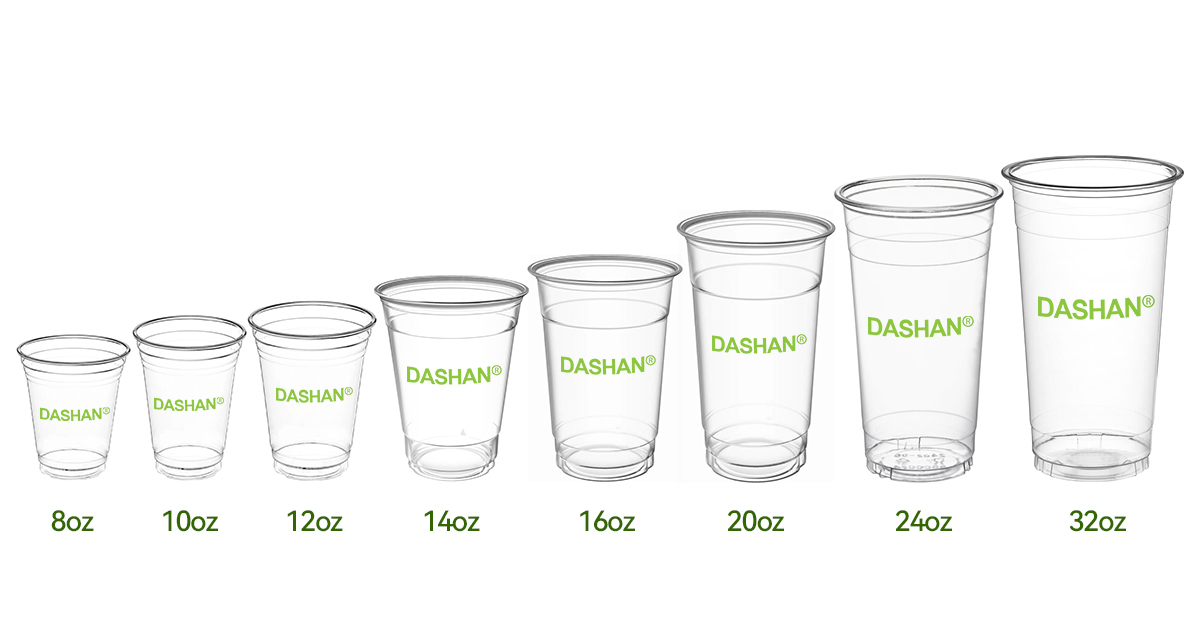

PLA Cups and Lids: A Practical Example

Disposable drinkware is one of the clearest success cases for PLA.

PLA cups and lids are now widely used by cafés, foodservice chains, and takeaway businesses. They offer the look and performance customers expect, while supporting sustainability goals.

Manufacturers like DASHAN provide PLA cup and lid solutions designed for international markets, focusing on food safety, consistency, and stable supply. These products show how PLA can be applied responsibly at scale—when the material is used in the right context.

So, Is PLA the Future of Bioplastics?

PLA is not the future of all plastics—but it is very likely a key part of the future mix of materials.

When used correctly, PLA:

-

Reduces reliance on fossil resources

-

Lowers carbon emissions

-

Performs well in real foodservice applications

-

Fits within existing regulations

The future of sustainable packaging will not depend on one material alone. PLA will work best alongside recycled plastics and fiber-based solutions, each used where it makes the most sense.

Final Thoughts for Importers and Buyers

If you are selecting materials in 2026, the question is not “Which material is the greenest?”

The better question is: Which material is the most appropriate for this product, this market, and this waste system?

For cold drinks, takeaway cups, and short-life packaging, PLA remains one of the most practical and proven bioplastic options available today.

FAQ

1. Is PLA really environmentally friendly?

PLA generally has a lower carbon footprint than traditional plastics because it is made from renewable plant-based materials. However, its environmental benefits depend on proper production, use, and disposal.

2. Is PLA biodegradable in nature?

No. PLA is designed to break down in industrial composting facilities, not in oceans, soil, or natural environments.

3. Can PLA be used for food and drinks?

Yes. PLA is widely used for food-contact applications such as cups, lids, and containers, and it complies with food safety regulations when produced under approved standards.

4. Is PLA suitable for hot beverages?

Standard PLA is best for cold or room-temperature drinks. Hot beverages usually require special PLA grades or alternative materials.

5. Why are PLA cups and lids so popular?

They offer excellent clarity, neutral taste, and good rigidity, while supporting sustainability goals through renewable sourcing and compostability certification.

6. How does PLA compare with RPET?

PLA focuses on renewable materials and compostability, while RPET focuses on recycling and circularity. Both are sustainable options when used in the right context.

7. Is PLA accepted by global regulations?

Yes. PLA is widely accepted in the EU, US, and many other markets, as long as environmental claims are accurate and supported by proper certification.

Conclusion

PLA is not a perfect material, nor is it a universal replacement for all traditional plastics. However, when used in the right applications, PLA clearly offers real advantages. Its plant-based origin helps reduce dependence on fossil resources, its carbon footprint is generally lower than conventional plastics, and its performance in cold foodservice applications is already well proven.

In 2026, the future of sustainable packaging will not rely on one single material. Instead, it will depend on using the right material in the right place. PLA has earned its position as one of the most practical bioplastics available today—especially for cups, lids, and short-life food packaging where clarity, performance, and sustainability must work together.

For brands, importers, and foodservice operators, PLA should be seen as a reliable part of a broader material strategy, working alongside recycled plastics and fiber-based solutions to achieve both environmental and business goals.

Reference

-

European Commission – Packaging and Packaging Waste Regulation (PPWR)

https://environment.ec.europa.eu/publications/proposal-packaging-and-packaging-waste_en -

European Bioplastics – PLA Material Overview

https://www.european-bioplastics.org/bioplastics/materials/pla/ -

European Food Safety Authority (EFSA) – Food Contact Materials

https://www.efsa.europa.eu/en/topics/topic/food-contact-materials -

U.S. Food and Drug Administration – Recycled & Biobased Plastics in Food Packaging

https://www.fda.gov/food/packaging-food-contact-substances-fcs -

Ellen MacArthur Foundation – Global Commitment Progress Report

https://ellenmacarthurfoundation.org/global-commitment -

UNEP – Global Plastic Pollution Outlook

https://www.unep.org/resources/report/global-plastic-pollution-outlook -

NatureWorks – Life Cycle Assessment of PLA

https://www.natureworksllc.com/What-is-Ingeo/Sustainability/Life-Cycle-Assessment -

ASTM International – ASTM D6400 Compostability Standard

https://www.astm.org/d6400 -

European Committee for Standardization – EN 13432 Compostability Standard

https://standards.iteh.ai/catalog/standards/cen

Copyright Statement

© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.

All text, data, and images are the result of our independent research, industry experience,

and product development insights. Reproduction or redistribution of any part of this content

without written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information and

to upholding transparency, originality, and compliance with global intellectual property standards.