Quick Summary

PET (Polyethylene Terephthalate) packaging is a popular choice in the food industry, especially for fresh produce, due to its durability, transparency, and recyclability. Customizing PET boxes for different fruits helps in providing better protection, maintaining freshness, and enhancing visual appeal. The thermoforming process is key to creating these tailored packaging solutions by heating and molding PET sheets into various shapes to suit the specific needs of different fruits. This article discusses the customization process, the thermoforming techniques, and the best packaging solutions for different types of fruits like berries, apples, citrus, tropical fruits, and grapes. The article also emphasizes the eco-friendly benefits of PET and its role in sustainable packaging practices.

Introduction

PET (Polyethylene Terephthalate) packaging is one of the most popular materials used in the food packaging industry, especially for fresh produce. The ability to customize PET boxes for different fruit types ensures that they are protected, fresh, and visually appealing for consumers. With advances in manufacturing techniques like thermoforming, customizing PET packaging for various fruits has never been easier. In this article, we will explore the customization options for PET Box, delve into the thermoforming process, and highlight the best packaging solutions for various fruits, all while providing tips for optimizing the packaging design.

Why Customize PET Packaging for Fruit Types?

Every fruit type is unique, from its size and shape to its fragility and shelf life. Customizing PET packaging helps protect the fruit during transportation and storage, enhances the display, and extends the product’s shelf life. Additionally, customization allows manufacturers to incorporate branding, product details, and eco-friendly features, making PET an attractive option for sustainable food packaging.

Key Benefits of Customizing PET Packaging:

-

Protection: Custom PET packaging ensures that fruits are securely contained and shielded from external factors that could lead to bruising or spoilage.

-

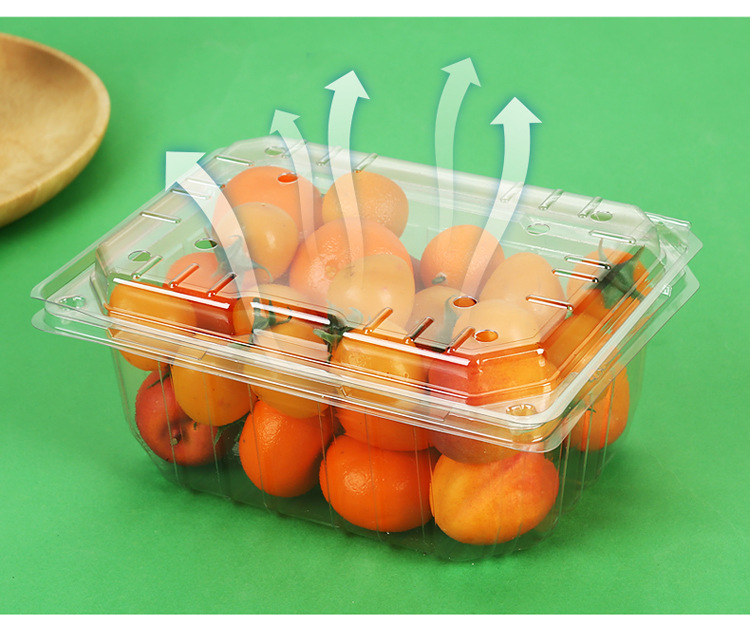

Freshness: Properly designed PET packaging with features like ventilation holes maintains the right balance of humidity and airflow, preserving fruit freshness for longer.

-

Brand Appeal: Custom packaging designs, colors, and prints help create an appealing product presentation that draws consumers’ attention in a crowded marketplace.

-

Eco-Friendly: PET is 100% recyclable, which makes it a sustainable packaging choice. Additionally, using recycled PET (RPET) further reduces the carbon footprint.

-

Cost-Effective: By selecting the right design and size for each fruit, manufacturers can optimize the use of materials, resulting in lower packaging costs.

The Thermoforming Process for Custom PET Fruit Packaging

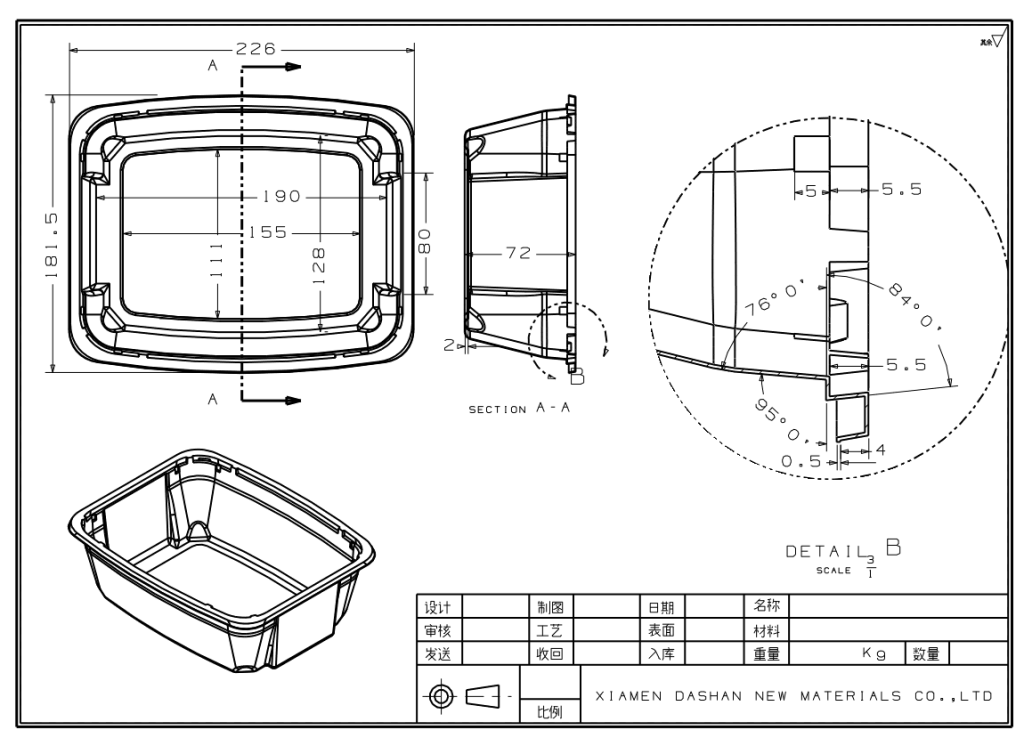

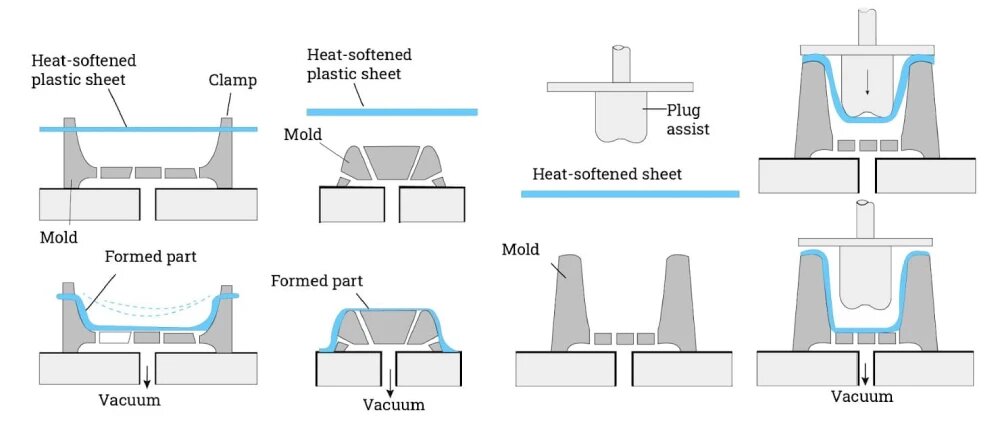

Thermoforming is the primary manufacturing process used to create custom PET fruit packaging. It involves heating a PET sheet until it becomes pliable, then molding it into the desired shape. The process is highly customizable, allowing for a wide range of packaging options for different fruits.

What is Thermoforming?

Thermoforming is a process where a plastic sheet is heated to a temperature at which it becomes soft and malleable. This sheet is then stretched over a mold using air pressure or a vacuum. Once the plastic takes the shape of the mold, it is cooled and trimmed into the final packaging product.

There are two main types of thermoforming processes used in fruit packaging:

-

Vacuum Forming:

-

How It Works: In vacuum forming, the heated PET sheet is placed over a mold, and a vacuum is applied to pull the material tightly into the shape of the mold. The vacuum creates a snug fit, ensuring that the packaging contours perfectly to the fruit’s shape.

-

Best for: This method is ideal for shallow containers, trays, and clamshell packaging for fruits like strawberries, grapes, and citrus fruits. The vacuum helps create smooth, consistent shapes with excellent clarity, making it easier for consumers to view the fruit.

-

-

Pressure Forming:

-

How It Works: Pressure forming uses air pressure to push the heated PET sheet into a mold. The pressure allows for more intricate shapes with fine details, providing greater control over the final design.

-

Best for: Pressure forming is often used when more detailed or complex packaging designs are required. For larger or sturdier fruits like mangoes, pineapples, and apples, this method ensures that the packaging is both strong and aesthetically pleasing.

-

Step-by-Step Thermoforming Process:

-

Material Selection:

-

The process begins with selecting the right grade of PET. The material is chosen based on factors like clarity, thickness, and the ability to withstand temperature fluctuations. For fruit packaging, the material is often chosen for its food-safe properties and its ability to maintain a strong structure while being transparent.

-

-

Heating the PET Sheet:

-

The PET sheet is fed into a heating chamber, where it is heated to the point of becoming soft and pliable. This step requires precise temperature control to ensure that the sheet doesn’t become too hot and lose its structural integrity.

-

-

Molding the PET Sheet:

-

Once the sheet is heated to the desired temperature, it is quickly placed over a mold. In vacuum forming, a vacuum is applied to pull the sheet over the mold, whereas in pressure forming, air pressure is used to push the sheet into the mold’s details.

-

-

Cooling the Packaging:

-

After the PET has been formed into the shape of the mold, it is cooled rapidly to set the material. The cooling process is critical for ensuring the shape holds and doesn’t warp or distort during handling.

-

-

Trimming and Finishing:

-

Once cooled, the formed packaging is trimmed along the edges to remove excess material. This ensures the final product has smooth edges and a polished finish. Depending on the design, additional features like ventilation holes, embossed logos, or compartments may also be added during this stage.

-

-

Quality Control and Packaging:

-

The final products undergo rigorous quality control checks to ensure that they meet the required standards. This includes checking the clarity, strength, and functionality of the packaging. The packaging is then ready for shipment, where it can be used for fresh fruit packaging.

-

Customization Options for Different Fruits

Now that we’ve explored the customization process, let’s dive into the specific packaging solutions for different types of fruits. The size, shape, fragility, and shelf life of the fruit play a major role in determining the best PET packaging solution.

1. Soft Fruits (Strawberries, Raspberries, Blueberries):

Soft fruits require delicate packaging to prevent crushing or bruising. PET packaging for these fruits typically features shallow trays or clamshell containers with ventilation holes.

-

Packaging Design: Low-profile, shallow trays with partitioned sections to keep fruits separate. Alternatively, clamshell boxes with clear, transparent covers allow for easy visibility while protecting the berries.

-

Customization Features: Ventilation holes, custom inserts to separate fruit, and smooth surfaces to avoid bruising.

2. Hard Fruits (Apples, Pears, Peaches):

Hard fruits like apples and pears require sturdy, rigid packaging to prevent damage. For these fruits, PET packaging is often designed with compartments or thicker walls for added protection.

-

Packaging Design: Trays with compartments, often made from pressure-formed PET to create reinforced corners. Clamshell containers are also a popular option.

-

Customization Features: Reinforced edges and corners to support the weight of the fruit, optional inserts for additional padding, and clear, high-clarity packaging to display fruit.

3. Tropical Fruits (Mangoes, Pineapples, Avocados):

Tropical fruits are large and can be more vulnerable to impact damage. These fruits require heavy-duty PET packaging that offers both cushioning and a secure fit.

-

Packaging Design: Large, sturdy clamshell containers or trays with additional inserts to ensure that the fruit remains in place. In some cases, custom packaging may include foam or padding to reduce shock during handling.

-

Customization Features: Custom foam inserts or molded padding to cushion the fruit, larger trays for bulkier fruits, and breathable features to reduce condensation buildup.

4. Citrus Fruits (Oranges, Lemons, Limes):

Citrus fruits require packaging that maintains airflow to prevent moisture buildup, which can lead to spoilage.

-

Packaging Design: Clamshell boxes with perforated ventilation holes or slotted trays. These designs allow for better airflow and prevent condensation from forming inside the container.

-

Customization Features: Ventilation holes, slotted designs for air circulation, and clear plastic that allows the consumer to view the fruit inside.

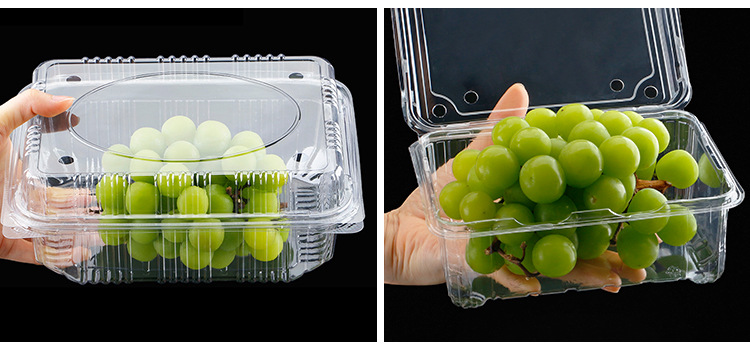

5. Grapes:

Grapes are typically packaged in small clusters and require flexible yet sturdy packaging to prevent squishing and to keep the fruit fresh.

-

Packaging Design: Small PET trays or clamshell boxes with a grid design to allow air circulation while keeping the fruit protected. Packaging can include dividers or mesh inserts to separate the grapes.

-

Customization Features: Light, flexible PET material to prevent squishing, custom compartments to separate clusters, and clear packaging to show the quality of the grapes.

FAQ: Frequently Asked Questions About Customizing PET Packaging for Fruits

1. Why should I choose PET packaging for fruit?

PET packaging is a popular choice for fruit packaging because it is lightweight, durable, and provides excellent protection for fresh produce. It also helps maintain the freshness of fruit for longer periods due to its ability to control moisture and air circulation. Additionally, PET is highly recyclable, making it an environmentally friendly option.

2. How can PET packaging be customized for different fruit types?

PET packaging can be customized in terms of size, shape, and design to suit different fruit types. For example, small fruits like berries may use shallow trays with compartments, while larger fruits like mangoes or pineapples may require more robust, reinforced packaging with padding. Custom features like ventilation holes, transparent windows, or foam inserts can also be added to enhance the packaging’s functionality.

3. How does the thermoforming process work for PET packaging?

Thermoforming involves heating a sheet of PET until it becomes pliable, then molding it into a specific shape using either a vacuum or pressure. Once the PET takes the mold’s shape, it is cooled, trimmed, and finished for packaging. This process allows for the creation of custom packaging shapes and sizes suitable for different fruits.

4. What are the benefits of using vacuum forming for fruit packaging?

Vacuum forming creates a tight, snug fit around the fruit, ensuring protection from external damage and preventing bruising. It is especially useful for fruits like berries or citrus, where visibility and freshness are key. The process is also cost-effective for high-volume production.

5. Can PET fruit packaging be eco-friendly?

Yes, PET is 100% recyclable, which makes it a sustainable option for fruit packaging. Additionally, many manufacturers use RPET (Recycled PET) in the production of fruit containers, further reducing the environmental impact of packaging.

6. How do I choose the right packaging for my fruit?

The right packaging depends on the type of fruit, its size, fragility, and the desired shelf life. Soft fruits like strawberries require shallow trays with air holes, while hard fruits like apples need more robust and compartmentalized packaging. Tropical fruits may require foam inserts for additional protection, and citrus fruits benefit from ventilation holes for moisture control.

7. Is custom printing available for PET fruit packaging?

Yes, PET packaging can be customized with printing or embossing. This allows businesses to display branding, product information, and graphics, improving the shelf appeal and providing valuable product information to consumers.

8. What is the shelf life of fruit packaged in PET containers?

The shelf life of fruit packaged in PET containers depends on factors like the type of fruit, the packaging design, and storage conditions. Properly ventilated and moisture-controlled PET packaging can extend the shelf life of fresh fruit by maintaining optimal conditions during storage and transport.

Conclusion: Custom PET Packaging – The Future of Fruit Protection

Customizing PET packaging for different types of fruits offers a range of benefits, including better protection, extended shelf life, and increased visual appeal. By understanding the specific needs of each fruit and leveraging the flexibility of thermoforming, manufacturers can create tailored packaging that enhances product presentation and preserves the quality of the fruit.

The thermoforming process is essential to this customization, allowing for the creation of unique packaging designs that meet the specific requirements of various fruits. Whether for soft fruits like strawberries, hard fruits like apples, or tropical fruits like mangoes, custom PET packaging ensures that the fruit stays fresh, safe, and appealing from farm to table.

Incorporating branding, eco-friendly features, and sustainability into the design further elevates the value of PET packaging. As consumer demand for eco-friendly and visually appealing products grows, the future of fruit packaging will continue to focus on innovation, customization, and sustainability.

References

-

PET Plastic: Advantages & Disadvantages in Packaging – Packaging Strategies, 2023.

Available at: https://www.packagingstrategies.com -

Sustainable Packaging: Eco-Friendly Materials for the Future – Green Packaging International, 2022.

Available at: https://www.greenpackaging.org -

The Role of Thermoforming in Food Packaging Design – Thermoforming Association, 2021.

Available at: https://www.thermoforming.org -

Understanding the Environmental Impact of Packaging Materials – Environmental Protection Agency, 2021.

Available at: https://www.epa.gov