Quick Summary

At DaShan, product safety is not just a requirement—it’s the foundation of everything we do. As a trusted manufacturer of food-grade PET, CPET, and PP packaging, DaShan guarantees that every cup, tray, and clamshell container meets international food safety standards including FDA, EU, and ISO certifications. Through rigorous quality control, advanced material testing, and continuous improvement, DaShan ensures that food packaging is non-toxic, hygienic, heat-resistant, and environmentally responsible.

Introduction: Why Food Packaging Safety Matters

Food packaging serves as the critical barrier between food and external contamination. A safe package ensures that consumers enjoy fresh, uncontaminated, and high-quality meals. In a world increasingly aware of health and sustainability, safe plastic packaging has become essential for restaurants, retailers, and consumers alike.

However, ensuring safety is not as simple as using any plastic material. Manufacturers must follow stringent international safety regulations, maintain traceability, and adopt scientifically tested materials suitable for direct food contact.

That’s where DaShan stands out.

1. Commitment to Food-Grade Materials

1.1 PET, CPET, and PP — The Safest Choices for Food

DaShan’s packaging is made primarily from PET (Polyethylene Terephthalate), CPET (Crystallized PET), and PP (Polypropylene)—materials known for their high purity and safety in the food industry.

-

PET: Non-toxic, transparent, and 100% recyclable, ideal for cold drinks, salads, and fruit packaging.

-

CPET: Crystallized for heat resistance up to 220°C, perfect for oven-safe and airline meal trays.

-

PP: Microwave-safe, durable, and resistant to chemicals, widely used for multi-compartment lunch boxes.

These materials are BPA-free and meet the strict EU Regulation (EC) No 1935/2004, FDA CFR 21, and LFGB food safety requirements.

1.2 Strict Supplier Qualification

DaShan sources all raw materials from certified global suppliers with food-grade documentation. Each incoming batch undergoes Material Safety Data Sheet (MSDS) verification and traceability checks to ensure zero contamination from additives or industrial-grade plastics.

1.3 No Compromise on Additives

DaShan avoids using harmful additives such as phthalates, heavy metals, or bisphenols, ensuring packaging remains odorless, tasteless, and safe for food contact.

2. Comprehensive Quality Control System

2.1 ISO-Certified Production Environment

DaShan’s facilities are built under ISO 9001:2015 and ISO 22000:2018 quality management systems. Every production step—from extrusion and thermoforming to packaging and shipment—is monitored, recorded, and traceable.

2.2 On-Site Quality Inspections

Our quality control team performs inspections at multiple stages:

| Inspection Stage | Focus Area | Frequency |

|---|---|---|

| Raw Material | Purity, certification, traceability | Every batch |

| In-Process | Thickness, temperature, hygiene | Hourly |

| Final Product | Visual, weight, and safety compliance | 100% sampling |

These inspections guarantee that every packaging unit leaving our factory meets DaShan’s “Zero Defect” safety policy.

2.3 Hygienic Production Environment

The entire factory follows GMP (Good Manufacturing Practice) standards. Employees wear protective clothing, hairnets, and gloves; equipment is sanitized daily; and dust-free rooms ensure no physical contamination during production.

3. Advanced Testing and Food Contact Safety

3.1 Internal Testing Laboratory

DaShan operates an in-house testing laboratory equipped with advanced instruments to evaluate:

-

Migration testing for food contact safety (EU/FDA standards)

-

Thermal stability under heat and cold

-

Impact resistance and stress cracking

-

Color consistency and transparency

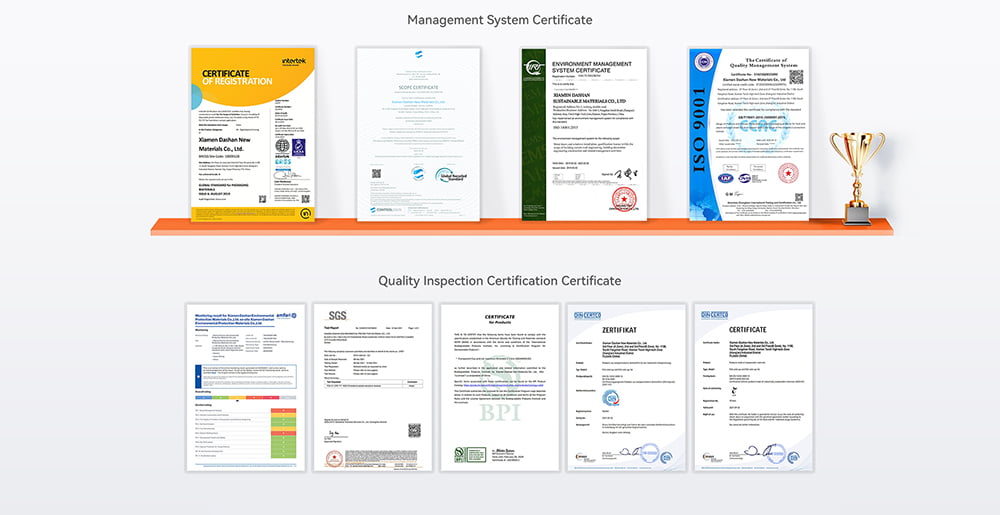

3.2 Third-Party Certification

DaShan’s materials and finished products are tested by independent organizations such as SGS, Intertek, and TÜV, ensuring compliance with:

-

FDA 21 CFR 177.1630 (PET)

-

EU No. 10/2011 (Plastic Materials for Food Contact)

-

REACH and RoHS standards

-

China GB4806 Food Contact Plastic Regulations

This third-party validation ensures that customers can confidently use DaShan products in domestic and international markets.

4. Traceability and Transparency

Every DaShan product carries a unique production code, linking back to the raw material lot, machine line, and operator responsible. This full traceability system allows DaShan to track and manage product safety in real-time.

In the event of any issue—though rare—DaShan can immediately isolate affected batches, analyze root causes, and provide full documentation to clients and authorities.

5. Clean Manufacturing: Hygiene & Safety Standards

DaShan’s facilities are designed to eliminate risks of contamination:

-

Air filtration systems maintain clean production zones.

-

Metal detectors and optical scanners detect impurities.

-

Anti-static control systems prevent dust adhesion.

-

Regular microbiological swab tests ensure cleanliness in the production line.

All staff receive annual hygiene and safety training, emphasizing their role in protecting consumers through responsible manufacturing.

6. Compliance with Global Food Safety Regulations

DaShan complies with a wide range of global certifications and standards, including:

-

FDA (U.S. Food and Drug Administration)

-

EU Regulation 10/2011 (Plastic Materials Intended for Food Contact)

-

GB4806 & GB9685 (China National Food Safety Standards)

-

LFGB (Germany Food Safety Testing)

-

REACH & RoHS (Environmental Compliance)

Each shipment includes Compliance Declarations and Testing Certificates, giving distributors and food brands confidence in cross-border trade.

7. Product Design with Safety in Mind

7.1 Leak-Proof and Tamper-Resistant

DaShan’s engineers use precision molds to ensure a perfect lid fit, preventing leaks, spills, or air exposure that could lead to bacterial growth.

7.2 Temperature Resistance

From -20°C freezing to 220°C baking, DaShan’s CPET and PP containers retain their structure and integrity without releasing harmful substances.

7.3 Ergonomic and Functional Design

Smooth edges, tight sealing, and stackable designs not only ensure consumer safety but also operational efficiency for restaurants and retailers.

8. Continuous Improvement and Innovation

Safety standards evolve constantly. DaShan invests in R&D to enhance both product performance and consumer safety. Our innovations include:

-

RPET packaging using recycled materials verified safe for food contact.

-

Antifog lids to improve visibility without chemical coating.

-

Eco-sealing technology reducing need for adhesives or glues.

Each innovation is tested for food safety compliance before entering mass production.

9. Customer Education and After-Sales Support

DaShan partners with global clients to provide technical data sheets, certificates, and training on proper storage, transportation, and usage. We help brands understand:

-

Safe temperature ranges for each product type.

-

Suitable food types (hot, cold, oily, acidic).

-

Cleaning and reuse guidance for recyclable containers.

Our goal: ensure that safety continues beyond the factory—all the way to the consumer’s hands.

10. Sustainability and Long-Term Safety

DaShan’s safety philosophy extends to the environment. We ensure safety not only for consumers but for the planet by:

-

Using recyclable and eco-friendly materials (PET, CPET, RPET).

-

Reducing energy consumption through closed-loop recycling systems.

-

Ensuring all materials are non-toxic, odorless, and fully compliant with international eco-safety standards.

By aligning safety with sustainability, DaShan contributes to a circular economy where quality and responsibility go hand in hand.

FAQ Section

Q1: How does DaShan guarantee the safety of its food packaging materials?

DaShan uses food-grade PET, CPET, and PP materials sourced from certified suppliers. All materials are BPA-free and tested for compliance with FDA, EU, and GB standards.

Q2: Are DaShan’s products suitable for hot and cold foods?

Yes. PET is ideal for cold food and beverages, while CPET and PP are safe for hot foods, ovens, and microwaves.

Q3: How does DaShan control hygiene during manufacturing?

DaShan operates ISO-certified clean production lines, uses dust-free environments, and performs regular hygiene inspections to maintain sanitary conditions.

Q4: What certifications support DaShan’s food safety claims?

DaShan holds ISO 9001, ISO 22000, FDA, EU 10/2011, LFGB, and SGS certifications, proving full compliance with international food safety standards.

Q5: Does DaShan offer documentation for export compliance?

Yes. Every order is accompanied by Declarations of Conformity and Testing Reports, ensuring smooth import/export clearance in global markets.

Conclusion

Product safety is not a one-time process—it’s a culture. At DaShan, every employee, from engineer to packer, shares the mission of delivering safe, hygienic, and reliable food packaging to the global market. Through certified materials, strict testing, traceability systems, and environmentally conscious innovation, DaShan ensures that every tray, cup, and clamshell embodies trust and safety.

From sourcing to shipping, safety is our promise—DaShan delivers it daily.

References

-

FDA CFR Title 21, Section 177.1630 — Polyethylene Terephthalate for Food Contact

https://www.ecfr.gov/current/title-21 -

European Commission Regulation (EU) No 10/2011 — Plastic Materials for Food Contact

https://food.ec.europa.eu -

ISO 22000:2018 — Food Safety Management Systems

https://www.iso.org/iso-22000-food-safety-management.html -

SGS Food Contact Testing Services

https://www.sgs.com/en/food -

DaShan Official Website

https://www.dashanpacking.com

Copyright Statement© 2025 Dashan Packing. All rights reserved.

This article is an original work created by the Dashan Packing editorial team.All text, data, and images are the result of our independent research, industry experience,and product development insights. Reproduction or redistribution of any part of this contentwithout written permission is strictly prohibited.

Dashan Packing is committed to providing accurate, evidence-based information andto upholding transparency, originality, and compliance with global intellectual property standards.