Quick Summary

The CT-1813H45-2C is a compact two-compartment CPET meal tray designed for airline catering, frozen ready meals, and institutional foodservice. With dimensions of 185 × 135 × 45 mm and a lightweight 23 g design, it delivers exceptional heat resistance, food separation, sealing reliability, and freezer stability. This tray is engineered for high-volume meal production workflows, offering durability, operational efficiency, and premium food presentation.

Introduction

In the modern airline catering industry, packaging must withstand repeated temperature cycles, long-distance logistics, high-density stacking, and precise portioning requirements. For hot entrées paired with vegetables, rice, pasta, or complementary sides, maintaining flavor separation and structural integrity is crucial. The CT-1813H45-2C CPET tray is developed specifically to address these challenges.

As a compact two-compartment format, this tray ensures that multi-component dishes remain visually appealing and structurally stable from preparation and freezing to reheating and inflight service. Despite its compact footprint, its ergonomic layout provides optimal space utilization while preserving food separation, making it ideal for airlines, railways, meal delivery companies, frozen food manufacturers, and institutional kitchens.

CPET (Crystallized Polyethylene Terephthalate) is recognized globally as one of the best-performing materials for ready-meal packaging due to its superior thermal stability, barrier properties, and food-safe characteristics. The CT-1813H45-2C tray fully leverages these advantages while delivering a professional presentation suited for premium meal programs.

Technical Specifications

Model: CT-1813H45-2C

Material: CPET

Structure: Two compartments

Size: 185 × 135 × 45 mm

Weight: 23 g

Temperature Resistance: –40°C to +220°C

Color Options: Black / White

Applications: Airline catering, railway meals, frozen foods, central kitchens, hospital meals, ready-meal programs

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Model | Material | Capacity(ml) | Product Size (mm) | Wegiht (g) |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 13 |

| CT-1610H35-1C | CPET | 350 | 160*105*35 | 14.5 |

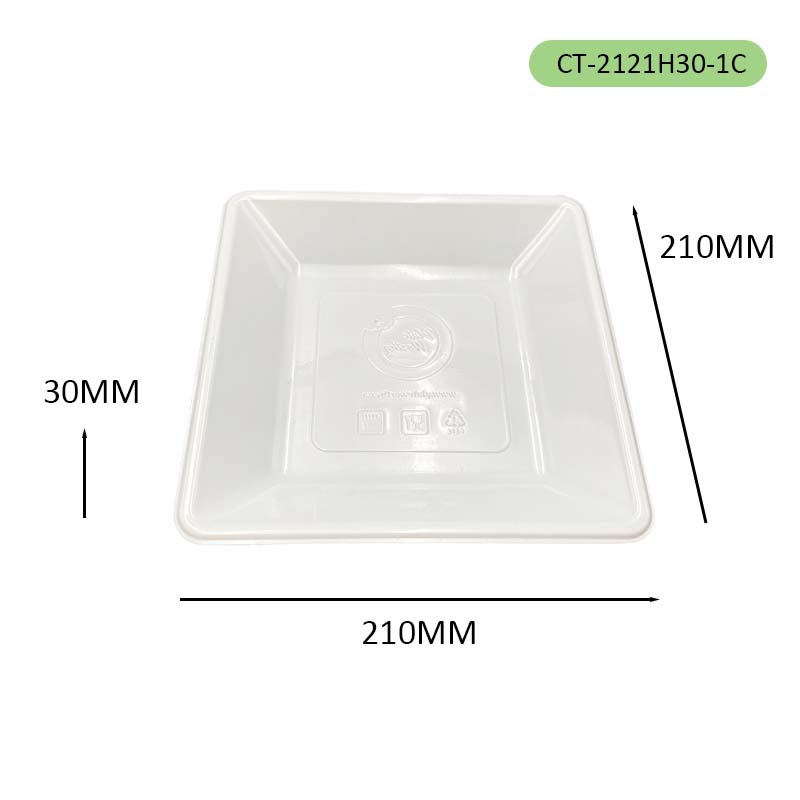

| CT-2121H30-1C | CPET | 650 | 210*210*30 | 33.2 |

| CT-1813H35-1C | CPET | 550 | 185*135*35 | 17.3 |

| CT-1813H45-1C | CPET | 650 | 185*135*45 | 23 |

| CT-1813H35-2C | CPET | 500 | 185*135*35 | 17.3 |

| CT-1813H45-2C | CPET | 600 | 185*135*45 | 23 |

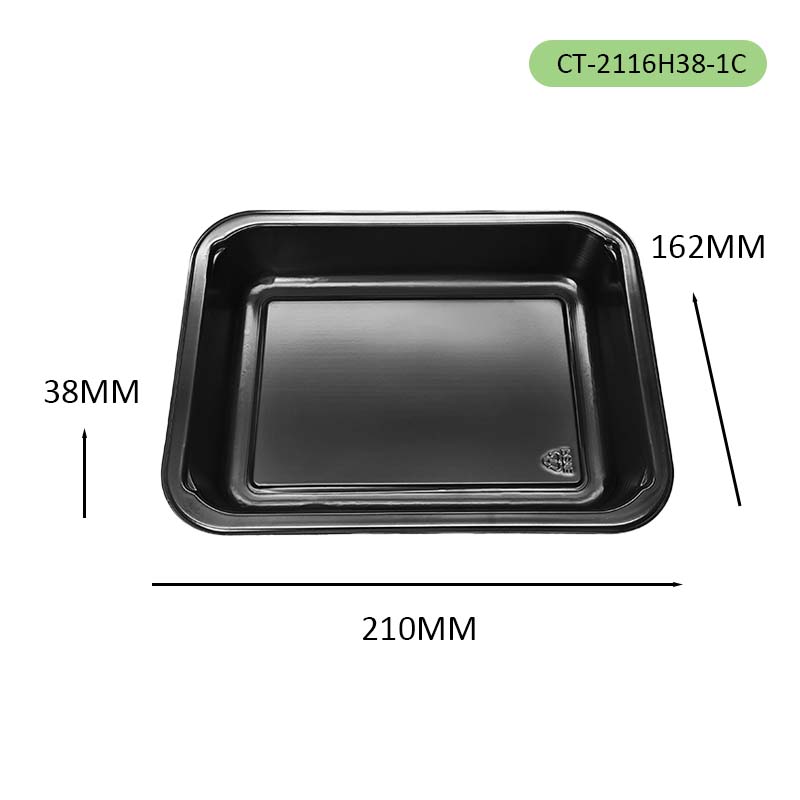

| CT-2116H38-1C | CPET | 800 | 210*162*38 | 30 |

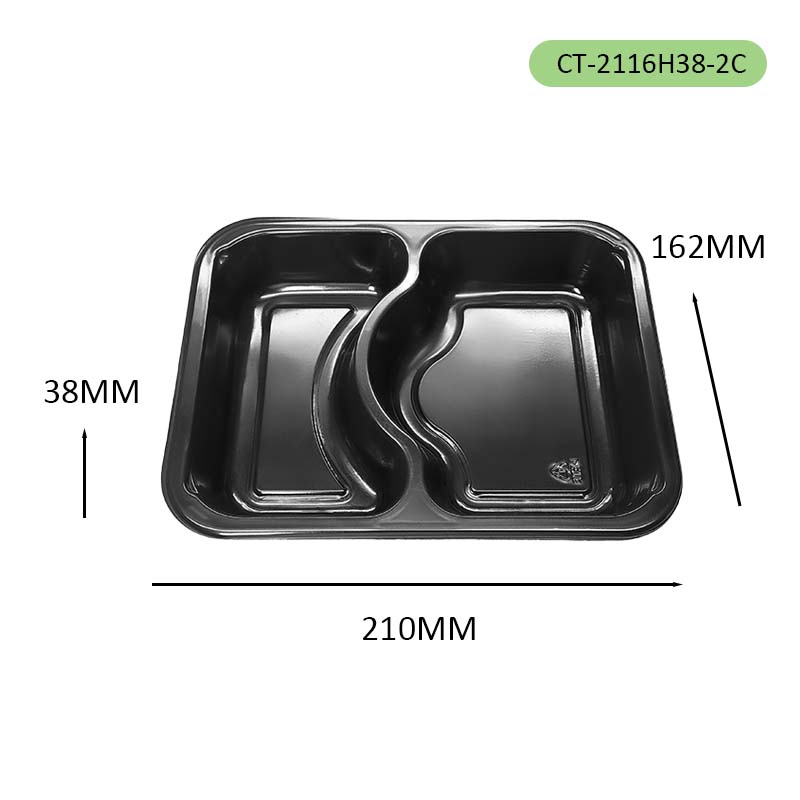

| CT-2116H38-2C | CPET | 750 | 210*162*38 | 30 |

| CT-2116H38-3C | CPET | 750 | 210*162*38 | 30 |

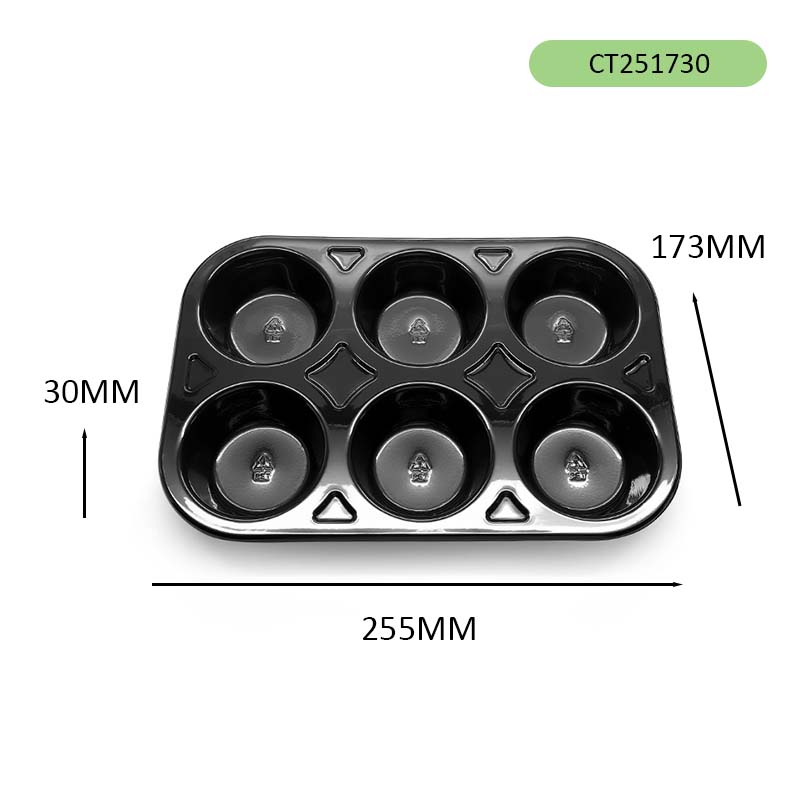

| CT251730 | CPET | 6C | 255*173*30 | 31.8 |

| CT170935 | CPET | 350 | 171*97*35 | 12.6 |

| CT161035 | CPET | 350 | 163*102*35 | 14+10 |

| CT171235 | CPET | 480ml | 170*120*35 | 15 |

| CT171335 | CPET | 500ml | 176*132*35 | 18 |

| CT181345 | CPET | 650ml | 185*135*45 | 21 |

Outstanding Temperature Performance

The CT-1813H45-2C tray is engineered to handle the full range of temperature conditions encountered in today’s industrial foodservice systems. CPET’s crystallized molecular structure allows it to maintain rigidity, avoid warping, and ensure food safety even under demanding thermal cycles.

Key temperature capabilities include:

-

Safe freezing at –40°C

-

Stability during blast-chilling

-

Resistance to cracking during long-term cold storage

-

Oven-safe reheating up to 220°C

-

Microwave-safe heating across global airline catering units

-

No deformation during convection or steam oven cooking

This wide temperature range allows seamless transitions between:

-

Industrial cooking

-

Rapid chilling

-

Freezer storage

-

Transport under cold-chain conditions

-

Oven or microwave reheating

-

Passenger serving conditions

Even with the two-compartment internal layout—where cheaper plastics often buckle or collapse—the CT-1813H45-2C maintains structural integrity, ensuring food separation and intact presentation.

Superior Food Separation and Compartment Design

The purpose of a two-compartment airline meal tray is to keep flavors, textures, and sauces from mixing. The CT-1813H45-2C is carefully designed with balanced compartment depths and reinforced inner walls to prevent collapse even when holding dense, hot meals.

Benefits of the dual-compartment layout:

-

Prevents moisture transfer between dishes

-

Keeps sauces, vegetables, and proteins visually distinct

-

Enhances premium plating aesthetic

-

Supports balanced portion control

-

Improves heat distribution consistency

This makes it ideal for combinations like:

-

Chicken with vegetables

-

Pasta with sauces

-

Rice with curry

-

Fish with salad

-

Meat entrée with starch sides

The layout is engineered to withstand stacking pressure from dozens of filled trays during storage and transport, ensuring zero leakage and sustained compartment rigidity.

Food Safety and Material Integrity

Produced from food-grade CPET resin, the CT-1813H45-2C meets strict global food-contact safety standards. It contains:

-

No BPA

-

No harmful additives

-

No odor release during heating

-

No chemical migration into food

CPET’s semi-crystalline structure provides excellent resistance to:

-

High-fat foods

-

Tomato-based sauces

-

Acidic or salty ingredients

-

Oily or strongly flavored foods

-

Thermal shock from rapid temperature changes

Even with repeated cycles from freezer to oven, the tray remains stable, clean, and safe.

High Barrier Performance for Extended Shelf Life

The CT-1813H45-2C features CPET’s natural barrier properties, protecting the meal from oxygen, moisture, and external contamination.

Compatible with all standard sealing options:

-

Heat-seal lidding film

-

Aluminum foil lids

-

Rigid CPET lids

-

MAP (Modified Atmosphere Packaging) systems

These sealing options ensure:

-

Reliable leak prevention

-

Extended shelf life

-

Freshness retention

-

Secure stacking in airline trolleys

-

Clean reheating without spills

Optimized for Airline Catering Workflows

1. Seamless automation compatibility

The tray’s dimensions fit international standards for airline meal trays, enabling efficient use with automated sealing machines.

2. Lightweight for fuel efficiency

At just 23 g, it helps reduce overall aircraft catering weight—and therefore fuel costs.

3. High stacking strength

CPET’s rigidity prevents deformation under high stacking loads in cold rooms and airline carts.

4. Ideal for sauced or moist foods

Both compartments are engineered to prevent cross-contamination and maintain sauce containment.

Premium Food Presentation

Visual presentation is a major factor in passenger satisfaction. The CT-1813H45-2C enhances meal appearance with:

-

Clearly defined compartment lines

-

Professional plating layout

-

Color choices of black or white for different cuisine types

-

Smooth surfaces for clean reheating results

-

Consistent heat distribution for uniform serving temperature

Even after reheating, food retains its shape, portion definition, and color contrast—important for airline meal standards.

Applications Across Foodservice Industries

While designed for airlines, the CT-1813H45-2C is widely used in:

1. Railway Catering

Stable during vibration and long hours of transport.

2. Frozen Ready Meals

Ideal for 6–12 month storage with no cracking.

3. Central Kitchens

For hospitals, corporate cafeterias, schools, and military meal programs.

4. Cruise & Marine Catering

Withstands onboard ovens and extended storage cycles.

Customization Options

-

Embossed airline or brand logos

-

Custom colors

-

Tailored compartment ratios

-

Coordinated sealing film

-

Custom carton packaging for automated lines

These options support branding consistency, operational efficiency, and premium meal program requirements.

Why CPET Is the Best Material for Airline Meal Trays

Compared to PP, PS, aluminum, and paper-based trays, CPET offers:

✔ Heat resistance to 220°C

✔ Excellent rigidity under load

✔ High barrier performance

✔ Recyclability in PET streams

✔ Clear and elegant food presentation

✔ Reliable sealing performance

✔ Long freezer shelf life

FAQ

1. Is the CT-1813H45-2C tray oven-safe?

Yes. Made from CPET, the tray is safe for use in convection and steam ovens up to 220°C, ensuring reliable reheating for inflight, railway, and ready-meal applications.

2. Can the tray be frozen for long-term storage?

Absolutely. It remains stable at –40°C, making it ideal for frozen ready meals, cold-chain transport, and long-term storage without cracking or warping.

3. What sealing options are compatible?

It works with heat-seal films, aluminum foil lids, rigid CPET lids, and MAP sealing systems, ensuring strong sealing integrity and excellent leak resistance.

4. Is the tray food-safe and BPA-free?

Yes. The tray is manufactured using BPA-free, food-grade CPET resin that is odorless, non-toxic, and compliant with global food-contact regulations.

5. What industries typically use this CPET tray?

It is widely used in airline catering, railway meals, frozen meals, hospital and institutional kitchens, and cruise catering, especially when dual-compartment separation is required.

Conclusion

The CT-1813H45-2C CPET two-compartment airline meal tray is a high-performance, compact packaging solution designed for today’s demanding airline and food production environments. With excellent heat resistance, freezer durability, food separation, sealing compatibility, and food-safe material integrity, it ensures that meals remain fresh, visually appealing, and structurally stable throughout the entire service chain—from industrial preparation to final serving.

Its lightweight design, professional compartment layout, and global compatibility make it the ideal choice for airlines, frozen food manufacturers, railway catering services, and central kitchens seeking reliable and premium-quality meal packaging.