Introduction

The food packaging industry has undergone rapid transformation in recent years. From the rise of compostable materials to the global push for a circular economy, businesses face increasing pressure to adopt eco-friendly solutions. Yet in 2025, polypropylene (PP) food packaging continues to stand out as one of the most reliable, versatile, and sustainable options.

This article explores why PP packaging remains a top choice for foodservice providers, supermarkets, and catering businesses. It covers market trends, material benefits, real-world applications, and sustainability considerations—and explains why DASHAN, a certified packaging manufacturer, is a trusted partner for businesses worldwide.

I. Understanding PP Food Packaging

What is Polypropylene (PP)?

Polypropylene is a thermoplastic polymer known for its durability, lightweight properties, and recyclability. It is widely used for:

-

PP Cups for cold drinks and parties.

-

PP Trays for takeout and ready meals.

-

PP Plates and Bowls for catering and buffets.

-

PP Clamshell Boxes for restaurants and fast-food packaging.

-

PP Lids for cups and food containers.

Key Properties of PP in Food Packaging

-

Microwave-safe → Can handle reheating.

-

Food-grade safety → BPA-free and certified for direct contact.

-

High durability → Resists cracks and leaks.

-

Recyclability (#5) → Compatible with many recycling streams.

II. Why PP Packaging Dominates in 2025

1. Cost-Effectiveness & Scalability

Compared to PLA or bagasse, PP offers competitive pricing while delivering strong performance. For global brands and catering businesses, scalability is essential, and PP provides an efficient supply chain solution.

2. Performance Across Food Types

-

Hot meals → Microwave reheating without deformation.

-

Cold foods → Excellent clarity for salads, desserts, and beverages.

-

Takeout & delivery → Leak-proof designs for safe transport.

3. Consumer Trust & Food Safety

A 2024 NielsenIQ survey revealed that 74% of consumers prioritize packaging that guarantees food safety. PP’s FDA and SGS certifications ensure it meets international standards【FDA†source】.

4. Recycling & Circular Economy

While compostable packaging garners attention, recycling remains more scalable. PP (#5) is widely collected in municipal systems, making it one of the few plastics with a viable recycling pathway【EPA†source】.

III. Expert Insights

“PP’s recyclability and durability make it a practical transition material as the industry shifts toward circularity. It balances affordability with safety.”

— Dr. Helena Ruiz, Materials Scientist (Springer Journals)

“Consumers demand sustainable options, but food safety cannot be compromised. PP packaging meets both needs effectively in 2025.”

— James Lee, Food Packaging Analyst (Packaging Insights)

IV. Case Studies

Case Study 1: Airline Catering

A major Asian airline switched to compartmentalized PP trays for in-flight meals. The result? Reduced food waste and lighter weight per meal, cutting fuel-related CO₂ emissions.

Case Study 2: Supermarket Chains

European supermarkets have adopted clear PP trays for fresh produce and ready meals. Customer surveys showed improved confidence in food hygiene due to tamper-evident PP lids.

Case Study 3: Restaurant Takeout

A U.S. fast-casual chain implemented PP clamshells for hot meals. Feedback showed 30% fewer complaints about leaks, enhancing brand loyalty.

V. PP vs. Other Packaging Materials

| Feature | PP Packaging | PLA Packaging | Bagasse Packaging | PET Packaging |

|---|---|---|---|---|

| Microwave Safe | ✔ Yes | ✘ No | ✔ Yes | ✘ Limited |

| Compostable | ✘ No | ✔ Industrial Only | ✔ Yes | ✘ No |

| Recyclable | ✔ Yes (#5) | Limited | Compost Only | ✔ Yes (#1) |

| Cost-Effectiveness | ✔ High | Medium/High | Medium | Medium |

| Durability | ✔ High | Medium | Medium | High |

👉 PP offers the most balanced performance, making it the material of choice in 2025.

VI. The Role of Sustainability

-

Light weighting → Reduced resin use without losing strength.

-

Mono-material designs → Simplify recycling.

-

Reusable options → PP trays and clamshells reused before recycling.

-

Integration with PP → Incorporating recycled polypropylene into new packaging.

VII. DASHAN — Professional PP Packaging Manufacturer

XIAMEN DASHAN NEW MATERIALS CO., LTD is a professional food packaging manufacturer with over 10 years of experience in PP and eco-friendly materials.

Why businesses trust DASHAN:

-

Global supply → Serving 60+ countries.

-

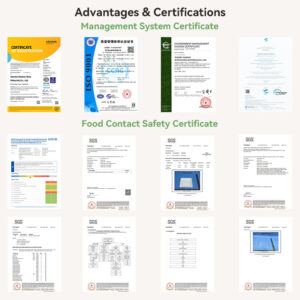

Certified quality → FDA, SGS, LFGB, BRC, ISO 9001 & 14001.

-

OEM/ODM → Custom shapes, colors, branding, and logos.

-

Eco portfolio → PP, PLA, rPET, bagasse, and cornstarch solutions.

👉 Learn more: Company Profile

FAQ

1. Why is PP still popular in 2025?

Because it combines cost-effectiveness, recyclability, and food safety better than most alternatives.

2. Is PP packaging safe for hot meals?

Yes. PP is microwave-safe and heat-resistant, unlike PET or PLA.

3. Can PP packaging be branded or customized?

Yes. PP containers can be printed, embossed, or customized for logos and marketing.

4. How sustainable is PP compared to bagasse or PLA?

While not compostable, PP is widely recyclable, making it a practical solution for large-scale use.

5. Why choose DASHAN as a supplier?

Because DASHAN combines certified quality, global reach, and customization, offering sustainable solutions for businesses worldwide.

Conclusion

In 2025, PP food packaging remains the industry’s top choice due to its unique balance of performance, safety, recyclability, and cost-efficiency. From airlines to supermarkets and restaurants, PP continues to meet the needs of businesses and customers alike.

DASHAN, with its certifications, OEM/ODM capabilities, and eco-friendly product line, is a trusted partner for companies seeking reliable and sustainable PP packaging.

👉 Contact DASHAN today to explore tailored PP packaging solutions.

References

-

FDA — Food Contact Substances and Safety https://www.fda.gov

-

SGS — Food Packaging Testing Services https://www.sgs.com

-

EPA — Containers and Packaging Data https://www.epa.gov

-

NielsenIQ — Packaging Design & Consumer Impact https://nielseniq.com

-

Springer — Polypropylene in Food Packaging https://link.springer.com

-

McKinsey — Future of Food Packaging Trends https://www.mckinsey.com

-

Packaging Insights — Why PP Packaging Persists https://www.packaginginsights.com

-

Ellen MacArthur Foundation — Circular Economy and Plastics https://www.ellenmacarthurfoundation.org

-

Food Packaging Forum — Material Safety in Food Packaging https://www.foodpackagingforum.org

-

DASHAN — Company Profile https://www.dashanpacking.com/company-profile/