Introduction

In today’s global food industry, packaging isn’t just about preserving freshness—it’s about compliance, safety, and trust. For manufacturers and buyers alike, understanding food packaging certifications has become essential.

These certifications—such as FDA, SGS, LFGB, BRC, and ISO—serve as proof that packaging materials are safe for direct food contact, free from harmful chemicals, and produced under strict quality controls.

This guide breaks down the major certifications you’ll encounter, their meanings, global recognition, and why choosing a certified manufacturer like DASHAN ensures quality, safety, and international acceptance.

Why Food Packaging Certifications Matter

1. Consumer Safety

Food packaging directly touches consumables, so any contamination or migration of chemicals can endanger health. Certified packaging ensures compliance with strict food safety standards, minimizing risks.

2. Market Access

Without proper certification, exporting food packaging products can be extremely difficult. For example:

-

FDA compliance is mandatory for the U.S. market.

-

LFGB is required in the European Union and Germany.

-

SGS testing ensures alignment with multiple international standards.

3. Brand Reputation

For global buyers, certifications demonstrate commitment to quality assurance and ethical production. This transparency builds trust and positions a manufacturer as a credible long-term partner.

The Key Certifications in Food Packaging

Below is a breakdown of the most recognized global food packaging certifications and what they mean.

| Certification | Region / Issuer | Scope | Key Purpose |

|---|---|---|---|

| FDA (Food and Drug Administration) | USA | Regulates materials that come into contact with food | Ensures safety, non-toxicity, and migration limits |

| SGS Testing & Certification | Global (Independent) | Third-party testing and certification | Verifies compliance with international food safety standards |

| LFGB (Lebensmittel-, Bedarfsgegenstände- und Futtermittelgesetzbuch) | Germany / EU | Testing of food contact materials | Confirms materials are safe and odorless, non-toxic |

| BRC (British Retail Consortium) | UK / Global | Food safety management systems | Evaluates factory hygiene, traceability, and risk management |

| ISO 9001 & ISO 14001 | Global | Quality & environmental management | Ensures consistent quality and eco-friendly production |

| EN 13432 | EU | Compostability certification | Confirms biodegradability of packaging materials |

| ASTM D6400 | USA | Biodegradability & compostability | Standard for compostable plastics in the U.S. market |

FDA: The Global Gold Standard

What Is FDA Certification?

The U.S. Food and Drug Administration (FDA) regulates all materials that come into direct contact with food under 21 CFR (Code of Federal Regulations).

FDA-compliant packaging must meet:

-

Migration limits (no chemical leaching).

-

Material purity (no toxic additives).

-

Production traceability (record-keeping and labeling).

Why It Matters

-

Required for importing food packaging into the U.S.

-

Trusted benchmark worldwide for non-toxic, food-safe materials.

-

Essential for plastics like PP, PET, PLA, rPET, and cornstarch-based packaging.

Example:

DASHAN’s PP food trays and PET cups are all FDA compliant, ensuring safe use for both hot and cold food packaging.

SGS: Independent Global Verification

SGS: Independent Global Verification

What Is SGS Certification?

SGS (Société Générale de Surveillance) is a Swiss-based inspection and testing organization. Rather than issuing a single “certificate,” SGS provides testing reports verifying compliance with standards such as FDA, EU 10/2011, and LFGB.

Why It Matters

-

Confirms food contact safety through laboratory analysis.

-

Provides neutral third-party validation for importers.

-

Increases buyer confidence, especially for OEM/ODM exports.

Example:

Before exporting to Europe, DASHAN conducts SGS migration tests to verify that its PP, PET, and PLA packaging meets EU standards.

LFGB: The European Compliance Standard

What Is LFGB Certification?

LFGB stands for Lebensmittel-, Bedarfsgegenstände- und Futtermittelgesetzbuch, Germany’s food and feed code. It sets one of the strictest requirements for materials intended for food contact.

Why It Matters

-

A prerequisite for selling packaging in Germany and most EU countries.

-

Tests include odor, taste, migration, and heavy metal analysis.

-

Recognized across Europe as a mark of premium food safety.

Example in Practice

LFGB-certified PP plates and clamshells from DASHAN have passed extensive testing to ensure they are odorless and non-toxic—ideal for European catering and retail packaging.

ISO and BRC: Quality Management & Factory Standards

1. ISO 9001 — Quality Management

Ensures the manufacturer maintains consistent production quality, including traceability, documentation, and corrective action systems.

2. ISO 14001 — Environmental Management

Demonstrates that production aligns with environmental protection goals, waste control, and sustainability practices.

3. BRC Global Standard for Packaging

3. BRC Global Standard for Packaging

Developed in the UK, BRC evaluates entire production facilities, covering:

-

Hygiene and contamination control

-

Employee training and quality audits

-

Supply chain risk assessment

Why They Matter:

These certifications guarantee not just safe materials, but safe and responsible manufacturing environments—a major advantage for buyers sourcing at scale.

Eco Certifications: EN 13432 and ASTM D6400

As sustainability becomes central to packaging innovation, compostable and biodegradable standards have gained importance.

EN 13432 (EU)

Defines the criteria for compostability in European markets. Products must:

-

Fully biodegrade within 6 months under industrial composting.

-

Leave no toxic residue.

ASTM D6400 (U.S.)

The U.S. counterpart to EN 13432, specifying that materials must break down into CO₂, water, and biomass within a controlled composting environment.

Why These Matter

For packaging materials like PLA, cornstarch, or bagasse, these certifications confirm true eco-friendly performance—not just “greenwashing.”

How to Verify Certification Authenticity

Unfortunately, certification misuse is not uncommon. To verify a supplier’s legitimacy:

-

Request original certificates — PDF or official documents with license numbers.

-

Cross-check validity — Use issuing body websites (FDA database, SGS Verify, ISO registry).

-

Look for test reports — Real certified factories can provide recent migration test data.

-

Check renewal dates — Certifications usually expire every 1–3 years.

-

Evaluate consistency — Reputable companies maintain certifications across all product lines.

Case Studies: How Certifications Impact Business

Case 1: Export Success with FDA Compliance

A Southeast Asian food packaging company gained entry to the U.S. market only after acquiring FDA certification for its PP cups and trays. Within one year, exports increased by 35%.

Case 2: European Buyer Trust Boosted by LFGB

A German retail chain switched to suppliers offering LFGB-certified PP packaging, citing fewer consumer complaints about odors and improved food perception.

Case 3: Sustainability Recognition

A catering company in France adopted EN 13432 certified bagasse tableware, enabling them to market fully compostable meal kits aligned with EU environmental policies.

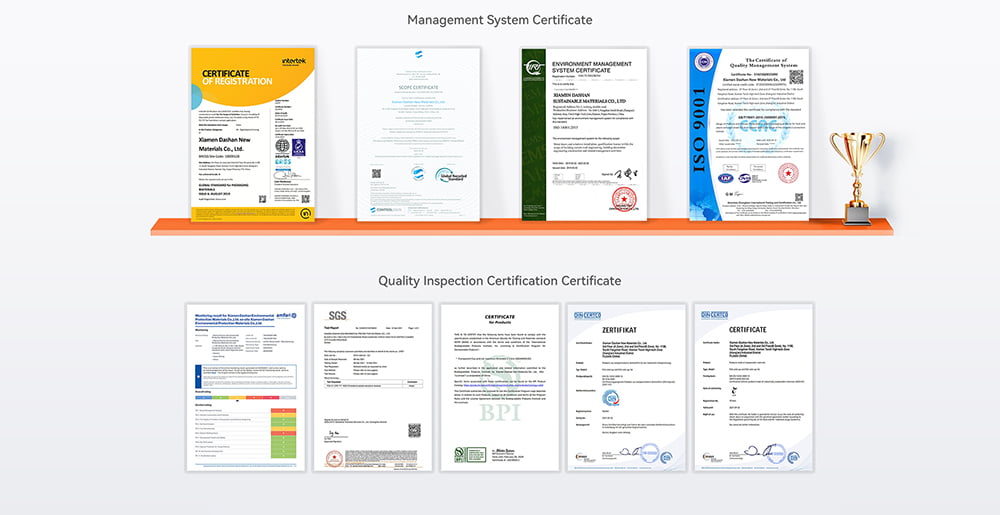

DASHAN — Certified Food Packaging Manufacturer

XIAMEN DASHAN NEW MATERIALS CO., LTD is a professional manufacturer of food-grade and eco-friendly packaging, holding multiple global certifications.

Certifications Held by DASHAN:

-

FDA (U.S.) — Food contact safety.

-

SGS — Comprehensive third-party testing.

-

BRC — Quality and hygiene management.

-

ISO 9001 / 14001 — Quality and environmental systems.

-

EN 13432 / ASTM D6400 — Compostable standards for PLA and bagasse products.

Why Global Brands Choose DASHAN:

-

Over 10 years of manufacturing experience.

-

Exporting to 60+ countries.

-

In-house extrusion, thermoforming, and printing facilities.

-

Full OEM/ODM customization with fast delivery.

👉 Learn more: DASHAN Company Profile

Expert Insights

“Food packaging certification is not just paperwork—it’s a reflection of a manufacturer’s commitment to consumer health and responsible production.”

— Dr. Helena Ruiz, Food Packaging Specialist, Springer Environmental Materials Journal

“When importers see SGS and LFGB certificates, they instantly know the products meet EU standards. That trust speeds up deals and builds brand reputation.”

— Alan Chen, Packaging Procurement Consultant, Global Trade Review

Comparison Table: Certification Overview

| Certification | Market Focus | Primary Requirement | Typical Material Coverage | Validity Period |

|---|---|---|---|---|

| FDA | USA | Migration and toxicity limits | PP, PET, PLA, rPET | Ongoing |

| SGS | Global | Independent safety verification | All food-contact materials | 1–3 years |

| LFGB | EU / Germany | Sensory and migration tests | Plastics, metals, ceramics | 3 years |

| BRC | UK / Global | Factory hygiene & risk management | All packaging | 1 year |

| ISO 9001/14001 | Global | Quality & environmental systems | Manufacturing operations | 3 years |

| EN 13432 | EU | Compostability & biodegradability | PLA, bagasse, cornstarch | 3 years |

| ASTM D6400 | USA | Biodegradability standards | PLA, compostable plastics | 3 years |

FAQ

1. Is FDA certification mandatory for all food packaging?

Yes, if you plan to export to or sell in the U.S. market. It ensures the material is food-safe and compliant.

2. What’s the difference between SGS and LFGB?

SGS is a third-party testing agency that can certify compliance with LFGB or other standards. LFGB is a legal requirement in the EU, while SGS validates it.

3. Do compostable certifications like EN 13432 apply to PP or PET?

No, they apply to biodegradable materials such as PLA and bagasse. PP and PET are recyclable, not compostable.

4. Why should brands care about BRC or ISO certifications?

They ensure factory-level quality control, hygiene, and sustainability—crucial for B2B buyers and retail audits.

5. How can I verify a supplier’s certifications?

Request the original certificates and check them on the official certification body’s website (FDA, SGS, ISO).

Conclusion

In a world where food safety and sustainability drive purchasing decisions, certified food packaging is no longer optional—it’s essential.

Certifications like FDA, SGS, LFGB, and ISO are not just technical checkboxes; they are symbols of credibility, compliance, and global readiness.

Choosing a partner like DASHAN, with all major certifications in place, ensures your packaging is not only safe and compliant but also trusted by international buyers.

👉 Partner with DASHAN to access globally certified, food-safe, and eco-friendly packaging solutions that protect your products—and your brand reputation.

References

-

FDA — Code of Federal Regulations (21 CFR) https://www.fda.gov

-

SGS — Food Contact Material Testing https://www.sgs.com

-

European Commission — Food Contact Materials https://food.ec.europa.eu

-

LFGB — German Food and Feed Code https://www.gesetze-im-internet.de/lfgb

-

BRCGS — Global Standard for Packaging Materials https://www.brcgs.com

-

ISO — Quality and Environmental Management Standards https://www.iso.org

-

ASTM — Biodegradable Plastics Standard D6400 https://www.astm.org

-

EN 13432 — Compostability of Packaging Materials https://standards.cen.eu

-

Packaging Insights — Global Food Packaging Compliance Overview https://www.packaginginsights.com

-

DASHAN — Company Profile https://www.dashanpacking.com/company-profile/