Polypropylene (PP) food trays have become one of the most essential and widely adopted solutions in modern foodservice packaging. From bustling restaurant kitchens to supermarket shelves and catering events, PP trays provide a reliable balance of safety, strength, and sustainability. As global consumers demand packaging that protects food while minimizing environmental impact, PP has emerged as the most practical material choice for the future.

In this ultimate guide, we explore everything you need to know about PP food trays—their material science, performance benefits, real-world applications, sustainability profile, and why DASHAN stands as a trusted global manufacturer in this evolving industry.

Introduction

In the fast-paced foodservice industry, packaging plays a crucial role in preserving quality, ensuring safety, and enhancing presentation. Among various options, PP food trays have gained worldwide recognition for their balance of practicality and sustainability. They are widely used in takeaway meals, cold-chain supermarket packaging, and large-scale catering services.

The reason is simple: PP trays deliver exceptional heat resistance, durability, hygiene, and recyclability, making them suitable for both hot and cold foods. In a market where safety and eco-consciousness drive purchasing decisions, polypropylene food trays stand out as a proven and future-ready packaging solution.

What Are PP Food Trays?

Polypropylene (PP) is a thermoplastic polymer known for its light weight, mechanical strength, and safety in food contact applications. As a member of the polyolefin family, PP offers a unique balance of flexibility and resilience, which makes it ideal for producing rigid yet functional packaging such as cups, plates, and especially food trays.

PP food trays are available in several structural designs to suit diverse needs:

-

Disposable PP Trays – Common in fast-food outlets and large-scale catering, designed for single-use convenience.

-

Compartmentalized PP Trays – Divided into sections for portion-controlled or multi-course meals.

-

Lidded PP Trays – Include tight-sealing covers to prevent leakage and maintain freshness during delivery or storage.

-

Customized PP Trays – Adapted to brand identity through color, shape, or embossed logos.

Material Characteristics of PP Trays

-

Microwave-safe up to 120°C (248°F) – suitable for reheating without warping or leaching.

-

Freezer-safe – can withstand sub-zero storage for frozen or chilled meals.

-

Chemically inert – resists oils, acids, and alcohol, ensuring hygienic food contact.

-

Lightweight – reduces transportation weight and costs.

-

Available in various finishes – including transparent, matte, and colored options for better presentation.

These qualities make PP trays versatile and adaptable for daily use across foodservice, retail, and household contexts.

Advantages of PP Food Trays

1. Food Safety

Food safety is at the heart of every packaging decision. PP trays are certified as food-grade under international standards such as FDA (U.S.), SGS, LFGB (EU), and ISO 22000. They are BPA-free, odorless, and non-toxic—ensuring no harmful chemicals migrate into the food, even during reheating.

PP’s moisture-resistant and grease-resistant surface prevents contamination, while its resistance to bacteria and mold ensures hygienic storage. This makes PP trays a dependable choice for sensitive applications like ready meals, salads, meats, and desserts.

2. Durability & Performance

Unlike paper or bagasse trays that can soften or deform with liquids, PP trays maintain rigidity and shape under pressure. They are strong enough to hold heavy meals, resist cracking, and survive rough handling during transport.

PP also provides excellent thermal performance—microwave-safe and suitable for refrigeration and freezing. When paired with tight-fitting lids, these trays become leak-proof, ensuring that soups, curries, or sauces remain sealed and spill-free.

3. Eco-Friendly Benefits

PP’s sustainability lies in its recyclability and reusability. Categorized under recycling code #5, it can be recycled in many municipal waste systems worldwide. Moreover, because PP is lightweight, it consumes less raw material per unit and reduces CO₂ emissions during shipping.

Before recycling, PP trays can also be reused multiple times for meal prep or food storage, aligning with circular economy principles that extend product life and minimize waste.

4. Branding & Customization

PP trays are also excellent for branding. They can be produced in various shapes, sizes, and colors, and support logo embossing, hot stamping, or labeling. This flexibility allows foodservice companies and retailers to create packaging that strengthens brand recognition while maintaining cost efficiency.

Use Cases for PP Food Trays

PP trays are remarkably versatile and have become indispensable across multiple sectors:

Restaurants & Catering

Professional kitchens use PP trays for serving hot and cold dishes alike. Multi-compartment trays simplify portion control and allow chefs to serve balanced meals. Their sturdy designs also enhance the visual appeal of dishes during buffet presentations.

Takeaway & Delivery

In the booming delivery economy, PP trays have become a standard for maintaining temperature and preventing leaks. Their microwave compatibility allows consumers to reheat food directly, providing unmatched convenience and satisfaction.

Supermarkets

Retailers value PP trays for their clarity, hygiene, and sealing performance. Clear-lid trays protect perishable foods like sushi, fruits, meats, and ready meals while ensuring visibility that appeals to consumers. Tamper-evident closures further enhance consumer trust.

Buffets & Events

For large gatherings or outdoor events, PP trays offer a hygienic, disposable, and cost-effective solution. They are easy to handle and dispose of, reducing cleanup time while maintaining professional presentation standards.

Healthcare and Institutional Use

Hospitals, airlines, and schools also depend on PP trays for their durability, safety, and portion control capabilities. The trays maintain food integrity across different temperature environments and support mass catering efficiency.

Expert Insights

“Polypropylene trays are one of the few packaging options that satisfy both food safety and business efficiency. Their durability and recyclability make them a smart choice for 2025 and beyond.”

— Dr. Helena Ruiz, Materials Scientist, Springer Journals

“Consumers demand packaging that reassures them about hygiene while being eco-friendly. PP trays meet this balance better than most alternatives.”

— James Lee, Senior Packaging Analyst, Packaging Insights

Industry analysts agree that the combination of safety assurance, production flexibility, and environmental responsibility positions PP as a leading material for next-generation packaging systems.

Case Studies

Supermarket Cold-Chain Meals

A leading Asian supermarket chain replaced PET packaging with PP compartment trays featuring tamper-evident clear lids. The results were notable:

-

Extended product shelf life by 12%.

-

Reduced plastic cracking issues during refrigeration.

-

Achieved a 15% increase in ready-meal sales due to improved presentation and freshness perception.

Takeout Restaurant Chains

A North American fast-casual chain switched from paper-lined containers to PP trays for hot dishes. Customer feedback showed:

-

30% fewer leakage complaints.

-

Improved temperature retention and product appearance.

-

Higher customer retention and repeat order rates.

Corporate Catering

A European catering service introduced black PP trays with transparent lids for high-end events. The outcome:

-

Enhanced buffet aesthetics.

-

Reduced packaging waste through reuse.

-

Secured new long-term contracts with premium corporate clients.

These case studies show that PP trays deliver measurable business advantages—balancing cost efficiency, presentation, and customer satisfaction.

PP Trays vs. Other Food Tray Materials

| Feature | PP Trays | PET Trays | Bagasse Trays | Aluminum Trays |

|---|---|---|---|---|

| Microwave Safe | ✅ Yes | ❌ No | ✅ Yes | ✅ Yes |

| Recyclable | ♻️ Yes (#5) | ♻️ Yes (#1) | Compostable Only | ♻️ Yes |

| Compostable | ❌ No | ❌ No | ✅ Yes | ❌ No |

| Cost-Effectiveness | High | Medium | Medium–High | Medium |

| Durability | High | Medium (brittle) | Medium | High (heavier) |

| Customization | Excellent | Good | Limited | Limited |

While PET and aluminum have strengths in rigidity or temperature tolerance, PP offers the best overall balance between functionality, safety, and environmental performance.

Sustainability Factors

Sustainability is one of the most critical considerations in modern packaging design. PP trays contribute to greener practices through multiple pathways:

-

Light-weighting: Manufacturers can reduce material usage without compromising strength.

-

Mono-material design: Single-material trays simplify recycling processes and improve recovery rates.

-

Recycled PP integration: Advanced technology allows incorporating post-consumer PP into new trays without losing quality.

-

Reusability: Consumers can wash and reuse trays several times before recycling, reducing waste.

-

Lower energy production: PP requires less energy to process than many bioplastics or aluminum, resulting in reduced carbon emissions.

According to PlasticsEurope, polypropylene’s life-cycle carbon footprint is among the lowest of conventional plastics, making it an eco-efficient choice for sustainable food packaging.

Global Regulations and Compliance

PP trays comply with stringent food contact and recycling regulations across major global markets.

-

European Union: Regulation (EU) No 10/2011 ensures PP used for food contact is safe and migration-tested.

-

United States: The FDA’s 21 CFR regulations approve PP for repeated use in direct food contact applications.

-

Asia-Pacific: Countries like Japan and China have included PP in their positive lists for food-contact materials, reflecting global acceptance.

This regulatory compliance ensures that PP trays can be safely exported and used worldwide without reformulation or re-certification—an advantage for global brands seeking consistent packaging standards.

Market Trends and Future Outlook

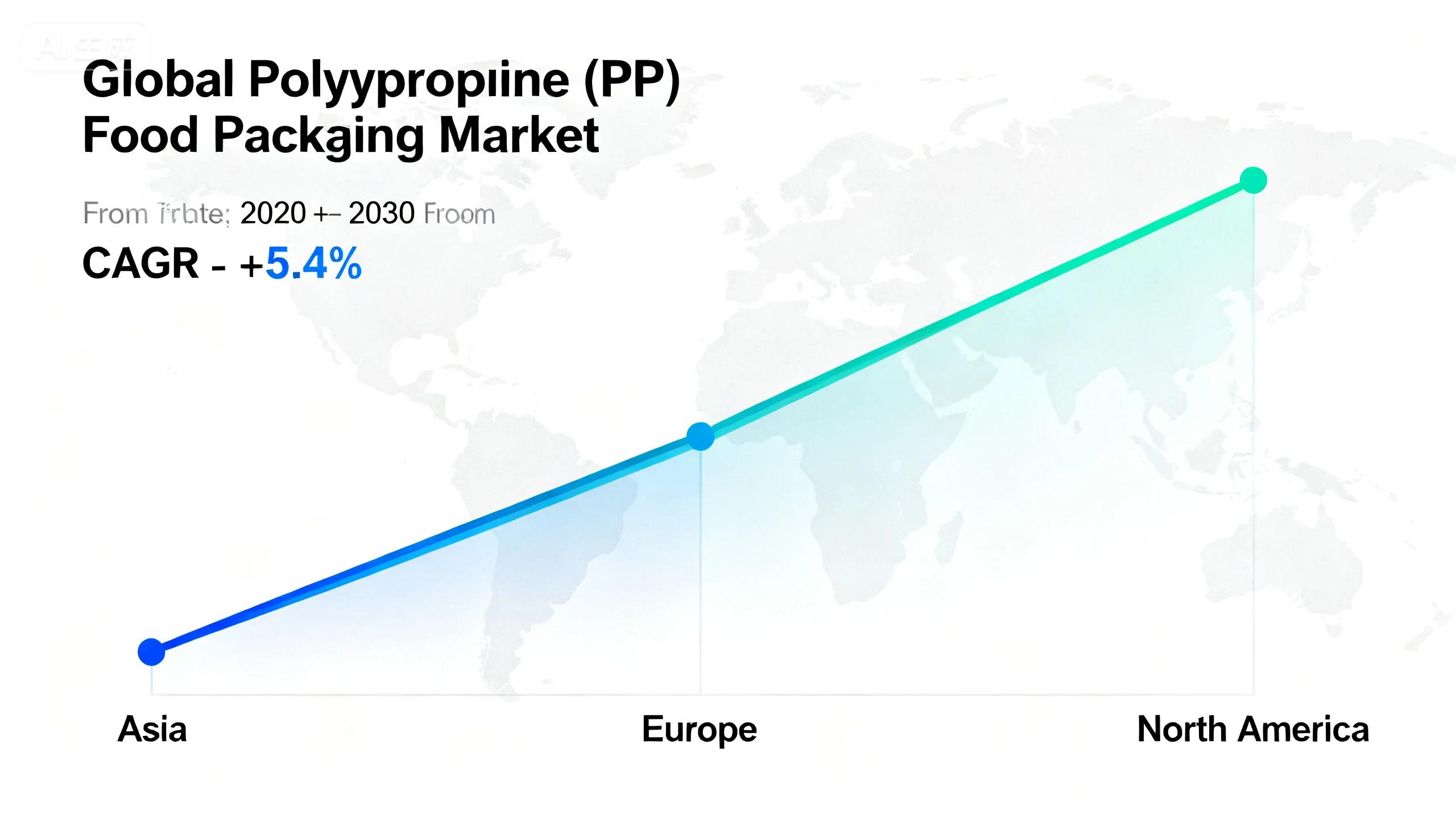

The global demand for PP food trays continues to rise, driven by urbanization, e-commerce food delivery, and sustainability policies. According to industry research, the PP food packaging market is projected to grow by 5.4% annually through 2030, largely due to its recyclability and cost-effectiveness.

Innovations shaping the next generation of PP trays include:

-

Bio-based PP resins derived from renewable sources.

-

Advanced heat-resistant coatings for improved performance.

-

Smart packaging integration, including QR codes for traceability and recycling guidance.

-

Closed-loop manufacturing systems to enhance circularity within production chains.

With these advancements, PP trays are set to remain central to sustainable packaging development for decades.

DASHAN — Professional PP Tray Manufacturer

XIAMEN DASHAN NEW MATERIALS CO., LTD is a professional manufacturer specializing in eco-friendly food packaging. With more than a decade of expertise, DASHAN has established itself as a trusted partner for businesses seeking reliable, safe, and sustainable packaging solutions.

Why Businesses Choose DASHAN

-

Certified Quality: FDA, SGS, LFGB, ISO 9001, and ISO 14001 compliant.

-

Global Reach: Exports to over 60 countries across Europe, North America, the Middle East, and Asia.

-

OEM/ODM Services: Tailored customization for color, logo, embossing, and tray structure.

-

Comprehensive Product Line: Includes PP trays, cups, plates, clamshells, and lids.

-

Sustainability Commitment: Continuous innovation in recyclable and renewable materials.

With advanced manufacturing facilities and strict quality management, DASHAN ensures each product meets international safety standards and customer expectations.

FAQ

1. Are PP trays microwave safe?

Yes. PP trays can withstand heating up to 120°C (248°F) and are safe for microwave reheating.

2. Can PP trays be recycled?

Absolutely. PP trays are recyclable under code #5 and accepted by many recycling facilities worldwide.

3. Do PP trays keep food fresh?

Yes. PP trays with clear, tight-fitting lids help preserve freshness and prevent cross-contamination.

4. Can PP trays be branded with logos?

Yes. DASHAN offers full OEM/ODM customization for branding, colors, and shapes.

5. Why choose PP trays over bagasse or PET?

Because PP trays deliver superior durability, cost efficiency, and consistent food safety compared to most alternatives.

Conclusion

In 2025 and beyond, PP food trays continue to stand out as one of the safest, most versatile, and eco-friendly food packaging options available. Combining durability, recyclability, and affordability, they align perfectly with the modern industry’s shift toward sustainable yet practical solutions.

With certified quality, innovation, and global manufacturing capacity, DASHAN remains a trusted partner for businesses seeking dependable PP tray solutions that meet today’s food safety and sustainability standards.

Contact DASHAN today to explore your tailored PP tray options.

References

-

European Commission – Food Contact Materials Regulation (EU) No 10/2011: https://food.ec.europa.eu

-

U.S. Food & Drug Administration – CFR Title 21, Food Contact Substances: https://www.fda.gov

-

PlasticsEurope – Polypropylene (PP) Overview: https://plasticseurope.org

-

British Plastics Federation – PP Material Guide: https://www.bpf.co.uk

-

Packaging Europe – Trends in Polypropylene Recycling: https://www.packagingeurope.com